What are the methods for boosting an engine?

Forcing in translations: with it. language – strengthen; from French language – force – acceleration or intensification of any activity. There is another meaning of the word “force” - to overcome.

In relation to cars, engine boosting falls into the category of work such as engine tuning. Namely, modification of factory designs and parts to increase power.

By boosting the engine, you strengthen or overcome the factory parameters in order to obtain higher output from components and mechanisms.

At the moment when the idea that you need to boost the engine matures and takes hold in your head, ask yourself a couple of questions.

Why do you need engine boost? Are you ready to incur considerable financial costs by boosting the engine? If the answers are ready, then you will be helped by materials that describe in detail engine boosting, video materials in which you will see the results and the process of engine boosting.

The first, more suitable for modern cars, is chip tuning. Chip tuning is essentially an intrusion into the electronic brain of a car to correct firmware (control programs).

As a rule, this is a correction of the engine control unit or installation of additional controllers - modules in order to increase engine power. Without special knowledge and equipment, it is not recommended to carry out chip tuning yourself.

The second method is mechanical boosting of the engine. This includes a lot of activities, both to refine existing units and to replace them with new, more productive and efficient ones. And, although you know how to hold a hammer and chisel in your hands, this is not a reason to immediately start boosting the engine.

Do not forget that any type of tuning, be it boosting the engine, or, begins with calculations of changes in the behavior of the car. It is important.

So, what are the most common methods of boosting an engine?

How to boost the engine more efficiently

Increase in engine displacement. In another way, this method is called “boring” the cylinders. Everyone knows that the higher the engine displacement, the more powerful it is. Therefore, increasing the displacement is mandatory when boosting the engine. The expansion of the cylinder walls is carried out as an adjustment to the new size of the pistons. This suggests that boring cylinders “from scratch” is unacceptable. First of all, the necessary pistons and connecting rods are purchased, and then an increase in volume.

- Sleeving . This method can be called as an addition to the first. The fact is that when the cylinder walls are bored, they lose their properties and become less durable. Thus, the likelihood of cylinder block failure increases markedly. To reduce wear on the cylinder walls, it is necessary to install special liners inside that have good wear resistance. Thus, the service life of the motor increases significantly.

- Application of a lighter crankshaft . Lightening the crankshaft is also a prerequisite for boosting. In fact, such a part is made of more durable material and has more weight compared to the standard one. However, when the speed reaches 3000 rpm, the force of inertia begins to work, which spins it even stronger. Thus, efficient engine operation is achieved at a given speed.

Do not forget that along with replacing the crankshaft, a special bed with liners is installed in the block. This measure is necessary to reduce wear on the cylinder block, which is achieved by friction of a harder material against a softer one.

- Replacing pistons . Along with the purchase of enlarged pistons, their weight and design are taken into account. As you may have guessed, when boosting the engine, it is mandatory to install lightweight pistons that move noticeably faster. Many craftsmen lighten the weight of standard pistons by drilling holes in them. This is strongly not recommended. The shape of the pistons in the working part allows for the best compression of the mixture. A good compression ratio will give you maximum compression and therefore help you achieve more power.

Along with the change in volume, the cylinder head, in particular the combustion chamber, changes or is bored. Many parts of the cylinder head are subject to change, as well as parameters such as gas distribution. Indeed, along with the change in volume, the amount of mixture supplied to the cylinder must be increased. Setting the cylinder head parameters requires a lot of skill, so it is not recommended to do it yourself.

- Application of turbocharging . The most serious step towards increasing power can be considered the installation of a turbocharger. It is a pump that pumps an additional portion of air into the combustion chamber under high pressure. The compressor works due to the force created by the exhaust gases in the exhaust manifold and makes the maximum increase in power for the engine.

Why do they boost the engine? Is this necessary?

Despite all the advantages of a forced engine with increased power, its use for everyday driving cars is inappropriate. The fact is that a powerful engine definitely has two disadvantages: increased consumption of lubricants and fuel, as well as a shorter service life.

Such a motor can only be installed on a racing car, which is repaired after each race. In this case, its maximum speed characteristics are needed only for a short time - a race or a small series of races, and a long and monotonous drive on city roads will be completely uneconomical. That is why, before tuning the engine, it is recommended to ask yourself the question “do I need it?”

