medvedbor › Blog › Semi-automatic transmission for Lada

Amazing things are happening in our city. About six months ago, I drove a LADA car with an automatic clutch control system for the first time. This car had a traditional gear lever, but it could be operated without squeezing the clutch. I got behind the wheel, drove around the yards a little and realized that this was something more than handicraft and a circle of “crazy hands”. This is at least cool.

The system works smoothly and without problems. You can move off intensely, with a slight slip, or you can move smoothly, without rushing, depending on how you press the gas. To shift, just release the gas and use the lever to engage the next gear. In this semi-automatic mode, the clutch pedal is tilted upward so that it does not interfere. But by simply pressing a button on the front panel, you can return to the usual pattern of pressing the clutch with your foot.

People with disabilities. Inexperienced drivers. Women. Residents of megacities, often stuck in traffic jams. Yes, this is not a full-fledged automatic transmission (rather, a transitional option from “mechanics” to “automatic”), but it could be a real help for many, many car enthusiasts. This really makes driving a car with a manual transmission easier because it completely frees the driver from controlling the clutch pedal. Is the game worth the candle? Yes, it's worth it. The entire kit that makes up the system costs several thousand rubles! After this first trip, I was impressed, but one fly in the ointment in this story greatly spoiled the barrel of honey - no one undertook to produce such a system in Tolyatti (even though it was developed here).

The idea was not implemented at VAZ, and could not find it, although everything possible was done for this. However, it was implemented in several popular models. We worked on the system for about eight months, tried various options (from hydraulics to electronics), but in the end the solution turned out to be quite simple. This semi-automatic transmission design has no electronic components, only mechanics, which is what makes it so affordable. According to the developers, Moscow companies produce electronic systems that provide similar consumer properties, but they cost many times more - and this is only the product itself, without delivery and installation.

One of the running samples has been in intensive use for about a year and works without any complaints or breakdowns. Its installation does not require intervention in the car’s design; all its components and mechanisms remain standard. The original components include only three brackets and one valve. The system is applicable to all front-wheel drive VAZ cars - with carburetor and injection engines, as well as with an electronic gas pedal.

The main working element of the system is the most common vacuum booster from the brake system, powered by a vacuum in the engine intake manifold - now your car will have two of these. The additional vacuum seal is mounted on the gearbox housing on an additional bracket. Switching on and off occurs using a solenoid valve from automotive gas equipment. And the control is via a mechanical valve connected through an additional cable to the throttle valve. This valve is responsible for the correct operation of the entire system and contains the author's know-how. Two microswitches are installed inside the car - one is responsible for monitoring the position of the gas pedal, and the second monitors the engagement of the gear.

The transmission is switched from traditional mode (when the clutch pedal is depressed by the driver's foot) to semi-automatic (when the pedal does not need to be touched) using a button on the instrument panel, and can occur on the go. As I already said, the system’s operation is adaptable: the nature of the activation depends on how you press the gas. When pressed slowly, the activation is smooth, starting almost at idle, and when pressed sharply, the engine first rapidly gains speed, and only then a sharp inclusion occurs. The system works taking into account four parameters: the position of the accelerator pedal, the position of the brake pedal, the position of the gearshift lever and (most importantly) the engine operating mode, that is, crankshaft speed and load.

An important point for an inexperienced driver is that the possibility of an error when starting is excluded, because The “automatic” will not allow the engine to stall, and under any loading conditions: say, when starting up a hill, the clutch engages at elevated speeds. When switching from second to third and beyond, the clutch engages quickly to avoid slipping and wear. You can brake with the engine - to do this, you just need to press a button on the shift lever.

Installation is carried out by one person, takes three hours and takes place without a lift - all work is carried out under the hood and in the cabin. No additional drilling or adjustments are required; all elements are attached using standard holes. The already installed system has two adjustments: on the vacuum rod to ensure full squeeze (installed once) and on the cable bracket on the throttle, it sets the moment the clutch is engaged (adjustable as the clutch disc wears out, located in an easily accessible place). Clutch pedal adjustment remains standard. The mechanism, specially designed for VAZ front-wheel drive vehicles, is maximally unified for all models.

So, the system has a number of advantages, both over traditional “mechanics” and over similar semi-automatic systems (we have already said about the difference in prices):

There are no changes to the factory design of the car, there is no impact on the normal operation of other components, the factory warranty is maintained. The mechanism can be installed independently; there is no need for modifications or special tools. A simple and reliable design that does not consume additional energy, does not contain an electronic part, and is not connected to engine control sensors. It is completely mechanical, and therefore suitable for all models, and is not sensitive to the technical condition of the car or changes in engine settings. It has the ability to quickly switch from semi-automatic mode to the usual “mechanical” mode and back. Prevents overloads in the transmission, eliminates shocks, jerks, slipping, provides full squeezing and easy gear shifting, thereby increasing the service life of transmission components and increasing the convenience of driving. Eliminates errors at the beginning of movement, as well as unwanted slipping in 2nd, 3rd and subsequent gears. The system adapts to any driving style and makes it possible to move off smoothly or abruptly, depending on the nature of pressing the accelerator pedal. When driving in city traffic jams, the system frees the driver from unnecessary manipulations, leaving only the gas and brake pedals, that is, it practically works like an automatic transmission.

