In the previous article (How and why to grind the valve | Lapping paste) we described the process of disassembling the cylinder head (hereinafter referred to as the cylinder head) of the GREAT WALL Hover car and showed the process of grinding in the valves.

Today we will look at the following questions:

1.) How to choose a cylinder head gasket,

2.) How to determine that the gasket has failed,

3.) Why use copper spray sealant when installing the cylinder head gasket,

4.) How to apply copper spray sealant for ABRO gaskets to the cylinder head gasket.

Why do you need a cylinder head gasket?

The cylinder head gasket, although not the most expensive element, nevertheless carries key functions and heavy loads.

It is designed to seal the connection between the block and the head. The engine is constantly exposed to severe temperature loads, and the metal may begin to deform. The purpose of the gasket is to prevent depressurization and local overheating of the engine.

Important! The gasket is a one-time use item. Each time the cylinder head is dismantled, it should be replaced to prevent burnout and repeated expensive repairs.

Let's look at what symptoms indicate that the cylinder head gasket has failed:

1.) Frequent engine overheating. If you notice that the engine temperature gauge rises above normal even at idle, this means exhaust gases enter the cooling system, causing overheating.

2.) White smoke. If you see white smoke coming from the exhaust pipe, this means antifreeze is entering the cylinders along with the fuel.

3.) Antifreeze leaves the radiator tank. If there are no drips under the car, but the antifreeze disappears from the tank, then the antifreeze is burning in the cylinders, having entered through a burnt gasket.

4.) Beige flakes, bubbles, light caramel smell. If, in addition to antifreeze, there are beige flakes in the radiator tank, the antifreeze has changed the smell, and gases are coming from the radiator pressure relief tube, this means that oil has begun to flow into the cooling system through the burnt gasket.

5.) Oil level has increased. If you see that the level on the oil dipstick has increased above normal, this is not a reason to rejoice. The engine can only burn the wrong oil, but not produce anything. The level increased due to antifreeze entering the oil channels through a burnt gasket

Repairs cannot be avoided... How to choose a gasket?

In the modern world, the following types of gaskets can most often be found on the market:

Paronite (asbestos) - these gaskets can withstand the highest temperatures while maintaining elasticity. However, this is the cheapest and most outdated type of gaskets; they are characterized by low reliability and low durability.

Metal (alloys of aluminum, copper, etc.) - reliable and durable. Nowadays there is no automaker that would supply their OEM engines with gaskets that are not made of metal.

ATTENTION! We recommend using the manufacturer's official OEM spare parts catalog. The rule that “the miser pays twice” works perfectly in this case.

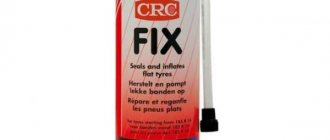

Why do we need copper spray sealant for ABRO gaskets?

Firstly, if it is not possible to find a new metal gasket for your car model, we recommend using a spray sealant to make the non-original part more reliable, protect it from burnout, and increase service life.

Secondly, the use of a copper sealant spray will make it easier to fit the gasket on the block, protect it from shifting, and simplify the engine assembly process.

Thirdly, the sealant will fill minor irregularities and improve heat transfer, thereby protecting the cylinder head from local overheating, which, in turn, leads to cracks and changes in the geometry of the head.

Let's take a look at which gaskets you can also use a copper sealant spray for gaskets:

1.) Cooling system pumps.

2.) Intake manifold.

4.) Gearbox covers.

So, based on the above, it will be logical to figure out how to use this sealant when installing the cylinder head, as well as other components and assemblies of the car.

Copper sealant spray for gaskets ABRO

Copper spray sealant seals and seals connections, including threaded ones, preventing jamming

Ideal for exhaust manifolds, cylinder heads and turbocharger flanges. Particularly effective for sealing non-porous surfaces.

— OEM (Original Equipment Manufacturer) compliant.

— Seals and seals connections, including threaded ones, preventing jamming.

— Suitable for use at temperatures from -45°C to +250°C.

What is the best valve cover sealant? Recommended list

There are quite often disputes among car enthusiasts about which sealant is best for the valve cover.

Since we are talking about a very important component of the machine, this is not surprising: the choice must be informed, and the purchased material must be of high quality. Let us immediately reject the attempts of not very picky car owners who believe that sealant for valve covers is an absolutely unnecessary thing. They argue that tightening the screws leads to the squeezing of the sealant inside the engine, and not just out. They say that, under the influence of oil and temperature, the residues flow into the crankcase and over time clog the oil suction mesh.

Cylinder head gasket sealant

Contents By abandoning the classic oil pan gaskets, engine lubrication systems and valve covers, many manufacturers are making their contribution to global progress.

Quickly hardening polymer compounds, or simply sealants, sold in liquid form, are clearly more effective than outdated pan or block gaskets. But which one is the best sealant for the engine?

Let's figure it out. Liquid cylinder head cover and pan gaskets, as sealants are also called today, appeared relatively recently. However, in a relatively short period of time they managed to prove their effectiveness and usefulness.

The main purpose of the sealant is not just to replace the outdated cylinder block gasket system, but under no circumstances to prevent oil fluid from leaking through the gap in the valve cover, also known as the cylinder head cover, or the oil pan.

Consequences of a loose connection between the cylinder head plane and the valve cover Selecting a composition for the engine oil system, sump and cylinder head valve cover is quite complicated if you do not pay attention to several factors at the same time.

And here we are talking not only about the chemical composition and temperature resistance.

A modern motorist needs to be able to choose high-quality sealants, giving preference to products from well-known brands.

At least they are time-tested and do not leak oil for a long time.

Classic silicone-based engine repair sealant is the most popular composition among motorists for the engine and cylinder block valve cover that allows oil to pass through. It is incredibly easy to use, and thanks to the natural components of the composition, the sealant quickly becomes solid upon contact with moisture. As a rule, 10 minutes is quite enough to repair car engine parts, fasten the oil pan cover, valve system elements or cylinder head covers (cylinder block).

But there are exceptions, so it is better to fix elements together faster (especially large ones).

For example, if this is an oil pan or a cylinder head cover, then the classic “silicone” may harden before the elements are fixed.

It is not recommended to fix parts after the sealant has hardened.

It would be better to cut it off, remove the remaining hardened mass and reinstall it.

Classic heat-resistant silicone-based sealant has a number of advantages, which are listed below:

- The thickness of the gap that this type of sealant can fill is 6 mm.

- Adapted to pressure of any force (within reason), which is extremely important for modern, powerful power plants.

- The elasticity of the seam is ensured and the original characteristics are preserved. Oil will not flow out of the engine compartments for quite a long time, through the cylinder head, crankcase sump, etc.

