Home » Armaments of the future » Vulya connecting rod engine.

Armaments of the future

boroda 01/21/2019 3279

14

in Favoritesin Favoritesfrom Favorites 8

I present to your attention another, so to speak, engine of the future. Its design is not as revolutionary as that of the Kuznetsov engine, but it has one undeniable advantage - such a motor is built and works.

View of a diesel connecting rod engine from the radiator side

Since the advent of the internal combustion engine, specialists around the world have been continuously improving it. What kind of designs have not been invented over the past time. However, only a small part of them managed to become production models. The rest, despite the originality of the ideas, never left the experimental stage. However, there are power plants that, before winning their “place in the sun,” go through a thorny and long path. One of them is the connecting rodless engine.

Motor without a crankshaft: advantages and difficulties of implementation

So, the main task and purpose of any internal combustion engine is to convert the energy obtained from fuel combustion into mechanical work. Simply put, the fuel burns in a closed volume, the gases exert pressure on the piston, and through the crank mechanism the reciprocating motion of the piston is converted into rotational motion.

As a result, engine torque is created, which is transmitted through the transmission to the wheels of the car. It is noteworthy that although more than 100 years have passed since the creation of the first engines and their introduction to the masses, the overall design of the internal combustion engine has not changed.

Even taking into account the fact that modern engines have received high-precision, developed electronic injection and control systems, it has become possible to change valve timing, etc., the well-known crankshaft continues to form the basis of a power unit running on gasoline, diesel fuel or gas.

At the same time, work is constantly underway so that the engine can operate without a crankshaft. The fact is that the usual crank mechanism is not without a number of certain disadvantages. It is for this reason that engineers are trying to get rid of this unit.

The fact is that the operation of a crankshaft is associated with the inevitable creation of friction and significant lateral forces, which lead to wear of the cylinder walls. As a result, the cylinder mirror is damaged, the piston rings are destroyed, etc. In terms of friction losses, the overall efficiency of the engine is noticeably reduced.

Article on the topic: EGR in a diesel engine: what is it

Also, an engine with a crankshaft is difficult to maintain, since removing the crankshaft without removing the engine is extremely difficult to implement on many cars. It is quite obvious that if these shortcomings are eliminated, the engine will become more productive and its service life will increase.

To solve the problem, designers offer different approaches, but in practice, most solutions are simply not possible to implement efficiently. The Balandin engine and the Frolov engine deserve the greatest attention in this area today. Let's look at mechanisms without connecting rods and crankshafts in more detail.

Content

- 1 History of creation

- 2 Types of internal combustion engines

- 3 Fuel octane number

- 4 Ratio of cylinder diameter to stroke

- 5 Gasoline 5.1 Gasoline carburetor

- 5.2 Gasoline injection

- 10.1 Turbocharging

Balandin connecting rod engine

This motor is known for the fact that it does not have connecting rods. The transformation of the reciprocating movement of the pistons in the cylinders occurs due to the use of a special eccentric mechanism in the design.

The general structure of a connecting rod engine requires the presence of the following parts:

- special piston rod

- special design crankshaft

- crank bearing and crank

- power take-off shaft

- piston

- rod slider

- cylinder

In such an internal combustion engine, instead of connecting rods, piston rods were used, which are rigidly attached to the pistons (in a conventional unit, a piston pin is used for connection). These rods, like conventional connecting rods, cover the crankshaft journals.

Also, sliders are made on the rods on both sides of the bearing. These sliders slide along special guides in the engine crankcase. As a result, this design makes it possible to relieve the piston and cylinder walls from lateral forces. In fact, in such an implementation scheme, the piston can be considered a regular holder for piston rings that seal the gap between the cylinder and the piston.

The absence of lateral forces allows for reduced tolerances on piston dimensions. The engine becomes more productive, economical, and its service life increases. It is also worth noting the compactness of such an internal combustion engine and reduced weight. However, the main disadvantage of the entire design can be considered the extremely high requirements regarding the overall manufacturing accuracy of the specified eccentric.

