Front suspension Ford Focus 2

- 14991 views

The front suspension is independent, MacPherson strut type, with telescopic shock absorbers, coil springs, lower wishbones and anti-roll bar.

The main element of the front suspension is a telescopic shock absorber strut, which combines the functions of a telescopic element of the guide mechanism and a damping element for vertical vibrations of the wheel relative to the body. The shock absorber strut contains a coiled coil spring 8, an upper support 9 assembled with a bearing and a compression buffer, through which the load is transmitted to the car body.

The shock absorber strut is connected to the lower suspension arm 4 by a ball joint 13. The lower arms are attached to the front suspension cross member using silent blocks 14 and rubber bushings 3 of the rear support. The cross member, in turn, is attached to the side members of the body.

The anti-roll bar with rubber bushings installed on it is connected to the cross member 15 of the front suspension of the car by two brackets 2, and to the front suspension strut by stabilizer struts 5.

The hubs of the 12 front wheels are mounted on double-row angular contact ball bearings.

List of works during maintenance 5 (mileage 100 thousand km.)

- Repeat maintenance 1 - change the oil, oil filter, cabin filter and air filter.

- Replacing the coolant.

It is recommended to pour Ford Super Plus Premium antifreeze (red), its catalog number (1 l.) is 1336797, and the price is approx. 300 rubles.This is a concentrate that is diluted with water in a 1:1 ratio. Total filling volume (including the heating radiator up to the MAX mark):

- for engine 1.4 - 5.5 liters;

for the 1.6 Duratec engine - 5.8 liters;

- for the 1.6 Duratec Ti-VCT engine - 6.0 l.;

- for the 1.8 Duratec-HE engine - 6.5 liters;

- for 2.0 Duratec-HE - 6.3 l.

- Changing transmission oil.

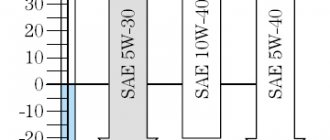

For manual transmission you need Ford WSD-M2C 200-C oil; its catalog number is 1790199, and the price is approx. 1370 rubles for 1 l. You can also use heavy-duty gear oil with a viscosity of SAE 75W90. The volume of transmission oil for manual transmission iB5 is 2.3 l, MTX-75 is 1.9 l, MMT6 is 1.75 l, MM-66 is 2.0 l.For automatic transmission type AT 4F27E, oil specification WSS-M2C 202-B is required; its catalog number is 1565889, and the cost is approximately 900 rubles per 1 liter. The total volume of the system is 6.7 liters. For automatic transmission type AT CTF23, oil specification WSS-M2C 928-A is required; its catalog number is 1256871, and the cost is approximately 1250 rubles per 1 liter. The total volume of the system is 8.9 liters.

Ford Focus 2 front suspension repair: let's look into it in detail

The suspension of the Ford Focus 2 is quite reliable, as evidenced by the technical characteristics of the Ford Focus 2. It has a long service life, but if you repair the Ford Focus 2 suspension, then some problems often arise. It is not easy to fix breakdowns yourself. In view of this, if you choose this model, you will have to immediately look for a good service station.

The average cost of major repairs to the front suspension of a Ford Focus 2 is 13 thousand rubles. Repairing the rear suspension of a Ford Focus 2 will cost 23 thousand rubles.

What is the reason for such a noticeable difference in price?

The thing is that the design of the front suspension of the Ford Focus 2 is quite common and simple. It consists of a shock-absorbing strut with a spring, a lever equipped with a ball end, a stabilizer link and a steering end. This is the well-known McPherson type. By the way, the Ford Focus 2 fuel filter is located not far there, just under the hood.

With the rear suspension of the Ford Focus 2, the situation is much more complicated. It is multi-link-spring (on each side there is 1 longitudinal and 3 transverse levers), independent. Among other things, the suspension is equipped with a stabilizer bar and telescopic shock absorbers.

Step-by-step process for replacing spark plugs on a Ford Focus 2

You will need new consumables, simple tools and rags.

- We stop the engine, wait until the unit cools down, and disconnect the battery terminal.

- Remove the protective plastic visor of the cylinder block on 3 hinges.

- On each of the 4 coils, unscrew and remove the fastening bolt 8 (the high-voltage wires do not need to be disconnected), and remove the coil itself from the well after first releasing the latch.

- Using a 16 mm socket wrench with a magnet or an elastic band to hold it counterclockwise, unscrew it and take out the candle recessed in the well, for which you first need to tear it out of place, because it usually sticks to the engine housing during operation.

- This point cannot be missed, it is extremely relevant! We check the spark plug gap between the central electrodes and the housing. Its indicator should not exceed 1.1 on the probe.

