What is a Sequential Box

A sequential gearbox on a car means that the driver selects gears not randomly, but in a clear sequence, moving the gearbox selector in one direction. This is the difference between this box and the “mechanics”, where after squeezing the clutch the lever can be moved to any of the positions.

Such a gearbox is a relatively new invention, appearing in the early 90s of the 20th century. Initially, racing cars were equipped with these units: for example, BMW 3 Series sports cars from the motorsport division of the automaker. The choice of a sequential gearbox for equipping sports cars was dictated by test results: studies have shown that with the help of such a gearbox the driver can better control the car compared to a classic automatic transmission, while he still has the opportunity to influence the process of changing gears as effectively as “ mechanics." This advantage of the sequential unit is especially evident where it is necessary to change the driving speed sequentially.

The new gearbox gained the love of car owners, although some complained about some “slowness” of switching gearbox stages. But the second generation of sequential boxes solved this problem too.

Important: the sequential gearbox, like the automatic transmission, does not have a clutch pedal.

Appearance of the shift lever:

Shifting “up” increases the gear, “down” - downshifts. Some cars may also be equipped with steering wheel switches for driver convenience. The role of the clutch pedal is performed by a hydraulic mechanism under the control of an electronic control unit, the latter also takes over the switching if the box is operating in “full” automatic transmission mode.

Interesting: this type of gear shift is widespread in racing, the design of agricultural machinery, heavy-duty vehicles and motorcycles with a small number of transmission stages.

Rally gearbox

I would divide the transmissions used in rallies into several types.

1. Full drain.

Factory synchronized manual transmission. No changes. It is almost never used in motorsport and rallying since the standard gearbox is designed for city-highway operation, and is too long for rallying and the car with it is slower than it could be.

2. Tuning stock.

operating principle of the synchronizer

When the main pair and gear ratios of the gearbox are changed, most often a limited slip differential (worm or disk) is installed, which greatly improves the dynamic capabilities of the car on slippery surfaces.

worm limited slip differential

Limited slip disc differential

The gearbox is still based on synchronizers and helical gears. Often used for tuning city cars. T.K. Compared to stock, it greatly improves the dynamics of the car. This is what rally driving looks like like a gearbox. This is my onboard from the Russian Rally Cup - Rally Golden Domes 2013

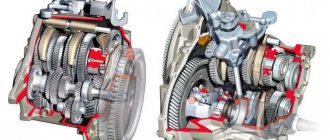

3. Cam gearbox.

It takes its name from cam clutches, which replace synchronizers and allow you to engage quickly and without squeezing the clutch, making shock engagements, both up and down, the gear will engage reliably.

The gears in this gearbox are straight-cut. Used in conjunction with a limited slip disc differential. This gearbox is no longer used for urban tuning because has a reduced resource and high cost. This is what driving with a cam transmission looks like, shifting quickly and without a clutch.

4. Sequential gearbox.

The difference from a simple cam gearbox is that instead of the usual switching pattern, this gearbox has lever travel only forward (downward gear) and backward (upward gear). In fact, the difference is in the mechanism and switching principle, and the clutches and spur gears are the same as in a conventional cam gearbox. At the moment, in rallying this is the top, everything else is prohibited. Such gearboxes are used on all modern and fast rally cars, including WRC World Rally Championship cars. Here's an example of what driving with a sequential gearbox looks like:

But let's get back to my car.

When I bought a Logan there was a JH3 box in its body there was a symbiosis of a shortened Main Pair and a short row. This allowed a car with a weak engine to be much faster than a standard Logan. After finishing driving in the Renault Mono Cup, where changes to the gearbox were prohibited by technical requirements, I decided to further improve the dynamics of the car by installing a short final drive.

I managed to find a 4.9 gear (my ex 4.5, factory 4.3) in Europe,

The table shows how the speed changes in a gear, but unfortunately it’s quite difficult to show how the car’s dynamics improve

Unfortunately, it turned out to be not cheap; at the same time, the gearbox housing was strengthened so that the increased torque from the internal combustion engine could be transmitted.

This ultimately played a cruel joke. Due to poor quality work performed by third party specialists, the gearbox broke down twice and then completely fell apart.

The reason was in the reinforcing plate, which was designed to keep the shaft seats from moving. After that I decided to take it to the next level. A new cam gearbox from the Baltic company Samsonas was purchased.

