What is a dual clutch automatic transmission?

Nowadays, probably everyone knows about manual and automatic transmissions, but not everyone has heard about a dual-clutch transmission. What is it? Let's figure it out now.

The dual-clutch transmission itself is very complex in its structure and operating principle. Some call it automated manual transmission because it incorporates the best qualities of manual and automatic transmissions.

Operating principle of a dual-clutch transmission

The bottom line is that this box contains 2 clutches that control gear shifting and 2 shafts on which the gears are located. Thanks to this, switching takes less than 0.07 seconds (and in some cars it is impossible to calculate this interval at all).

To understand why changing speed in this gearbox takes such a short period of time, you need to familiarize yourself with its design. As previously mentioned, there are 2 shafts. One of these shafts is located inside the other, and each of them has gears: the first has odd gears, and the second has even and reverse gears. Also on the shafts are synchronizers that engage gears when they are changed. If we compare it with mechanics, where the first clutch is the driver’s pedal, and the second is located in a box on the shaft, here they are both located in the gearbox, and they are controlled by computers and hydraulics. Based on all this, the following is obtained: when the car is driving, for example, in first gear, the computer is already preparing the second, which is located on a different shaft.

Then, during the shift, one clutch opens and the second closes, so the energy coming from the engine, through the drive gear of the main gear, which in turn spins the drive wheels through the differential, goes to another shaft, where the next gear is already ready. Thus, the flow of energy is not interrupted, and the entire process takes place without loss of power, in a short time and without any jerks, as could be the case with a manual transmission for an inexperienced driver.

All these innovations make the dual-clutch transmission the best because it combines the smoothness of an automatic with the agility of a manual. Although it appeared in the automotive industry recently, it has already become very popular and the demand for it is only growing. But, like everything in this world, it has its own weak side, despite the fact that it is very fast, economical and comfortable. But this disadvantage lies in the complexity of its design, and as a result in the high cost of the box itself and the high cost of its repair. But despite this, the future lies with her.

vipwash.ru

Main purpose

The gearbox must constantly transmit torque from the beginning to the end of the vehicle's movement. Operation includes driving on all rough roads when there is a need for frequent changes of speed. By changing gear, the driver moves the rocker lever, which in turn sets a specific gear in motion.

The gearbox also allows the car to move in reverse. The transmission also has a clutch, which serves as the ability to disconnect the engine and wheels, and this is simply necessary, since changing gears without this device is simply impossible. Also, any gearbox has a neutral gear, it is necessary for coasting or in winter, when you need to warm up the engine, as well as when stopping at a traffic light.

There are also contract gearboxes - these are units removed from damaged cars and sold as used parts. It is the contract gearbox that is in active demand among taxi drivers.

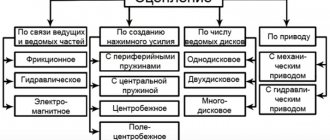

Automatic transmission clutches. What are they, how do they work and why do they burn?

The most common breakdown of an automatic transmission is wear of the friction discs, or simply friction clutches. This happens in any case, even if you take care of it and change the oil in a timely (correct) manner (although this will happen with a decent mileage of 300 - 450,000 km). If they burn out, then the car’s automatic transmission gears will not engage or slip (more on this below). Not many people know about these discs, but they are a very important element in the structure of the entire box as a whole. If I can put it roughly, this is a kind of automatic clutch; it is these elements that contribute to the inclusion of one or another gear. Personally, I searched for a very long time for a simple, clear article on these disks, but I never found it, so I decided to write this article for a general understanding...

THE CONTENT OF THE ARTICLE

Let's start with a definition.

Friction clutches (friction discs) are a clutch element between gears, similar to a manual transmission. At a programmed moment they close (using oil pressure) and stop the desired gear, at another moment they open - the gear begins to rotate.

Device

Essentially these are ordinary disks, which are divided into two components:

- Metal. They are always in engagement with the automatic transmission housing and are almost always motionless.

- Soft. Which rotate together with the sun gears. Previously, they were made from pressed cardboard, but now they are increasingly beginning to be made with graphite coating.

I would also like to note that in old automatic transmissions, the friction discs were only one-sided, that is, there were no linings on them - there was a separate metal disc and a paper one.