Article on the topic: Mass air flow sensor

Fuel octane number

Main article: Octane rating

Energy is transferred to the engine crankshaft from the expanding gases during the power stroke. Compressing the fuel-air mixture to the volume of the combustion chamber improves engine efficiency and increases its efficiency, but increasing the compression ratio also increases the heating of the working mixture caused by compression according to Charles's law.

If the fuel is flammable, the flash occurs before the piston reaches TDC. This, in turn, will cause the piston to turn the crankshaft in the opposite direction - this phenomenon is called backfire.

Octane number is a measure of the percentage of isooctane in a heptane-octane mixture and reflects the fuel's ability to resist self-ignition when exposed to temperature.

Higher octane fuels allow a high compression engine to operate without the tendency to self-ignite or detonate and therefore have a higher compression ratio and higher efficiency.

The operation of diesel engines is ensured by self-ignition from compression in the cylinder of clean air or a lean gas-air mixture incapable of spontaneous combustion (gas diesel) and the absence of fuel in the charge until the last moment.

Combined internal combustion engine

Main article: Combined internal combustion engine

- - an internal combustion engine, which is a combination of piston and blade machines (turbine, compressor), in which both machines participate to a comparable extent in the implementation of the work process. An example of a combined internal combustion engine is a piston engine with gas turbine supercharging (turbocharging). A great contribution to the theory of combined engines was made by the Soviet engineer, Professor A. N. Shelest.

Turbocharging

| This section needs to be completely rewritten. There may be explanations on the talk page. |

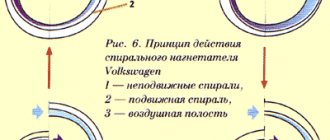

The most common type of combined engine is a piston with a turbocharger. A turbocharger or turbocharger (TC, TN) is a supercharger that is driven by exhaust gases. It got its name from the word “turbine” (French turbine from Latin turbo - vortex, rotation). This device consists of two parts: a turbine rotor wheel, driven by exhaust gases, and a centrifugal compressor, mounted on opposite ends of a common shaft. The jet of the working fluid (in this case, exhaust gases) acts on the blades fixed around the circumference of the rotor and sets them in motion together with the shaft, which is made integral with the turbine rotor from an alloy close to alloy steel. On the shaft, in addition to the turbine rotor, there is a compressor rotor made of aluminum alloys, which, when the shaft rotates, allows air to be pumped into the cylinders of the internal combustion engine. Thus, as a result of the action of exhaust gases on the turbine blades, the turbine rotor, shaft and compressor rotor simultaneously spin. The use of a turbocharger in conjunction with an air intercooler (intercooler) allows for the supply of denser air to the cylinders of the internal combustion engine (in modern turbocharged engines this is exactly the scheme used). Often, when a turbocharger is used in an engine, people talk about the turbine without mentioning the compressor. The turbocharger is one unit. It is impossible to use the energy of exhaust gases to supply an air mixture under pressure into the cylinders of an internal combustion engine using only a turbine. The injection is provided by the part of the turbocharger called the compressor.

At idle, at low speeds, the turbocharger produces little power and is driven by a small amount of exhaust gases. In this case, the turbocharger is ineffective, and the engine operates approximately the same as without supercharging. When a much higher power output is required from the engine, its speed, as well as the throttle clearance, increases. As long as there is enough exhaust gas to rotate the turbine, much more air is supplied through the intake manifold.

Turbocharging allows the engine to run more efficiently because the turbocharger uses energy from the exhaust gases that would otherwise be (mostly) wasted.

However, there is a technological limitation known as “turbojam” (“turbo lag”) (with the exception of engines with two turbochargers - small and large, when a small turbocharger operates at low speeds, and a large one at high speeds, jointly ensuring the supply of the required amount of air mixture to the cylinders or when using a variable geometry turbine, in motorsport forced acceleration of the turbine using an energy recovery system is also used [2]). The engine power does not increase instantly due to the fact that a certain time will be spent on changing the rotation speed of the engine, which has some inertia, and also due to the fact that the greater the mass of the turbine, the more time it will take to spin it up and create pressure, sufficient to increase engine power. In addition, increased exhaust pressure leads to the fact that the exhaust gases transfer part of their heat to the mechanical parts of the engine (this problem is partially solved by the manufacturers of Japanese and Korean internal combustion engines by installing an additional cooling system for the turbocharger with antifreeze).