That's all you need to know about boosting the engine. We hope this article will help you make the right choice regarding this issue.

Reduced mechanical losses

Mechanical engine losses include: auxiliary equipment drives, friction, pumping losses.

- Friction in the cylinders of the block. Their reduction is carried out due to: the use of prefabricated oil scraper rings, increasing, lightening the connecting rod. In theory, it is recommended to carefully balance and select the weight of all parts of the crank mechanism.

- Pumping losses. This is mostly friction in the crankshaft journals. The installation of a camshaft with wider phases also leads to a reduction in pumping losses. Plus, it is necessary to use a “dry sump” system, which will reduce the pumping losses expended by the crankshaft. After all, oil getting on it slows down the rotation.

- Auxiliary equipment. Timing drive, air conditioning, power steering, generator and water pump. This all leads to a decrease in engine efficiency. It is recommended for cars with a forced engine to increase the gear ratio of the water pump and generator drive.

Optimization of the mixture combustion process

Without going into the theory of the combustion process of the air-fuel mixture in the chamber, a recommendation. The combustion chamber must be compact to reduce heat loss and the likelihood of detonation, and ensure efficient mixing of air and fuel.

Do you know, dear motorist, what a forced engine means? Such a motor allows you to significantly increase power, and thus the car receives acceleration dynamics that are scary to even think about. In essence, you become the owner of a real racing car, which is too expensive to purchase, and not every Russian can afford to buy it. But you can turn a regular engine into a forced one. We will talk about this in this article.

Boosting an engine means increasing its performance by reducing the loss of internal combustion engine energy spent on friction and the operation of additional equipment. In addition, increasing engine performance implies unlocking its hidden reserves.

Answers@Mail.Ru: Maybe someone knows what a forced engine is. Thank you

The Chairman answered correctly, this is an engine with increased power. The fact is that the engine designer is always faced with a compromise task, to obtain maximum power with minimum fuel consumption and maximum durability (there are also other factors, weight, price, etc.). If you don’t care about the price and reduce the resource, you can significantly increase the power, this is called boosting. Personally, in makeshift conditions, I managed to achieve a specific power of a motorcycle engine of 200 hp/l, but at the same time the service life became 40 minutes (that is, after each race a major overhaul was required).

Hmm...well, generally speaking, increase its output power....

Prechamber, for example. It’s faster to find it in a search engine than to type text here.

This is an engine with a changed compression ratio, so if the head is “cut”, then it is forced; if, on the contrary, a gasket is added (increasing the combustion chamber), then it is called derated (for example, switching to 80-octane gasoline)

engine with increased power compared to the base model

Afterburner is a second-stage supercharger, when exhaust gases from the engine exhaust manifold do not simply escape into the atmosphere, but participate in the additional process of turbocharging (exhaust gas compressor) which forces fuel under pressure into the combustion chamber. The efficiency of such motors reaches 50%, and power and torque increase accordingly. The disadvantages include increased fuel consumption, as well as severe wear of rubbing parts, so some auto developments are labeled with the TURBO label, which are used in record races, but not in everyday life.

A boosted engine is an engine with increased power (and torque) compared to the original engine, and how this was achieved is not at all important. (Engines are boosted in different ways: by installing a turbine on the intake manifold, with mechanical superchargers there, by boring the cylinders, thereby increasing volume, trimming the cylinder head (increasing the compression ratio), well, in general there are many ways and each has its own pros and cons. Read specialized literature on engines, everything is described in detail there.

touch.otvet.mail.ru

What it is

To begin with, I would like to note that boosting the engine is not news or fantasy, but a very real procedure that has been successfully used by many companies for a long time. And such a concept as tuning means the modification of such factory designs and parameters that are not fully disclosed. In fact, each internal combustion engine has reserves that you need to know and be able to disclose.

By boosting the engine, you get the opportunity to enhance the factory performance of the internal combustion engine. And this is done for a specific purpose - to obtain higher performance of various components of the power unit.

The video shows what a boosted engine is:

In other words, boosting the engine means increasing the power of the internal combustion engine due to something, and in our case, due to increasing the displacement. And this approach is used not only by so-called tuning companies, but also by car manufacturers. For example, the internal combustion engine of the VAZ 2106 was obtained by boosting the internal combustion engine of the VAZ 2103. And there are many such examples.

Niva with turbine

The most common way to add power to an engine is to install a turbine or compressor, which will significantly increase the volume of air entering the power plant.

Installing a turbine is not a complex tuning solution, since the turbine itself has a fairly simple structure. The supercharger and turbine impellers are mounted on the same shaft, and the exhaust gases are the drive. Thus, we can observe the most efficient use of energy from combustion products in a car. The absence of interaction between the crankshaft and the turbine shaft also increases the efficiency of the power plant.

In general, the Niva engine can and should be modified, and then your car will become more powerful and last much longer. This is what we should strive for!

Read news about the new Niva

- Engine 21214 Features characteristics and tuning

- Niva urban engine

- Engine tuning: Niva 4x4 - increasing power using common methods || Niva boost engine

- Niva Lynx buy in Vladimir - prices for the new Lada “Bronto” (Niva Pickup)

- The design of the injection engine Niva 2121, Niva 2131

- What kind of diesel engine can be installed on the Niva?

- Chevrolet Niva: turbo kit, turbo kit for Chevy Niva

- Turbocharging on the Niva injection engine

Also interesting: What kind of oil to pour into the transmission, transfer case and axles of Niva Chevrolet

Several ways to improve internal combustion engine performance

Engine boosting has basic principles, and such work can be carried out in different ways. The most popular and widespread method is, as mentioned above, to increase the working volume of the combustion chamber. If it is difficult to change such a parameter in a racing car, since it is strictly prescribed in the technical regulations, then this is possible. According to the standard of all passenger car models produced today, only the geometric size of the cylinder head is limited.

The first method of mechanical boosting involves replacing the crankshaft with another one - with a larger stroke and cylinder diameter.

In addition, you can strengthen the internal combustion engine using another method. This can be done by installing a drive compressor. This method is very popular in Western countries, in particular. A drive compressor or the same mechanical supercharger is installed on the car, which is carried out from the crankshaft. What's happening? Thanks to this method (however, the same thing happens when using the first method), the torque increases throughout the entire operating range of the internal combustion engine.

The next way to increase the performance of an internal combustion engine is to shift the peak torque. This method is used mainly in sports. Peak torque shifts towards high rpm and the main goal is to reduce drag as air enters the cylinders. How to achieve this? Very simple. It is necessary to eliminate certain steps that form in the area where the intake manifold connects to the cylinder head and carburetor. To do this, the intake manifold is usually polished, after which larger valves are inserted using special heads.

Then it is often replaced using a dual version with a horizontal flow. As a result, this method of boosting the internal combustion engine results in an increase in the total cross-section of the diffusers, and the mixture is distributed evenly across all cylinders, because the flow of the fuel mixture does not have to change direction at the exit from the carburetor.

The next way to increase the power of an internal combustion engine is to install a completely different camshaft. In other words, it needs to be installed with wide phases, which significantly improves the filling of the combustion chamber at high speeds and this happens by reducing the torque “at the bottom”. Because of this, a car equipped with such a camshaft, when driving, forces the driver so that the engine speed does not drop, and the power unit itself, so to speak, does not become stupid.

Tuning the intake and exhaust is another way to increase engine power. What does this method provide? Thanks to it, it is possible to increase the torque supply in a narrow range due to resonance. Boosting the internal combustion engine using this method allows you to increase engine power, and you have to install not ordinary, but light forged pistons in order to maintain acceptable inertial loads.

Finally, increasing the compression ratio makes it possible to increase the performance of the internal combustion engine. This is explained by the fact that detonation at high speeds occurs quite rarely. True, the owner of such an engine must be able to provide his car with high-octane gasoline, but if you know how, the method will be the best.

In other words, this method of boosting the engine involves changing the valve timing.

RESULT

Boosting an engine is a very complex job that requires delicate calculations, which allows you to achieve high performance and speed results. Almost all components and assemblies are involved here, you will even need to change the firmware! So such work must be carried out consciously, with an understanding of why you are doing it! Then engine performance can be raised to a whole new level. I personally saw when more than 200 horses were squeezed out of simple VAZs.

Most car owners love speed. But not all cars are able to satisfy such a desire. As a rule, there is only one reason - lack of power. Boosting the engine is a good way to eliminate it. Then the iron horse is able to turn into a thoroughbred horse that will show the most enviable results. In addition, comfort will noticeably increase, and driving pleasure will increase several times.

Engine boosting can be done in two ways: “brain flashing”, as well as “surgical intervention”. The first one was called chip tuning. Here the engine settings are simply changed. The fact is that, which allows you to develop average performance over the entire range of engine speeds and loads. Boosting the engine allows you to shift maximum performance closer to higher speeds. Thus, if previously, for example, the maximum torque developed at 3000 rpm, then after flashing it will be developed, for example, at about 5000. This is done in order to increase the dynamics of acceleration, as well as the maximum speed.

But it should be remembered that the engine will lead to a serious loss of power “at the bottom”, although if such measures are carried out, then, most likely, operation at low speeds is not planned.

The second method involves boring the cylinders to a larger volume, reducing the combustion chamber, installing lightweight parts, modifying the manifolds, power supply and lubrication systems. Let's look at all this separately.

Boosting a VAZ engine is worth starting with this, since they all have a rather small displacement. An increase in volume can be achieved by installing with a large knee, which will lead to a loss of rev. The increase in piston diameter also cannot be infinite, since the block is completely cast from cast iron. In addition, honing the walls can only be carried out at a certain thickness; after removing this layer, the use of the cylinders will no longer be possible.

Installing lightweight parts has a positive effect on engine response because less energy is required to rotate and move them. In addition, installing lighter valve train parts reduces the speed of its response to valve timing, which is beneficial for ventilation and the power system. The latter also includes the modification of collectors, since it is the gases that do all the work. A different air filter with higher performance is also installed on the engine.

But, like all improvements, it has its downsides. For example, forcing leads to a serious reduction in its service life. This is logical, because more energy that is transferred to the wheels wears more, which is the heart of the car. In addition, it is worth thinking about the clutch, since it is not designed for high engine performance, and with proper boost, it can almost double.

No serious car tuning is complete without boosting the engine. This procedure seriously increases engine power, and therefore increases the speed characteristics of the car. In this article we will look in detail at what engine boosting is, how it is done, why it is needed and is there a need for it?

Electronic and mechanical boosting of internal combustion engines

The video shows a simple way to boost the engine:

Let us now consider methods for boosting internal combustion engines from a general point of view, without going into all the details. The most suitable and common method is, which is ideal for modern cars. Knowing this method of boosting the internal combustion engine is, in essence, a method of how you can boost the engine by invading the electronic brain of the vehicle. Thanks to certain correction methods or “firmware”, it is possible to manage programs that automatically increase productivity. In this case, additional controllers or modules should be installed, which will essentially become components that will increase engine power. The disadvantage of this method is that it is simply impossible to carry out it, since it requires special knowledge and, most importantly, expensive equipment.

As for mechanical boosting of the internal combustion engine, this method is simpler. As mentioned above, the method involves modifying existing vehicle components or replacing them with new ones.

Although this type of tuning is simple, it is not worth starting without special calculations.

Refinement of the power plant

To begin with, it is worth noting that almost any engine, regardless of the type of fuel on which it runs, can be boosted. If you go through the factory engine and take into account all the subtleties and nuances missed during assembly line assembly, you can get a power increase of 10-20%. The fact is that during mass assembly, individual adjustment and adjustment for each unit is not used. The task of the conveyor is to ensure that the motor falls within the established range of tolerances and fits.

During individual assembly, even the smallest errors are taken into account in order to achieve maximum performance when reaching engine afterburner. In addition, parts and assemblies are replaced with stronger ones that can withstand heavy loads.

The disadvantage of this method is the significant price and the need to replace other components of the car (brake system, gearbox, etc.).

We minimize mechanical losses

The video talks about the pros and cons of boosting the engine:

Almost all methods of boosting an engine are aimed at one thing - reducing the mechanical losses of the internal combustion engine. Where does a considerable part of the engine energy go? It turns out that the friction that occurs in the cylinders of any internal combustion engine reduces performance. In this case, it is possible to install prefabricated oil scraper rings, thereby increasing the gaps between the cylinder and the piston. This method is not carried out with a bang. You must first carefully balance the components and select all parts of the crank mechanism by weight.

Friction in the cylinders is not the only reason for the loss of power of an internal combustion engine. In addition, losses are also explained by friction in the crankshaft journals. In this case, as mentioned above, they use a camshaft with wider phases and additionally install a system that significantly reduces the pumping losses expended by the crankshaft. It should be remembered that oil getting on the crankshaft significantly slows down its rotation.

A significant part of the engine's energy can also be spent on auxiliary equipment. For example, these include parts and devices such as air conditioning, water pump, power steering and much more. In this case, it is necessary to increase the gear ratio of the generator and the water pump drive.

Boosting a two-stroke engine is not just a modernization of the internal combustion engine, but a necessity in our time. If a four-stroke engine has a longer service life and efficiency, which makes boosting a right thing, but not necessary, then on a two-stroke internal combustion engine it is already important to do this. In addition, according to experts, boosting is easier on two-stroke engines.

Boosting is an increase in engine output parameters: power and torque, usually speed. It is implemented through a whole range of measures.

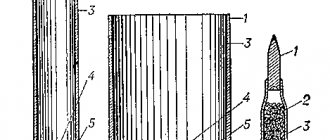

Classic boost - direct-flow dual carburetors

Many people would like to have as many “fast horses” under their feet as possible, but not everyone can imagine what price they will ask for. And not only in conventional units. Therefore, first you need to find out the limits of your desires, based on the capabilities of not only your conto, but also the source material. That is, the existing car and its engine. One limit may be for a purebred Bavarian, and a completely different one for a purely Soviet Muscovite or Volgar. I’ll say right away that the last clients are already close to their limit of disintegration, so talking about forcing them is simply ridiculous.

Flow turbulence at sudden changes in channel cross-section

So we have a tough, modern car, preferably with four valves per cylinder, two camshafts in (each) head, and the hope that it can give and take more. Where to start? Let's see what ways there are to increase power. And one more thing, if you decide to boost the engine, then the reasons for the high fuel consumption should not interest you, since as the engine power increases, the consumption will naturally increase.

Practical injection

The main method of boosting is to facilitate the “breathing of the engine”. This means not only a decrease in the passive resistance of the intake and exhaust channels, but most importantly, an increase in the “time-section” parameter of the valves, which depends on the width of the valve timing and the valve lift height. That is, the higher the speed (and increasing it is the most effective way to increase power), the earlier the intake valve must open and later close so that fresh charge has time to fill the cylinder. However, if the opening is too early and the closing is too late, the mixture will be pushed back, and for each engine speed there is its own optimum. It is different for each engine, so it is finally selected on a test bench. The higher the degree of boost, the narrower the operating speed range of the engine, which forces the use of multi-speed gearboxes. This drawback can be eliminated or weakened by mechanisms with adjustable phase change, but they have not yet entered into tuning practice and require significant reconstruction of the gas distribution mechanism and head.

The resistances of the intake and exhaust tracts must have smooth cross-sectional transitions without sharp bends characteristic of production cars, and steps in their junctions with the channels in the head, a smooth surface, preferably polished or even chrome-plated, as well as the maximum possible flow sections.

On the surface lies the idea of using the natural high-speed pressure of the air flow to recharge the cylinders. However, this head pressure is too low to affect filling and power. So, at a speed of 100 km/h it is 0.0047 kr/cm2, at 200 - 0.0189, and at 350 - 0.06. Low intake air temperature has a greater influence.

The best filling is provided by fuel injection systems. A good effect is achieved by Italian racing twin parallel carburetors Weber 40(45) DCOE, which for many years have completely adorned racing equipment, and now hot rods in their various versions. For forced engines, single horizontal and inclined Dell'Orto carburetors are also designed, which give a good peak of power, but higher fuel consumption, and are more sensitive to adjustments. The most elastic characteristics are provided by English SU carburetors and similar ones by Stromberg and Bing with a constant vacuum in the diffuser, as well as Japanese Keihin. Americans prefer local four-barrel carburetors such as Holley or Carter, especially in compressor versions.