Hydromechanical and electromechanical transmissions with manual shift[edit | edit code]

The first widely used type of PAKP was created by Chrysler in the 1930s and was widely used on its cars until the 1950s. Type M4 (on pre-war models, commercial designations Vacamatic or Simplimatic) or M6 (from 1946, commercial designations Presto-Matic, Fluidmatic, Tip-Toe Shift, Gyro-Matic and Gyro-Torque) and was originally a combination of three units — a fluid coupling, a traditional manual gearbox with two forward stages, and an automatically (on M4 by vacuum, on M6 by electric drive) activated overdrive (which played the role of a gear divider in this design). Each block of this transmission had its own purpose:

Fluid coupling Made the vehicle start smoother, allowed it to “drop the clutch” and stop without disengaging the gear or clutch. Later it was replaced by a torque converter, which increased torque and significantly improved vehicle dynamics compared to a fluid coupling (which somewhat worsened acceleration dynamics). Manual transmission Served to select the operating range of the transmission as a whole. There were three operating ranges - lower (Low), upper (High) and reverse (Reverse). There were two gears in each range. Overdrive Automatically switched on when the car exceeded a certain speed, thus shifting gears within the current range.

Gear shifting was done with a conventional lever located on the steering column. Later versions of the shifter imitated automatic transmissions and had a range quadrant indicator above the lever, like an automatic transmission - although the gear selection process itself did not change. There was a clutch pedal, but it was used only for range selection and was painted red.

It was recommended to start in normal road conditions in the High range, that is, in the second gear of the two-speed manual transmission and the third gear of the transmission as a whole - the high torque of the six- and eight-cylinder Chrysler engines made this possible.

When climbing and when driving through mud, it was necessary to start driving from the “Low” range, that is, from first gear. After exceeding a certain speed (varied depending on the specific transmission model), a switch to second gear occurred due to the overdrive automatically switching on (the manual transmission itself remained in first gear).

If necessary, the driver switched to the upper range, and in most cases fourth gear was engaged immediately (since overdrive was already engaged to obtain second gear) - it had an overall gear ratio of 1:1.

It was almost impossible to go through all four available gears during practical driving, although the transmission was formally considered a four-speed one.

The reverse gear range also included two gears and was engaged as usual once the vehicle had come to a complete stop.

Thus, for the driver, driving a car with such a transmission was very similar to driving a car with a two-speed automatic transmission, with the difference that switching between ranges occurred by pressing the clutch.

This transmission was available from the factory or as an option on all Chrysler vehicles of the 1940s and early 1950s. After the introduction of the true two-speed PowerFlite automatic transmission, and later the three-speed TorqueFlite, the Fluid-Drive family of semi-automatic transmissions were discontinued as they interfered with sales of fully automatic transmissions. The last year of their installation was 1954; in this year they were available on the cheapest brand of the corporation - Plymouth.

In fact, such a transmission became a transitional link from manual transmissions to hydromechanical automatic transmissions and served to “test” technical solutions later used on them.

Around the same time in Europe, some expensive cars were equipped with an electromechanical or hydropneumatic automatic clutch drive.

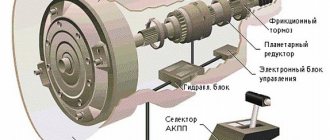

Operation of a semi-automatic gearbox

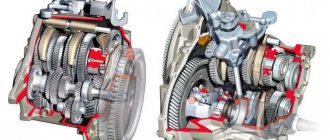

The work of shifting gears when a semi-automatic gearbox is engaged is based on the operation of two clutch mechanisms, in contrast to a conventional mechanical one.

As a rule, each of the mechanisms is associated when interacting with a specific set of gears. For example, the first clutch includes the first, third and fifth of six gears, and the second only includes the “even” ones - second, fourth and sixth.

This was done to reduce the time spent by the driver on switching, as well as to increase the smoothness of switching and obtain maximum performance from the engine during acceleration.

The need for the clutch pedal itself is automatically eliminated, since there is no need to disconnect the engine from the transmission parts.

Gear shifting occurs due to the operation of electronic systems that take into account various parameters of the vehicle’s movement, the operation of internal mechanisms, and issue commands to hydraulic mechanisms to enable one or another mode.

If necessary, such a box is also subject to driver control. This may be required, for example, if after intense acceleration you need to fix a quiet driving mode, or this particular gear is needed when cornering.

In this case, the box will obey when acting on special steering column switches.

Distinctive features of the semi-automatic box

Like any mechanism, a semi-automatic transmission has its own distinctive features, which can be understood by considering the advantages and disadvantages.

Advantages:

- smooth, uniform acceleration due to fast gear shifting (from 8 milliseconds);

- full use of the engine's capabilities, which also affects the dynamics of the car;

- fuel efficiency is recognized at the level of 10-20%, which is associated not only with the capabilities that the box provides, but also with the ability to effectively use less powerful engines;

- comfort for the driver.

