Straight circular cylinder.

The Tycho Brahe Planetarium building, Copenhagen, its roof is an example of a cylindrical section

.

(ancient Greek κύλινδρος - roller, roller) - a geometric body bounded by a cylindrical surface and two parallel planes intersecting it.

Is there no method against scrap?

The reliability of the cylinder also depends on how effectively it can withstand forceful hacking options:

- drilling;

- knocking out;

- breaking;

- tearing out, etc.

Today there are many developments that help counter any of the above options. First of all, they relate to the raw materials from which the cylinders are made - for example, it can be hardened steel or other hard alloys that undergo hardening. Almost no drill can take such materials.

Separately, we can recall Mauer cylinders, made using a special “red line” technology, when when trying to break the mechanism, only the front part breaks off, and the cylinder itself remains inaccessible to burglars, but at the same time continues to function reliably when using the original key.

Almost all models of Mottura brand cylinders are, in turn, equipped with a special knockout protection system, and therefore they effectively withstand any method of force, except drilling.

Most cylinder manufacturers offer consumers to purchase additional armored linings, which will significantly increase the security of the mechanism and, accordingly, the safety of the room.

Therefore, when determining which cylinder is better, do not forget about the linings, which are divided into two types depending on the installation option:

- mortise;

- invoices.

The first type of lining is mounted on the lock. Some of the most reliable products are considered to be ]Cisa [/anchor], Mottura (Mottura). It is virtually impossible to tear these models away from the door leaf, and therefore their protective properties are incredibly high.

The overhead protection is mounted on the outer door leaf. Although, they are often considered more decorative, since they provide protection from drilling only until they are torn off. The most popular products are from Kale, Ritko and others.

What kind of tricky “beast” is this cylinder?

First, let's try to figure out what a cylinder is. This is a special device with the help of which the bolts are opened - the force of the key turned in the keyhole is transferred to the internal mechanism that ensures the movement of the door lock's shutoff valves. In addition, it is in the cylinder that all the secrecy of the lock is hidden.

The incredible accuracy and peculiarity of the cylinder structure allows only the “original” key supplied with the product to open the lock (most often there are from three to five “original” keys).

The cylinders are available in two of the most popular shades, harmonizing with locks and doors of any color:

- nickel plated;

- brass

Depending on the type of locking mechanism, cylinders come in two systems:

- key-key (a key is used to close or open the door from the outside and inside);

- key-screw (the lock is opened and closed from the outside with a key, and from the inside - with a rotary handle).

When trying to understand which cylinder is better, you should realize that no matter how reliable the mechanism is, it needs additional protection, which is provided by armored linings.

What is a cylinder in an engine for? Engine cylinders

How easy it used to be for our Soviet car enthusiasts. They were not faced with the problem of choosing the number of cylinders in the engine. Then all passenger cars had only four of them, but now there are five, six, twelve cylinder engines. There are also exotic engines with sixteen and even eighteen cylinders. How to understand all this, and who is it suitable for?

Corrosion marks on wet jacket. In addition to electrolysis, the cylinders suffer from a coolant attack, that is, when water does not mix with the radiator additive or is mixed in the wrong ratio. Thus, water can attack the outer walls of the jacket, especially if the water used is not demineralized water, since mineral water has aggressive compounds that will attack the walls of the cylinder. Another way to accelerate chemical corrosion of the cylinders is to allow air into the cooling system.

First, let's find out why we need so many cylinders in the engine. Designers around the world are faced with the challenge of creating more and more advanced engines that meet the demands of ever-increasing power demands. But more power requires even more volume, and accordingly, to increase it, the number of cylinders in the engine also increases.

This increases the concentration of oxygen, which rustles the cylinder walls. When we use only mineral water in the cooling system, over time and use they form crusts and settle at several points in the cooling system. When crust accumulation occurs on the outer surface of the cylinder, this crust forms a layer that prevents the cylinder from conducting heat to the coolant, causing the engine to overheat.

However, due to cylinder wear problems associated with the cooling system, the worst of all is called cavitation. Cavitation is vacuum bubbles that get trapped inside a hydraulic pipe. In internal combustion engines, this is caused by combustion of the engine itself. When the engine is running, burns follow, each combustion results in a pulsation that strengthens the engine components, the cylinders, when receiving these huge impulses, are deformed by millimeters and very quickly. When coolant comes into contact with the outer walls of the cylinder, it would be natural for the fluid to quickly fill the small space.

Their location varies: . After all, we know that the greater the number of cylinders in the engine, the higher and more uniform the torque. The multi-cylinder engine is very responsive and is able to deliver its power sharply, the car literally “shoots” from a stop, like in Formula 1.

Such a motor is better weighted, and therefore more balanced. Plus, it has an optimal ratio of weight, size and power. And it works quieter and with less vibration.

However, the cylinder deforms and returns to its normal shape very quickly, not allowing time for liquid to fill the space that is created, thus creating vacuum bubbles on the outer walls of the cylinder. When these vacuum bubbles burst, small pieces of metal are released from the cylinder wall to the point where the cylinder is punctured and fully engaged.

Engine oil circulates throughout the block. Under no circumstances will an internal combustion engine run without wearing out its internal components, and replacing some engine components after a long mileage can even be considered preventive maintenance. However, even if wear and tear is unavoidable, it can be minimized with a good preventive maintenance plan. Taper and ovalization are directly related to the quality of the lubricant, the extent to which the lubricant can adhere to the cylinder walls and form an oil film, which guarantees wet friction and minimizes cylinder wall wear.

But these were the pros, and now let's discuss the cons. An engine with more cylinders is larger and therefore heavier. And when weight increases, a trail of other problems follows:

- need more powerful;

- must be strengthened;

- need a high-tech gearbox;

- the brakes must be strengthened;

- needed with increased volume.

By the way, how much, in your opinion, can it differ between two identical models, but with a different number of cylinders?

Once the oil has expired, it should be replaced, but by delaying the oil change, we use a lubricant that no longer performs its properties, then the protection of the lubricant is lost. Another very important factor in the smooth operation of the cylinder block is the cooling system. The engine requires its heat to be removed from the cylinder, the coolant performs this function. But as soon as system maintenance is neglected, engine oxidation accelerates. Small leaks allow air to enter the system and should be repaired quickly.

The cost of a car with an engine of ten or even twelve cylinders can sometimes be 100% higher than the cost of the same car, but with an engine of four or six cylinders. In other words, the buyer will have to pay twice as much for power.

Yes, the difference is serious. But multi-cylinder engines give the car real sporting ambitions. Such “athletes”, of course, need good summer tracks, preferably autobahns, where there are practically no speed limits. There their capabilities will be fully revealed!

Never run a system using water without an additive, which, in addition to accelerating oxidation, allows minerals to be screwed into the jackets, causing overheating. Water must be mixed with the additive in the proportion specified by the manufacturer. The crankcase was once considered a part of the engine, earlier the engine was also divided into three parts, but the last one was the crankcase. The crankcase in older engines was the part of the engine that included components such as the oil pump and valve control shaft, which was covered by a cast iron or aluminum casting cover.

This cap served as a reservoir for lubricating oil, into which the fisherman pumped through a pipe. Currently, the crankcase is limited to only one cover that covers the bottom of the block. Despite this, the crankcase retains its role as a reservoir for lubricating oil, and sometimes also has a cooling function, as some crankcases are equipped with fins. There is an oil drain bolt installed in the crankcase, this bolt is magnetized to attract any metal parts that may be transported by oil, which could cause engine damage if they get caught in the small oil passages.

But, if you think about it, do you really need a car with more engine cylinders than the usual four, five or six? After all, this is definitely not a hard worker for every day, but just an expensive car for pleasure. And as you know, you have to pay for pleasure!

Engine cylinder configuration

The usual number of cylinders on an engine is four; basically like a diesel. Also, you have six, eight, twelve cylinders; for the "high end". But it is true that in recent years there has been a real “explosion” in the number of three-cylinder engines!

Builders are being forced to make engines ever more sober due to future carbon emissions standards! And one way to get there is by tackling the first source of consumption: the engines themselves! How will a three cylinder engine consume less than four cylinders: It is a matter of friction, the "internal" friction in the engine between the various moving parts.

The previous article discussed the operation of a single-cylinder internal combustion engine, but such engines are not currently used in cars. In the automotive industry, multi-cylinder engines with a number of cylinders from 2 to 12 are used. There are, however, rare exotic engines with 16 and even 18 cylinders.

Why haven't manufacturers created three cylinders yet? These were small, fuel-efficient engines; which existed only for cost reasons. To ride, they were "cleansing"! Today, the new three-cylinder engines are better. Within 2-3 years you have new generations of three cylinders.

And then, the very last thing: a real surprise! But production resumed with Chinese capital. Today negotiations are underway with another Chinese shareholder; and with Indian Mahindra. In an internal combustion engine, the cylinder is the tubular part in which the piston moves. The piston stroke in this case is carried out using a connecting rod driven by rotation of the crankshaft. Cars have multi-cylinder engines in which the piston is housed with several metal segments mounted around their outer surface often made up of two segments, one providing a compression seal and the other providing an oil seal.

Based on the location of the cylinders, automobile engines are divided into in-line

,

V -shaped

and

opposed

.

They are installed on cars and other, rarely found cylinder configurations, for example, W -shaped

.

It should be noted that it is these configurations of internal combustion engines that have found wide application in automobile engines, which means that in other areas of application of engines (shipbuilding, aviation), there were much more configurations of engine cylinders. In aviation, engines were generally used in which the crankshaft did not rotate, but was fixed motionless, and on the contrary, the engine cylinders rotated around a stationary crankshaft. There have been engine configurations with two crankshafts and many other very interesting exotics, but in this article we will only consider those configurations that are widely used in automobile engines.

The role of the cylinder is to provide a proper basis for the combustion process of the engine, which is subject to wear and tear due to friction during use. But despite these precautions, the cylinder eventually wears out and becomes slightly oval in shape over time, so the inner walls need to be reloaded. In addition, the cylinder cannot extend beyond the highest point reached by the piston compression ring.

This would actually create a wear zone, so that when the motor is first used at low speed in the beginning, and then it is used at high speed, the slight stretching of the bars at high speed can push the top compression ring to reach the wear edge, causing it to rupture, It is therefore important that the engine, after replacing it, is used from time to time in all modes so that the wear develops conically and not in a localized area. When we love cars, we often become interested in mechanics.

1 – In-line engines

In-line engines are called engines with cylinder axis, which are located along the axis of the crankshaft. Currently, in-line engines are produced with a number of cylinders from 2 to 6. Such engines are usually designated R 2, R 3, R 4 ... R 12.

The most common engines are R 4.

Over the next few weeks we'll give you an overview of the wonderful world of engines. We will demystify the various operating principles, their advantages and disadvantages. First of all, let's talk about tempo, do you want it? We hear from the engine that it is two-stroke or four-stroke.

As we often talk about the engine that creates beautiful music, imagine a musical measure. You can tap your foot while listening to a song. Every time you step, time passes. Are you saying that some measures are two strikes and others are four strikes? In the case of engines, every time a measurement is completed, there is an explosion that produces power.

2 – V-shaped engines

Typical modern American V-8 engine

The first V-engine (V 2), manufactured by the German engineer Daimler in 1889

V-shaped engines are those whose cylinders are arranged in two rows (two separate blocks, but with a common crankcase) in the form of the Latin letter “V”. The pistons of both rows are connected by connecting rods to one crankshaft common to both blocks. Cylinders in opposite rows are offset along the axis of the crankshaft. Typically, the camber angle of the two cylinder blocks is 60º or 90º. The most widely used engines are V 6, V 8 and V 12. The V 8 engine is generally a national feature of American cars.

We understand that the measurement of a two-stroke engine is shorter, it will create more explosions in the same number of times, considering a four-stroke engine. His cycle is twice as fast. This is why we find two stroke engines in small engines. For smaller sizes they are more powerful, but as they get more involved they are less reliable, which is why we don't see this type of mill in cars, with a few exceptions. Your mower or motorcycle will most likely be equipped with two-stroke engines.

Basically, time is the movement of the piston up or down in the cylinder. In a 4-stroke engine, the piston changes position four times before exploding. For simplicity, imagine a piston raised in a cylinder. First it lowers, allowing air and gas into the firebox.

3 – Boxer engines

Opposed engines are those in which the cylinders are located in the same plane, opposite each other on both sides, located in the middle of the crankshaft.

4 –

VR engines

The name is quite arbitrary, this is what Volkswagen called this engine, the first to develop an engine of this configuration, but since there is no other more familiar name, we will designate this type of engine as such. The "VR" cylinder configuration engine is something between an in-line and a V-twin engine. When developing it, the designers tried to combine the advantages of in-line and V-shaped engines. This engine also has cylinders arranged in two rows at a certain angle, but in one single cylinder block with a cylinder head common to both rows. The cylinder camber angle is very small, from 10º to 15º. Therefore, cylinders that are offset along the axis of the crankshaft are located not in two separate blocks, but in one. The first engine of this configuration, the VR 6, was developed to facilitate the installation of a powerful multi-cylinder engine under the hood of a small car.

In the second stage, the piston rises and thus compresses the air and gasoline into a small space. When we talk about the compression ratio of an engine, we measure it. The third time - explosion! The spark plug fires compressed air and gasoline, causing an explosion that pushes the piston down the cylinder. This pushing force sets in motion the movement of other pistons; power produced!

On the fourth stroke, the piston rises, pushing the gaseous residues of the explosion towards the exhaust system. And it starts again thousands of times per minute! So, it is easy to understand that in a four cylinder there is only one cylinder that produces power. In an 8-cylinder engine it's two at a time. This is why adding cylinders increases power as there are more explosions each time.

5 – W-shaped engine

W engine structure

- Composite intake manifold

- Right cylinder head valve cover

- Right cylinder head

- Cylinder block

- Connection line between the top and bottom of the crankcase, passing through the center of the crankshaft

- Crankcase Lower Section (Common Main Bearing Cap Assembly)

- Oil pan

- Left cylinder head

- Left cylinder head valve cover

W-shaped engine design

A two-stroke engine is different in that the pistons only make two trips to generate power. Every time the piston of a two-stroke engine rises, it compresses air and gasoline. When an explosion occurs, the piston is pushed down, producing power.

Once the piston is at the bottom of the cylinder, the remainder of the explosion is evacuated. When the piston begins to rise again in the cylinder, air and fuel enter the cylinder, which must be compressed. The cycle is simplified to the extreme. Online engines are easy to imagine. This is an engine whose cylinders are mounted one after the other perpendicular to the crankshaft. This configuration is one of the most popular and can be found in most cars on our roads.

Having perfected the technology for producing the VR 6 block, Volkswagen took the next step. Began production of W-shaped engines. The configuration of this engine was achieved by installing two VR type blocks, as was done when connecting two in-line engines at a certain angle in the form of the letter V, when designing a V-shaped engine. Volkswagen has developed a number of engines of this configuration: W-8, W 12 and W 16. And for the most powerful car in the world, the W 18 engine was developed, however, this engine has not two, but three cylinder blocks.

It should be noted that previously W-engines were engines that had three separate cylinder blocks with a common crankcase. In each block, the cylinders were arranged in a row along one axis. The piston connecting rods of all three rows of cylinders were connected to a single crankshaft, like a V-engine.

In its configuration, this engine differs significantly from engines now called W-shaped. This 12-cylinder engine has not two, but three cylinder blocks, each of which has four cylinders arranged in a row. Modern W 12 engines have two cylinder blocks, each of which resembles the VR 6 engine. In this case, two banks of cylinders combined in one block have one common cylinder head

(cylinder head), that is, this engine has three separate cylinder heads.

This picture shows the air-cooled T955 W 18 diesel engine, produced back in 1943 by one of the oldest automobile companies in the world, Tatra.

A quick comparison of different engine configurations

Each engine configuration has its own advantages and disadvantages. In-line engines are technologically advanced and therefore have low production costs, which is very important for mass car manufacturers in the competitive struggle. The technology of their design and production is well established. Therefore, the most common car engine in the world is the inline four-cylinder engine.

The inline six-cylinder engine is excellently balanced.

The disadvantages of these engines include installation restrictions. An in-line engine with more than 6 cylinders cannot be placed under the hood of a modern car. Even a 6-cylinder in-line engine can be quite conveniently installed only on rear-wheel drive cars of a classic layout. But most of the most popular cars in the world currently have a different layout, in which the engine is installed across the axis of the car, and the front wheels are driven. Only Volvo was able to install an in-line 6-cylinder engine on a front-wheel drive car, but for this it was necessary to develop a unique, shortest gearbox in the world. The disadvantages of in-line engines also include the insufficient rigidity of the crankshafts and camshafts due to their large length.

Issues of balancing engines of various configurations due to their complexity and volume will be discussed in another article.

An Alfa Romeo 8C car with an R 8 engine under the hood.

Pay attention to the ratio of the length of the hood and the length of the passenger compartment of the car; nowadays, when the car has become a utilitarian item, no one can afford such a luxury. Inconvenient layout dimensions became one of the reasons for the extinction of in-line engines.

To create powerful engines, it is necessary to increase the total volume of the cylinders, but the size of the cylinders is also subject to technical restrictions, so the number of cylinders has to be increased. Engines with V-cylinder configurations are more complex and therefore more expensive to manufacture, but have a significantly shorter length with a slight increase in width compared to in-line engines with the same number of cylinders. Such engines have better design characteristics. Imagine the length of the engine hood under which an inline 12-cylinder engine is installed. True, in the history of the world automotive industry there have been cars with an in-line 16-cylinder engine. But then there was a lot of space in the cities, but there were few cars, and there were few royals for whom such cars were produced even then.

V-shaped engines are difficult to balance, especially the widespread V 6. Since the engine has two cylinder blocks, the number of many parts has to be doubled - cylinder heads, camshafts, camshaft drive parts and valve train drive parts, which increases frictional energy costs in engine mechanisms.

A boxer engine can be considered a special case of a V-shaped engine with a cylinder camber of 180º. The advantage of the boxer engine is exceptionally good balancing, but this engine is difficult to manufacture and has very poor design characteristics, so it is not widely used. Currently, such 4- and 6-cylinder engines are used only by Porsche and Subaru.

Engines of the “VR” type and, especially W-shaped ones, are very difficult to produce; many car manufacturers will not only not be able to produce such complex-to-manufacture engines at an acceptable cost, but also cannot produce them at all due to the lack of necessary technologies. Only the Germans, with their highest technology and eternal desire for technical perfection, can undertake such an experiment. And among the Germans, only Volkswagen produces such engines. When designing the VR-6 engine, the specialists had the task of putting a powerful multi-cylinder engine under the hood of standard cars, and they coped with this task perfectly. By combining the technology of creating V-shaped engines and VR engines, Volkswagen specialists created a whole family of W-shaped engines.

The question may arise, what is the optimal number of engine cylinders? In multi-cylinder engines, the power stroke does not occur in all cylinders at the same time. The alternating stroke allows multi-cylinder engines to run smoother than engines with fewer cylinders. The more cylinders, the smoother the engine runs. Engines with 1 to 3 cylinders must have a massive flywheel that smoothes out the pulsation of engine torque.

It is clear that the number of engine cylinders cannot be increased indefinitely. Therefore, the question arises - how many cylinders should an engine have? To obtain more power from the engine, it is necessary to burn as much of the air-fuel mixture as possible. One of the main ways to achieve this is to increase the volume of the cylinders. But if you make a single-cylinder engine with a very large displacement, the inertial force of the massive reciprocating parts of this engine can destroy the engine. And if you make an engine with a very large number of cylinders, the sharply increased friction forces in the engine mechanisms will increase the internal losses of the engine and make its operation ineffective. Currently, the total volume of one cylinder of a multi-cylinder automobile engine rarely exceeds 0.5 ÷ 0.6 liters

,

accordingly, a reasonable maximum number of cylinders for a production engine lies in the range of 10 ÷ 12 cylinders.

True, there are modern engine configurations (the names of these engines contain the letter W) in which the number of cylinders reaches 16 and even 18. In this section, engine balancing was mentioned. It is impossible to create an engine that operates without vibration at all. But there are engines with excellent balancing, and there are engines whose vibrations are accepted as acceptable due to the low cost of production of this engine. The issue of engine balancing is quite complex. Our task now is to understand the principles of engine operation; therefore, we will postpone the issue of balancing the engine until a later discussion.

The most popular in the global automotive industry is the in-line 4-cylinder engine. This engine is installed on most cars produced both in the past and currently. And, although in theory, an inline 4-cylinder engine is considered unbalanced, due to various technical tricks (mainly by reducing the weight of the cylinder-piston group parts) and limiting the volume of the cylinders, it was possible to significantly reduce the vibrations of this engine. But besides the disadvantages, the inline 4-cylinder engine has great advantages. The main advantage is the low cost of production and proven technologies for its production (which allows reducing the overall cost of the car) made it competitive in comparison with other types of engines in the production of affordable mass-produced cars.

E.N. Zhartsov

Related definitions

Cylindrical surface

- a surface obtained by moving a straight line (generator), parallel to any given one, intersecting a curved line (director) lying in a non-parallel to a given straight plane.

Plane figures formed by the intersection of a cylindrical surface with two parallel planes are called cylinder bases

.

The cylindrical surface between the base planes is called the lateral surface

of the cylinder. If the plane of the base and the plane of the guide are parallel, the boundary of the base will coincide in shape with the guide.

Cylinder surface area

The surface area of a cylinder is determined as follows:

Let us now find formulas for calculating the area of the lateral surface and base.

Since circles lie at the base, it is obvious that

Theorem 1

The lateral surface area of a cylinder is determined as the product of the length of the circle that limits the base of the cylinder and its height.

Finished works on a similar topic

- Coursework Cylinder 470 rub.

- Abstract Cylinder 230 rub.

- Test work Cylinder 200 rub.

Receive completed work or specialist advice on your educational project Find out the cost

Proof.

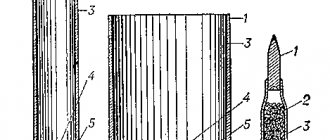

To prove this theorem, we need to find the development area of the lateral surface of the cylinder (Fig. 3).

Figure 3.

We see that the development of the lateral surface of the cylinder is a rectangle. The height of the rectangle is equal to the height of the cylinder $h$, and the length is equal to the length of the circle bounding the base of the cylinder, that is

The theorem has been proven.