Knight engines at the present stage

Knight motors lost popularity in the 30s of the 20th century, and today they are not represented on the world market. It has been replaced by improved valve timing mechanisms, which not only solve the problem of excessive noise, but also have many advantages over the Knight system. However, some scientists are considering the possibility of valveless engines in modern production cars. Such statements are regularly published in the media and cause numerous disputes among representatives of the scientific and technical industry.

Engines without a crankshaft - a new era in the automotive industry

The first automobile engines were invented more than a century ago. Since that time, little has changed in their design.

Engine without crankshaft

Of course, engines are improved, modernized, become environmentally friendly, lightweight and compact, but the fundamentals of the design remain the same. Nowadays they are increasingly talking about internal combustion engines without a crankshaft.

Why do you need to remove the crankshaft? How do such units work? Are they so perfect or do they still have some negative characteristics?

Additives for engine restoration: myth or reality

In this article we will talk about whether it is possible to restore a worn engine with additives.

At a certain stage of vehicle operation, any engine experiences increased oil consumption due to waste, fuel consumption increases and power decreases. In this situation, any car owner wants to restore the engine at minimal cost. Since traditional engine overhauls are expensive, many people are looking for engine rebuilding additives. Let's figure out whether there really are additives for engine restoration and whether it is even possible to restore an engine without disassembling it.

First, let's figure out why power decreases and fuel and oil consumption increases. The reasons have long been known - this is due to wear of parts of the cylinder-piston group, as well as coking of the piston rings.

To eliminate these causes, you can go in different ways: wait for maximum wear and carry out a cap. repair the engine or, without waiting for complete wear and tear, try to restore the engine using special “additives”.

Carrying out a major overhaul is quite a complicated matter and, it must be said, expensive. In addition, the engine service life after cap. repair costs are reduced by 1.5-2 times. This is due to the low quality of the spare parts used, the low accuracy of boring and grinding of parts, and often the low qualifications of the performers. Having spent a lot of money on engine repairs, we often get results that are very far from what we wanted.

Now let's talk in more detail about "additives" for engine restoration. In fact, there are no additives for engine restoration, but “tribo compounds” exist. The difference is that an “additive” is something that changes the properties of the oil, while a “tribo-composition” changes the properties of friction surfaces and can restore them, creating various protective coatings that compensate for wear. But since car enthusiasts will still call tribo compounds additives, then in the rest of the article we will also call them additives for engine restoration.

They started talking actively about additives for engine restoration in the late 90s and early 2000s, and then they began to appear on the shelves of auto stores. Many engine restoration additives were created on the basis of declassified military developments, and many simply hid behind this legend in order to fool gullible buyers. As a result, there were many engines that were not restored and, in the end, damaged, and a massive distrust of additives for engine restoration began.

However, the market is developing, and science does not stand still. Today, many have heard about additives for engine restoration such as Suprotek, XADO, Forsan, Rimet and others. Today we will talk about the developments of a group that has created a series of additives for engine restoration. In practice, these additives give excellent results in restoring the operating parameters of engines with significant wear. The cost of rebuilding an engine using these additives is tens of times lower than the cost of capital repairs. repair.

How to choose additives to restore your engine? It’s very simple, based on the existing symptoms. If the engine pulls poorly and fuel consumption has increased, but there is no increased oil consumption, then it is advisable to measure the compression. If it is significantly lower than the passport values, then there is wear on the cylinders and piston rings. This is the very case when the engine can be restored with an additive. It is very important to choose the correct dosage of additive for engine restoration.