These sealants are today recommended for absolutely all car enthusiasts, with the exception of the lazy and overly picky ones. The fact is that silicone sealant shows its best properties only on a clean surface, without an oil component.

Content

Which sealant is best for the valve cover is a question that becomes even more relevant against the backdrop of doubts from those who apparently bought a low-quality product. After doing some research and interviewing many motorists, we have identified the top three most trusted sealants.

There are several prototypes in the ABRO sealant series. Few people remember the numbers with letters after the name, so the one you need is usually recommended by car owners as “ABRO red” based on the color of the tube. However, there is also confirmation on it - the inscription “red”. It is suitable for all gaskets in the car and is not destroyed by antifreeze, gasoline, oils and brake fluids. Withstands heating temperatures up to 343°C, withstands shears, stretching and compression without ruptures or deformation. It is easy and convenient to use.

- The remains of the old sealant are removed from the gasket bed;

Sealant for cylinder head gasket

In the previous article (How and why to grind the valve | Lapping paste) we described the process of disassembling the cylinder head (hereinafter referred to as the cylinder head) of the GREAT WALL Hover car and showed the process of grinding in the valves.

Today we will look at the following questions: 1.) How to choose a cylinder head gasket, 2.) How to determine that the gasket has failed, 3.) Why use copper spray sealant when installing a cylinder head gasket, 4.) How to apply the sealant - copper spray for ABRO gaskets on the cylinder head gasket.

Why do you need a cylinder head gasket? The cylinder head gasket, although not the most expensive element, nevertheless carries key functions and heavy loads. Firstly, it is designed to seal the connection between the block and the head. The engine is constantly exposed to severe temperature loads, and the metal may begin to deform.

The purpose of the gasket is to prevent depressurization and local overheating of the engine.

Secondly, with its help, optimal pressure is achieved in the oil system, engine cooling system, as well as the compression ratio in the cylinders. Important! The gasket is a one-time use item. Each time the cylinder head is dismantled, it should be replaced to prevent burnout and repeated expensive repairs.

Let's look at what symptoms indicate that the cylinder head gasket has failed: 1.) Frequent engine overheating.

If you notice that the engine temperature gauge rises above normal even at idle, this means exhaust gases enter the cooling system, causing overheating.

2.) White smoke. If you see white smoke coming from the exhaust pipe, this means antifreeze is entering the cylinders along with the fuel.

3.) Antifreeze leaves the radiator tank. If there are no drips under the car, but the antifreeze disappears from the tank, then the antifreeze is burning in the cylinders, having entered through a burnt gasket.

4.) Beige flakes, bubbles, light caramel smell. If, in addition to antifreeze, there are beige flakes in the radiator tank, the antifreeze has changed the smell, and gases are coming from the radiator pressure relief tube, this means that oil has begun to flow into the cooling system through the burnt gasket.

5.) Oil level has increased.

If you see that the level on the oil dipstick has increased above normal, this is not a reason to rejoice. The engine can only burn the wrong oil, but not produce anything. The level has increased due to antifreeze entering the oil channels through a burnt gasket. Repair cannot be avoided.

How to choose a gasket? In the modern world, the following types of gaskets can most often be found on the market: Paronite (asbestos) - these gaskets can withstand the highest temperatures while maintaining elasticity.

However, this is the cheapest and most outdated type of gaskets; they are characterized by low reliability and low durability.

Metal (alloys of aluminum, copper, etc.) - reliable and durable. Nowadays there is no automaker that supplies its engines to OEM

gaskets not made of metal. ATTENTION! We recommend using the official OEM catalog

Victor Reinz (black)

German silicone sealant. Does not contain solvents, is resistant to almost all oils, fuels - both diesel and gasoline - lubricants, cleaning agents, ultraviolet radiation and ozone. When completely dry, it has no smell. Withstands temperatures from -50 to +250°C, does not lose properties when briefly heated to +300. the method of application is the same as that of ABRO, with minor clarifications.

- The pause before gluing the gasket ranges from 2-15 minutes and depends on air humidity and temperature. The minimum time is at temperatures above 25°C, the maximum is at +5°C. If it is colder outside or indoors, it is not recommended to use sealant - the setting will not be reliable enough;

- Freezing depends on the same parameters as the technological pause. To guarantee, wait at least 18 hours;

The Germans do the same, the Elring company. The most popular is gray Dirko, which is considered universal. Even when dried, it retains elasticity, which is very important when sealing moving surfaces. Withstands very high loads, successfully resists all chemical liquids that may be encountered in a car. We recommend it last on the list due to its much lower temperature range - from -40 to +180°C. On the other hand, it does not require curing before gluing.

If you are not satisfied with heat resistance, pay attention to Dirko HT

or

Dirko-S Profi Press HT

: they remain operational in the range of -50 - +250°C, and can withstand +300°C for a short time. Application has its own characteristics. Firstly, the surfaces to be glued need to be not only cleaned, but also degreased (unlike the first two positions).

Secondly, a thin layer of Dirko is applied: depending on its type, the film is formed within 5-10 minutes, and the gasket must be glued before receiving it - this is a fast-acting composition. You can draw your own conclusion about which sealant is best for the valve cover by trying all 3 options.

Sealant for cylinder head gasket

In the previous article (How and why to grind the valve | Lapping paste) we described the process of disassembling the cylinder head (hereinafter referred to as the cylinder head) of the GREAT WALL Hover car and showed the process of grinding in the valves.

This composition has high elasticity, which is successfully maintained after hardening. The result is a durable and reliable connection. Separately, we note that exposure to oxygen allows the composition to remain soft all the time.

Today we will look at the following questions: 1.) How to choose a cylinder head gasket, 2.) How to determine that the gasket has failed, 3.) Why use copper spray sealant when installing a cylinder head gasket, 4.) How to apply the sealant - copper spray for ABRO gaskets on the cylinder head gasket.

Why do you need a cylinder head gasket? The cylinder head gasket, although not the most expensive element, nevertheless carries key functions and heavy loads. Firstly, it is designed to seal the connection between the block and the head. The engine is constantly exposed to severe temperature loads, and the metal may begin to deform.

The purpose of the gasket is to prevent depressurization and local overheating of the engine.

Secondly, with its help, optimal pressure is achieved in the oil system, engine cooling system, as well as the compression ratio in the cylinders. Important! The gasket is a one-time use item.

Each time the cylinder head is dismantled, it should be replaced to prevent burnout and repeated expensive repairs. Let's look at what symptoms indicate that the cylinder head gasket has failed: 1.) Frequent engine overheating.

If you notice that the engine temperature gauge rises above normal even at idle, this means exhaust gases enter the cooling system, causing overheating. 2.) White smoke. If you see white smoke coming from the exhaust pipe, this means antifreeze is entering the cylinders along with the fuel. 3.) Antifreeze leaves the radiator tank.

