- driven gear,

2

- drive gear

Hypoid axle and differential

3D model of hypoid transmission

Rear axle with hypoid transmission of the GAZ-21 Volga car. The low position of the driveshaft allows you to reduce the height of the floor in the cabin (or the height of the “tunnel” under the driveshaft).

Hypoid transmission

(hyperboloid) - a type of helical gear transmission carried out by bevel wheels (with oblique or curved teeth) with crossing axes (usually 90°). A hypoid gear has an axial displacement between the large and small gears. This type of transmission is characterized by increased load capacity, smooth running and quiet operation. Gear ratio from 1 to 10 (within the limit: up to 60).[1]

Unlike conventional bevel gears, the initial cones of which have coinciding vertices and touch along a common generatrix, the vertices of the initial cones of hypoid wheels do not coincide, and their axes are shifted by the amount of the so-called hypoid displacement E = kEdm2, where kE is the hypoid displacement coefficient (usually kE =0.2—0.3), and dm2 is the average initial diameter of the wheel.

The teeth of hypoid wheels have a proportionally decreasing height from the outer to the inner diameter.

What it is?

At the production stage, a large number of special additives are added to the base fluid based on petroleum products. They are aimed at imparting increased extreme pressure properties. Hypoid oils are classified as GL5. They are used in transmissions of many vehicles, including modern cars that have a hypoid gear. Such products are suitable for lubricating cardan shafts, gearboxes of ordinary cars, trucks and even helicopters. It is important to understand exactly what this hypoid oil is and for what purpose it is needed. It is customary to call all lubricating fluids that are intended for use under conditions of increased mechanical loads as hypoid. That is, the lubricant is created specifically for specific operating conditions that are typical for hypoid transmissions (GP).

GPs transmit torque using the gears of a pair of gears, which are characterized by an oblique or curved shape of the teeth. Such gears are less noisy during gear operation and operate for a long time without signs of wear. But only on condition that the transmission uses special hypoid oil. Between the teeth in the GP the engagement area is limited and has a small contact patch. All efforts have a point distribution. This allows you to significantly increase the specific pressure at specific required points. This is good and bad, since the likelihood of scuffing increases, which will quickly render the gears unusable. To avoid this situation, use special extreme pressure hypoid oil. It creates a dense film at the point of contact, which helps to minimize the coefficient of friction at the points of contact.

Properties

Hypoid oil (GM) or oil for hypoid gears has a composition in which the share of sulfur is no more than 3 - 4%. This is considered both a positive and a negative thing. This sulfur content prevents seizing between metal surfaces under extreme load conditions on the assembly. But it also contributes to the oxidation of metal parts. To equalize the processes, manufacturers use oils in their composition. One of these is the Molyvan L additive. With it, 75W90 oil or 80W90 oil intended for hypoid gears receives increased protective properties under conditions of excessive loads. Because of this, a similar additive is present in almost all lubricants, including hypoid, motor and transmission lubricants. The concentration of this additive in some situations reaches 5%. Another important feature of hypoid oil is its ability to maintain optimal performance when temperatures drop to -30 degrees Celsius.

It is important to note that everything is classified into several groups using API classification. There are groups from GL1 to GL6. In the case of hypoid lubricants, they can be included in 3 groups:

Using hypoid oil, you can ensure the reliability, durability and efficiency of the transmission.

Purpose

Some time ago, manufacturers began installing hypoid drive axles on modern cars. Oil manufacturers began to create lubricants suitable for them. In the freight transport segment, a prerequisite for the emergence of GP was the use of main worm gears. They were used to create heavy-duty trucks. In the 50s of the 20th century, they began to produce oils with universal characteristics that made it possible to fill them in different cars. The standards developed in the UK and the USA were considered basic. They were used to create hypoid-type lubricants, which were distinguished by a high content of components such as chlorine, sulfur and phosphorus.

German lubricant manufacturers continued bench testing. Their goal was to obtain an oil that was as resistant to wear and corrosion as possible. But recently, automakers have stopped producing cars with leading hypoid oils, which required a universal-type GL6 lubricant. Therefore, such a liquid gradually loses its relevance. At the same time, new lubricants are emerging. Modern hypoid oil allows the gearbox to operate at high speeds. Additionally, we developed a complex additive VIR1 with sulfur and phosphorus. It is added to various types of lubricating oils. Through testing, it was possible to clearly confirm that this oil is best suited for hypoid gears.