On the group's official website, in the description of restoring additives, there is an exact calculation of how many ml of additive is needed for a specific engine, depending on its displacement and mileage. By the way, most additive manufacturers do not provide such a calculation, offering everyone their standard set of additives, and this is bad.

How additives work to restore a group engine

Additives or Protective-restorative compounds of the group are produced under two brands “Motoresurs” and “RESTART”. The additive is naturally poured into the oil. Once in the oil, the additive with the oil enters the friction zones, where, under the influence of temperature and pressure, it begins to form a protective-restorative coating of organic-metal-ceramics on the rubbing surfaces. Essentially, it is a crystal that grows on a metal lattice. Moreover, where the temperature and pressure are higher, the coating will grow more actively, because it is these factors that activate the growth of the protective coating. Consequently, in areas where the load is higher and parts wear out more, the coating will grow faster and grow in a thicker layer. Thanks to this effect, it is possible to eliminate wear of parts of 0.05-0.07 mm, and 2 times more for the cylinder diameter (two thicknesses of the protective coating). This action of the additive greatly restores the worn-out engine, because with wear of 0.15 mm it is already recommended to carry out a major overhaul.

The protective coating created by the engine rebuild additive is stronger than high-alloy steel. It will wear out after 50-100 thousand km of car mileage, depending on the drug you choose. We have 2 types of additives for engine restoration “STANDART” and “SUPER”, which create protective coatings with different service lives, up to 50 and 100 thousand km, respectively.

If, at the same time as poor traction, the engine has increased oil consumption due to waste, then you cannot do without an additive to restore the engine. Increased oil consumption usually indicates coking of the piston rings, so first you will have to decoke them. After all, if the rings are coked, then no additive, even the most expensive one, for engine restoration will give a good effect.

And again, the drugs of the group, which produces compounds for decarbonizing rings “Decoking Titan”, Antikoks RESTART and Antikoks RESTART SUPER, will come to the rescue.

But in this case it’s easier to buy a special set of additives for engine restoration: “4 in 1 restoration complex “Motoresurs””. It includes 4 drugs that perform 2 main tasks: decoking of rings and restoration of worn rubbing surfaces.

As a result of using this set of additives for engine restoration, we have repeatedly been able to increase compression from 8 to 12 kg/m and increase engine power and torque by 20%.

This set costs about 1,700 rubles. This is tens of times cheaper than repairing or replacing the engine.

However, dear motorists, the choice is yours.

You can ask any question regarding the products described by us on the website www.motoresurs.ru or by phone 8-923-120-75-75

Addresses of stores in the Krasnoyarsk Territory:

- Krasnoyarsk, Sovetsky district, Severny microdistrict, Kosmonavtov street, 17G, Vi-Day LLC, t., 8-908-030-00-11

- Krasnoyarsk, Akademgorodok microdistrict, 18A, AcademAuto LLC, 8(391)272-10-00

- Krasnoyarsk, Avenue named after Gazeta Krasnoyarsky Rabochiy, 113, store "Auto Korea Detail", t.

- Krasnoyarsk, st. 9 May 79, t.c. “Dommer”, 2nd floor (entrance from the “Planet” shopping center), “Autozoom24” store, tel. 8-933-339-06-66 or.

- Krasnoyarsk, Aviatorov Street, 54, Dealer - Alfa-Korea store, t.

- Krasnoyarsk Territory, Achinsk, Magistral TsST LLC, Baikal Highway 644 km, building 8. Nano Techno Store, YuVR 31, 8-950-407-43-63 Gimatdinov Rinat Gabdullovich

- Krasnoyarsk region, Zheleznogorsk, Oktyabrskaya street, 4, store "Auto Korea Detail" t.

- Krasnoyarsk Territory, Uzhur, Autostop store, 8-983-503-09-20

- Krasnoyarsk region, Sharypovo, Transitnaya street, 5, Auto Parts store, 8(39153)26135

- Krasnoyarsk Territory, urban settlement Solnechny, Autotuning store

How did the modern internal combustion engine originate?

