Greetings to you all, my dear subscribers and regular readers of the blog! Just a couple of decades ago, a car with an automatic transmission was a curiosity on our roads. Today, many motorists choose it for its convenience and comfort while driving. However, it has its own varieties, which differ in design and principle of operation. At the request of our readers, today I want to pay attention to the question of how a variator differs from an automatic transmission.

Design and principle of operation of the variator

Many people think that the CVT was invented later than the automatic transmission, but this is not so. The principle of operation of a continuously variable transmission was discovered in 1490 by Leonardo da Vinci, but he was unable to implement it, since at that time there was no type of motor that is used in modern cars today.

The principle of cones, which are directed in opposite directions, and tensioned conical belts, was discovered by this scientist. Such devices were used in mills. At that time, such a mechanism was a primitive variator. Then they forgot about this mechanism, and only in the 19th century they began to use it on machine tools in production, but it has not yet reached cars. The first engineer who decided to use this invention for automobile transport was the Dutch engineer Hubert van Doorn. He invented the continuously variable transmission, which was installed on cars in 1958.

The variator was installed on cars with an engine of 0.59 liters of useful volume. This was a great success, and then other manufacturers began to think about installing a continuously variable transmission on their cars.

Before moving on to the comparative parameters of an automatic transmission and a variator, it will be useful to familiarize yourself with the operating principle and design of both mechanisms. This data will help you make the right choice. Let's start our consideration with the variator.

The main difference between a CVT and another gearbox is that it does not have separate gears. Each variator has a certain range in which there is a transmission force under certain conditions at a certain point in time. This condition is possible because the variator operates based on a different operating principle, unlike a gearbox.

Let's understand the principle of operation of the variator. It consists in the use of a belt drive, usually in modern cars a chain (metal belt) is used, which transmits torque between the engine crankshaft and the driven shaft connected to the wheel drive. The gear ratio changes smoothly by smoothly changing the diameter of the driven and drive shafts. For such purposes, special methods are used. All modern car manufacturing plants have their own developments in this regard. But all variators are divided into two main types:

- V-belt variator.

- Toroidal appearance.

The main element of a V-belt drive can be called a toothed belt with a trapezoidal cross-sectional shape. Some factories use a belt or chain made of metal plates. The other component is two pulleys formed by conical disks that can change the diameter. This allows you to change the speed and magnitude of the transmitted torque.

The work is performed in the following order. When you press the gas pedal, the drive pulley transmits torque from the motor to the driven shaft. But its design is such that when exposed to centrifugal forces due to an increase in speed, the two halves of the disks converge and push the conical belt from the middle of the pulley to the edges. The reverse procedure is carried out on the driven shaft. It has the two halves of the disc separate and the belt moves to the middle of the pulley. This is how the gear ratio and force changes slowly. When the gas pedal is released, the reverse process is performed.

The toroidal type of variator works in a different way. Instead of shafts, there are two wheels that have a spherical surface. Rollers are clamped between the wheels, one of which is driving and the other driven. A change in the magnitude of the torque and gear ratio appears due to a change in the friction force of the rollers and wheels. Changing the location of the rollers in a perpendicular plane makes it possible to change the gear ratio. When the roller is positioned horizontally, the driven and driving wheels rotate at the same angular speed. And if the rollers are in a different position, then the gear ratio changes.

But due to the complexity of the device and production technologies of some elements, toroidal variators are rarely used. Therefore, in the future we will consider the most common V-belt variators in car production.

Lubricants for CVTs differ from other transmission fluids. They are marked CVT. These fluids not only lubricate the parts, but also prevent them from slipping. Thanks to this property, the belt can operate to transmit torque between shafts. Therefore, you should not allow the gearbox to become “oil starved,” otherwise the chain or belt will slip along the surfaces of the shafts, which will lead to their rapid wear.

Which elements in the variator are susceptible to malfunctions?

This device requires high-quality maintenance. The oil must be changed every 80 thousand km, as specified in the manufacturers' regulations. This must not be forgotten, otherwise problems will arise that will require a large investment of money.

- The oil pump and valve body may become dirty.

- As a result, the shafts are not able to normally open and tighten the belt, which is slipping.

- If the belt slips, a lot of wear occurs. With increased wear, it will quickly rupture, which will create big problems in the box.

- Scores appear on the ground areas of the shafts, which negatively affects the belt.

- The CVT transmission has a serious drawback in the presence of a large amount of electronics, reaching 50%.

CVT service life

Here it is necessary to remember the need for timely replacement of lubricant, otherwise the service life will be significantly reduced. However, if you regularly service the gearbox, then after 150 thousand km it is recommended to replace the belt so that it does not break and cause harm to the mechanism. Therefore, a CVT gearbox is a more problematic mechanism, unlike other types, and its service life cannot reach 300 thousand km.