With this transition, I simultaneously improved the dynamics of the car, increased reliability, and improved handling. The fact is that my previous gearbox did not have a so-called “locking” limited slip differential. And this gearbox has an on-disc gearbox, which allows you not to lose during acceleration and improves exits from corners.

Cam or sequential

By creating a sequential gearbox, the developers set a goal to reduce the interval between speed changes. Thanks to the design features of such a transmission, this is achieved by simplifying switching and eliminating operations with the clutch pedal. This is especially important for new and inexperienced drivers who have difficulty performing switching procedures correctly. But professionals will also appreciate the gearbox, thanks to its convenience and the ability to subtly sense and control the behavior of the car, using the maximum of its capabilities.

Automatic transmission

To simplify driving, an automatic transmission was invented, which freed the driver from having to choose a driving mode on a particular section of the road. The automatic switches itself, while the driver, working with one foot, either increases speed or slows down. Driving a car with an automatic transmission requires less qualifications, and it is not for nothing that the permit to operate such a vehicle is now allocated to a separate category.

They are ideal where shock loads are expected because all parts are in compression rather than tension as is the case with traditional gear teeth. Their reliability and durability are outstanding! Disclaimer: Because the authors, publishers and resellers do not know the context in which the information presented in this article is to be used, they are not responsible for the consequences of the use of information contained or implied in any articles.

If you have any maintenance recommendations for equipment maintenance, particularly troubleshooting and preventing plant and equipment failure, or have made successful improvements to equipment reliability, please feel free to send me your articles for publication on this website.

But work on improving the mechanical transmission did not stop. The result is a sequential transmission, which also does not include a clutch pedal, but operates on different principles. And its main feature is strictly sequential gear shifting.

Get maximum reliability for your company at a global level

You can contact me by email. Now give your company a reliable system to ensure world-class operational asset reliability, minimal maintenance costs and maximum operating profits. Most of these blocks can be easily replaced given the correct interface parts. The major variations in the rear housing, rear clutch and third control shaft are consistent, as well as some changes to the external configuration of the bell.

Advantages and disadvantages of a sequential box

The features of the sequential box and its design lead to obvious advantages:

- Ease of shifting and high gear change speed.

The ECU and hydraulics reduce shift times to 150ms, which is critical for professional racers. This result cannot be achieved by any, even the most advanced, classic manual or automatic transmission. In addition to speed, the sequential gearbox eliminates “missing” the desired gear, because the transition between them is carried out strictly sequentially.

- The speed of the car is not lost when switching.

When working with a manual transmission, the speed decreases slightly when changing gears. This is relevant for turbocharged engines, which manage to fall into the turbo hole while the driver is manipulating the transmission.

- Economy of the car.

- Ease of control thanks to the possibility of using steering wheel paddle shifters.

- Possibility of selecting modes - manual and fully automatic switching.

Traditional box and automatic

The first option is most often found on domestically produced cars, and the neutral position in them is in the middle. To start moving, you have to squeeze the clutch and engage first gear. After this, increasing the mode, gears must be switched sequentially.

But there is no obstacle to starting to move from second speed if the condition of the road surface and the capabilities of the engine are suitable for this. And if the car needs to be started by a tow, then to facilitate the actions it is possible to set the gearbox to third or fourth speed. The automatic transmission was invented to make driving the car easier. Switching occurs automatically, the driver only has to use the gas to increase or decrease the mode.

So, the use of a cam mechanism creates a strong load on the motor, transmission and even the drive. And it has a significant noise effect. There are advantages in driving, but they do not compensate for the disadvantages that may arise.

Peculiarities

The sequential box has four main features:

- Consecutive speed changes.

The driver will not “miss” the desired gear and can always set exactly the gearbox stage that is needed at the moment, passing sequentially through the others.

- Lack of a third pedal – clutch.

Its role is performed by an electronic unit controlled by signals from numerous sensors.

- Use of spur gears in the design.

These elements have greater efficiency compared to conventional helical gears from a classic manual transmission, although they transmit less torque (to compensate for this, larger gears are installed).

- Gear shifting is carried out by hydraulic servos.

For comparison: a robotic gearbox uses electric drives. Therefore, calling a sequential box a “robot” is technically incorrect.