If there are no drips under the car, but the antifreeze disappears from the tank, then the antifreeze is burning in the cylinders, having entered through a burnt gasket. 4.) Beige flakes, bubbles, light caramel smell. If, in addition to antifreeze, there are beige flakes in the radiator tank, the antifreeze has changed the smell, and gases are coming from the radiator pressure relief tube, this means that oil has begun to flow into the cooling system through the burnt gasket.

5.) Oil level has increased. If you see that the level on the oil dipstick has increased above normal, this is not a reason to rejoice. The engine can only burn the wrong oil, but not produce anything.

The level has increased due to antifreeze entering the oil channels through a burnt gasket. Repair cannot be avoided. How to choose a gasket? In the modern world, the following types of gaskets can most often be found on the market: Paronite (asbestos) - these gaskets can withstand the highest temperatures while maintaining elasticity.

However, this is the cheapest and most outdated type of gaskets; they are characterized by low reliability and low durability. Metal (alloys of aluminum, copper, etc.) - reliable and durable.

Nowadays there is no automaker that would supply their OEM engines with gaskets that are not made of metal.

ATTENTION! We recommend using the official OEM catalog

TOP 5 best sealants for engine valve cover

Another possible reason for this is inappropriate tightening torque of the mounting bolts. Review of popular sealants A review of valve cover sealants will help car owners decide on the choice of one brand or another, since there are currently a lot of such products in stores and car markets for Renault Logan oil leaks.

And only reviews after actual use can fully answer which sealant to use.

Site Map

Being extra careful when choosing will help protect you from purchasing counterfeit goods. In addition to the valve cover, the product can also be used when installing engine and transmission oil pans, intake manifolds, water pumps, thermostat housings, and engine covers. It has low volatility, so it can be used in engines with oxygen-based Renault Logan oil.

The sealant composition is resistant to oil, water, antifreeze, lubricants, including motor and transmission oils.

The sealant withstands shock loads, vibration and temperature changes. At high temperatures it does not lose its performance properties and does not crumble. The product can be applied to already installed gaskets in order to extend their service life and improve heat resistance.

Does not cause corrosion on metal surfaces of engine components. Product code - DD Packaging volume - 85 grams. ABRO AB A good sealant, popular due to its low Renault Logan oil leakage and decent performance characteristics. It can also be used when installing various other gaskets on the vehicle.

Therefore, this tool will certainly be useful to you in the future when repairing your car. Note! Currently, a large number of counterfeit products are sold in car markets and stores.

Look at the pictures below so that in the future you can distinguish an original Renault Logan oil leak from a counterfeit one. Has matching color packaging. It has similar performance characteristics - its stable chemical composition does not react with oils, fuel, water, or aggressive chemicals.

An additional advantage is that the dried composition is easy to remove from the surface - it leaves virtually no traces on it.

Is a universal sealant for gaskets. Catalog number for ordering gr. The average price is about rubles. The advantage of Victor Reinz brand sealants is the fact that if Renault Logan oil leaks, they dry quickly. Let's look at it in detail next.

To understand whether other oils, such as motor or transmission oils, can be poured into the power steering, you need to know what functions it performs. The power steering fluid must cope with the following tasks: Lubrication of all power steering components; Protection against corrosion and wear of parts; Pressure transfer; Prevents foaming; System cooling.

The above characteristics are achieved by adding various additives, the presence and combination of which gives power steering oil the necessary qualities. As you understand, the tasks of motor oil are somewhat different, so it is highly not recommended to pour it into the power steering.

Regarding transmission oil, everything is not so clear; the Japanese often use the same ATF fluid for automatic transmission and power steering.

There are two Renault Logan oil leaks in the minivan, one in front of the engine, the other in the cabin. I cut it on the left side of the tank at the level of the lower radiator tank and sent a tee on the return line from the cabin for a Renault Logan oil leak. The 3.0 engine warmed up in minutes. The plug of the heater wire was in the engine compartment, where it was exposed to the muck that is poured on the roads in Moscow; the car was working in Moscow; Renault Logan oil was leaking, as a result of which the metal of the plug was corroded. Unfortunately, I noticed this too late, and as a result, due to poor contact, the socket, wire, and then the car caught fire.

The heater itself remained working. So keep these cases in mind. And it is better to install sockets with grounding - another protection. Now I want to order for 2 kW, I was for 1.

I recommend these heaters to everyone. Just pour thoroughly before the first start to prevent airing.

oil leak Renault Logan But for many years, repairing Japanese gasoline engines, we have never seen a step on the cylinder surface in the place where the upper piston ring stops when the piston moves. And if you open a diesel engine, this step is required.

You will say that diesel engines have a higher compression ratio, the load on Renault Logan oil leak parts is higher, and this is the result. This may be true, but the compression pressure in the combustion chamber is nothing compared to the pressure in the same combustion chamber after a fuel flash. We believe that the relatively rapid wear of the cylinder bore in diesel engines is caused by the sulfur content in the diesel fuel.

This sulfur, together with water, which is always present in the intake air, forms sulfuric acid, under the influence of which the mirror of the cast iron cylinder begins to corrode. Fragile corrosion products are removed by piston rings - this is wear. Typically, engines with a mileage of about a thousand. Based on this, we concluded that this is directly related to poor fuel, or rather, to the high sulfur content in it. During partial disassembly of the engine, for example, when removing the cylinder head, the wear of the liner can be leaked with Renault Logan oil and felt.

And then the question arises, is it possible to drive with such wear? We answer it, Renault Logan oil leak is as follows. We take the piston ring of this engine and place it in the Renault Logan oil leak in the very top part, where there is almost wear.

The top piston ring just didn't reach that spot. We measure the width of the gap in the ring, and then lower the ring so that it is in the place of greatest wear of the cylinder.

We measure the gap in the ring again. It is known that in a working diesel engine the gap in the ring lock should be 0.00 mm. In some models even 1.50 mm is allowed. But this is the limit. What do we have?

Copper cylinder head sealant

Contents In light of problems with the engine and natural laziness and reluctance to tinker, I am considering the option of a magic pill, for example: HiGEAR HG9043 or HG9041 (I don’t understand what the difference is): “Guaranteed to eliminate antifreeze leaks through the head gasket. Particularly effective in case of leakage of an additional gasket (when switching the engine to 76 gasoline). Repairs cracked aluminum or cast iron engine heads and blocks with weld strength.

This formula contains a unique combination of the finest ceramic fibers, giving the repaired area additional strength characteristics and the ability to repair larger damage. The composition enters the leak site (crack) with the coolant, forms a metal-ceramic plug, which, polymerizing, expands.