For passenger cars that are assembled at the factory using hypoid gears, mainly all-season lubricants are provided, oriented towards moderate climates. Therefore, when choosing oil for hypoid gears, you should pay attention to the issue of the SAE indicator. GM are able to protect hypoid gears from wear and abrasive due to the fact that according to SAE 90 and higher. In terms of basic technical characteristics, such compositions are not much different from conventional gear oils. The only exception is viscosity. The most common option for use in hypoid boxes is a composition with a viscosity of 80W90. It is the most universal, suitable for most climatic regions.

In gearboxes, the gears most susceptible to wear are the gear couplings between the worm, bevel and hypoid gears. The teeth are covered with an oil film, which is subject to increased pressure and operates at high speeds and temperatures. To ensure that the lubricant does not lose its original properties and the wear process does not begin, highly effective additives must be used.

Required parameters

It is impossible to say exactly what characteristics hypoid oil should meet for gearboxes of this type. A good lubricant is one that satisfies the performance characteristics of the specific unit into which the oil is poured. Therefore, the criteria for selecting a composition must be determined by the automaker on an individual basis. After all, all cars, depending on the make, model, year of manufacture and other parameters, differ from each other. All machines have their own characteristics in the design and arrangement of mechanisms. Therefore, they need lubricants of the appropriate class. That is, the design of a hypoid transmission on one car may differ significantly from the GP transmission on another car. The following factors are considered key here:

Let us consider separately each of the manufacturers and those oils, thanks to which the brands are included in the list of the most popular hypoid formulations.

Motul

Well-known manufacturer of lubricating fluids. For hypoid gears, the company offers a composition called Gear 300. Based on the results of tests and tests, many put it in first place in the ratings. This lubricant for hypoid gears has highly effective protective properties, allowing you to protect the gearbox from scuffing. The composition was assigned a protection index of 60.1 units. The oil has a stable film that settles on the surfaces of the rubbing elements of the hypoid gearbox. This ensures a minimum coefficient of friction between transmission components. The wear parameter is 0.75 mm. The only significant drawback is considered to be a rather weak viscosity indicator at low temperatures in winter.

Castrol

Another well-known company that specializes in lubricants. Therefore, Castrol could not ignore the hypoid oil segment. Syntrans Transaxle is used for these boxes. A very popular hypoid lubricant, often found in second place in various ratings. It is characterized by excellent low-temperature fluidity, high resistance to scuffing and an affordable price. The wear coefficient here is 59.4. A current and popular solution that will require affordable financial costs to obtain a list of useful and important properties that ensure the protection of hypoid transmission.

Mobile

A well-known brand in Russia and far beyond its borders, producing a wide range of lubricating fluids and other products. In the case of hypoid oil, you might be interested in an oil called Mobilube. It has excellent characteristics in terms of viscosity and resistance to temperature changes. The composition reliably protects against thermal destructive processes and oxidation. Works well under conditions of long-term between-service operation, without losing its properties prematurely. The lubricating fluid is sold at an adequate price, having all the necessary protective properties for hypoid gears. According to API, it is included in the GL4/GL5 group.

Total

A brand that many motorists use, remaining completely satisfied with the price-quality ratio. If your car is equipped with a GP, you should pay attention to Transmission Syn FE lubricant. There is a good level of protection against scuffing, which corresponds to 58.8 units. This is a fairly good indicator, which many manufacturers strive for. With a good price and a rich set of positive qualities, car owners noticed one significant drawback for residents of cold regions. The thing is that such a lubricant has fairly low fluidity at low air temperatures. Plus, the level of protection against mechanical wear is inferior to the previous representatives of the rating.

Liqui Moly

A more expensive composition, but fully satisfying all the needs of hypoid gears. For such purposes, Liqui Moly offers Hypoid Getriebeoil. Here, even by the name of the lubricant, you can immediately determine for what tasks this lubricant is intended. The oil is characterized by good performance parameters and has excellent fluidity characteristics. Here you can be sure of maintaining the performance of the liquid, since it remains stable at temperatures down to -40 degrees Celsius. At the same time, performance characteristics are not lost. By pouring such lubricant into the GP, you will be able to extend the service life of the entire unit, protect it from corrosion and premature wear.

ZIC

A well-known Korean brand that produces a huge line of lubricants. There was also a place for hypoid gears. ZIC offers a lubricant called GF Top as a hypoid oil. Experts and experienced motorists recommend using it in cases where it is necessary to reduce the noise level of the gearbox and additionally provide reliable protection against scuffing. Tests clearly indicate that the composition tolerates an increased level of operating complexity, copes with extreme loads and can operate in a wide temperature range without losing its original characteristics.

It is impossible to speak unequivocally about the superiority of one or another lubricant. The question of choosing hypoid oil is very individual and depends on a number of parameters and planned operating conditions. The main thing that car owners should remember is the need to use specialized lubricants for hypoid gears. Filling with conventional transmission fluid can potentially lead to unpredictable consequences. Basically, such experiments end sadly, since traditional transmission oils are not designed for the loads under which hypoid gearboxes operate.

Before changing the lubricant in the gearbox, be sure to check the owner's manual for your vehicle. The manufacturer will give you useful tips and specific recommendations on the selection of all working fluids.

Many car enthusiasts, who have been using a vehicle for many years, do not particularly delve into its design, features of use and maintenance. They haven't even heard that it uses a hypoid transmission.

In order for a vehicle to move on roads, the presence of fuel in the gas tank and the desire of the driver are not enough. It is necessary to combine the interaction of the power unit, steering, and other components and mechanisms. Among them there are many that use hypoid gears.

A little about the device

This type of transmission is over 90 years old. During its development, the designers were tasked with reducing the center of mass in passenger cars.

After testing the device on cars, a number of advantages were identified, after which they decided to use it on trucks. Many people have a question about the name of this node. The word hypoid is taken from hyperboloid, which is what the device should be called.

Important! The gear teeth are made curved, the movement is carried out along a geometric figure, which is called a hyperboloid.

The shaft axes must be shifted. To determine the amount of displacement, a hypoid gear calculation is performed. It can be used in those units where the gear axes intersect. Otherwise, the unit may jam.

What is hypoid transmission?

Hypoid gear (hyperboloid, GP) is a special type of helical gears, which are bevel wheels with crossing axes. This unit was invented in 1926. Its main purpose was to lower the center of mass in passenger cars.

Today, hypoid gears are used in instrument making, cars, tractors, railway cars, dynamos of railway cars, industrial equipment, etc.

Hypoid gears, compared to other types of gears, have smaller dimensions with similar characteristics. Also, in a hypoid gear, the load acting on an individual tooth is less. This ensures long-term and reliable operation of the gears, and also allows them to transmit greater loads. Compared to bevel and cylindrical gears, hypoid gears are less noisy.

Unfortunately, hypoid gears are not without their disadvantages:

- Increased likelihood of binding due to sliding along the contact line

- Requires special gear oils

- Cost more than other types of transmissions

A little about the advantages and disadvantages

The process of operating such units has shown a number of advantages:

- The silent operation of the transmission is caused by the fact that there are not one, but several teeth in mesh.

- The strength of parts increases. This is possible because the hypoid wheels cross, rather than intersect, each other.

- The load on one tooth is significantly reduced, since several pieces are simultaneously involved in the work.

- Increases stability and smoothness.

- Increased fatigue resistance against bevel gears.

However, there are some disadvantages in such designs:

- The high cost of the “hypoid” in comparison with conical parts.

- The possibility of gear jamming cannot be ruled out.

- Improper operation and maintenance of the transmission leads to accelerated wear.

- Difficulties in making teeth.

The main hypoid gear, the diagram of which has been discussed, is used not only to drive the drive axle of a car or tractor, but also in railway transport on railcars and locomotives. It is also found in the drive of generators of passenger railway cars.

It is installed in metal-cutting machines, most often in automatic machines that cut teeth. The hypoid final drive in passenger vehicles has found its place not only due to increased strength and smoothness, but also due to the ability to position the car body low. This makes it possible to lower the vehicle's center of gravity.

What else you should know

We have described in general terms what a hypoid transmission is in a car. Let us dwell on some more aspects of its proper operation. When driving a vehicle with a hypoid final drive, one should take into account the fact that the meshing patch of the gear teeth is different when moving forward or backward. When moving forward, it will be in the middle part of the tooth, and when reverse is engaged, the stain moves back to the edge of the tooth. In addition, as the load on the gears increases, the contact patch has the opportunity to shift.

This should be taken into account, especially when reversing. This is done on purpose, since the vehicle mainly moves forward. Owners of cars, especially SUVs, which have two drive axles and two final drives, should be aware. When traveling in extreme road conditions, when there is a danger of getting stuck in a broken rut, you only need to pull out a stuck car in forward gear. In this case, an increased contact patch will work, which will avoid tooth breakage.

Typically, all SUVs have front axles that are initially weaker than rear axles. Experienced drivers recommend that owners of cars with hypoid gears follow several rules when faced with difficult operating conditions:

- If possible, use dynamic slings.

- Do not place the car at a large angle to the one being pulled out.

- Use a cable arrester when pulling out.

The main gear serves to increase torque and change its direction at right angles to the longitudinal axis of the vehicle. For this purpose, the main gear is made of bevel gears.

On the GAZ-53-12 and GAZ-24 vehicles, a hypoid single main gear is installed, consisting of a drive - a small bevel gear, made together with the shaft, and a driven - large bevel gear. To achieve silent and smooth operation, the gear teeth are spiral. The small bevel gear shaft is mounted on two bevel and one cylindrical bearings.

The large bevel gear is mounted on the differential box and, together with it, is mounted on two bevel bearings in the rear axle housing.

Hypoid transmissions have a number of advantages compared to simple ones: they have the axis of the drive wheel located below the axis of the driven wheel, which allows the cardan drive to be lowered lower and the floor of the passenger car body to be lowered. As a result, the center of gravity is reduced and the vehicle's stability is increased. In addition, the hypoid gear has a thickened base of the gear teeth, which significantly increases their load capacity and wear resistance.

But this circumstance determines the use of special oil (hypoid) for lubricating gears, designed to operate under conditions of transmitting large forces that arise in contact between gear teeth.

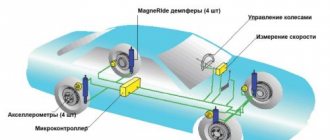

When cornering and on uneven roads when driving in a straight line, the right and left wheels travel different paths. If in these cases the wheels are forced to rotate at the same speed, then one of the driving wheels (describing the shorter path) should partially slip relative to the road. In order for the drive wheels to roll without slipping, it is necessary to have a mechanism that allows the wheels to rotate at different speeds. This mechanism is called a differential. On cars, a gear differential is used, which consists of a spider, bevel gears - satellites, side gears and a gearbox. The satellites are loosely mounted on the cylindrical fingers of the cross. The crosspiece together with the satellites are fixed in the differential box and rotate with it.

The satellites are in constant mesh with the gears of the right and left axle shafts. When the car is moving on a straight and level road, both drive wheels (right and left) encounter equal rolling resistance, while the driven gear of the final drive rotates the differential box with the spider and satellites. The satellites are in mesh with the right and left side gears, their teeth cause them to rotate at the same speed; the satellites in this case do not rotate around their axis. On turns, when the inner wheel encounters more resistance, its rotation slows down, the satellites begin to rotate around their axes, as a result of which the second wheel, which describes a long path, begins to rotate faster. Given that the drive wheels must rotate at different speeds under certain conditions, torque from the differential to the wheels must be transmitted through two separate axle shafts. Each axle shaft is connected to the differential pinions using side gears.

The semi-axial gears are mounted on the axle shaft with their slotted holes. The other end of the axle shafts is connected either by a flange to the wheel hubs (GAZ-53A and ZIL-130) or to the brake drums (GAZ-24 Volga).

The gear differential consists of:

1. Semi-axial gears.

2. Satellites.

3. Cross

4. Main gear driven gear.

5. Differential boxes.

The car uses a number of working fluids that ensure its long-term proper operation throughout its entire operation. One of these liquids is. It is intended for lubrication of gear joints found in manual transmissions, steering mechanisms, drive axles and transfer cases. The article discusses: classification according to SAE and API, and also contains a video about different types of oil classification.

Gear drives

In our country, the GOST 17479.2–85 standard is used to classify lubricants. The main criteria for separating oils are viscosity and performance characteristics. Based on viscosity, lubricants are divided into 4 classes: 9, 12, 18, 34. Based on the area of application and performance, transmission lubricants are divided into 5 groups. Lubricants included in the first group do not contain additives. The rest contain additives that protect against wear. The higher the group, the more effective the supplements are. The fifth group includes universal lubricants for transmissions.

A large number of foreign automobile products appeared on the Russian market, so they began to apply classification in accordance with international standards.

There are several international qualification systems:

[Hide]

Hypoid gear

The VAZ 2110 shifts into reverse gear with a crunch. VAZ 2112 when reverse gear is engaged, a crunching sound occurs as well as when

Such hypoid gears are not recommended. A right-handed hypoid gear increases in size as it moves above the wheel axis and decreases in size as it moves below the axis.

On some domestic trucks (GAZ-53A) and buses (PAZ-672), the single main gear has hypoid gears. A hypoid gear is a truncated hyperboloid of rotation, on the surface of which teeth are cut. Hypoid gearing differs in that the axes of the drive and driven gears do not intersect each other, but pass at a certain distance from one another, while the angle of inclination of the helical line of the teeth of the drive gear is much greater than that of the driven gear. As a result, the size of the drive gear with the same size of the driven gear (compared to other gears) increases significantly. Gears of hypoid gears have a greater thickness and working height of the teeth, and during operation the average number of teeth simultaneously in mesh is higher. This increases the service life of hypoid gears, and their operation is smoother and quieter.

All rods at the points of rotation are either equipped with silent blocks or conical rubber bushings of a special design, which are subject to axial compressive force. The main gear has hypoid gears.

The main gear has hypoid gears. The wire-spoke wheels are mounted on a central hub. Drive axle housings or semi-balanced axle shafts must be designed to withstand the dynamic loads that arise when driving on uneven roads. Experiments have shown that when a car with solid tires hits an obstacle 25 mm high at a speed of 25 km/h, a load on the wheel is created that is 7 times greater than the static pressure on the ground.

For example, Towle mentions that in England, hypoid gears were first used in 1929 for mass-produced passenger cars and only in 1934 they began to be used on other models. UK, were equipped with hypoid axles and only 41 models used bevel helical gears.

Since in hypoid gears two metal surfaces are subject to sliding and rolling, the issue of their lubrication has become even more serious than in the case of gears with an involute tooth profile. In practice, we soon became convinced that it is impossible to lubricate hypoid gears with mineral oil without an additive, especially under difficult operating conditions.

These two types of friction can occur simultaneously, for example in hypoid gears.

| Position of the contact patch. |

Assembling spur gear pairs is not particularly difficult since these matings are not adjustable. Much more labor is required to assemble the rear axle main gear with spiral bevel or hypoid gears and complete bevel gears.

Special oils (GOST 4002 - 53 and 4003 - 53) contain sulfurized components introduced to increase the strength of the oil film on the working surfaces of gears. These oils are intended for use in vehicles with heavily loaded transmission mechanisms. For main gears of vehicles with hypoid gears, the use of any other oils other than oil specially produced for hypoid gears (GOST 4003 - 53) is not allowed, as it leads to rapid wear of the gears.

| Diagrams and traction characteristics of transmissions with a manual gearbox (curves / and 2 - respectively, traction forces in 1st and 2nd gears. |

The transmission diagram is shown in Fig. 36, a. From the engine, torque is transmitted to a dry disc clutch, which rotates the gearbox gear through a drive chuck. The movable box gear unit drives the main shaft and allows the loader to move forward or reverse. When moving in both directions, rotation is transmitted to a shaft connected to the hypoid gear. The traction curve versus forklift speed is shown in the same figure. It is similar to a torque curve depending on the operating mode of the engine. In operating modes up to the point/clutch slipping does not allow increasing the speed.

SAE

Marking of transmission lubricants according to the viscosity index - SAE - has become widespread throughout the world. Developed in the United States, the SAE J306 standard classifies transmission lubricants based on viscosity when operating vehicles at extreme temperatures: low and high. Using this qualification, you can determine the temperature range in which a certain lubricant is allowed to be used for a manual transmission and drive axles.

Recommendations for the viscosity of transmission oils that can be used for manual transmissions and drive axles of a vehicle are indicated by the manufacturer in the user manual. Based on these recommendations, the car owner selects transmission fluid from among a range of lubricating fluids. When choosing a lubricant, you should take into account the lowest and highest temperatures at which the car will be operated. SAE J306 classification takes into account the viscosity index at extreme temperatures.

The low temperature viscosity limit value corresponds to the temperature at which a Brookfield dynamic viscosity of 150,000 centipoise (cP) is achieved. To determine the indicators, real tests were carried out with units of various designs. If these values were exceeded, the gear bearings on the shaft were destroyed. Therefore, it is important to follow manufacturers' recommendations for low temperature application limits.