Advantages of the variator:

- Good acceleration dynamics, better than automatic.

- Low fuel consumption, lower than with an automatic transmission.

- There are no gears, which means there is no jerking when switching, which provides additional advantages in terms of dynamism and smooth movement.

- Increased efficiency, 10% more than an automatic transmission.

- The vehicle is easy to control; novice drivers do not need to learn how to drive a car with a CVT transmission, change gears, and start off.

- A car with a CVT does not emit many environmentally harmful substances due to lower gasoline consumption.

- Gentle mode of action. The selection of operating conditions is carried out by an electronic system that selects the best operating modes in order to reduce wear on the elements and increase their service life.

Disadvantages of a CVT gearbox:

- A complex repair method that has not yet been fully mastered by specialists, so its repair can only be performed by official dealers, which costs a lot of money. Finding a good CVT technician is very difficult, especially in small towns.

- A complex electronic system, if it malfunctions, you need to visit an official dealer and invest a lot of money.

- The cost of replacing belts is an expensive procedure; not all car repair shops do it.

- Special CVT oil is expensive and not easy to find. The brand of oil also plays a big role; if you fill it with a different oil, the box will not work.

- The CVT box cannot be mounted on cars with powerful engines, more than 220 hp, since powerful engines exert a lot of force on the drive belt and the CVT roller.

- On a car with a CVT transmission, it is prohibited to tow another car or trailer, or tow the car itself with the engine not running.

Advantages and disadvantages

Despite the complexity of the design and high cost, this type of transmission is becoming increasingly widespread. Like any other device, a variator has certain pros and cons.

To more accurately evaluate a mechanism, you should decide on the criteria, or better yet, analyze the advantages and disadvantages in comparison with other mechanisms that are closest in function.

The main advantages of the variator:

- Continuity of power flow transmitted from the engine to the drive wheels.

- Smooth change in gear ratio without jolts or jerks.

- Possibility of ensuring optimal engine operation.

- Low noise level from the operating mechanism, slightly varying characteristic buzzing.

- Reduced fuel consumption.

- Maximum optimization of loads on the power unit and other drive elements.

On the other hand, the above advantages are achieved due to the high complexity of the mechanism and the presence of a number of devices that ensure its operation.

This entails higher construction costs and increased operating costs. Special transmission technical fluids are poured into the variators, which provide cooling of parts and removal of wear products from the working area.

Automatic transmission

This mechanism appeared primarily in shipbuilding in the early 20th century. Its inventor is the German professor Fettinger. He developed a hydrodynamic transmission that separated the ship's engine and propeller. This is how the hydraulic coupling arose, which is the most important element of automatic transmissions. Subsequently, in 1940 in America, engineers began installing the first automatic transmissions on cars.

Their structure has remained virtually unchanged to this day. An automatic transmission has two main elements - a gearbox and a torque converter, which works instead of a clutch. Its principle of operation is to smoothly change gears. The gearbox is designed so that the gears are in continuous mesh with each other. This makes it possible to obtain a single, small-sized mechanism with several stages.

From the very beginning, cars did not have front-wheel drive, they were all rear-wheel drive, and with this design, automatic transmissions were equipped with only three gears, which was enough. Today the situation is different, and cars have front-wheel drive, there are more speeds, there are up to six speeds.

Automatic transmission device

Today, this design has been worked out for years, and its design has now been brought to perfection (main types). The design of this box is quite reliable and durable. The rotational torque from the engine is transmitted through the torque converter device, as we discussed, it has no mechanical gearing, it operates due to oil pressure. If there is no rigid clutch, then the reliability of the mechanism is high, but the design includes a planetary gear and shafts, as well as clutches with discs.

The clutches work as a clutch and when they are released and compressed, the necessary clutches come into operation at the appropriate speeds.

Important elements are the hydraulic unit and the high-pressure pump. These are the most important details.

What can go wrong in an automatic transmission?

All automatic transmission malfunctions, as well as manual transmissions, arise from untimely repairs and maintenance, or oil changes. Typically, many drivers do not change the oil in an automatic transmission even with significant mileage, which leads to contamination of the cooling radiator, valve body, and filter. As a result, the oil pump is unable to supply operating pressure. Due to this situation, the clutches on the metal discs spin, similar to how the clutch disc slips on a manual transmission. In this case, the speeds are difficult to engage, the car jerks when changing gears.

For this reason, when purchasing, it is recommended to check the automatic transmission oil for smell, since burnt fluid means that the clutches are worn out or burnt. If there is such a smell, then purchasing such a machine is not recommended. Of course, if the automatic transmission is “started”, then there may be more malfunctions: wear of the gears of the planetary mechanism, the friction lining of the torque converter, and many other parts.