To reduce mechanical losses and reduce dynamic loads on parts of engine mechanisms, critical parts are lightened: pistons, connecting rods, valves, pushers (except for light cups), crankshaft and flywheel.

For a high degree of boost, pistons are made by forging from wrought aluminum alloys of the AK group. Such pistons can withstand higher loads, but have a higher coefficient of thermal expansion, which requires a larger working clearance when cold. An oil passage under the bottom is very useful to cool the hot areas of the piston, but this is a difficult task. Some boosters manage to do it from the inside. Mahle, a well-known F1 company, solved the problem differently. She cuts out an annular channel from the top of the bottom and welds the annular cover there with an electron beam.

Racing pistons are made with a minimum height and friction surfaces and a minimum number of rings - 3 or even 2. The rings themselves are very thin: 1 -1.2 mm to reduce vibration stress and friction losses. Of course, the resource of such parts is small.

The mass of the connecting rods has a great influence on the loads of the crank mechanism and the mechanical efficiency. For example, replacing connecting rods with lighter ones in the Skoda sports version automatically increased power by 5 hp. Audi tuners lighten standard connecting rods by 100 g. An even greater effect is achieved by using lightweight forged aluminum connecting rods. However, few companies make them and they are much more expensive than steel ones. Very cool companies, like Porsche and the like, use titanium connecting rods in their racing engines. Their production requires complex technology, and, in addition, their low thermal conductivity creates problems with overheating of the liners. More promising is the manufacture of connecting rods from composite materials. It goes without saying that the use of high-quality inserts from reliable companies is implied, otherwise all the work is meaningless.

Standard lubrication systems need to be improved to avoid oil leakage from machine parts, especially distribution gear, under the influence of inertial force in intense turns of the track. To do this, additional channels and tubes for draining oil from the head are made, oil receivers are changed, and oil pumps of higher capacity are used. Sometimes an additional oil pump is installed. After these modifications, of course, the engine does not smoke when cold. Improvements may also be needed for the cooling system.

5 kg lighter and standard Audi crankshaft

The effect also gives relief to the crankshaft and flywheel. For a stressed engine, both must be steel, since the strength of cast iron is insufficient for high speeds. The middle crankshaft is lighter by 5 kg. Flywheels are sometimes made of duralumin with a pressed crown and clutch lining.

And after all these labor and financial feats, all you have to do is add a racing clutch, a “short” gearbox, a limited-slip differential, good shock absorbers, reinforced brakes, add rigidity to the lightweight body, appropriate spoilers, wide tires, find out what gasoline and what oil is better and fill it them - and you are almost a racer. Don't forget the helmet and what you wear it with.

Anyone who decides to seriously tune their car is unlikely to ignore the engine. What does forced mean? In medicine there is such a thing as forced diuresis. This means an accelerated method of detoxification. The key word here is “accelerated.” This is precisely the concept that is included in the phrase “boosted engine”.

What it is?

Setting the goal of boosting the engine, they use various methods to improve its characteristics, thanks to which the engine reveals all its capabilities and begins to operate at much greater power. It is often possible to increase quality indicators twice or more. And all this without loss of engine life.

Ways to increase engine performance are:

- actions that do not have the nature of constructive changes;

- actions with design changes;

Work without structural changes

The most common way to boost an engine is by flashing the ECU unit or, as it is often called, chip tuning. In this case, the standard program is replaced with a more “working”, enhanced one. It will increase power by about ten percent.

Another well-known method is to replace the manifolds - intake and exhaust. The common “spider” will increase power by another five percent.

In order for the engine to “breathe fully”, completely, however, it should be taken into account that they will be much dirtier.

The last modification without design changes is carried out in the same part - the muffler. Here they install a direct flow. Then the exhaust will not come into contact with various partitions, which will increase power.

Such methods are the simplest and cheapest. But if the goal is to make the engine truly boosted, this will require more serious work.

Tuning with design changes

Such actions are more expensive. They can cost up to the motor itself. Some elements, for example, are changed to reduce friction. In general, you need to understand in this case that the motor will be completely rebuilt.