Principle of operation

When you independently engage a gear and press the gas pedal, special sensors inform the electronic unit, which transmits a signal to the box.

It also has sensors installed that transmit their signal about the speed of the car to the progressive block. The latter, in turn, makes adjustments to the speed limit, coordinating the operation of the gearbox mechanisms. This takes into account the engine speed, the operation of the air conditioner and the readings on the instrument panel. Gear shifting is carried out using servos (actuators), which on a sequential gearbox are hydraulic. If the servos are electric, then such a gearbox is called robotic (in practice, a gearbox with both hydraulics and electric actuators is called robotic). The command to change gear is given by the driver manually or using the on-board computer.

SMG gearbox: sequential transmission

As you know, at the initial stage in the automotive industry, only manual transmissions were used.

However, later engineers developed other types of transmissions, with the main goal being to make driving as easy as possible.

A real breakthrough was the emergence of an automatic transmission, which made it possible to select and change gears automatically, that is, without driver participation.

At the same time, the hydromechanical “automatic” did not supplant traditional mechanics for a number of reasons; manual transmissions continued to be refined, and the design was constantly improved. As a result, one of the varieties of manual transmission became the sequential gearbox.

In a nutshell, this transmission differs from analogues in that upshifts and downshifts are engaged only in a certain sequence. To put it simply, the driver of a car with a so-called sequential gearbox shifts strictly in order “up” to engage an upshift, or “down” to engage a downshift.

At the same time, with conventional mechanics, the driver can change gears according to the “search” principle, that is, arbitrarily. The main thing is that the gear matches the speed, etc. In practice, for example, you can start from second and immediately switch to fourth. A sequential checkpoint will not allow you to do this.

Design and principle of operation of a sequential gearbox

As already mentioned, a sequential gearbox (sometimes called a selective gearbox) is based on a simple manual transmission. However, there are also differences from manual transmission.

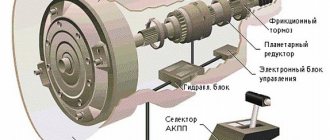

First of all, there is no clutch pedal, that is, the sequential gearbox is similar to a classic automatic transmission. Also, the design uses spur gears instead of helical ones. A separate ECU is responsible for “squeezing” the clutch instead of the driver; gear shifting is realized through a special hydraulic mechanism.

Such features make it possible to achieve high switching speeds, which is indispensable for sports cars, racing cars, etc. By the way, it is on such vehicles that a sequential gearbox is often installed, although this type of gearbox can also be found on civilian versions.

- The fact is that at high speed the car vibrates strongly, as a result of which it is quite difficult to engage the desired gear with conventional mechanics, and this must be done very quickly.

As you can see, the sequential gearbox is actually a more common “robot” today. Also, a conventional automatic transmission with a gas turbine engine, which has the ability to be manually controlled (Tiptronic), in this mode resembles the operation of a sequential gearbox.

Minuses

But this box also has its drawbacks. The hydraulic mechanism is subject to significant wear due to heavy load during operation. On cars participating in racing, mechanics repair the gearbox after the second race. Production cars have a much greater durability resource.

During use, they do not experience as much stress as sports cars. Therefore, with proper operation, the service life of a sequential gearbox is no less than that of a manual or automatic gearbox. But if you operate such a box without thinking about the consequences, then you are guaranteed premature failure

Whether it is a hydraulic clutch drive, another component or unit, it is not so important. The main thing to remember is that repairing a sequential box is very expensive.

Currently, the sequential gearbox is attracting more and more car owners. It is installed on many new car models and even motorcycles. The technologies of this transmission are being improved and brought to ideals. The time is not far off when not only sports cars equipped with a sequential gearbox, and even a cam gearbox, will use a convenient transmission, but also many car owners will be able to appreciate the advantage of sequential gear shifting.

Sequential gearbox: features, pros and cons

Today there are a large number of different types of gearboxes: manual, automatic and robotic gearboxes. At the same time, “automata” and “robots” may also have different devices.

For example, automatic transmissions are represented by automatic transmissions and CVT variators; a manual transmission can be either a simple robot with one clutch or a preselective gearbox with two clutches such as DSG. In this article we will talk about what a sequential gearbox is.

Read in this article