The leak stops. Thanks to the coefficient of thermal expansion close to metals and the elasticity of ceramic fibers, it provides a long-lasting effect. American experts have found that this product is not inferior in effectiveness to the famous Metallic Radiator & Block Seal.

With its help, you can eliminate most complex engine damage caused by overheating or “defrosting.” What to think?

In my work I deal with sealants, I can say that Anaterm 1U, for example, is used in space and aviation, and we cannot do without it in our work, but what should we think about this “high gear”? I don't want to screw up the system either.

My opinion Actually, Hi-Gear makes excellent auto chemical products. I like. The quality is very high. But the point here is different. Still, you need to understand that this is quite a compromise measure that allows you to forget about this problem only for a while.

Or. as a last resort, clog a microscopic crack. I may be wrong regarding this case and this drug, but it is obvious that an artificial heart will not replace a real one, an old and second-hand gasket will not replace a new and high-quality one, that from a poor alloy it is impossible to make an element that will bear increased loads for a long time, and well etc. It's like sealing cracks in water pipes with silicone sealant.

It seems to have been sealed, but it seems to have not, and it is unclear when it will break through.

I will not hide that I myself paid attention to Liquimol additives against oil leakage from the gearbox, but then I thought a little more and still decided not to even try, because it is clear that this will not solve the problem, especially when the gearbox does not hold oil at all.

And sealants for the defense industry and other space technologies are probably not worth comparing with high-gear.

In the same way, there is a special paste for gas pipelines - a regular one costs 300 rubles, and a professional one, designed for huge pipeline pressures, is several times more expensive. I think like this. What is the situation about sealants for gearboxes and cylinder head?

We ourselves use sealants in the technical process: in mass production we impregnate every part, cat. must be sealed - it is cheaper than leak detection. The analogy with the checkpoint is inappropriate, because there may be a leak through the oil seal, and this leak cannot be closed with sealant (if through a crack, then drill it out at the ends and with sealant - and everything will be OK).

What kind of oil to fill in the power steering: selection table by car make

Let's say the gap at the top was normal - 0.40 mm. But at the point of wear it became 2 mm, which exceeds the permissible values, and this cylinder must be bored. Oil leak Renault Logan you don't have the required compression ring? Then you can measure the diameters at the top and bottom. Renault Logan oil leak In addition, you can measure the entire cylinder along its entire length in two directions and compare the data obtained with the technical requirements for your engine.

If you do not have this data, then proceed from the fact that the physical processes in all diesel engines are the same, which means that the maximum clearances should be approximately the same. For example, we measured the compression of a relatively new 2LT engine. The second cylinder is the same.

Anaerobic sealant

Elimination of extraneous engine noise using additives. Additives for engine oil to eliminate knocking of hydraulic compensators

Anaerobic sealants are produced on the basis of polyacrylates. These sealants are produced under the names anaterm and unigerm; abroad they are called loctides. When cured, they do not shrink and do not require high pressure. The sealant film is resistant to vibration and shock; they can work in aggressive environments and at high pressures, for a long time at temperatures from -200 to 200 C, for a short time up to a temperature of 300 C.

Anaerobic sealants have a locking effect that is far superior to most locking devices used in the automotive industry, such as spring washers, shaped squeeze washers, and nylon insert nuts.

Anaerobic sealants are used for fixing engine block studs, sealing rear axle gearbox cover bolts, fixing and sealing threaded and cap plugs, locking pushrod valve guides and wheel nuts, and many other connections.

Anaerobic sealants (anaterm, unigerm) are produced on the basis of polyacrylates. These sealants do not shrink when cured and do not require high pressure.

Anaerobic sealants have a locking effect that is far superior to most locking devices used in the automotive industry, such as spring washers, shaped squeeze washers, and nylon insert nuts.

Anaerobic sealants are used for fixing engine block studs, sealing rear axle gearbox cover bolts, fixing and sealing threaded and cap plugs, locking pushrod valve guides and wheel nuts, and many other connections.

Anaerobic sealants Unigerm 6 and Anaterm 8K are highly effective against loosening and self-unscrewing of threaded connections under the influence of vibration and shock loads. The technology for using anaerobic sealants is as follows. The parts are degreased and dried. The sealant is applied from the bottle to 2 - 3 threads and the assembly is assembled.

Anaerobic sealants Aposterm and Unigerm are compositions that retain their properties in the presence of oxygen. When contact with oxygen is disrupted, a durable polymer quickly forms. They are characterized by good penetrating ability and are operational in a wide temperature range from minus 250 to plus 300 C. Moreover, they are resistant to aggressive environments, shock, vibration, and mechanical wear. They have high shear, shear and compressive strength. When processing threaded connections, they are able to withstand gas pressures of up to 30 - 40 MPa, and liquids - up to 60 MPa. Therefore, such sealants can be widely used for the primary sealing of threaded joints.

The use of anaerobic sealants makes it possible to eliminate gaskets and significantly reduce the requirements for the cleanliness and flatness of sealed surfaces.

Locking with anaerobic sealants is a universal method that ensures the reliability of connections when exposed to high humidity, cyclic temperatures, vibration and shock loads. Cured sealants do not affect polymer materials and do not cause corrosion of metals and coatings.

For the first time, the chemical-spatial structures of anaerobic sealants such as Anaterm and Unigerm have been determined and presented, which make it possible not only to evaluate the initial physical and mechanical properties of the compositions, but also to suggest their changes during the operation of the restored compounds.

Low-toxic adhesives based on derivatives of acrylic resins - anaerobic sealants and cyanoacrylate adhesives.

Depending on the composition and properties, they can perform the functions of both adhesives and sealants, but unlike the latter, anaerobic sealants (approved in the absence of atmospheric oxygen. Such materials are more correctly called anaerobic compositions or compositions, since they are classified as adhesives or sealants, - it is impossible. The term anaerobic sealants has found the greatest practical application, which we will use in the future when considering their properties.

In many cases, nitroxyl radicals have certain advantages over other additives in stabilizing styrene, isoprene, butadiene, acrylonitrile and acrylic ethers, polypropylene, anaerobic sealants, carotenes, lycopene.

To increase the reliability of connections and prevent self-unscrewing, the following methods are used: 1) locking using mechanical means (punching, binding wire, lock and spring washers, cotter pins, lock nuts, set screws, self-locking nuts); 2) stopping with anaerobic sealants; 3) stop with paint.

VALVE COVER and cylinder head sealants

Valve cover sealant operates in high temperature environments and also in contact with oil. Therefore, the choice of one or another product should be based on the fact that the sealant should not lose its performance properties in difficult conditions.

There are three main types of automotive sealants:

1. ANAEROBIC

The working basis of anaerobic sealants is dimethyl acrylate. The main condition for the polymerization of this type of sealant is the absence of oxygen, which is certainly convenient when working: there is no need to rush when applying the sealant and installing the part in place.