If we compare a car with the human body, then it is the engine that will act as the heart. Without it, operating the vehicle is simply impossible. The word motor itself, translated from Latin, means to set in motion. And in a nutshell, this device is responsible for converting energy from fuel combustion into mechanical energy, without which the car will not start.

The first time we heard about such a unit was back in 1801, and the French engineer Philippe Lebon should be thanked for this invention. But the creator of the samples closest in structure to modern engines is considered to be the self-taught German engineer Nikolaus Otto. The world learned about his achievements more than 70 years later, in 1877.

Five years earlier, Brighton tried to implement a power unit that would run on kerosene; previous devices operated on gas. The attempt was unsuccessful. But in 1882, a new unit powered by liquid fuel – gasoline – came to life. And humanity owes its thanks to the German designer, engineer and industrialist Gottlieb Daimler for its birth.

It will be useful Rubber bands for windshield wiper blades: selection and operation

Communities › Kulibin Club › Forum › Engine without crankshaft.

I found this video on YouTube youtu.be/s6GW0-iwMSM Do you think this is true?

or another Turkish charlatan. The main thing is to pay attention to the written indicators of this engine. no one seems interested

Somehow I don’t trust this hairy guy)

here I am about the same thing... the coolest thing is that he shows the mechanism saying (look, I opened everything for you. Everything is visible) the most important thing is that nothing is visible. and the design is not clear... so there is no trust. Yes, and it also gives me something to think about. that he could steal some kind of patented system of mechanisms. So he doesn’t seem to want to pretend himself.

yeah, instead of fingers I put ball joints that will fucking vomit

Well, with people like that, it’s easy

yeah, instead of fingers I put ball joints that will fucking vomit

so it won’t vomit when stretched, there’s no load, but I don’t believe the hairy one

this is not fake. The unit is working but short-lived. This motor was shown in cross-section at one of the exhibitions. The point is in the modified connecting rod. In general, the bottom of the connecting rod does not sit on the knee as on conventional internal combustion engines, but is an oval gear with internal gearing and on the knee, accordingly, there is a fixed gear that meshes with the connecting rod.

the mechanism is very flimsy - I think if you put a load on it, the gear teeth won’t last long...

Look on YouTube - there are videos where this internal combustion engine is shown in cross-section)))

How do you like this engine? something really crazy

Now I understand everything about that hairy guy... without a crank engine at all. Yes, he invented the “bicycle”, but he doesn’t want to patent it. because everything has been patented for a long time. Such crankless (connecting rodless) engines are already being produced in full for aviation. small of course. The small size and weight reduction are very tempting. (that’s why they are used in aviation) but you’ll be tired of servicing them, here’s someone’s thesis

but the working version is only the connecting rodless system is probably different. (let's watch this video, I thought it was a normal motor movement. But the location of the hooks made me think. How are they connected there if they are in the same plane)

last video - this engine is very similar to a radial one, it was invented a long time ago, here are some interesting links

www.volnovoidvigatel.ru/star-engine.html and there are descriptions on Wikipedia!

Additional units required for internal combustion engines

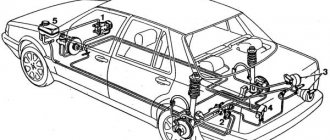

The disadvantage of the internal combustion engine is that it produces its highest power only in a narrow rpm range. Therefore, an integral attribute of an internal combustion engine is the transmission. Only in certain cases (for example, in airplanes) can one do without a complex transmission. The idea of a hybrid car, in which the engine always operates in optimal mode, is gradually conquering the world.

In addition, an internal combustion engine requires a power system (for supplying fuel and air - preparing a fuel-air mixture), an exhaust system (for removing exhaust gases), and also cannot do without a lubrication system (designed to reduce friction forces in engine mechanisms and protect parts engine from corrosion, as well as together with the cooling system to maintain optimal thermal conditions), cooling systems (to maintain optimal thermal conditions of the engine), starting system (starting methods are used: electric starter, using an auxiliary starting engine, pneumatic, using human muscle power ), ignition system (to ignite the fuel-air mixture, used in engines with forced ignition).