- complexity of the design and, as a consequence, repair;

- high cost;

- lack of readiness to respond in a timely manner in unusual traffic situations.

What is a semi-automatic gearbox

Most modern automakers provide the buyer with the opportunity to choose a semi-automatic type of installed transmission, although the mass introduction of such transmissions began back in the 1930s. Despite its considerable age, the semi-automatic transmission still has no obvious opponents or fans.

According to experts, this is due to a poor understanding of its structure and principle of operation. To ensure conditions for changing gears, the driver of a car with a semi-automatic transmission just needs to take his foot off the gas pedal. It provides the most optimal conditions for the functioning of the engine when the car is moving, which not only extends its service life, but also reduces fuel consumption.

Advantages of motorcycles with automatic transmission

Modern automatic machines operate softly and smoothly, timely adjusting to the ratio of speed and load on the engine. This allowed the motorcycle market to show people all the advantages of automatic transmission:

- Ride comfort. The pilot doesn't have to watch upshifts and downshifts, listen to the revs, or monitor the tachometer;

- Safety. Due to the absence of the need to be distracted by squeezing the clutch, the pilot can better concentrate directly on controlling the bike and assessing the road situation;

- The engine of motorcycles with an automatic transmission is subject to less stress and its operation is better balanced. Accordingly, this increases its resource.

There are not many disadvantages to automatic transmissions. They consist of greater weight of the entire structure, complexity and high cost of maintenance, as well as increased gasoline consumption. And you’ll have to forget about sharp, disruptive acceleration. That's why so many bikers still prefer a manual transmission.

Semi-automatic box device

Any semi-automatic machine has two clutch mechanisms at once - this is the main difference between such a system and a classic manual gearbox. The most common operating scheme for such semi-automatic devices is the interaction of mechanisms only with a certain group of available gears, which can be even or odd. This arrangement can significantly reduce the time spent on switching, and also improves the clarity and smoothness of this process.

In practice it looks like this. When the car moves, the system analyzes information from all sensors and other systems. Based on the information received, when a gear is already engaged, the semi-automatic gearbox prepares in advance to engage the next one. This happens immediately after certain conditions occur. As a result, it was possible to reduce the switching time to 8 milliseconds - not every modern automatic transmission can boast of such indicators.

The semi-automatic transmission, the principle of operation of which is quite complex, is distinguished by the presence of a mass of electronic systems that take into account numerous parameters when driving a car in which there is no clutch pedal as unnecessary. All internal mechanisms must work synchronously and very clearly - it is in this case that high comfort is achieved when driving such a car. The driver can make his own adjustments to the operation of such a box using special switches, usually located under the steering wheel. Today, several variations of such boxes are already known - the final design will depend on the car manufacturer. The types of boxes are described in the video:

Advantages and disadvantages of semi-automatic boxes

As practice shows, it is impossible to consist of only advantages - any component in a car also has certain disadvantages. The undeniable advantages of semi-automatic machines over manual transmissions include the following:

- maximum comfort for the driver;

- excellent dynamic performance of the car during acceleration;

- using all the capabilities of the engine, which also increases its dynamics;

- a number of modifications of such boxes are also compact, which is important for small cars;

- a pronounced reduction in fuel consumption, due not only to the gearbox itself, but also to the possibility of installing less powerful engines.

Automatic or semi-automatic – which is more reliable?

Many drivers who purchase a new car cannot decide until the very end what to choose. Many people consider an automatic machine to be more modern, reliable and easy to use, but in fact, all this is far from the truth. The semi-automatic transmission is, in fact, a proven mechanics that has been proven for decades, equipped with modern additional systems - an automatic clutch switch and a gear shift system. While driving, the control unit of such a box is “guided” not only by the operating algorithms embedded in it, but also receives signals from the driver and other vehicle sensors.

A semi-automatic transmission is characterized by increased reliability and, unlike an automatic transmission, allows you to save on fuel because it reduces its consumption. Since installing a semi-automatic machine is cheaper for the automaker, the cost of the car is also reduced for the buyer. The number of serious breakdowns with semi-automatic transmissions is also significantly lower, and repairing them, compared to an automatic transmission, is much easier. As a result, it turns out that a semi-automatic machine allows you to save not only on purchasing a car, but also reduces its operating costs.

Gearboxes for trucks: what is the difference with cars?

What features distinguish gearboxes for trucks from their passenger “brothers”? We study in detail. Both the “passenger car” and the multi-ton tractor differ in appearance only in size. Both have an internal combustion engine, a body and wheels. And all this “good” must be connected to each other by a transmission, otherwise the equipment simply will not work. But truck gearboxes, naturally, have their own characteristics. And they are due precisely to the impressive mass. A multi-ton mountain of metal carrying a load of enormous weight and dimensions must have an ultra-reliable gearbox with as many steps as possible. After all, it is the multi-stage nature that allows you to use the motor with maximum efficiency.

But the designers couldn’t just pile up 15-20 steps in the gearboxes. Such gearboxes for trucks would be too cumbersome, and the driver would be exhausted in searching for the required speed. Therefore, two absolutely indispensable devices for heavy equipment were invented - a divider and a demultiplier.

Divide and rule

It is the divider and range-multiplier that allow you to work with trucks without problems, without complicating the design of the gearbox. What are these two units and on what principles do they work?

A divider is something like an additional “box for a box”. It is made in the form of a two-stage gearbox, where the first stage is direct and the second is step-up. Thus, installed on a four-speed transmission, this device doubles the number of gears (4x2=8). The multiplier is also a two-stage gearbox, but with a lowering lower stage. Here is the answer to the question of how sixteen-speed gearboxes for trucks are made. It's simple: a standard box is crossed with both a divider and a range multiplier (4x2x2=16).

To control the gearboxes described above, buttons or levers on the gearbox are most often used. They are especially useful when the car is going uphill and the engine stops pulling. In addition, a box with a divider and range-multiplier lasts longer and provides additional fuel savings.

Informed decisions

The mass of parts is also important for passenger cars, but for commercial vehicles this indicator is especially significant. Therefore, good manufacturers always try to make gearboxes for trucks as light as possible. For these purposes, lightweight materials such as aluminum alloys are used. A search is also underway for more modern methods of manufacturing the body and internal “filling”.

For the end user, every kilogram of machine weight saved means a commercial benefit. This is both a chance to avoid payments under the Platon system and the opportunity to take on additional cargo. Therefore, the leading positions in the Eurasian gearbox market for trucks are occupied by German and Chinese products. It most closely meets the requirements of cargo carriers.

In conclusion, let’s say a few words about “automatic machines”. Unlike passenger cars, they are much less common on trucks. And all because of the same desire to save money. Drivers highly value “mechanics” for closer control over the car and the ability to save fuel when driving correctly. In addition, manual transmissions are much cheaper to maintain and repair due to the simplicity of the design. Maximizing benefits and minimizing costs is what business needs above all. Therefore, automatic transmission in heavy-duty truck cabs still remains a rarity and exotic.

Operating principle of a semi-automatic box

All the work of the mechanical part of such a box is almost identical to the “actions” of the mechanical one. Significant differences are observed in the presence of the electronic component, which determines all the existing driving comfort. A special unit is responsible for controlling this complex system, containing all the algorithms necessary for effective gear shifting. At the same time, during operation, he is able to take into account information coming from the systems available in the car and the driver himself. This provides unrivaled precision and efficiency in shift control.

Despite the presence of a sufficient number of electronic systems in the box, the main work when changing gears is performed by its steel mechanical parts, which take on the main load. Considering that all electronics are reliably protected, the semi-automatic gearbox has a huge service life. The only condition is that it should be serviced only by professional mechanics - their incorrect actions can lead to the car trying to “move off on its own,” for example, from a traffic light at a busy intersection. As a result, it turns out that a semi-automatic transmission is, today, the most optimal means of ensuring gear changes in a car.

Semi-automatic transmission and its operating principle

Today on the automotive market there are a huge number of models, each of which has its own unique design, as a result of solving certain technical problems. One of the important criteria for each car is speed and acceleration time. The gearbox plays an important role in the direction data, since it is responsible for transmitting the power of the engine and its operation. If you have a bad gearbox, driving becomes worse. Today there are three main types of gearboxes:

- Manual Transmission;

- Automatic;

- Semi-automatic.

Manual Transmission

The most popular are the first two types. The fact is that they are used most often, although recently more and more cars have an automatic transmission. If we talk about supporters of one type or another and the arguments on which they rely, we can say the following: the first two have them, while the semi-automatic transmission does not have pronounced supporters. What's the matter? Again in popularity. Since automatic and mechanical are used more often, more people know about their structure, pros and cons, while the principle of operation of a semi-automatic is not familiar to many, and therefore it is not possible for an ordinary person to highlight obvious positive aspects and disadvantages. So how does a semi-automatic transmission work?

Semi-automatic transmission

The first widely used type of PAKP was created by Chrysler in the 1930s and was widely used on its cars until the 1950s. Type M4 (on pre-war models, commercial designations Vacamatic or Simplimatic) or M6 (from 1946, commercial designations Presto-Matic, Fluidmatic, Tip-Toe Shift, Gyro-Matic and Gyro-Torque) and was originally a combination of three units — a fluid coupling, a traditional manual gearbox with two forward stages, and an automatically (on M4 by vacuum, on M6 by electric drive) activated overdrive (which played the role of a gear divider in this design). Each block of this transmission had its own purpose:

Fluid coupling Made the vehicle start smoother, allowed it to “drop the clutch” and stop without disengaging the gear or clutch. Later it was replaced by a torque converter, which increased torque and significantly improved vehicle dynamics compared to a fluid coupling (which somewhat worsened acceleration dynamics). Manual transmission Served to select the operating range of the transmission as a whole. There were three operating ranges - lower (Low), upper (High) and reverse (Reverse). There were two gears in each range. Overdrive Automatically switched on when the car exceeded a certain speed, thus shifting gears within the current range.

Gear shifting was done with a conventional lever located on the steering column. Later versions of the shifter imitated automatic transmissions and had a range quadrant indicator above the lever, like an automatic transmission - although the gear selection process itself did not change. There was a clutch pedal, but it was used only for range selection and was painted red.

It was recommended to start in normal road conditions in the High range, that is, in the second gear of the two-speed manual transmission and the third gear of the transmission as a whole - the high torque of the six- and eight-cylinder Chrysler engines made this possible.

When climbing and when driving through mud, it was necessary to start driving from the “Low” range, that is, from first gear. After exceeding a certain speed (varied depending on the specific transmission model), a switch to second gear occurred due to the overdrive automatically switching on (the manual transmission itself remained in first gear).

If necessary, the driver switched to the upper range, and in most cases fourth gear was engaged immediately (since overdrive was already engaged to obtain second gear) - it had an overall gear ratio of 1:1.

It was almost impossible to go through all four available gears during practical driving, although the transmission was formally considered a four-speed one.

The reverse gear range also included two gears and was engaged as usual once the vehicle had come to a complete stop.

Thus, for the driver, driving a car with such a transmission was very similar to driving a car with a two-speed automatic transmission, with the difference that switching between ranges occurred by pressing the clutch.

This transmission was available from the factory or as an option on all Chrysler vehicles of the 1940s and early 1950s. After the introduction of the true two-speed PowerFlite automatic transmission, and later the three-speed TorqueFlite, the Fluid-Drive family of semi-automatic transmissions were discontinued as they interfered with sales of fully automatic transmissions. The last year of their installation was 1954; in this year they were available on the cheapest brand of the corporation - Plymouth.

In fact, such a transmission became a transitional link from manual transmissions to hydromechanical automatic transmissions and served to “test” technical solutions later used on them.

Around the same time in Europe, some expensive cars were equipped with an electromechanical or hydropneumatic automatic clutch drive.

Principle of operation

It is worth immediately noting the fact that the system in question has a more complex structure than the above-mentioned types of boxes. So, when a semi-automatic gearbox operates, there are two switching mechanisms at once. This is precisely the fundamental difference. The essence of the operating principle is that each of the mechanisms is assigned a certain set of gears, for which it is responsible for switching. For example, the most popular is the following distribution system: the first mechanism switches to first, third and fifth gears, and the second to second, fourth and sixth. It is worth saying that this principle is used by a gearbox that has six stages. What did the designers want to achieve when creating this mechanism? First of all, this design allows for faster switching, increased smoothness of the process, and also, most importantly, a significant increase in engine output, this makes it possible to achieve, even on not very powerful engines, quite high results that were not previously achieved.

Automatic transmission

If we continue the theme of design issues, the obvious feature will be the absence of a clutch pedal. This became possible due to the fact that it is no longer necessary to separate the engine from the transmission parts itself, and, therefore, there is no need for an additional pedal. Thus, a car with the type in question also has two pedals, just like with an automatic transmission. A new question arises: How is the gear shifting process carried out? The fact is that switching occurs, first of all, due to the operation of electronic systems, which conduct a general analysis of all vehicle systems and, depending on their condition, make switches, but it is also worth noting that, unlike an automatic transmission, you can use manual adjustment, which will allow you to independently regulate which gear your car is in. This can be useful in a number of cases, for example, to optimally pass a certain intersection you need to use a certain gear, and so on.

Who is a bike with automatic transmission suitable for?

The list of automatic motorcycles is quite extensive. It includes equipment of completely different classes. But there are several points that unite them all:

- The automatic is ideal for traveling on good, smooth roads. If you are a fan of “dalnyaks”, you will definitely like this ride;

- With automatic transmission it is very convenient to drive in the city, with its numerous intersections, traffic lights, and crossings. Pizza delivery people, couriers and just people who prefer to ride in “human anthills” are increasingly choosing such a box;

- Typically, motorbikes with automatic transmissions are not purchased by poor people (because the unit itself costs much more), who do not care if they are very gluttonous regarding fuel);

- But if you are a lover of off-road driving, difficult transport conditions, or a resident of mountainous areas, you’d better take a closer look at a manual transmission. With it you will have better control of your bike while riding in the mud.

The opinion that motorcycles with an automatic transmission are chosen by women or lazy people who do not want to master the “subtleties” of manual control is fundamentally wrong. This is the same as calling a person lazy who prefers to live in a city apartment rather than in a forest hut. The concept of comfort is different for every motorcyclist, and arguing about a manual or an automatic is a pointless exercise.

What distinctive features are there in the operation of a semi-automatic machine?

Since the semi-automatic machine has a radical new structure, we can talk about its advantages and disadvantages compared to other types. Below are the main positive points:

- Smooth acceleration. This is achieved through smooth gear changes that achieve a minimum time of 8 milliseconds;

- Only when using the box model in question can you fully use all the capabilities of the engine, starting from the lowest speeds and reaching the maximum. This undoubtedly has a positive effect on the overall dynamics of the car;

- Economical. By making fuller use of the engine, the box saves fuel. If we talk about the numerical value, the savings reach 10, and sometimes even 20 percent;

- Driver comfort. All of the above factors allow you to achieve a more comfortable driving experience.

Unfortunately, like any other type of box, semi-automatic has its own disadvantages, which again stem from the design features.

Semi-automatic transmission for Alfa Romeo

- Complexity of design. This fact will entail quite a large number of consequences. Firstly, the difficulty of repair, which arises due to the large number of nuances. Secondly, high cost;

- Lack of ability to respond quickly. Due to the design features developed by engineers, this box model reacts very poorly to rapidly changing conditions. Thus, if the need for any sudden maneuver arises, it may not work perfectly, which will lead to bad consequences. Perhaps this is the most serious drawback of this mechanism.

What's the result?

Nevertheless, such a box has proven its performance. Despite the emergence in the arsenal of auto manufacturers of the option of using continuously variable variators, where gears do not need to be changed at all, semi-automatic transmission continues to be improved.

According to various estimates, up to a quarter of the car market will be equipped with a similar gearbox. After all, she has more advantages than disadvantages.

Heading

Today on the automotive market there are a huge number of models, each of which has its own unique design, as a result of solving certain technical problems. One of the important criteria for each car is speed and acceleration time. The gearbox plays an important role in the direction data, since it is responsible for transmitting the power of the engine and its operation. If you have a bad gearbox, driving becomes worse. Today there are three main types of gearboxes:

- Automatic;

- Semi-automatic.

The most popular are the first two types. The fact is that they are used most often, although recently more and more cars have an automatic transmission. If we talk about supporters of one type or another and the arguments on which they rely, we can say the following: the first two have them, while the semi-automatic transmission does not have pronounced supporters. What's the matter? Again in popularity. Since automatic and mechanical are used more often, more people know about their structure, pros and cons, while the principle of operation of a semi-automatic is not familiar to many, and therefore it is not possible for an ordinary person to highlight obvious positive aspects and disadvantages. So how does a semi-automatic transmission work?

Semi-automatic box device

Often, a vehicle is equipped with either an automatic or manual transmission type. Experienced motorists know the features of their structure, strengths and weaknesses. While the specifics of the functioning of a semi-automatic device are not familiar to many. That is why it is necessary to consider the main characteristics of this box.

The functioning of semi-automatic gearbox options is based on the operation of two clutch mechanisms. This is its difference from manual transmission. The first clutch activates the odd-numbered gears, and the second – the even-numbered gears. Thanks to this, the time when changing speed modes is reduced.

A distinctive design feature of the semi-automatic gearbox is the absence of a clutch pedal (it is pressed automatically). It allows the engine to operate in optimal modes and develops the necessary power. In parallel with this, information from the sensors is analyzed, on the basis of which the box selects the required speed mode.

Principle of operation

To engage gears on this type of gearbox, the driver needs to remove his foot from the gas pedal. Actuators belonging to the transmission system control the operation of the clutches.

One of the advantages of this gearbox is the ability to control the vehicle manually. In particular, if the driver needs to change from low to high gear. It should be noted that there are special steering column switches.

Thus, the semi-automatic machine is equipped with a control unit that receives signals from various sensors. This device increases driving comfort and eliminates jerking. The function of the sensors is to analyze the driver’s actions, vehicle speed, etc. Thanks to this, the necessary precision in controlling the operation of the transmission is achieved. This box includes a set of gears of various diameters. Each of the semi-automatic mechanisms is assigned a specific set of gears.

Semi-automatic gearbox: design and principle of operation

So, let's start with the fact that this type of gearbox was developed a little less than a hundred years ago. At the same time, for a number of reasons, a semi-automatic transmission was not able to compete with automatic transmissions for a long time, as a result of which this solution cannot be called a mass solution.

If we look at this gearbox in more detail, first of all, there is no clutch pedal. This means that the driver does not have to independently “break” the power flow from the engine to the transmission in order to engage the desired gear (as is the case with a manual transmission). To engage gears, the driver only needs to remove his foot from the accelerator pedal.

It should also be noted that this box allows the engine to operate in optimal modes; engine power is transferred to the transmission with minimal losses, while at the same time fuel consumption is reduced. In other words, a semi-automatic transmission, unlike an automatic transmission, is a more economical solution and also provides the car with better dynamics.

- Let's move on. To understand what semi-automatic transmissions are, it is enough to imagine a manual transmission that has two clutches. The operation of the clutches is controlled by separate actuators.

In the same way, the selection of the desired gear takes place, taking into account the specific driving conditions of the vehicle. As a result, the presence of such devices (servomechanisms) allows you to automate the process of selecting and turning on/off the gear, as well as turning on/off the clutch.

Let us also add that a semi-automatic gearbox is conventionally two manual gearboxes, which are combined in one housing. To make it clearer, one such box has its own clutch and gears corresponding only to even-numbered gears. Accordingly, the other also has a clutch and a set of odd gears.

Thanks to the presence of two clutches, it is possible to significantly reduce shift times; gears are engaged almost imperceptibly for the driver, which significantly increases comfort, eliminating jerks, delays and failures typical of AMT-type gearboxes with one clutch.

When the car is moving, the transmission control unit receives signals from various sensors. This unit has prescribed algorithms for the most efficient and comfortable gear shifting. Also, individual parameters can be dynamically changed taking into account information received from sensors that analyze the driver’s actions, the load on the internal combustion engine, driving speed, etc.

This allows you to achieve precision when controlling the operation of the gearbox and shifting gears. Taking into account the fact that one gear is already engaged, the semi-automatic transmission, thanks to the presence of a second clutch, quickly “prepares” the next one for engagement.

The transmission will engage as soon as the conditions for its engagement are optimal. In this case, the switching speed will be very high. In practice, this type of gearbox changes gears much faster than the vast majority of automatic transmissions.

Pros and cons of semi-automatic transmission type

A semi-automatic transmission makes it possible to effectively use engines with low power. All internal mechanisms of the box work synchronously, there is clarity when changing speeds.

Advantages of a semi-automatic box:

- Engine power is transmitted to the transmission with minimal losses.

- Low fuel consumption.

- Good driving dynamics are ensured.

- Smooth acceleration up to 100 km/h.

- The engine operates in optimal mode.

Considering that a semi-automatic transmission consumes a small amount of fuel, purchasing a car with it is more profitable than with an automatic transmission. Gears change without long delays.

In terms of price, cars with a semi-automatic automatic are installed by the manufacturer are cheaper than a car with an automatic.

Disadvantages of a semi-automatic box:

- Electronic transmission sensors and clutch units quickly fail; replacing them is labor-intensive and expensive.

- Due to the complexity of the box design, not every service center undertakes to repair a semi-automatic machine.

Semi-automatic machines are found both on cars with a small internal combustion engine and on cars that produce more power. Thanks to the rapid switching of speeds, smooth acceleration is observed.

To prevent the car owner from prematurely encountering problems with the operation of the high-speed gearbox, one should not adhere to an aggressive driving style and constantly use manual gear shifting mode.

Pros and cons of semi-automatic gearbox

As mentioned above, fuel economy, high transmission efficiency, shift speed and comfort, as well as engine operation in optimal modes are the main advantages of this type of gearbox.

Semi-automatic machines can be installed both on cars with a small internal combustion engine and on powerful power units with high torque.

- If we talk about the shortcomings, first of all, we should note a large number of electronic sensors and servomechanisms, as well as the low reliability and maintainability of these elements.

Another weak link is the clutch assemblies, since this element is subject to loads and fails quite quickly. At the same time, replacing the clutch on a semi-automatic gearbox turns out to be labor-intensive and expensive.

In practice, the high cost of spare parts, the high cost of repairs and the complexity of the design often become the reason that not every service, even an official one, can properly repair a semi-automatic transmission.

- Taking into account the above, it becomes clear why, when choosing one type of automatic transmission or another, many people prefer a conventional automatic transmission. However, if we compare semi-automatic and hydromechanical transmissions, the semi-automatic gearbox is also quite reliable when used correctly.

In fact, the unit itself is a manual transmission with an automatic clutch switch, as well as gear shift mechanisms. In other words, the semi-automatic transmission also has a proven design, and can significantly reduce fuel consumption compared to an automatic transmission. The weak point of such a box is the actuators (servomechanisms), and not the gearbox.

If we talk about the cost of cars with automatic transmission or semi-automatic transmission, it is in the second case that the price will be lower. The reason is that semi-automatic transmissions are cheaper to produce than classic automatics. It turns out that a semi-automatic is cheaper to purchase at the start, and the costs for further operation of the car are also somewhat reduced.

Features of servicing a semi-automatic box

Despite the positive aspects of the semi-automatic transmission option, this box requires careful handling. It is important to change the oil on time so that the unit does not lose its operating properties ahead of schedule.

A semi-automatic machine should be serviced by services that specialize in repairing transmissions of this type. Otherwise, after repair and restoration work, interruptions in the functioning of the transmission may occur. If the box breaks down, it will be difficult to change gears.

If you follow the basic rules for operating a car with a semi-automatic transmission, the transmission will function for a long time.

Thus, a semi-automatic transmission resembles a manual one, which is equipped with additional systems that provide automatic change of speed modes. Its mechanical part is reliable. One of the criteria for choosing cars with this type of transmission is speed and acceleration time.

Semi-automatic gearbox: features

Checkpoint, outside view

Despite the positive aspects of the semi-automatic transmission option, this box requires careful handling. It is important to change the oil on time so that the unit does not lose its operating properties ahead of schedule.

A semi-automatic machine should be serviced by services that specialize in repairing transmissions of this type. Otherwise, after repair and restoration work, interruptions in the functioning of the transmission may occur. If the box breaks down, it will be difficult to change gears.

Thus, a semi-automatic transmission resembles a manual one, which is equipped with additional systems that provide automatic change of speed modes. Its mechanical part is reliable. One of the criteria for choosing cars with this type of transmission is speed and acceleration time.

Today, the auto industry offers consumers both a conventional manual transmission and several types of automatic transmissions. Among the “classic” automatic transmissions, hydromechanical automatic transmissions should be highlighted, and CVT variators are also installed on many cars.

Another separate group is represented by the so-called semi-automatic boxes. Next, we will talk about how a semi-automatic transmission works and works, what it is and what features this type of transmission has, and we will also look at the strengths and weaknesses of the unit.

So, let's start with the fact that this type of gearbox was developed a little less than a hundred years ago. At the same time, for a number of reasons, a semi-automatic transmission was not able to compete with automatic transmissions for a long time, as a result of which this solution cannot be called a mass solution.

If we look at this gearbox in more detail, first of all, there is no clutch pedal. This means that the driver does not have to independently “break” the power flow from the engine to the transmission in order to engage the desired gear (as is the case with a manual transmission). To engage gears, the driver only needs to remove his foot from the accelerator pedal.

It should also be noted that this box allows the engine to operate in optimal modes; engine power is transferred to the transmission with minimal losses, while at the same time fuel consumption is reduced. In other words, a semi-automatic transmission, unlike an automatic transmission, is a more economical solution and also provides the car with better dynamics.

- Let's move on. To understand what semi-automatic transmissions are, it is enough to imagine a manual transmission that has two clutches. The operation of the clutches is controlled by separate actuators.

In the same way, the selection of the desired gear takes place, taking into account the specific driving conditions of the vehicle. As a result, the presence of such devices (servomechanisms) allows you to automate the process of selecting and turning on/off the gear, as well as turning on/off the clutch.

Let us also add that a semi-automatic gearbox is conventionally two manual gearboxes, which are combined in one housing. To make it clearer, one such box has its own clutch and gears corresponding only to even-numbered gears. Accordingly, the other also has a clutch and a set of odd gears.

Read more: How to replace a car's engine control unit

Thanks to the presence of two clutches, it is possible to significantly reduce shift times; gears are engaged almost imperceptibly for the driver, which significantly increases comfort, eliminating jerks, delays and failures typical of AMT-type gearboxes with one clutch.

When the car is moving, the transmission control unit receives signals from various sensors. This unit has prescribed algorithms for the most efficient and comfortable gear shifting. Also, individual parameters can be dynamically changed taking into account information received from sensors that analyze the driver’s actions, the load on the internal combustion engine, driving speed, etc.

This allows you to achieve precision when controlling the operation of the gearbox and shifting gears. Taking into account the fact that one gear is already engaged, the semi-automatic transmission, thanks to the presence of a second clutch, quickly “prepares” the next one for engagement.

The transmission will engage as soon as the conditions for its engagement are optimal. In this case, the switching speed will be very high. In practice, this type of gearbox changes gears much faster than the vast majority of automatic transmissions.

As mentioned above, fuel economy, high transmission efficiency, shift speed and comfort, as well as engine operation in optimal modes are the main advantages of this type of gearbox.

Semi-automatic machines can be installed both on cars with a small internal combustion engine and on powerful power units with high torque.

It should also be noted that the acceleration dynamics with this transmission, compared to a hydromechanical automatic transmission or manual transmission, turns out to be better, since even an experienced driver is not able to change gears faster than an automatic.

- If we talk about the shortcomings, first of all, we should note a large number of electronic sensors and servomechanisms, as well as the low reliability and maintainability of these elements.

Another weak link is the clutch assemblies, since this element is subject to loads and fails quite quickly. At the same time, replacing the clutch on a semi-automatic gearbox turns out to be labor-intensive and expensive.

It is very important that in a semi-automatic transmission all mechanisms work clearly and smoothly, otherwise jerks, jolts, slipping, etc. are inevitable. Also, the resource of this box is noticeably reduced if the driver practices an aggressive driving style, constantly using only manual gear shift mode.

In practice, the high cost of spare parts, the high cost of repairs and the complexity of the design often become the reason that not every service, even an official one, can properly repair a semi-automatic transmission.

In fact, the unit itself is a manual transmission with an automatic clutch switch, as well as gear shift mechanisms. In other words, the semi-automatic transmission also has a proven design, and can significantly reduce fuel consumption compared to an automatic transmission. The weak point of such a box is the actuators (servomechanisms), and not the gearbox.

If we talk about the cost of cars with automatic transmission or semi-automatic transmission, it is in the second case that the price will be lower. The reason is that semi-automatic transmissions are cheaper to produce than classic automatics. It turns out that a semi-automatic is cheaper to purchase at the start, and the costs for further operation of the car are also somewhat reduced.

What's the result?

As you can see, a semi-automatic transmission is a type of manual transmission, which is additionally equipped with electronic systems and actuators. For example, DSG and other analogues.

Read more: How to remove a manual transmission and automatic transmission