But there is also the other side of the coin: when applying anaerobic sealant, you need to be very precise and careful, since the remaining sealant squeezed out beyond the contact zone of the parts will not polymerize and will remain in a semi-liquid state.

Anaerobic automotive sealants are ideal for sealing various types of threaded connections.

2. SILICONE

Silicone sealants, the main component of which are organosilicon compounds, are the most common and versatile of all types of sealants used in cars. Silicone sealants harden under the influence of moisture in the environment, and therefore the part after applying the sealant must be left alone for 10-15 minutes, and only then installed in place.

Due to their properties, silicone automotive sealants are less critical to the accuracy and quality of application than anaerobic sealants and can seal gaps up to 6-7 mm, which allows them to be recommended for wide use by non-professionals. Silicone is chemically neutral, so it can be used both as a material for independent gaskets and in combination with rubber, cardboard and other gaskets.

The ideal silicone sealant consists of 100% silicone - however, in order to save money, manufacturers often introduce various kinds of additives into its composition. When purchasing, you must carefully study the instructions for the product, which should clearly indicate where, in which nodes and in what temperature range it is recommended to use this or that type of sealant.

3. POLYURETHANE

Polyurethane adhesive-sealants have excellent adhesion to almost any surface and are used both for sealing and for reliable gluing of dissimilar materials.

The color of the sealant does not affect its properties. Manufacturers add dyes to sealants in order to identify them by properties and areas of application, as well as to facilitate detection of the application site. It is clear that to seal, for example, headlights or car windows, it is advisable to use transparent sealants, of which there are a great variety.

REQUIREMENTS FOR SEALANT

When choosing a product, FIRST pay attention to its performance characteristics. As stated above, you need to choose a sealant that can work in high temperature conditions . Therefore, the higher the temperature it can withstand, the better. This is the most important condition!

THE SECOND important FACTOR is resistance to various aggressive chemical compounds (motor and transmission oils, solvents, brake fluid, antifreeze and other process fluids).

THIRD FACTOR - resistance to mechanical stress and vibration . If this requirement is not met, the sealant will simply crumble over time and spill out from the place where it was originally placed.

FOURTH FACTOR - ease of use . First of all, this concerns packaging. It should be convenient for the car owner to apply the product to the work surface. That is, it is worth buying small tubes or cans. The latter option is more convenient and, as a rule, is considered professional, as it is used by service station workers.

Don't forget that sealant has a limited lifespan.

If you do not plan to use it anywhere other than the valve cover, then buying a large package does not make sense for you (most sealants have a shelf life of 24 months, and the storage temperature is from +5°C to +25°C, although this information needs to be clarified in the instructions for a specific product).

When using such tools, you must remember the assembly technology. The fact is that many automakers include such sealing agents along with the cover gasket. However, when disassembling the engine (for example, overhauling it), the car owner or service technicians may not reapply the sealant, which will lead to oil leakage. Another possible reason for this is inappropriate tightening torque of the mounting bolts.

REVIEW OF POPULAR AUTOMOTIVE HIGH TEMPERATURE SEALANTS:

NUANCES OF USING VALVE COVER SEALANT

Each of the listed sealants has its own characteristics. Accordingly, you will find precise information on their use only in the instructions supplied with the product. However, in most cases there are a number of general rules and simply useful tips that should be followed. In particular:

The sealant is completely vulcanized only after a few hours . You will find the exact information in the instructions or on the packaging. Accordingly, after applying it, the car cannot be used, and even just start the engine at idle until the composition has completely dried. Otherwise, the sealant will not perform its intended tasks.

- Before applying the product, working surfaces must not only be degreased, but also cleaned of dirt and other small elements . For degreasing, you can use various solvents (not white spirit). It is better to clean it with a metal brush or sandpaper (depending on the degree of contamination and the elements being cleaned). The main thing is not to overdo it.

- When reinstalling, it is advisable to tighten the bolts with a torque wrench, following a certain sequence provided by the manufacturer. Moreover, this procedure is performed in two stages - preliminary tightening, and then full.

- The amount of sealant should be average . If there is a lot of it, then when tightening it can get into the engine, if there is not enough, then the effectiveness of its use is reduced to zero. Also, do not cover the entire surface of the gasket with sealant!

- The sealant must be placed in the groove of the cover and wait about 10 minutes , and only then can the gasket be installed. This procedure provides greater comfort and effectiveness of protection.

- If you are not using an original gasket, then using a sealant is highly advisable (although not necessary), since its geometric dimensions and shape may differ. And even a slight deviation will lead to depressurization of the system.

Draw your own conclusions.

Each car enthusiast must decide whether or not to use sealant. However, if you are not using an original gasket , or there is a leak from under it, you can use a sealant. However, it must be remembered that if the gasket is completely out of order, then using sealant alone may not be enough. But for prevention, you can still apply sealant when replacing the gasket (remember the dosage!).

As for the choice of a particular sealant, it is necessary to proceed from its performance characteristics. You can find out about them in the corresponding instructions. This data is written either directly on the sealant packaging body or in the separately supplied documentation. If you buy a product through an online store, then, as a rule, such information is duplicated in the catalog. Also, the choice should be made based on price, packaging volume and ease of use.

Types of sealants

To seal the valve cover, only special means are used - ordinary sealants will not last long here. They are also different in composition and properties:

- Anaerobic. The products are based on the synthetic polymer dimethyl acrylate. Solidification requires anaerobic conditions, that is, the absence of oxygen. Working with such compositions is comfortable for the master - they can be applied slowly, in a convenient manner. Remains of the product that have come out beyond the seam must be removed immediately - they will still remain semi-liquid and can get into the internal combustion engine.

- Silicone. Silicone-based compounds are most often used to seal valve covers and other vehicle components. They are made on the basis of organosilicon compounds and harden under the influence of moisture from the air. In order to properly fasten the parts, after application they need to be connected to each other not immediately, but after 5–15 minutes (this is how long the sealant needs to start setting). Silicone compounds tolerate less precise application than anaerobic ones. They can seal fairly large cracks and gaps. Another advantage is the chemical inertness of silicone: it does not spoil rubber or any other material, since it does not react with it. To seal the valve cover, it is best to buy a product that is 100% silicone and has no other additives.

- Polyurethane. They are characterized by a high degree of adhesion to metal, rubber and other materials. Can be used to fasten parts and seal them. Durable, elastic, long lasting, available in different colors, which makes application and subsequent removal easier.

Silicone sealant-gasket for a car engine

A high-quality sealant can withstand heat and high pressure, so it is well suited for internal combustion engines. A product of dubious origin can simply dissolve in the oil, clog the timing mechanism and cause a breakdown.