Nowadays, modern machines have improved discs; even the metal has graphite linings on the sides. They are impregnated with oil and effectively remove heat from the metal disk, and also help extend the service life of the soft disk.

These discs are assembled in packages, that is, one is metal, the other is soft, and so on several times. In ordinary 4-speed automatic transmissions, there can be two or three such sets, it all depends on the device.

Principle of operation

As I already noted above, this is essentially an analogue of the clutch on a manual transmission. They are installed on the so-called sun gears, each of the gears is responsible for transmission. The machine has a different operating concept; here all the work is done by the so-called planetary gearboxes, in conjunction with which the sun gears work.

There are approximately the same number of gears as there are gears, but they are not located separately, as, say, in mechanics, they are assembled into a common structure. I would also like to note that in a transmission with 6 gears, there may be two planetary mechanisms and about 4 - 5 clutch packs.

So how do they work?

If the gear is turned off, the friction discs rotate freely, there is no pressure from the pump and they are not clamped. But after the gear is engaged, the oil pump creates pressure, it passes through the valve body to a special channel and the disks are pressed against each other, thus the desired gear is activated and the rest are stopped. This is not easy to understand, especially for a beginner, so below there will be a detailed video where you can see the principle of operation.

In any case, you need to understand that these discs are a very important element in the operation of the entire automatic transmission as a whole, without them there would be no principle of an automatic transmission.

Friction disc resource

The disks themselves have a fairly long service life, even now I’m afraid to guess. They rotate not in air, but in oil (ATF fluid), so the resource is truly enormous.

My personal opinion is that this is a minimum of 350 thousand kilometers, and a maximum of 500 thousand; still, nothing lasts forever!

BUT if you don’t change the lubricant on time, or don’t change it at all, but rely on the name - a maintenance-free machine (although this is nonsense). Then they can fail after only a short mileage, and will not even last up to 100,000 km. So oil is really the deciding factor for them. Why? Read on.

Reasons for failure

There are not so many of them and they are all related to the ATF fluid in the machine. Let's list it point by point:

- Dirty oil. Most manufacturers regulate replacement of their automatic transmissions at approximately 60,000 km. However, now so-called maintenance-free machines are starting to appear, the owner relaxes and does not replace them at all! Therefore, problems appear already at 80–100,000 km. But why? A “gearbox” is a complex mechanism, as we have already figured out, a lot happens here from oil pressure, its service life is exactly 60,000 km, after which it already loses its properties by about 30 - 50%. It begins to burn, a lot of dirt and chips form in it (because the filter also becomes clogged), and in the end it cannot pass normally through the channels of the valve body and oil pump. The pressure drops, it is no longer able to compress the friction discs, and they simply begin to slip against each other - they simply burn! That's why the oil smells burnt, with this breakdown - it's from the discs.

- Insufficient level. If the fluid level for the “machine” is not sufficient, this will lead to a similar situation described in the first paragraph.

- The oil filter is clogged. If the filter is clogged, oil cannot pass through it and the pressure drops. The discs slip and they burn.

- Radiator. Due to dirty oil, it becomes clogged, the liquid can no longer circulate in it, and therefore is mainly located in the working area. At high temperatures (and they can reach up to 150 degrees), it burns, becomes thick and simply kills your machine gun.

- Water ingress. Rarely, but it happens, for example, in drowned cars from the “West”. If water gets into the oil, it very quickly destroys the soft friction linings, because they are made of pressed types of paper and are simply afraid of water.

These are the main reasons for the failure of these discs, as you can see, 4 out of 5 points are associated with the ATF fluid of the machine, or rather with its timely replacement.

Let me emphasize once again - guys, change the oil in your automatic machine - ALWAYS! AND DO IT RIGHT! Then this transmission will delight you for hundreds of thousands of kilometers.

Now we’re watching the video version, it’s more detailed.

And with that, I say goodbye, read our AUTOBLOG.

auto-blogger.ru

What is included in a car transmission and what are its types?

Depending on what type of energy is converted, this type of transmission can be:

- mechanical (converts and transmits mechanical energy);

- electrical (converts mechanical energy into electricity, and after supplying it to the drive wheels, converts electrical energy back into mechanical);

- hydrostatic (converts mechanical energy into the energy of fluid movement, and after supplying it to the drive wheels, back - the energy of fluid movement into mechanical energy);

- combined or hybrid (combination of electromechanical and hydromechanical).