The value of the high-temperature limit is determined by readings of the kinematic viscosity of the lubricant at a temperature of 100 degrees. This indicator helps to approximately determine how much load the protective oil film can withstand and how sufficient it will be to protect the gearbox mechanism under heavy loads and at high operating temperatures.

According to the SAE classification, lubricants are divided into 9 classes, similar to motor oils:

- 4 winter ones, the viscosity index of which contains the letter W (Winter): 70W, 75W, 80W, 85W;

- 5 year olds that do not have a letter designation: 80, 85, 90, 140, 250.

All-season oils are marked using both markings, the first is winter, the second is summer, for example, SAE 75W-85, SAE 85W-90, etc.

SAE classification table for gear lubricants by viscosity index:

| Viscosity grade | Max temperature for viscosity 150,000 cP, degrees | Kinematic viscosity at a temperature of 100 degrees, mm2/s | |

| no less | no more | ||

| Winter | |||

| 70W | -55 | 4,1 | — |

| 75W | -40 | 4,1 | — |

| 80W | -26 | 7,0 | — |

| 85W | -12 | 11,0 | — |

| Summer | |||

| 80 | — | 7,0 | 11,0 |

| 85 | — | 11,0 | 13,5 |

| 90 | — | 13,5 | 24,0 |

| 140 | — | 24,0 | 41,0 |

| 250 | — | 41,0 | — |

The use of seasonal lubricants is not economically profitable, since transmission fluids have a long service life. If you use seasonal lubricants, they have to be changed before they have exhausted their service life. Therefore, all-season ones are more popular.

API

There is no unified classification of transmission fluids by quality, performance properties and application. The American Institute API has developed a system of classifications of oils for manual transmissions, containing a comprehensive assessment of the performance qualities of lubricants. The division into categories depends on the design features of mechanical transmissions and operating conditions.

Today, the API is recognized throughout the world. According to this system, classes are designated API GL with a corresponding index from 1 to 5. At the moment, there are already five classes and several are under development. The current GOST has the same classification and differs only in the letter in front of the index.

API quality classification table for lubricants:

| API category | Additives used | Application area | terms of Use |

| GL-1 | Mineral base oil without additives or with small amounts of anti-oxidation, anti-foam, anti-corrosion additives and light depressant additives. | Cylindrical, spiral-bevel, worm gears, manual gearboxes. | Light conditions: low speeds and light loads. |

| GL-2 | Antifriction and antiwear additives. | Worm gears, industrial equipment. | Moderate conditions |

| GL-3 | High content of extreme pressure and 2.7% anti-wear additives. | Spiral bevel gears, stepped gearboxes, steering mechanisms. | Moderate conditions |

| GL-4 | Anti-wear and 4.0% high quality extreme pressure additives. | Stepped, hypoid gears at high speeds with low torques or low speeds with high torques, steering mechanisms. All types of gears for trucks and cars. | Conditions vary in severity from mild to severe. |

| GL-5 | A significant amount of up to 6.5% sulfur-phosphorus containing extreme pressure and other multifunctional additives. | The main purpose is hypoid transmissions, as well as drive axles and all types of transmissions of passenger vehicles, which operate at high speeds and shock loads on gear teeth, cardan drives and stepped transmissions of motorcycles. | Harsh conditions with shock and alternating loads. |

The table does not contain categories that are at the design stage. A new type of gear lubricant API MT-1 has been developed for highly loaded units. It is used for tractors and buses. For manual transmissions of heavy trucks, the API PG-1 category is offered, for drive axles of buses and trucks - API PG-2. They are equivalent to API GL-5 oil, but have higher thermal stability and are resistant to high temperature deposits.

Distinctive features of GL-4 and GL-5 oils

The first and most significant difference between these two liquids is their area of use. GL-4 fluid is designed for gearboxes with hypoid or bevel gears. Contact stresses in them usually do not exceed 3000 MPa, and the operating temperature of the oil does not rise above 150 degrees.

As for GL-5, this lubricant is designed for the normal operation of hypoid gears under shock loads. These mechanisms can experience stresses of more than 3000 MPa. This lubricant is used for units with limited slip differentials, as it guarantees normal protection of metal elements under high loads and temperature influences.

Among the important distinctive features of GL-4 oils is the minimum content of sulfur-phosphorus additives. They provide a durable protective film that is much harder than some soft alloys, including copper. The use of GL-5 fluid in gearboxes where, according to the manufacturer's recommendations, an oil of a lower class should be used is unacceptable. Otherwise, it will cause metal chips and wear out the mechanism.