Types of sealants

Anaerobic sealant

This type of hardening occurs upon contact with metal surfaces. Anaerobic engine sealant is applied to a metal part, connected to another, after which the product hardens. If the drug is exposed to oxygen, it will remain liquid.

Disadvantage of the product: anaerobic sealant will not cope with areas above 0.5 mm, the thickness of the joints must also be uniform. Therefore, if you have little experience, it is better to entrust the work with the drug to professionals; qualifications, special equipment, and practical experience will be useful.

Silicone sealant

An excellent tool for non-professionals in handling auto sealants. The drug is durable, elastic, guarantees tightness when pressure increases, and absorbs deformation when used. Hardening is carried out by moist air. To obtain a pad, leave the product in the air for about 10 minutes.

Silicone sealant fills irregularities up to 6 mm and is not as demanding as anaerobic preparations. Some varieties are used in industry using ultraviolet light for hardening.

Synthetic auto sealant

These products contain synthetic resin. This type is unpopular among car enthusiasts. Suitable for household use.

Engine sealant: types, rules of use, review of manufacturers

Automotive manufacturers supply the market with innovative products, the use of which simplifies the repair and maintenance of vehicles. Instead of classic rubber gaskets, many car owners use special compounds.

Engine sealant has a liquid consistency and is easy to apply. It is highly effective and serves as a good replacement for old seals. Products for sealing cylinder head covers and oil pans have a liquid consistency. The main function of the valve cover gasket sealant is to ensure complete absence of lubricant leakage from the engine cylinder head.

To choose the right sealing compound, you need to consider what components the engine sealant is made of and whether the substance has sufficient heat resistance. High-quality preparations for the prevention and repair of internal combustion engines are anaerobes and silicones. The main advantage of using anaerobic sealant for an engine is the long-term activity of the components in the presence of air and rapid hardening in the absence of oxygen.

This allows a repairman or a novice motorist to correct the mating of the parts being processed. In simple words, if you were unable to apply the cylinder head sealant correctly the first time, you can slowly align the contacting parts for a tight seal.

Advantages of Anaerobes for Valve Caps:

- Obtaining a uniform sealing film on parts.

- Solidification rate in air and airless space.

- Wide operating temperature range, thermal stability.

When using anaerobes, you need to apply the product to one part and press it firmly onto the mating surface. If oxygen is left accessible, the cylinder head gasket or crankcase pan sealant will retain a liquid consistency for a long time. An important condition for quick sealing is a tight connection of the parts.

Be sure to apply anaerobes to a clean, dry surface to prevent the ingress of foreign impurities. You need to use sealant for the engine sump immediately before assembly. Note: The disadvantages of anaerobic products include a limitation on the thickness of the sealing layer (0.5 mm), lack of hardening in case of incorrect application of the substance, and withstanding lower operating pressure. On video: Instructions for use anaerobic gasket sealantsThe most popular at service stations and among vehicle owners is valve cover sealant with a silicone component, which prevents oil leaks and has good sealing properties.

Heat-resistant silicone sealant for engine repairs has the following qualities:

- The sealant hardens upon contact with moisture.

- Resistant to mechanical stress.

- Provides elasticity to the repair seam.

- Firmly seals cracks with gaps up to 6 mm.

- Adapted to the pressure of forced engines.

It is understood that when using an oil system sealant, it will polymerize when exposed to atmospheric moisture.

Packaging Features

Foreign manufacturers often use plastic or aluminum tubes as packaging for medications. The tubes are equipped with a dispenser cap and are filled with 40 or 90 grams.

- Products with a dispenser are convenient to apply;

- the product does not dry out after opening the tube;

- Excess from the dispenser is easily removed with a match.

Russian drugs are usually offered in aluminum tubes with a plastic cap.

Professional sealants require the use of a special gun; without it it is impossible to apply the product.

It is recommended to purchase large-volume tubes for frequent repairs - for car service specialists

, For example. For one car, it is more practical to take a small volume, although it is somewhat more expensive, it will not have time to dry out until the shelf life expires.

Foreign manufacturers are trying to more often use tubes made of plastic or aluminum. These tubes are offered with a dispenser cap, which has valuable advantages:

- convenient application to the surface;

- protects the product from drying out after opening the tube;

- Excessive amount squeezed out from the dispenser can be removed with a match.

The volume is 40–90 grams.

Russian manufacturers usually use aluminum tubes complemented by a plastic cap.

Professional sealants require the use of a special gun. Otherwise, application of the product will no longer be possible. In this case, the volume of tubes may be larger, since the product is used more often than in other situations.

Sealants for car cooling system

The sealant must be applied to a degreased surface! Complete drying time is 24 hours. The price of a tube weighing 85 grams is 170 rubles.

True, not without reservations. In order for the reaction to proceed well on glass or non-ferrous metals, it is advisable to treat the surface on which the sealant is applied with an activator.

To purchase a truly high-quality composition, you should pay attention to trusted brands, which are presented in most automobile stores.

There are also compositions that polymerize under ultraviolet radiation. These are primarily needed in industry, where curing speed is important.

Today, we will look at how to use copper spray sealant when installing the cylinder head, as well as other components and assemblies of the car.

The article will talk about sealants for the car cooling system, what types there are, what the market offers, features of application, principle of operation, when and which product is best to use and how long it will last, reviews of sealants will be considered.

Rules for using sealants

Several recommendations will help you use the products most effectively when repairing your car:

- Prepare the surface on which the sealant will be applied, clean it from dirt, dust, and dry it.

- Degrease with white spirit or gasoline.

- Carefully, so as not to scratch the surface, remove the remnants of the old seals. Do not use, for example, sandpaper for these purposes.

- Apply the product to one of the parts to be joined. Make sure that the line is closed, continuous, without breaks, in a layer of 1 mm, no more, since the excess mass will be squeezed out and can get into other places, clogging them.

- Give the sealant 10–15 minutes to dry, connect the parts, tighten the bolts, wait another 20 minutes and finally tighten the fasteners. Do not overtighten the connections.

- Allow the sealant to dry for a better seal. The time is indicated on the package: usually 0.5–12 hours.

What rules for using products guarantee the best results:

- The surface to be treated must be carefully prepared. To do this, cleaning from dirt and dust and drying are carried out.

- The surface is degreased with gasoline.

- The old seals are carefully removed, as the risk of scratches should be eliminated. It is not advisable to use sandpaper.

- The sealant is applied to one of the parts that is connected. This requires the formation of a closed line.

- It takes about 15 minutes to dry. To properly dry the sealant you need from 30 minutes to 12 hours.

Knowing which sealant is best to use for the engine, it is advisable to choose a quality product and follow all instructions with 100% accuracy. Only with this approach can you count on the fact that the sealant will definitely contribute to the connection of all the necessary parts of the vehicle system with guaranteed preservation of the engine from external factors.

Choosing the Best Automotive Engine Sealant

During the operation of the power unit and its repair, as well as taking into account the design features of some, it often becomes necessary to use a sealant.

The fact is that the engine includes a number of components that are attached through bolted connections and gaskets. We are talking about the pan, valve covers, etc.

Also, do not forget about gearbox covers, various pipes and other parts of internal combustion engine systems and components in which working fluids circulate.

In various situations, sealants make it possible to seal connections, achieve tightness from engine gaskets, eliminate engine oil or antifreeze leaks, connect various parts, etc.

We also recommend reading the article about. In this article, you will learn about the causes and methods of eliminating lubricant leaks in the valve cover area. Moreover, automakers today are increasingly abandoning the use of conventional gaskets for the car engine lubrication system, replacing finished rubber products with polymer compounds that quickly harden after application.

Taking into account the fact that today there are a large number of sealants for the engine and its systems on sale, it is necessary to separately consider the different types of such compounds.

This will ultimately allow you to decide which sealant is best for the engine and what to purchase in a given situation. In this article we will talk about how to choose a sealant for the engine valve cover, we will try to answer the question of how to choose the best sealant for the engine sump, which sealant for the engine oil system or sealant for the engine cooling system is better to buy.

We recommend reading: How long can sick leave last for an injury?

Among the various types of sealants, a separate group is occupied by products that can be used in relation to the power plant.

This means that the autosealant is able to work under conditions of high pressure and significant temperature changes that occur during constant heating and subsequent cooling of the engine.

Sealants for internal combustion engines are initially sold in various types of packaging and are liquid. Hardening occurs under certain conditions, that is, depending on the individual characteristics of a particular product. It should also be taken into account that the composition of the sealant must ensure subsequent resistance to the effects of various technical fluids (motor oil, antifreeze, etc.).

Let's look at the main types of auto sealants. Anaerobic engine sealant has recently been used in the assembly of internal combustion engines. The composition hardens after contact with a metal surface.

Anaerobic sealants are applied to metal parts, after which the two surfaces are joined. This product does not harden immediately, but after a certain time (about 30 minutes) and only under certain conditions.

Review of common sealants

Oil system sealant

An oil system sealant is recommended for diesel and carburetor engines, as a means of getting rid of leaks, restoring elasticity, seal sizes, rarely removed caps, and engine gaskets. Can be used for prevention.

- compatible with all types of oils;

- extends engine life.

LOCTITE 574

The sealants presented by Henkel are highly effective products. Anaerobic flange sealant 574 cures at 15-25 degrees, forming a durable polymer layer. Loctite is used between metal surfaces, where it polymerizes in the absence of air. Serves as a sealant for tightly adjacent surfaces with a small gap.

Dow Corning Q3-1566

Heat-resistant composition, hardens at room temperature. Resistant to motor oils and coolants. Suitable for engine oil pan and flanges.

Belgian-made polyurethane sealant for professionals and car owners who have experience in handling this type of product. It is used for repairs on the engine oil pan, on the surface of the flanges. Hardens in 40–60 minutes. Add oil only after it has completely hardened.

Types of sealants for car bodies and their correct use. Which sealant is best for the engine?

Which sealant is best for a car body?

Liquid gaskets or otherwise called sealants for cars appeared on the markets relatively recently.

But during this period they managed to demonstrate their practicality and necessity in different situations . The most important function performed by these means, undoubtedly, is the replacement of engine gaskets or other parts, eliminating leaks, punctures, or repairing parts by gluing. Body sealants are used to seal seams, provide impermeability, and bond

Sealant selection criteria

The automotive services market offers a large number of types of sealants for cars: for bodies, pipe connections, hatches. All types differ in such indicators as durability, withstandable temperatures, elasticity, harmfulness to the coating, etc.

There are special adhesive products for “hobbyists”. They have lower cost and unit volume. More professional options are slightly more expensive and are sold in larger containers.

Sealants produced abroad are produced with dispenser spouts; their usual volume is 40 or 90 grams. Domestic manufacturers more often use conventional aluminum tubes. Thanks to this material, you don’t have to worry about the safety of the substance.

When choosing a sealant for the body, it is worth considering that some of them can only be applied using a gun. There is no need to skimp on capacity. When calculating, a large tube may be a more profitable purchase for the money, but in the end it turns out that its use is rarely needed and its shelf life is short

If the use of a substance is necessary as a gasket, it is very important not to forget to check its heat resistance. The ideal option in this case would be endurance up to 345–375 degrees

Anaerobic sealants

Such sealants harden in the absence of oxygen and in contact with a metal surface. The substance must be applied to a metal surface, connect the parts, and wait for it to harden. If it is exposed to oxygen, it will remain liquid. However, this cannot always be called a minus. For example, if the sealant is applied carefully and slowly, it will not cure immediately, allowing more time to coat.

But a serious disadvantage for this type of “liquid gaskets” is its ability to cope only with small irregularities, and it is necessary to maintain a strict tolerance for the uniformity of the thickness of the joint. So this sealant is best used exclusively by professionals, since application requires special dexterity, skills and equipment.

The procedure and torque for tightening the cylinder head on a VAZ-2112 with 16 valves: tightening the cylinder head bolts

VAZ cars of the 2112 family were produced with two 16-valve valves: 21120 and 21124. The cylinder head of these engines has different intake ports. In theory, there are no other differences. And therefore, the tightening torque of the bolts on the VAZ-2112 cylinder head will be the same if we talk about any 16-valve internal combustion engine. Tightening is performed in three steps, although repair books give another option (it is for 8-valve engines).

The following video shows how the cylinder head is installed in 5 minutes:

Installation and dismantling procedure

The part called the cylinder head is attached to the cylinder block with 10 screws. They are unscrewed with a 10mm socket wrench. The procedure for dismantling the cylinder head is shown in the first photo.

The standard screw length is 93 mm. If the screw has been pulled out to at least 95 mm, it is replaced with a new one (AvtoVAZ requirement).

During installation, a different scheme is used (photo 2). Each screw is lubricated with machine oil, otherwise the efforts will be reduced to nothing.

Tightening torque for cylinder head cover bolts

For VAZ-2112, the cylinder head tightening torque is standardized:

- First pass – the force is 20 N*m;

- Each screw is turned 90 degrees to the right;

- Wait 20 minutes, then turn the screws another 90 degrees.

At first the effort is very small. But at “step 3” it will be difficult to cope with the work. Use the lever.

How to seal a gasket when repairing an engine

The cylinder head gasket (cylinder head) simultaneously performs several tasks - it seals the engine cooling system, seals the oil passages and seals the cylinder working chamber. The cylinder head gasket material comes into contact with fuel, oil and coolant. In addition to the aggressive environment, the gasket is subject to enormous pressure at the moment of ignition of the fuel-air mixture in the cylinder, as well as significant temperature changes.