The following improvements are being made:

- increase the cylinders, expanding the engine volume from 1.6 liters to 2.0 in some cases;

- they do “sleeving”, that is, they install more wear-resistant parts;

- install another version of the crankshaft, made of high-strength metals and capable of withstanding heavy loads;

- it is placed in a special block with liners, which are replaced with more reliable ones;

- then the pistons, connecting rods and low-removal rings are replaced - in addition to special materials, they become lighter in weight;

- at the end it’s time to replace the cylinder head and camshafts - here the main task will be to better fill the combustion chamber, and for this the phases are made wider.

Geometry improvement work

Due to the low engine efficiency and low wear resistance, mechanical tuning of the Niva 4x4 engine is almost mandatory. Such work is called work to change the geometry of the power plant. You should start modifying the power plant by upgrading the carburetor. We do the following:

- We change jets with an indicator of 1 kam to a jet with an indicator of 2 kam;

- Renewing the accelerator pump nozzle.

If there is dirt or carbon deposits in the carburetor, we clean it manually. To do this we need a rag, gasoline and physical strength. If the dirt is very stubborn, a high-pressure cleaner or other device designed for washing the car will help. You can also use special “baths” to remove dried dirt from parts. In this way, the fuel supply to the gas distribution mechanism can be significantly improved.

If you are the owner of an injection Niva, then independently modifying the injector is unacceptable. Only a professional with knowledge of software can perform such tuning of the Niva engine.

Also interesting: Construction and repair of the VAZ 2121 Niva transfer case

Lubricant supplied through the oil pump extends engine life. To improve the performance of the oil pump when tuning the Niva engine, you need to take another pump and cut off part of the housing with the parting plane from it. The thickness of this “pancake” should be about 11 cm. Using milling, cut off the excess and leave a thickness of 10 mm.

Next, do the following to remove chamfers on the edges of the teeth:

- We compress, that is, remove, the drive gears.

- We trim one of the gears by 0.75 mm on each side.

- We cut the second gear to 11.5 mm (after trimming).

- We repeat the operation with the remaining gears (driven).

Let's start working on the body. To do this we do the following:

- We release the driven gear axis from the housing.

- We form a longer axis from the drive roller.

- We insert the resulting axle into the body.

- We press the narrow gear onto the second drive shaft.

- Press on the wide gear.

- We fix the wide driven gear in the housing.

- We install a narrow gear into the housing.

This sequence will prevent the gears from turning relative to each other. You can also improve the oil receiver of the Vase by cutting it a centimeter from the bottom. After this, we adjust the end gap and connect the entire structure with bolts.

What is boosting an engine?

In many languages, the word “boosting” can be translated as “strengthen”, “accelerate”, etc. Regardless of the type of engine, its speed characteristics are improved by replacing standard parts with improved ones, changing the size of certain chambers, adjusting power systems, exhaust, etc. Currently, there are many methods of boosting that allow, one way or another, to improve the dynamic properties and achieve the most efficient operation of the engine.

Power tuning: advantages and disadvantages

It’s worth starting with the fact that almost any gasoline or diesel engine can be boosted. The so-called “iron” tuning without installing a turbine provides a power increase of about 10-20%. Refining the engine by installing turbocharging provides up to a 40% increase in power.

As for the engine life, boosting can either significantly reduce or increase the service life of the power unit. Also, the resource will directly depend on the intended purpose and individual conditions in which a particular engine is operated.

As an example, we can compare a tuning unit and a factory one. If a new forced engine is assembled by specialists in a technical center, then under the same operating conditions, the tuning internal combustion engine will last one and a half or two times longer. The fact is that in the process of mass production at a factory, a conventional engine does not undergo individual tuning and adjustment during assembly. The main task of assembly on a conveyor is not maximum accuracy and subsequent reliability of the unit, but assembly in accordance with a number of standards and tolerances. As for an individually assembled engine, during its creation even tenths of grams and millimeters are taken into account (weight distribution, balancing, etc.) to achieve better performance, and reinforced parts and components are installed, initially designed for more severe loads.

The disadvantages of significantly increasing the power of the internal combustion engine include serious financial costs, as well as the need to modify other components of the car: suspension, gearbox, braking system, etc.

This increase in power is often achieved in conjunction with the installation of a turbocharger or mechanical compressor. For this reason, many car owners choose to modify the engine without installing a turbine.