Service life of the automatic transmission

With normal maintenance, the resource can be very large. Sometimes there are cars where, with timely oil changes, the automatic transmission lasts up to 400 thousand km, and this is on a regular four-speed automatic transmission. Automatic transmissions of the four-speed older versions are considered the most reliable, especially those made in Japan.

To make the transmission work longer, you need to follow some recommendations:

- Change the oil according to plan; if you need to change it after 70 thousand, then you need to do so. If you replace it earlier, it will be even better. You also need to know that there are no unserviceable boxes.

- Along with the oil, the filter must also be changed, which will significantly increase the service life.

- It is recommended to remove the radiator from the box and clean it, then rinse it.

- Clean the bottom of the box from various contaminants and clean the magnets.

Such rules are necessary, the service life will increase significantly, and can reach 300 thousand km. Due to this reliability, many people choose an automatic transmission.

Advantages of automatic transmission:

- Easy to drive, no need to decide how to get going and what gear to engage, the automatic machine will work itself.

- Reliability. With the necessary maintenance, this type of transmission can operate for a long time compared to other types.

- Maintainability. Automatic transmissions are well mastered and can be repaired in many car repair shops.

- Type of oil. For automatic transmissions, it is necessary to fill in special oil, but the parameters of this oil are lower compared to other gearboxes and the cost is lower.

- A small number of electronic elements, automatic transmissions function together with an electronic unit, but the electronic content is no more than 30%, the remaining parts are mechanical.

- Possible jerks and transfers. Today there are already six-speed transmissions, they already have a significantly higher threshold for maximum speed, the car will not hum much in fourth gear, they have soft gear changes, barely noticeable.

Disadvantages of automatic transmission:

- It does not have the dynamics of a CVT or manual transmission.

- The efficiency is lower, which means that the automatic transmission does not have a rigid engagement of the transmission with the engine. Everything is done through a torque converter and high oil pressure. Some of the useful work is spent on this engagement.

- Jerks when changing gears, as there are gears that other types of gearboxes do not have.

- The oil volume in the transmission is larger compared to other transmissions and reaches 10 liters. The CVT has a volume of 8 liters, the manual one has about 3 liters.

- Significant fuel consumption, higher than a CVT, but due to lower efficiency.

As a result, we can say that the reliability of this mechanism covers the existing shortcomings - low efficiency, jerks when switching, increased fuel consumption, poor dynamics. But with timely oil changes, the gearbox can work for a long time.

Features of automatic transmission

There are several interesting features that will help car owners decide on the type of transmission for their car.

- The volume of special oil in an automatic transmission is larger, although not much, depending on the make of the car. This usually does not affect the cost of the car, since the cost of the original variator lubricant is usually even higher.

- Filters and oil for the CVT transmission need to be changed more often. During operation, it is necessary to ensure that the oil does not darken or lose its properties, since its quality is important for this mechanism.

- Most often, car manufacturers advise changing the oil in the CVT transmission every 60 thousand kilometers, but, according to reviews from owners of cars with a CVT transmission, it is better to do this earlier (by 50 thousand). In this case, you need to replace both the oil itself and the filters, which are cheap.

- In a car with a CVT gearbox, you should not move away abruptly. The principle of its operation is to ensure the best speed and torque so that the device operates in a gentle manner. If you want to drive fast, then this type of transmission is not suitable for you. The CVT should not be used to slip or carry trailers or other vehicles.

- For a CVT transmission, it is not recommended to drive at too low or very high speeds. Under such conditions, the belt experiences high mechanical loads, which contributes to rapid wear. Also, the oil temperature increases. You need to take care of auxiliary cooling. If you live in a city and often get stuck in traffic jams, then you should think about whether to buy a car with a CVT transmission.

- When driving a car with a CVT in severe frost, it is necessary to warm up the engine in order to reduce the viscosity of the transmission oil, otherwise the CVT belt will begin to slip, and additional wear will appear on the surface of the belt and pulleys.

- It is not advisable to purchase a used car with a CVT gearbox. There is a big risk that problems will arise with this mechanism. It is quite easy to check the condition of the box belt. You just need to drive your car on a flat road at low speed for about 1 km. If you feel jolts while driving, then it is better not to purchase this vehicle.

- It is necessary to monitor the performance of the speed sensor. If it fails, the electronic system switches the variator for emergency operation. If such a situation occurs while driving, then the engine brakes, which has a negative effect on the car.

- Changing the oil in a CVT box in advance is an important factor. If the oil does not have the necessary performance properties, then the hydraulic unit of the box will slowly clog, which means that the oil pump will not create the required level of operating pressure. Therefore, the shafts will not be able to expand or compress the belt, as a result of which it will slip and wear out quickly. In the worst case, the belt will break, damaging all the internal elements of the device.