The first option is most often used in modern cars. If the torque change occurs automatically, then it is called automatic.

Automatic gearbox - what is it?

Passenger cars that support the installation of automatic transmissions have become widespread in the automobile market.

Explanation of the abbreviation AKPP: Automatic Gearbox.

What is automatic transmission? This is one of the popular types of transmissions, characterized by long-lasting performance. It includes a planetary mechanism with a torque converter. This unit plays the role of a clutch. It is distinguished by its ergonomics. Automatic cars began to appear in the first half of the 20th century. The first automatic transmission, which had two stages, was seen in the late 1940s. in a Buick car.

Advantages and disadvantages

Let's look at the pros and cons of automatic transmission. The benefits are as follows:

- makes driving easier;

- installation on crossovers and sports cars is supported;

- smooth (without delays) gear switching;

- has a long service life.

Innovative developments make it possible to purchase cars that are equipped with an automatic transmission, but at the same time there is the possibility of manual gear shifting. The presence of computer control on a car with an automatic transmission contributes to fuel economy. The operating principle of automatic transmissions is similar to the functional features of manual transmissions. However, the moment of changing speeds is automatically determined by the load on the engine.

By analogy with a variator, an automatic transmission has a rather complex structure. That is why, in the event of a transmission breakdown, you should contact a professional auto repair shop for repair and restoration work, where such services are guaranteed. In addition, the cost of automatic transmission servicing is considerable. In addition to the CVT, as a type of automatic transmission, there are also robotic types.

Let's take a closer look at how the machine works.

How does an automatic transmission work?

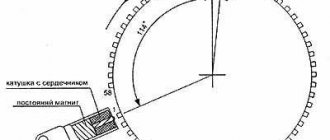

The basic operating principle of an automatic transmission should be considered. Through the installed torque converter, rotational movement occurs on the wheels of the machine. As a result, the wheels rotate uniformly. The torque converter includes the following components: pump wheel, stator, locking mechanism. Their work ensures conservation of the gearbox during acceleration, as well as during sudden increases in power plant speed. On cars where the automatic transmission can be designed at 8 stages, a high efficiency of the torque converter is noted (more than 90%).

The torque converter on any vehicle acts as a clutch. The centripetal turbine and pump present here are located close to each other. The fluid circulation that occurs during operation directly transfers energy from the power plant to the transmission system. The change in torque is provided by the stator. When the power unit starts, oil is supplied to the torque converter. When the speed is switched on and fuel is supplied, the pump wheel is activated. Incoming fuel flows gradually start the rotation of the turbine wheel. The automatic transmission is controlled by the accelerator and brake pedals. Planetary gears perform their functions effectively, competing in terms of dynamics with “mechanics” or a variator.

Let's look at the main automatic transmission modes. Vehicles equipped with an automatic transmission have the following positions on the selector: “P”, “R”, “N”, “D”, “L” (parking, reverse, neutral, driving mode, low speed). All gears shift smoothly. Additional modes include O/D (overdrive). It is important to turn it on if the entire trip on the road occurs at a constant speed.

What types of automatic transmission modes are there?

The automatic transmission type can operate in several modes. Those who like to make a measured drive choose the “economy mode”. The optimal amount of fuel is consumed for every km. With “sport” the engine works more efficiently and the car accelerates faster. If a breakdown occurs in the gearbox system, an “emergency mode” is activated, thanks to which it is possible to get to a workshop by vehicle, where they will diagnose the transmission in order to find out and eliminate the cause of the breakdown. For greater driving comfort, a “winter mode” is provided, which minimizes the risk of wheel slipping. The listed automatic transmission operating modes help optimize the trip.

Hydraulic and electronic automatic transmissions

The control system can be not only hydraulic, but also electronic. The first option is found on the basic equipment of many budget versions of cars.

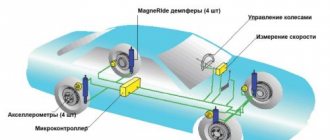

The electronic automatic transmission control system is characterized by the fact that it provides simplified gear control. When creating it, more complex schemes were used. This option has special electronic sensors that allow you to detect the rotation speed at the input/output of the gearbox, the temperature of the working fluid poured into the auto system, and the position of the gas pedal.

Measuring the oil level using a dipstick

It should be noted that not all automatic transmissions have a special dipstick that checks the oil and lubricant level. Where is the dipstick located on an automatic transmission? On car versions where this consumable is available, it can be found in the area of the power unit, closer to the radiator. This component is quite difficult to confuse with another mechanism. The probe handle has a characteristic bright color.

The arrow indicates the position of the probe

There are several notches on the surface of the part, by which you can visually determine the amount of oil present. If the oil level on the automatic transmission is below the established norm, this often indicates that there is a violation of the temperature regime of the fuel.

Automatic transmission resource and maintenance

Automatic transmission maintenance involves timely installation of the oil filter and adding new oil. These procedures can be carried out either independently or using the services of professional service centers, where the technicians know well how the automatic transmission works, as well as the structure of the automatic transmission.

Automatic transmission servicing and repairs are required ahead of schedule if the driver used low-quality oil, which caused a loss of power or slower acceleration. You need to seek help if there is an oil leak; problems with the valve body often arise.

The optimal automatic transmission temperature varies between +75°C…+90°C. Higher and lower values will shorten the service life of the automatic transmission, resulting in the need for premature automatic transmission service.

The service life of the automatic transmission is individual for each vehicle. On some versions of the car it can reach up to 150,000 km. On Japanese foreign cars, automatic transmissions with careful care can operate for more than 400,000 km.

prokpp.ru

Checkpoint structure

Typically, modern cars, as far as the gearbox is concerned, have steps. Most often this is a manual transmission. They have several gears. The gearbox includes four to five speeds, not to mention reverse.

Changing speeds is possible due to the movement of gears, they cling to each other, as a result, blocking occurs due to the forward movement of the device, which serves to synchronize the torque and the wheel. The gears can be controlled manually when a manual transmission is used, or this action occurs automatically when the automatic transmission is operating.

Old gearboxes had three- and four-speed ranges, but modern analogues can boast 8 speeds, or even higher. The calculation of the number of gears depends on the type of motor and other factors.

Let's look at what the gearbox includes, if we talk about the elements in more detail.

The first unit that makes everything come together is the body. This includes various transmission components, such as gear blocks, overrunning clutches and a reverse block. The clutch device is located next to the flywheel, which is mounted on the motor.

Given the principle of operation, the gears rub against each other a lot during operation of the gearbox, which means that they need plenty of lubrication. Therefore, the crankcase must be filled with oil to a certain level. The gearbox also has various types of devices, they are equipped with bearings, each of them is located in the crankcase, each block has several gears, the number of teeth of which is different.

The next part we will talk about is synchronizers. For any car, it is important that the gearbox is smooth, without unnecessary noise, shock, or vibration, so synchronizers equalize the operation of gears that rotate constantly.

Correct calculation of gear ratios allows the gearbox to convert engine torque and accurately distribute it to the drive axles. This technology has long been used by leading automakers.

In order to change gear in the gearbox, the driver depresses the clutch and moves the rocker lever to the desired position.

Everything is done in such a way that even with a strong desire to engage two gears at the same time, this is impossible to do. On the other hand, thanks to the rocker lock, the gears themselves cannot be switched or switched off.

Robot or automatic: which gearbox is better?

in fact, both are mechanical boxes. In a 7-speed DSG, the mechanical circuit is generally separate, and the switching unit is separate.

Manual transmission + robot driver

This is the text version of the Volkswagen Technical Site forum. Here is the full version of the forum.

Related articles:

- NEW NIVA AUTO Back in 1970, three automobile plants were supplied with an important...

- REPLACING TIMING BELTS Volkswagen Golf Club > TECHNICAL FORUMS BY MODELS > Golf Mk 5 & Plus >…

- AUTO WHEEL INFLATION SYSTEM Stroy-Tekhnika.ruConstruction machinery and equipment, directory System of centralized control of air pressure in tires Category: Equipment, body and controlsSystem…

- HOW TO REMOVE A GAS CYLINDER FROM A CAR How to remove an LPG from a car with your own hands Removing an LPG is inevitable during registration - GAZ logbook...