GDI

(

Graphics Device Interface

,

Graphical Device Interface

) is one of the three main components or "subsystems", together with the kernel and Windows API, that make up the user interface (GDI window manager) of Microsoft Windows.

GDI is a Windows interface for representing graphic objects and transferring them to display devices such as monitors and printers.

GDI is responsible for drawing lines and curves, displaying fonts, and handling palettes. It is not responsible for drawing windows, menus, etc.; this task is assigned to the user subsystem, located in user32.dll and based on GDI. GDI performs the same functions as QuickDraw on Mac OS.

One of the benefits of using GDI instead of directly accessing hardware is the unification of work across devices. Using GDI, you can use the same functions to draw on different devices, such as a screen or printer, getting almost the same images on them. This capability is at the heart of all WYSIWYG applications for Windows.

Simple games that don't require fast graphics can use GDI. However, GDI does not provide high-quality animation because it does not have the ability to synchronize with the frame buffer. GDI also does not have rasterization for rendering 3D graphics. Modern games use DirectX or OpenGL, giving programmers access to more hardware capabilities.

Short description

A software object called device context

"(Device Context, DC). A DC, like most GDI objects, encapsulates implementation details and data within itself and cannot be accessed directly.

For any drawing you need an HDC (Handle DC) object. When outputting to a printer, the HDC is obtained by calling CreateDC, and special functions are called on it to move to a new page of the printed document. When displaying on the screen, you can also use CreateDC, but this will lead to drawing on top of all windows outside their borders, so usually for drawing on the screen, calls to GetDC and BeginPaint are used, which no longer belong to GDI, but to USER, and return a context referencing the window clipping region .

Functionality:

- output by the same calls to the screen, printer, “screen in memory” (accessible to the application by pointer and the bitmap created by it in memory, it is also possible to allocate bitmaps in the memory of the video card - CreateCompatibleBitmap - and draw on them, such bitmaps are not accessible by pointer , but further redrawing from them to the physical screen occurs very quickly without loading the processor and bus, and especially quickly in the case of Remote Desktop).

- output to a metafile - storing a sequence of drawing commands in a file that can be “played” again; a vector graphics file .wmf is exactly this metafile with a small additional header at the beginning.

- text output in various fonts, including TrueType and OpenType, as well as fonts embedded in the printer (when displaying a document on the screen, the closest similar software-implemented font is used). Letters are always filled with one color (“current color”), the spaces between them either remain transparent or are filled with a different color (“current background color”). Arranging letters along a curve is not supported.

- a rich set of operations with bitmaps (bitmaps), including scaling, automatic conversion from typical formats to the current screen format without effort on the part of the programmer (StretchDIBits), drawing on bitmaps of several typical formats residing in memory, and a huge number of logical color combination operations 2 bitmaps - already existing on the destination device and drawn again.

- a rich set of vector graphics operations (about the same as in PostScript, but a different type of curves is used). The drawn line has attributes - thickness, dash pattern and color (collected together in the so-called PEN object) and a way to smooth the corners of polygons. The fill can be a single color, one of your choice of hatches, or an 8 by 8 bitmap (these attributes are collected in a “BRUSH object”). Windows NT also introduced Bezier curves.

- all colors in calls are always in RGB, regardless of the color system of the current device. The exception is individual pixels inside bitmaps, which can also be in the form defined by the device.

- support for clipping regions and all basic logical operations on them. The coordinates in them are 16-bit integers (which limited the screen size of Windows, even fairly recent versions, to 32K pixels).

- support for rotation/stretch matrix - World Transform, not supported for clipping regions, only for vector graphics.

Guys, who has any problems with automatic transmission, ask for advice, I will help. Guys, please tell me. I have a demon 3.0 gdi 1998, the check flashes and the rev is above 2000, there is no gas, error 93, what to do Mitsubishi Cedia CS2A 4G15 break in the secondary speed sensor, the car does not go, I turn on the automatic, as if the load has turned on, but the car does not go, the netralka is blinking, what to do Nikolay can you tell me, rv 1993 4g63 gearbox slips when cold, heats up - everything is fine, oil has been changed Nikolay can you tell me, RVR 1993 4g63 gearbox slips when cold, heats up - everything is fine, oil changed I think your solenoids are clogged. Computer diagnostics should show. But in general there are many reasons why the pump does not produce enough pressure. Start with diagnostics. If she shows everything is fine. Then you can’t do without an autopsy. What are solenoids, I just don’t know this abbreviation. But the diagnostics showed error 51. If it’s not difficult, tell me how to overcome error 51? Tomorrow I’ll try to find out your error code. Why don’t you want to take it to the specialists for repairs? Thanks, I already fixed everything myself. I can’t start the demo 3 liter Gdi Mitsubishi Diamond 1997 GDI 3 liter the coil on cylinder 1 gets very hot, I tried replacing it, it doesn’t help, what should I do and how to fix it? Tell me if anyone has encountered this Hello, I have a Mitsubishi space wagon 4×4 2.4 GDI produced in 1998, I started it in the cold, it ran for 10 seconds and stalled, after that the current stopped flowing to the second and third cylinders, what could be the reason, please tell me hello everyone. can anyone help with a hint? I have a Karisma 1.8 GDI manual transmission and the problem seems to be in the fuel pump?! since earlier I tried to repair it and changed my anchor to a 1.6 carisma. Now fuel consumption has increased...Full text: it doesn’t pull at more than 3000 rpm, but at 1000 rpm it starts to jerk! help, is the problem in the fuel pump? Is it possible to put a decimal? Hello, what is a decimal? Hello, what is a decimal? Hello! Mitsubishi space car 98g GDI 2.4l. Manual transmission. Such a problem, on a cold start it is normal, when it warms up after starting it goes off, it can stall while idling. Sometimes after starting the needle rises to 1500...Full text, check the air filter. Does anyone have the letter according to Galant '98? 1.8 GDII will sell a high pressure fuel pump (HPF) PETROL for a Mitsubishi Pajero Pinin 2001, engine capacity 2.0, GDI 3rd generation. In working condition. Selling a high pressure fuel pump (HPF) PETROL for a Mitsubishi Pajero Pinin 2001, engine capacity 2.0, GDI 3rd generation. In working order. +79817923649 St. Petersburg https://www.mitsubishidriver.ru/storage/719.jpg https://www.mits ...Full textSelling a high pressure fuel pump (HPF) PETROL for a Mitsubishi Pajero Pinin 2001, engine size 2 ,0,GDI 3rd generation. In working order. +79817923649 St. Petersburg The engine of a Mitsubishi pajero 3.5, GDI, 1999 stalls at low speeds. release. When the engine is cold, there are no problems, the problem arises when it reaches “condition”. Please help with advice, thanks in advance.pri malix oborotax gloxnet dvijok mashini Mitsubishi pajero 3.5, GDI, 1999. vipuska I have a Mitsubishi space car 1999 volume 2.4 gdi, manual transmission, when the gear is engaged, the engine stalls, tell me what's wrong? Hello everyone! I have a Carisma GDI 1999. The problem is the following: when starting the engine, the car itself picks up high speed for a couple of minutes both in summer and winter. Who can tell me why? An idle stepper motor costs about 220 bucks to wait a month from the emirates. Hello!! I have a Galant GDI 1.8 WHEN STARTING, the same thing happens, the revolutions are up to 3000, then after 20 seconds it drops to 1500. My wife’s Mitsubishi Karisma GDI 1998, 1.8 is all brainwashed, help who knows about this car, the revs fluctuate, it stalls at traffic lights, it won't idle, the engine knocks, it drinks gasoline instead of sniffing it, the oil is the same, the antifreeze is the same...Full text My wife's Mitsubishi Karizma GDI 1998, 1.8 is all brains gone, help who knows about this car, the revs fluctuate, it stalls at traffic lights, it doesn’t idle, the engine knocks, it drinks gasoline instead of sniffing it, the oil is the same, the antifreeze is the same...Full text My wife’s Mitsubishi Karizma GDI 1998, 1.8 is all brains, help who knows about this the car, the revs fluctuate, it stalls at traffic lights, it won’t idle, the engine knocks, it drinks gasoline instead of sniffing it, the oil is the same, the antifreeze is the same...Full textHello, I have a Mitsubishi Galant 1998. with a volume of 1.8 GDI. The problem is this! During a quiet ride and in small stretches up to a speed of 100, some kind of vibration appears, tell me how to solve this problem, maybe you have a meeting ...Full text gas breakthrough under the cylinder head due to damage (breakdown) of the gasket between adjacent cylinders (from personal experience). Check compression carefully with the throttle valve closed and open. Good luck to you! the GDI 1.8 150L belt is broken, are the valves bent? is the GDI 1.8 150L belt broken, are the valves bent? extremities, body EC3W. While flying low, I hit a piece of asphalt and broke the automatic transmission. I would like to know the model range from where I could get a donor automatic transmission W5A42-2-D6B I will sell a manual transmission for a Karisma 1.8 GDI 23000 rubles tel 89269121702 ask Evgeniy Hello everyone! I have a Galant 97 right-hand drive GDI. At the traffic lights in position D, the revolutions drop to 400, and sometimes The car stalls. I changed the fuel pump, changed the spark plugs too. Help me figure out the reason. Thank you in advance. They said I need to clean the nags...Full text I had the same problem on my Galanta. It turned out that there is an idle speed adjustment bolt on the intake manifold. only for precise adjustment you will need to connect a scanner, ideally you need to achieve the sensor step...Full textArtem, thank you very much! I'll try. Hello Georgy! One of my friends had the same case on an RVR GDI, when he cleaned the coke in the block after the air cleaner, and there was a lot of dirt there, everything went away. True, special equipment is needed for cleaning, I don’t remember what, but I think ma ...Full text

| All tags » | gdi | 1

"Further … … … … … … … … … …

Nikolai |

Almas |

| Sergey Fadeev |

| Yuri |

| Yuri |

Nikolai |

| Vladislav |

| pilgrim |

| Nikolai |

| Vladislav |

Andrey |

Ildar |

Victor Ovcharenko |

carizma1.8 GDI 4g93 |

carizma1.8 GDI 4g93 |

| Timur |

| Timur |

| Alexei |

Igor |

| Oleg Vladimirovich |

Paul |

Paul |

| Paul |

| Andranik |

Andranik |

[email protected] |

Alex |

French |

| Oleg |

| Aset |

Aset |

Aset |

Taalaibek |

Valentine |

| Vladimir |

Vladimir |

Anton |

Andrey |

Novel |

Georgy Pak |

Artem12345 |

| Georgy Pak |

| Oleg |

|

Implementation

In Windows 9x and earlier, it is implemented in a 16-bit GDI.DLL, which, in turn, loads the video card driver implemented as a DLL. The video card driver was originally required to implement all drawing, including drawing through bitmaps in memory in the screen format. Later, DIBENG.DLL appeared, which implemented drawing on bitmaps of typical formats; the driver was obliged to pass all calls into it, except for those for which it used the hardware accelerator of the video card.

The printer driver was loaded in the same way and had the same interface “from above”, but “from below”, instead of drawing in memory/hardware, it generated sequences of printer commands and sent them to the Job object. These commands were typically either binary and non-human readable or PostScript.

In Windows NT, GDI was completely rewritten from scratch, and in C++ (according to rumors, Microsoft did not have a compiler for this language at that time and they used cfront). The API for applications has not changed (except for the addition of Bezier curves), for drivers - wrappers in the C language around internals implemented in C++ (like BRUSHOBJ_pvGetRbrush).

GDI itself was first located in WINSRV.DLL in the CSRSS.EXE process, starting with NT4 - in win32k.sys. The drivers were loaded there too. DIBENG.DLL was rewritten and moved there, as well as a set of EngXxx calls - EngTextOut and others. The driver-GDI-DIBENG interaction logic remains approximately the same.

GDI32.DLL in user mode is implemented as a set of special system calls leading to win32k.sys (before NT4 - as a wrapper around the CsrClientCallServer call that sent a message to CSRSS.EXE).

Windows Vista introduced the WDDM driver model, which removed the ability to use 2D graphics hardware. When using WDDM, all GDI applications (that is, all the usual system parts of the Windows UI - window headers and frames, desktop, taskbar, etc.) use the GDI driver cdd.dll (Canonical Display Driver)[1], which draws on some bitmaps in memory, unique for each window (the contents of the window began to be remembered in memory, before Windows had never done this and always redrawn windows anew, except for some special windows with the CS_SAVEBITS flag). The images from cdd.dll are retrieved by the dwm.exe (Desktop Window Manager) process, which is a Direct3D application that renders “window pictures” on the physical screen via Direct3D.

The WDDM driver itself only supports DirectDraw and Direct3D and has nothing to do with GDI or win32k.sys, being interfaced with the dxgkrnl.sys module in the kernel.

Criticism

The Windows printing subsystem is extremely criticized, especially when compared with CUPS.

Reasons: the binary format of the print job stream (in CUPS this is PostScript) and the implementation of processing this stream in the form of several DLLs within a single SPOOLSV.EXE process (CUPS instead uses a regular pipeline of several processes like pstoraster | rastertoepson | parallel, which can be launched if desired from a regular UNIX shell). Thus, CUPS supports the development of print job filters (for example, for paid printers in hotels) even in scripting languages like Perl.

However, here we are talking more about the components below GDI.

However, CUPS has serious problems supporting WinPrinters like all the cheap Hewlett-Packard laser printers. Since they do not support the common PCL format, they require installation of huge packages that are complex to configure and build, such as HP OfficeJet (the “hpoj” port in FreeBSD). At the same time, CUPS perfectly supports inkjet printers, expensive Hewlett-Packard laser printers and PostScript printers.

GDI+

| Windows component |

| Microsoft Windows GDI+ |

| Component type | Microsoft Windows software and component[d] |

| Included in | Windows XP Windows Server 2003 Windows Vista Starter |

| Replaced | Microsoft Windows GDI |

| Has been replaced | Desktop Window Manager |

With the release of Windows XP, a descendant subsystem appeared, GDI+, based on C++[2]. The GDI+ subsystem is available as a flat set of 600 functions implemented in gdiplus.dll. These functions are “wrapped” in 40 C++ classes. Microsoft does not plan to provide support for code that accesses the flat set directly rather than through C++ classes and methods. The .NET Framework offers a set of alternative C++ wrapper classes under the System.Drawing namespace.

GDI+ is an improved environment for 2D graphics, which adds features such as antialiasing, the use of floating point coordinates, gradient fill, the ability to work internally with graphic formats such as JPEG and PNG, a much better implementation of clipping regions with the ability to use floating point coordinates in them (rather than 16-bit integers) and apply World Transform to them, transform two-dimensional matrices, etc. GDI+ uses ARGB colors. These features are used in the Windows XP user interface, and their presence in the underlying graphics layer makes it easier to use vector graphics systems such as Flash or SVG.

GDI+ dynamic libraries can be distributed with applications for use on previous versions of Windows.

GDI+ is similar to Apple's Quartz 2D subsystem and the open source libraries libart and Cairo.

GDI+ is nothing more than a set of wrappers over regular GDI. In Windows 7, a new Direct2D API has appeared, which is approximately the same, but is implemented “from top to bottom” right down to the video card driver (more precisely, it uses some Direct3D capabilities in this driver), and can use hardware acceleration - that is, a three-dimensional graphics video processor to draw some two-dimensional objects (antialiasing, etc.)

Vulnerabilities

On September 14, 2004, a vulnerability was discovered in GDI+ and other graphics APIs due to an error in the JPEG library code. This bug allowed arbitrary code to be executed on any Windows system. A patch to correct the vulnerability was released on October 12, 2004[3].

Mitsubishi GDi direct injection

Mitsubishi is the world leader in gasoline direct injection technology.

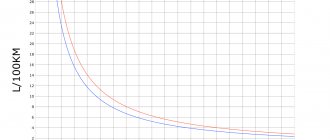

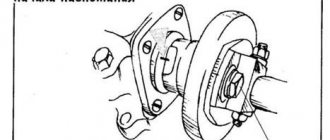

The concern produces GDi engines ranging from 1.5L to 4.5L V8 for most of its models. According to Mitsubishi, direct injection engines consume 20% to 30% less fuel and 20% less harmful CO2 emissions, while being 10% more powerful than traditional engines. The company developed the first low-emission engine, the MCA-Jet, in 1977. In 1982, its improved modification MD appeared. This was the first modulated engine. The Cyclone engine series, which appeared in 1986, was distinguished by increased fuel economy. The main problem of the engineers of the Japanese company in the 90s was the issue of global warming and saving natural resources, as well as the problem of air quality. Therefore, work began on an engine that could run on lean fuel. The goal was to increase environmental friendliness and fuel economy without affecting engine power. So in 1992 the MVV (Mitsubishi Vertical Vortex) engine appeared. It was made using Lean Burn technology, and could achieve a lean mixture of up to 25 parts air to 1 part fuel, while traditional engines operated at a ratio of 14.7 to 1. As a result, fuel economy of 13% was guaranteed when driving at a speed of 40 km/h. This meant less CO2 emissions, which are the biggest contributor to global warming. The MVV engine had a dual intake port to vertically feed air into the engine. As a result, air spread in several layers in the combustion chamber down to the lowest point of the two valves without mixing, and back up to the valves. The design of the combustion chamber was made in such a way that air mixes with small particles of fuel in the process of air turbulence in layers. This gave the effect of more power and more stable combustion. These engines were installed on some Minica (Towny) and Libero (Dancer Station Wagon) in Japan. In 1993, a new engine appeared with the MIVEC (Mitsubishi Innovative Valve timing and lift Electronic Control) system. MIVEC technology made it possible to save fuel already at a speed of 16 km/h in the urban cycle. Depending on the type of movement, the MIVEC system switched the operating mode of the engines from low load to high load and modulation mode (MD). The modified shape of the camshaft and rockers made it possible to select the most efficient engine operating mode in the first two modes. In MD mode, the engine only fired two of its four cylinders to save energy needed to deliver fuel. The energy consumption associated with the frictional force inside the engine has also been reduced. The MIVEC engines used the same air supply technology as the MVV. Engines were supplied for Lancer, Mirage, Colt, FTO. The introduction of the first engine with GDI technology in 1995 was a revolution in the world of engines, since for the first time fuel savings were actually combined with the reduction of harmful emissions into the atmosphere. It was first installed on the 8th generation Galant/Legnum for the Japanese domestic market. Subsequently, this engine was installed on two types of models in Europe and on almost all models in the domestic Japanese market. The new engine had two major innovations: 1. Because fuel is injected at high pressure directly into the combustion chamber a fraction of a second before the piston rises to its top position and ignition occurs, it is possible to precisely control the composition of the mixture and make it as lean as possible. 2. Direct injection is also carried out using a throttle body, so the power loss associated with the passage of air through the valve in a traditional engine became clear. In traditional engines, even with multipoint injection, fuel is atomized in the intake manifold, which is located near the intake valves, before entering the combustion chamber. The reason for this approach is that it is impossible to spray the fuel equally uniformly. If you inject fuel directly into the combustion chamber, the air mixture will be the same all the time. Air is supplied from above to the upper platform of the piston, which has a special shape. After air is supplied, it begins to swirl back and at this moment fuel is injected into the combustion chamber, which dissolves in the air. Another innovation is the fuel injector. It supplies fuel under high pressure. In the intake cycle, a portion of the fuel is pre-injected into the cylinder to cool it, which improves combustion efficiency and ensures a smooth mixture. As soon as the piston reaches almost the top of the cylinder, a second injection follows immediately after the pilot. Since the top of the cylinder is grooved, more fuel is concentrated around the spark plug and ignition occurs without detonation even if the mixture is very lean. Therefore, at light loads the air to fuel ratio can be 40 to 1, which is superior to LEAN BURN engines. More complete combustion is achieved. Mitsubishi gasoline engines achieve a particularly high pressure of 12.5:1. The result is high engine power. Detonation is prevented because the heated air is cooled by a new stream of fuel. Thus, appearing on the market in 1996, the new Legnum with 4G93 and good unleaded petrol reached a power of 110kW at 6500rpm and 178Nm at 5000rpm. Legnum was followed in 1997 by Carisma, which also used the 4G93. Legnum/Galant engine power has dropped to 103kW, the same as in the RVR for all-wheel drive and front-wheel drive. In 1998, GDi appeared on the Pajero iO and the 4G93 engine produced only 93kW at 5500rpm and 181Nm at 3500rpm. In the same year, the GDI Aspire, which replaced the Carisma, also only had a power of 103kW. And the power of the Legnum/Galant engine dropped to 99 kW. Finally, in 2000, the turbocharged Pajero iO appeared. It also had a high static compression of 10:1, was equipped with a turbine, an intercooler and could develop a maximum power of 118 kW. Unlike a non-turbocharged engine, the recirculated gases are directed to the turbine. This causes the turbine to spin faster when the throttle is closed and reduces the reaction time when the gas pedal is pressed and the throttle is opened, as if softening the acceleration moment. Many turbocharged engines at the time suffered from slow turbo response due to turbo lag at low speeds when there is little air flow. In a GDi engine, the recirculated gas flow through the turbine is twice that of a conventional engine. Therefore, by the time the throttle opens, the turbine is in a spin-up state and its response is faster. Because the compression in Gdi is higher, the turbocharged engine can operate at lower idle speeds and at moderate loads. At top revs, the turbocharged GDI delivers the same power as the regular GDI, but saves fuel. Also in 2000, the 4G93 GDI was fitted to the Lancer/Cedia with only 96kW of power. For the domestic market, the 4G63 engine appeared for the Dingo model. It had a lower compression of 11.6:1 and a power of 99kW. In 2001, GDI power increased to 121kW on the Lancer/Cedia. The same modification was used on Dion already in 2002. Mitsubishi modernized the engine, making the piston stroke longer and deepening the grooves on the pistons. A new modification of the 4G94 engine has appeared with two camshafts, a power of 107 kW at 5700 rpm and a compression of 11:1. The engine was installed on the Aspire, Legnum, Galant, Dion models (99-100 kW). Specification of GDI engines 4G93 and 4G94:

| engine's type | 1.8L GDI Turbo(4G93) | 2.0L GDI (4G94) | 1.8L GDI (without 4G93 turbine) |

| Volume(ml) | 1834 | 1999 | 1834 |

| Piston Diameter x Stroke (mm) | 81 x 89 | 81.5 x 95.8 | 81 x 89 |

| Compression | 10.0 | 11.0 | 12.0 |

| valves | DOHC 16 | DOHC 16 | DOHC 16 |

| Intake control | Electronic | Electronic | Electronic |

| Turbocharging | Turbine with intercooler | No | No |

| Petrol | Unleaded Premium | Unleaded Premium | Unleaded Premium |

| Maximum power kW/rev | 118 / 5200 | 100 / 5500 | 96 / 5500 |

| Maximum speed Nm/rev | 220 / 3500 | 191 / 3500 | 181 / 3500 |

Simultaneously with 4-cylinder engines, Mitsibishi began production of 6-cylinder engines of the 6G family. The first 3-liter 6G72 was supplied to Diamante in 1997 and had a compression of 10 to 1, power of 176 kW at 5750 rpm on 98 gasoline. In 1999 it was offered with the Chariot Grandis, but the compression was already 10.5 to 1 and the power was reduced to 158KW. Since 1999, a 2.5-liter version with model number 6G73 appeared on the Diamante. Despite the smaller volume, the power remained quite high - 147 kW at 6000 rpm. The largest GDI at that time was released specifically for the Challenger and Pajero models in 1997 and had a volume of 3.5 liters with four camshafts - 4G74 and an impressive power of 180 kW at 5500 rpm. Interestingly, versions of this engine after 1999 had a power of only 162 kW! The 8A80 is the only V8 engine with a displacement of 4.5 liters and two camshafts on each cylinder head. Available since 1999 on Produia and Dignity models. The engine has a compression ratio of 10.7:1, a power of 206 kW at 2000 rpm and was developed in collaboration with the Korean Hyundai Motor. One of the disadvantages of GDI engines is the high level of NOx. In order not to exceed the permissible emission level, a special catalyst had to be produced. However, Mitsubishi GDI engines were unable to overcome the ultra-high standards of American standards, since American gasoline is rich in sulfur, and its combustion products damage the catalyst. In the early 2000s, an English magazine tested the GDI engine from the Mitsubishi Carisma and concluded that the efficiency of traditional engines was equal to that of the GDI, despite the Japanese manufacturer's loud claims. The reason is also that gasoline in Europe is enriched with sulfur (150ppm in Europe compared to 10-15ppm in Japan, and even more in the USA). Therefore, in European versions of GDI, the Japanese were forced to tune the engine to operate with a richer mixture than in Japan. While in Japan the mixture ratio could be 40 to 1, in Europe only 20 to 1 was recorded, which is not far from the traditional ratio of 14 to 1. Thus, using a GDI engine on European gasoline is inefficient. Another problem with GDI is the different testing methods used in Europe and Japan. Tests in Japan are carried out to a light driving standard. Tests in Europe are carried out at high engine loads and at high speeds. Therefore, the test results are different. List of models: 1.5 l. 4 cylinders 4G15: Mirage Dingo, Lancer Cedia 1.8 l. 4 cylinders 4G93: Gallant, Legnum, Aspire, RVR, Pajero IO, Lancer Cedia 2.0 l. 4 cylinders 4G94: Dion 2.4 l. 4 cylinders 4G64: Chariot, Grandis, RVR, gallant, Legnum 2.5 l. 4 cylinders 6G73: Diamante 3.0 l. V6 6G72: Diamante 3.5 l. V6 6G74: Pajero, Challenger 3.8 l. V6 6G75: Pajero 4.5 l. V6 8A80: Pajero, Challenger, Proudia