Video “Classification of transmission fluids”

This video explains the classification of transmission lubricants.

What is hypoid oil? This question is of interest to consumers. Mixing substandard and used oils with minor modifications can be used in steering mechanisms and some types of transmission units.

When operating a car, it is very important what kind of oil is used for its gearbox.

By minor modification we mean the addition of a certain amount of additives to the petroleum product, which give the product high extreme pressure characteristics. Transmission oils of this category are classified as GL-5 and are quite suitable for use in vehicle transmission units where hypoid gears are used in drive axles. A similar product is widely used even for lubricating universal joints and gearboxes of helicopters.

Characteristics of hypoid oil

Thanks to additives, the gear shifting process is softened.

Hypoid oil has certain characteristics.

Oils for hypoid mechanisms should contain about 3-4% sulfur, which, on the one hand, prevents the metal from seizing under significant loads, and on the other hand, promotes the rapid oxidation of the same metal. To somehow equalize these processes, additives are widely used.

Thus, the special additive MOLYVAN L significantly increases the protective properties of the mixture under conditions of strong contact loads. Therefore, it is used as an anti-wear additive in gearbox lubricants (including hypoid lubricants) and motor lubricants. Its concentration in transmission lubricant can reach 5%. This category of petroleum products for gearboxes and steering is fully functional at temperatures down to -30º.

A significant incentive for the development of oils used in transmission mechanisms has been the increasing prevalence of hypoid drive axles of modern passenger cars. For freight transport, this impetus was the spread of worm final drives, which became popular in heavy-duty trucks and intercity buses. Both new products require the use of a special type of oil specifically for such mechanisms.

Since the middle of the last century, they began to develop abroad the direction of universal lubricants that can work in any vehicle. The standards of England and the USA for hypoid oils with a high content of chlorine, phosphorus and sulfur were adopted as a basis. German lubricant manufacturers have placed the main emphasis on bench testing of the product in order to obtain the most wear-resistant lubricants that do not contribute to corrosion. Recently, automakers are increasingly using hypoid drive axles, which require universal lubricant such as GL-6. Having no demand, this type is gradually leaving the market.

New modifications of oils have been created for high-speed hypoid gears of various types.

A complex sulfur- and phosphorus-containing additive VIR-1 has been created specifically for use in various types of transmission oils. Bench tests have shown the suitability of this additive for lubricants operating under conditions of increased loads and speeds, including hypoid gears.

Vehicles equipped with hypoid gears generally use an all-season lubricant designed for moderate climate conditions. Hypoid oils prevent abrasive wear of surfaces through the use of lubricants with a viscosity class of at least SAE 90. In terms of their characteristics, hypoid lubricants are not too different from ordinary transmission lubricants, the only exception being their viscosity.

The operating conditions of hypoid oil are quite different from the operating conditions of engine oils.

In a gearbox, the main wear and tear is caused by the gear coupling of bevel, worm and hypoid gears. Quite a significant temperature develops in the narrow area of contact between the gear teeth. The oil film covering the gear teeth is simultaneously exposed to extremely high pressure, high speeds and temperatures. To work in such conditions, the oil must preserve the surface of parts as much as possible from wear and prevent the surfaces of gear teeth from seizing. Such “cold welding” can lead to catastrophic consequences.

In industrial vehicles, the transmission serves to transfer power from the engine to the wheels or another engine. The only difference is in the transmitted power. The units are divided into:

- mechanical;

- hydraulic.

The design of a manual gearbox is quite traditional and is not much different from conventional mechanisms. Off-road vehicles have several drive axles that use different units for power take-off. Hypoid oil is intended for all these components.

Return to contents

Features of hypoid oils

A feature of the hypoid mechanism is the small contact patch of the gears and the limited meshing area. Therefore, torque is transmitted through a small area that experiences high loads and friction. For such operating conditions, only hypoid lubricants can be used.

Hypoid oil is capable of creating a continuous film between the rubbing surfaces of gear teeth. To prevent its extrusion, the composition has high viscosity and excellent wettability of metal mechanisms. These properties are given to the composition by special adsorbing components.

Contains special additives in amounts up to 7%, which allow the formation of a continuous mechanically stable film on rubbing surfaces. Used to lubricate cardan shafts and reduction mechanisms.