- The transmission belt should be replaced every 150 thousand km, regardless of the condition of the mechanism.

Despite the existing shortcomings of the variator, today they have become the most advanced mechanism in the transmission. Their merits are appreciated by many drivers in different countries. If we consider the shortcomings, then manufacturing plants are constantly improving the design of CVTs; we can say for sure that over time, CVTs will displace automatic and manual transmissions from the car market.

Differences

Automatic transmission and CVT

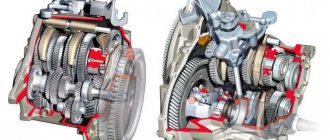

First, let's figure out what a traditional automatic transmission actually consists of and what is the main difference between a CVT and an automatic transmission. We will also provide photos and videos of these boxes and an example of how each works.

The automatic transmission design has the following elements:

- a torque converter that acts as a clutch;

- a gearbox, through the gears of which the gear ratio is changed;

- a brake band that blocks the necessary gears of the gearbox when changing gears;

- a control device that monitors the operation of all mechanisms.

In the case of a CVT transmission, it consists of a pair of pulleys, between which a V-belt is stretched. The belt changes the gear ratio between these pulleys.

As you can see, the designs are completely different and the operating principle of these boxes is completely different. For comparison, the video below shows an example of accelerating a car with a CVT.

Features of the CVT gearbox

Lastly, we will introduce you to data that will help drivers understand what nuances the CVT transmission hides.

- Driving style. If you want to drive your car dynamically, then a CVT transmission will be the best option for you. And if extreme driving is not suitable for you, then it is better to buy an automatic.

- For a CVT transmission, you should not drive for a long time at high or low speed.

- When using a variator at too low or high temperatures, special conditions must be created.

- A car with a CVT cannot be towed with the engine not running (it can be transported with the drive wheels suspended). It is also prohibited to tow other cars or trailers with the vehicle itself.

- You need to drive the car only on good roads, otherwise the transmission drive belt will break due to heavy loads.

- Change the oil and drive belt in advance.

Before purchasing a car with a CVT-based transmission, you need to be prepared for the conditions of subsequent operation. This is most relevant if you previously owned a car with a manual transmission. But over time, you will quickly get used to it and, most likely, you will be satisfied with the purchase. We must not forget to carry out timely maintenance of the transmission and follow the rules of driving a vehicle that we discussed earlier.

Which is better - automatic or variator

Considering all the information considered, it is impossible to give definite advice about which transmission is better. These two devices are significantly different from each other, and each mechanism has individual characteristics. Therefore, it is necessary to choose based on the operating conditions of the vehicle. It should also be remembered that today on the Russian automobile market there are CVTs that have not yet been fully developed. Vehicle manufacturers are constantly working to improve them, and there are all the prerequisites that one day they will occupy a high place in the market.

Here are some criteria by which you can choose a car:

- Driving style: CVT for fast driving, automatic transmission for more moderate driving.

- Technical specifications. If you need a car with smooth gear shifting, then take a CVT; if this is not important to you, but you want there to be no clutch pedal, then both transmission versions are suitable.

- Service life of the gearbox. Of course, the CVT version will work much longer if it is properly maintained, unlike an automatic transmission.

- Carrying out repairs. The CVT transmission is not yet as common as an automatic transmission, so not every car workshop can repair it, unlike an automatic transmission, which can be done for you in any workshop.

- Operating mode. Modern gearshift transmissions have different speed modes. There are three modes: economical, comfortable and sporty. In the first of them, the system automatically selects the best operating mode of the motor, trying to switch to high speed at the first opportunity. The sporty mode, compared to the economical mode, switches the motor to a lower speed, thereby ensuring that the motor has a power reserve. Comfort mode guarantees the smoothest switching operation.

- Gear shift method. New modern automatic transmission models have the option of manual gear shifting. This is a convenient feature for drivers who want to keep the car under constant control and change gears themselves. This type is usually used on those brands of cars that do not have a manual transmission from the very beginning.

It is impossible to unambiguously determine which transmission is optimal; each person chooses for himself what suits him. If you yourself cannot figure out which type of mechanism you should choose based on reliability and other factors, then it is better to turn to professionals. There are technicians at various service stations who can help you in this matter. They are well versed in all the disadvantages and advantages of different types of transmissions.

Results

Finding out whether a CVT or an automatic is more reliable, you can find arguments in favor of both types of transmissions. It is important to determine the future maintenance and operating characteristics of the vehicle. When buying used cars with these gearboxes, you should also take into account the degree of wear and maintenance of the components. It is also advisable to select more common options, which will subsequently be easier and cheaper to maintain yourself. But all other things being equal, good old time-tested automatic transmissions are more reliable than a relatively new CVT.

Interesting on the topic: