Hello! Surely, many of you, my dear readers, are active car enthusiasts and spend part of their lives behind the wheel. And if so, then you will be interested to know that some engines have such a system - a cylinder deactivation system. Why is she?

Every time you stop at a gas station and pay attention to the cost of fuel, you may have thought that it would be nice if the car consumed less of this precious liquid and allowed you to save money.

It turns out that not only car owners, but also car manufacturers are concerned about this idea, which is why technologies that can significantly reduce fuel consumption and increase the efficiency of engines appeared in the middle of the twentieth century. And this idea, as you guessed, is to turn off some of the cylinders when more power is not needed.

Cylinder deactivation system. Disable and save

How can you quickly and noticeably reduce fuel consumption? To answer this question, we need to remember that we waste gasoline or diesel fuel in the process of burning them in cylinders. If we want to reduce fuel consumption, it is logical to reduce the number of elements where it burns, but then the engine power will decrease, which is also not an option.

The designers have found a solution - you can simply temporarily turn off some of the cylinders, and when you need full engine output, turn them all on. This is the principle of operation of the system we are talking about today.

According to automakers, modern solutions in this direction allow saving up to 30% of fuel, which, you see, can have a beneficial effect on our pockets.

The idea is undoubtedly good and, most importantly, useful!

But how can you temporarily exclude cylinders from the well-coordinated engine mechanism, since it is impossible to stop the movement of the pistons in them - they are rigidly attached to the crankshaft?

In fact, everything is simple, whatever the type of shutdown system, the principle of operation is the same for all - blocking the fuel supply to the cylinders and turning off individual valves.

Thus, combustion of the mixture does not occur and some pistons do not perform any useful work.

There are no problems with solving the first problem, since the nozzles through which fuel is supplied are electronically controlled. As for the valves, here the developers had to show their ingenuity, because blocking the operation of individual elements of the gas distribution mechanism (timing mechanism) turned out to be not so easy, and many automakers offered their own options.

Disable immobilizer

The order of operation of an engine with 4, 6, 8 cylinders - simply about the complex

By and large, we, ordinary car enthusiasts, do not need to know the operating order of the engine cylinders. Well, it works and works. Yes, it’s hard to disagree with this. It is not necessary until you want to set the ignition yourself or start adjusting the valve clearances.

And it won’t be superfluous to know about the operating order of a car’s engine cylinders when you need to connect high-voltage wires to spark plugs, or high-pressure pipelines for a diesel engine. What if you decide to repair the cylinder head?

Well, you must admit, it would be funny to go to a car service center in order to correctly install the explosive wires. And how to go? If the engine troits.

What does the order of operation of the engine cylinders mean?

The sequence with which strokes of the same name alternate in different cylinders is called the order of operation of the cylinders.

What determines the order of operation of the cylinders? There are several factors, namely:

-engine cylinder arrangement: single-row or V-shaped; - number of cylinders; -camshaft design; -type and design of the crankshaft.

Engine duty cycle

The engine operating cycle consists of gas distribution phases. The sequence of these phases should be evenly distributed according to the force acting on the crankshaft. It is in this case that the engine runs smoothly.

A prerequisite is that the cylinders operating in series should not be located next to each other. For this purpose, engine manufacturers develop diagrams for the operating order of engine cylinders. But, in all schemes, the order of operation of the cylinders begins with the main cylinder No. 1.

For engines of the same type, but of different modifications, the operation of the cylinders may differ. For example, the ZMZ engine.

The cylinder firing order of the 402 engine is 1-2-4-3, while the cylinder firing order of the 406 engine is 1-3-4-2.

If we delve deeper into the theory of engine operation, but so as not to get confused, we will see the following.

The full operating cycle of a 4-stroke engine takes two revolutions of the crankshaft. In degrees this is equal to 72°. The 2-stroke engine has 360°.

The shaft elbows are shifted to a certain angle so that the shaft is under constant force from the pistons. This angle directly depends on the number of cylinders and engine stroke.

The order of operation of a 4-cylinder, single-row engine, the alternation of strokes occurs through 180°, but the order of operation of the cylinders can be 1-3-4-2 (VAZ) or 1-2-4-3 (GAZ).

The operating order of a 6-cylinder in-line engine is 1-5-3-6-2-4 (the ignition interval is 120°).

The operating order of an 8-cylinder V-engine is 1-5-4-8-6-3-7-2 (ignition interval 90°).