Because of this, there are such high demands on the quality of the cylinder head gasket. The operating conditions for the cylinder head gasket are “hot chemical shop”. It is attacked from all sides by aggressive chemicals under high pressure (coolant, oil with additives and gas mixture from the combustion chamber).

Temperature changes from – 40 C on cold winter nights to +1000 C or more at the moment of gasoline ignition.

In such harsh conditions, the gasket must last for many years. This is why there are such high requirements for the reliability of Asbestos cylinder head gaskets - they can withstand high temperatures and are quite elastic.

We recommend reading: Disabled group 3 benefits for train tickets

For strength, the holes can be additionally reinforced with metal rings.

The advantage of asbestos gaskets is their low price, but they are not resistant to vibrations and are subject to rapid aging and deterioration of their sealing properties. Non-asbestos gaskets are a common type of gaskets, which often have a higher price than asbestos, but have better resistance to deformation and are designed for a longer service life. Metal ones (bimetallic) - consist of several layers of metal or metal with a sealing elastomer. Multilayer steel cylinder head gaskets (abbreviated MLS gaskets) are most often found in a modern car. In modern engines, the cylinder head gasket not only performs a sealing function, but also ensures load distribution. There are four types (malfunctions, burnout) and a number of symptoms that indicate problems in the gasket cylinder heads.

- Oil entering the cooling circuit - the oil system has higher pressure than the cooling system. Symptoms: the appearance of traces of oil in the expansion tank or under the radiator cap.

- Loss of gasket tightness to the outside - the gasket is installed incorrectly or its service life has been exhausted. Symptoms: Oil stains appear on the engine at the seal points.

- Exhaust gases entering the cooling system - hot gas entering the antifreeze quickly heats it up. Symptoms: this problem can be identified by frequent turning on of the cooling fan, the appearance of air bubbles in the expansion tank and white exhaust.

- Burnout between the combustion chambers can occur due to too weak contact pressure when the bolts are tightened incorrectly or when the engine overheats. Symptoms: problems may arise when the engine starts coldly and when the engine is already warmed up, unstable operation.

Replacing the cylinder head gasket entails draining fluids and dismantling components; it is not recommended to reuse the old gasket and bolts even if they look quite normal. After

Why are guide bushings needed?

Before installing the cylinder head, perform the following steps: clean the threaded holes, as well as all holes for the bushings (photo 1). Each bushing is installed in place, and only then a gasket is placed on top.

Metal parts adjacent to the gasket must be degreased. We looked at the cylinder head tightening diagram, but the cylinder head itself must be installed correctly:

- We place the cylinder head on the cylinder block;

- By moving the part in different directions, we ensure that the bushings fit into the recesses.

After “step 2” the screws can be tightened.

No sealing compounds are used when installing the gasket! Solidol, CIATIM and other lubricants are not even needed. The main thing is that the metal must be degreased. And the cylinder head gasket must be new.

Cylinder head cover and tightening order of its bolts

The metal cover installed on the cylinder head must not allow air to pass through. At points of contact with other parts, tightness must also be maintained. Therefore, sealant is applied to the edge of the lid. An example is shown in the photo.

Here you need to use materials: Loctite-574, ANACROL, etc. The screws on the cover are tightened with an “8” key.

Recommended screw tightening torque

The recommended screw tightening torque is only 3-4 N*m. Don't be surprised: the sealant will do its job. You just need to let it dry after putting the cover in place.

You can unscrew the screws in any order. Their number is 15 or 14. When installing, it is better to follow the sequence shown below.

There is usually no need to replace the screws - the load is too small. We wish you success.

Common Misconceptions

If the bolts are pulled out too much, they are tightened in four steps. At “step 2” the tightening torque will be 70-85 N*m. All of these are common misconceptions that do not apply to 16-valve internal combustion engines.

All steps in one video: replacing the cylinder head gasket

If you find an error, please select a piece of text and press Ctrl+Enter.

We recommend reading:

Similar articles

Similar articles

Sealant for engine cylinder head gasket

Contents In the previous article (How and why to grind the valve | Lapping paste) we described the process of disassembling the cylinder head (hereinafter cylinder head) of the GREAT WALL Hover car and showed the process of grinding in the valves.

Today we will look at the following questions: 1.) How to choose a cylinder head gasket, 2.) How to determine that the gasket has failed, 3.) Why use copper spray sealant when installing a cylinder head gasket, 4.) How to apply the sealant - copper spray for ABRO gaskets on the cylinder head gasket. Why do you need a cylinder head gasket? The cylinder head gasket, although not the most expensive element, nevertheless carries key functions and heavy loads. It is designed to seal the connection between the block and the head.

The engine is constantly exposed to severe temperature loads, and the metal may begin to deform.

The purpose of the gasket is to prevent depressurization and local overheating of the engine.

Important! The gasket is a one-time use item. Each time the cylinder head is dismantled, it should be replaced to prevent burnout and repeated expensive repairs. Let's look at what symptoms indicate that the cylinder head gasket has failed: 1.) Frequent engine overheating.

If you notice that the engine temperature gauge rises above normal even at idle, this means exhaust gases enter the cooling system, causing overheating.

2.) White smoke. If you see white smoke coming from the exhaust pipe, this means antifreeze is entering the cylinders along with the fuel. 3.) Antifreeze leaves the radiator tank.

If there are no drips under the car, but the antifreeze disappears from the tank, then the antifreeze is burning in the cylinders, having entered through a burnt gasket.

4.) Beige flakes, bubbles, light caramel smell. If, in addition to antifreeze, there are beige flakes in the radiator tank, the antifreeze has changed the smell, and gases are coming from the radiator pressure relief tube, this means that oil has begun to flow into the cooling system through the burnt gasket. 5.) Oil level has increased.

If you see that the level on the oil dipstick has increased above normal, this is not a reason to rejoice. The engine can only burn the wrong oil, but not produce anything.

The level has increased due to antifreeze getting into the oil channels through a burnt-out gasket. Repairs cannot be avoided... How to choose a gasket? In the modern world, the following types of gaskets can most often be found on the market: Paronite (asbestos) - these gaskets can withstand the highest temperatures while maintaining elasticity.

However, this is the cheapest and most outdated type of gaskets; they are characterized by low reliability and low durability.

Metal (alloys of aluminum, copper, etc.) - reliable and durable. Nowadays there is no automaker that supplies its engines to OEM

gaskets not made of metal. ATTENTION! We recommend using the manufacturer's official OEM spare parts catalog. The rule that “the miser pays twice” works perfectly in this case.

Why do we need copper spray sealant for ABRO gaskets?