There is, for example, the order of operation of a 12-cylinder W-shaped engine: 1-3-5-2-4-6 are the left cylinder heads, and the right ones: 7-9-11-8-10-12

In order for you to understand this whole order of numbers, let's look at an example. The 8 cylinder ZIL engine has the following cylinder operating order: 1-5-4-2-6-3-7-8. The cranks are located at an angle of 90°.

That is, if a working cycle occurs in cylinder 1, then through 90 degrees of crankshaft rotation, the working cycle occurs in cylinder 5, and sequentially 4-2-6-3-7-8. In our case, one crankshaft rotation is equal to 4 working strokes.

The natural conclusion is that an 8-cylinder engine runs smoother and more evenly than a 6-cylinder engine.

Most likely, you will not need in-depth knowledge of the order of operation of the cylinders of your car's engine. But it is necessary to have a general idea about this. And if you decide to repair, for example, the cylinder head, then this knowledge will not be superfluous.

Good luck in learning the firing order of the cylinders in your car's engine.

Share the news with friends:

Similar

Everyone disconnects differently

To describe all existing cylinder deactivation systems, you will need more than one article, however, let's try to look at some of them.

So, back in 1999, Mercedes-Benz began using specially designed rocker arms in the timing belt, which consisted of two parts connected by a movable lock.

When the cylinder deactivation mode was turned on, the clamps moved and certain valves were immobilized. This technology is called Active Cylinder Control.

The Volkswagen concern proposed a slightly different approach. If other automakers, as a rule, equipped models with massive multi-cylinder engines with this system, the Germans decided that it would be useful in small units, even with compact in-line “fours”.

The technology was called Active Cylinder Technology, and its essence lies in the use of several camshaft cam blocks at once, which are controlled by special mechanisms.

The blocks have different cam configurations, which, when activated, allow the camshaft not to interact with some valves.

There are other ways to turn off extra cylinders. For example, specially designed pushers or a combination of several cam shapes and rocker arms with detents are used.

How is cylinder deactivation implemented?

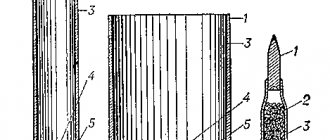

For engines with a lower camshaft, it is most convenient to turn off the cylinders using the valve rocker arm stop that is moved by an electromagnet. When the solenoid is turned on, the valve remains closed as the rocker arm, under the influence of the camshaft cam, rotates around the point of contact with the end of the valve stem. In this case, the rocker arm stop can move freely.

Due to design features, this method is not applicable for engines with an overhead camshaft, so cylinder deactivation is accomplished in other ways. For example, BMW engines turn off injection and ignition. In this case, exhaust gases are released from the working ones through the disconnected cylinders. Thanks to this, the operating temperature is maintained in the disabled cylinders.

In all engines, regardless of design, switchable cylinders alternate as evenly as possible with non-switchable cylinders to ensure the most balanced operation.

Specifications

This power unit was produced at the Mlada Boleslav Plant. The entire line of engines received the designation EA211. Engines have been produced since 2012 to the present day. The material from which the cylinder block is made is aluminum. As for the power system, an injector is used. This is an inline four-cylinder engine. 4 valves per cylinder. The cylinder diameter is 74.5 millimeters. The piston stroke is 80 millimeters.

The exact engine volume is 1395 cubic centimeters. In terms of power, the CHPA engine is capable of producing 140 horsepower, in the engine speed range from 4500 to 6000. Torque of 250 Newton meters is achieved at 1500 - 3500 engine speeds. The recommended fuel for engines and the 1.4 TSI EA211 line has an octane rating of 95 and 98. The engine weighs 106 kg. As for fuel consumption per 100 km, in the city the engine is capable of consuming 6.6 liters per 100 kilometers, on the highway - a ridiculous 4.3 liters, which leads to an average combined cycle figure of 5.2 liters per 100 km. During normal engine operation, oil consumption per 1000 km is about five hundred grams. The brand of oil used in the power unit is 5W-30 and 5W-40.

According to technical regulations, the oil must be changed every 15,000 km. But branded car services from Audi and Volkswagen recommend changing it every 7,500 kilometers. The engine operating temperature is about 90 degrees. Tuning potential is ready to offer about 150-180 horsepower on top. This engine is installed on Audi starting from A3, A5, Skoda Octavia, Skoda Rapid, Skoda Superb, Volkswagen Caddy, Golf, Jetta, Passat, CC, Polo and Tiguan.

Operation with the fuel injection pump cylinders disconnected

Cylinder shutdown most often occurs when fuel equipment fails - stuck plungers and injection pump valves, ruptured injector pipelines, or stuck injector needles. The reasons may be the use of dirty fuel, water getting into the fuel, corrosion and erosion of fuel equipment, too high (or vice versa, too low) fuel temperature, inconsistency of the fuel type with the gaps of precision pairs, violation of the cooling mode, poor manufacturing of fuel equipment. Less commonly, cylinders shut down due to failure of cylinder parts. Depending on the nature of the accident, partial or complete dismantling of the movement elements is possible.

Marine high pressure fuel pump

To turn off the cylinder, you first need to turn off the fuel supply (lock the plunger or the injection pump control valve in the upper position). Depending on the nature of the dismantling work and the design of the engine, it is necessary to reduce or completely turn off the cylinder lubrication. Check and adjust the cylinder lubrication lubricators, cool the cylinder, put plugs on the circulation lubrication system and on the gas exchange system. Particular attention should be paid to the need to disconnect the starting air line to the cylinder when the piston of the disconnected cylinder is suspended.

Spontaneous shutdown of the cylinder is detected by surge of the turbocharger. The influence of operational factors on the operation of the turbocharger and engine, a drop in rotation speed, a decrease in the temperature of gases at the outlet of the cylinder and an increase in the temperature of gases on the operating cylinders. The load on the remaining cylinders increases. The level of load increase depends on the method of speed control.

If the engine with a limiting speed controller was running at full speed in the mode characterized by point 1 in Fig. No. 4, then after the cylinder is turned off, the revolutions will decrease to a value of n2, and the mode of the remaining cylinders in operation will be characterized by the laws of the external characteristic ha1 = const (point 2). If the engine has an all-mode regulator, then when the speed drops, the regulator will move the fuel rail to a higher flow until the rack stops.

The load on the cylinders will increase significantly; the mode will be characterized by point 3, lying on the external characteristic of the rated power hanom = const. The rotation speed n1 will be greater than with the limit regulator, but less than before the cylinder was turned off. In both the 1st and 2nd cases, the engine operating mode goes beyond the limiting characteristic, the engine will be overloaded according to Re. Consequently, when the cylinder is turned off, it is necessary to move the fuel rail to a lower flow in accordance with the nature of the load limitation set by the builder.

Rice. 4 Changing the engine operating mode when the cylinder spontaneously turns off: 1-2 - with a limit regulator, 1-3 - with an all-mode regulator

If the company allows operation at the nominal average indicator pressure when turning off the cylinders: P1 = Pi nom, then the operating mode will be characterized by a rotation speed equal to:

np = VP i n ( ( V sn n 3 i r η m ) / 0.06 m N e n ) ( No. 1 )

- where Vs is the working volume of the cylinder;

- m—cycle factor;

- Neн - rated power;

- nn — rated rotation speed;

- ηm — mechanical efficiency;

- ip is the number of cylinders remaining in operation.

Mechanical losses of the engine decrease as the rotation speed decreases. When dismantling the movement elements of the emergency cylinder, mechanical losses are further reduced, which must be taken into account when determining ηm.

The rotation speed found in the above formula can be considered as the maximum possible when one or more cylinders are turned off. Such a rotation speed is possible only in naturally aspirated engines, where operation with the limiting characteristic Pi = const is allowed. In engines with gas turbine supercharging, it is necessary to reduce Pi when the cylinder is turned off in accordance with the laws of the limiting characteristic due to deterioration of air supply; rpm drops more significantly.

Fuel pump

Moreover, the speed has to be reduced even more due to vibrations of the housing and surge of the compressor. When the cylinders are turned off, an increase in the amplitude of the total tangential force TΣ leads to an increase in the degree of uneven rotation of the crankshaft, which, even without dismantling the movement elements of the emergency cylinder, can lead to unacceptably strong vibrations of the housing. Vibrations increase significantly when the cylinder is dismantled due to imbalance. The concept of balance. The effect of an unbalanced engine on the foundation and hull of the engine vessel.

Compressor surge when the cylinder is turned off is almost inevitable with pulsed gas turbine charging. To reduce surging, it is necessary to reduce the speed, further deteriorate the air supply by bleeding air from the purge receiver into the atmosphere (to reduce the back pressure at the compressor discharge), or even exclude another cylinder from operation.

Thus, when assigning a diesel operating mode when a cylinder is turned off, it is necessary to take into account not only the parameters for limiting the load of the cylinders, but also the “vibration” and “surge” indicators.

See also: a) Full speed modes b) Low speed modes c) Operation with a “heavy” and “light” propeller e) Engine operation during emergency shutdown of the turbocharger

Footnotes

Sea-Man