- We insert, lower the new spark plug and screw it into the threaded hole using a wrench. If there are no sealing rings on the spark plug, you should not clamp it too hard - the thread breaks off quite easily.

- Carefully place the coil with the bromine wire onto the spark plug.

- We perform a similar operation with the remaining 3 candles. An obligatory nuance is not to confuse the supply wires between them, although they are numbered.

- We put on the terminal.

The peculiarity of this event is that, unlike 8-valve engines, here the spark plugs are recessed deeper and a wrench with a longer working body is required. A pin-shaped bit or modern locksmith construction with a ratchet mechanism is used as a handle.

Ford Focus front suspension repair

The 2nd generation Ford Focus is equipped with an independent MacPherson strut suspension. The design includes a subframe, steering knuckle, hub, arm with ball joint, silent blocks, stabilizer bar and shock absorber strut. The service life of the front suspension elements is 100,000 kilometers. The exception is the wheel bearing - it must be replaced every 50,000 miles. When replacing this part, it is worth considering that on 1st and 3rd generation cars the bearing and hub cannot be disassembled, and the faulty unit is replaced entirely.

Since domestic roads are far from ideal, the planned service life of the suspension should be divided in two. This way you can estimate more realistic numbers. As a result, it turns out that the suspension repair of the 2nd generation Ford Focus needs to be done every 20,000 kilometers. As for fault diagnosis, the principle “the more often the better” applies here. If you fall into a hole at high speed, it is recommended to check the condition of the suspension as soon as possible, since in case of serious impacts it may be necessary to replace some consumables.

Most often, Ford Focus owners are concerned about the noise effect, which is classified as knocking while driving on an uneven surface. If you hear this knock, this is the first signal that something in the suspension is faulty and a wheel suspension diagnosis is required.

How to determine the condition of the Ford Focus 2 suspension?

It is best to check on an overpass or pit, lifting each wheel in turn. It is recommended to carry out this action every 20 thousand km. mileage or after the car received a strong blow while driving through a deep hole.

First you need to start with the wheels

- unscrew it with your hands. The rotation of the wheel should be uniform, without any extraneous sounds or jamming.

- grab the wheel from below and from above, the upper part must be pulled towards you, and the lower part in the other direction. Repeat the procedure, but in reverse.

When you do this, there should be no knocking or play. In a situation where there is play, you should ask your partner to press the brake and check the play again.

Now there is no play? This indicates that the wheel bearing has failed. Is there any backlash left? This means the reason is in another suspension part. The next thing we check in this case is the ball joints.

Checking ball joints

Insert a strong screwdriver between the steering knuckle and the suspension arm and press it out. Is there any play? So it's time to change the support. If the cover is cracked, it must be replaced.

Silent blocks of levers of the rear and front suspension of Ford Focus 2

Move the arm eye using a screwdriver inserted between the subframe and it. If it moves easily enough, the silent block needs to be replaced.

The rubber bushing of the silent block should not bulge, and there should also be no cracks.

Ball joints at the anti-roll bar struts

Move them with your hand. The appearance of play indicates that it is time to replace the stabilizer struts.

Inspect the protective covers of the stabilizer ball struts. Covers must be elastic and free of rips and cracks.

Telescopic front suspension struts, shock absorbers, rear suspension springs Ford Focus 2

If oil leaks from the shock absorber, it is faulty.

The telescopic stand requires replacement if the rubber element at the top support shrinks or breaks.

The springs must be intact. The shock absorber compression buffer, rubber bushings and cushions must be free of tears and cracks and without any deformation.

And then a video about repairing the Ford Focus 2 suspension:

You can also read on this topic:

Alex S February 21st, 2014

Published in: German cars, Russian cars

German cars, Tips for motorists

Repair schemes for the two most common problems with the front suspension of Ford Focus 2

Front wheel bearing replacement diagram

It is advisable to replace both bearings at the same time.

- Jack up the car, unscrew the hub bolt, unscrew and remove the wheel.

- To avoid damage, we release the stabilizer bar link.

- Disconnect the ABS (anti-lock braking system) sensor terminal.

- Release the tie rod end.

- Remove the brake caliper. We do not disconnect the brake system hose. We secure the brake caliper in such a way as not to damage the hose. We knock down the brake disc.

- We unscrew the ball fastening nut and press it out using a puller or knock the pin out of the lever with a hammer. Please note that under no circumstances should you hit the ball, we hit the bottom of the steering knuckle.

- Unscrew the bolt connecting the shock absorber and steering knuckle. Using a chisel and hammer, loosen the terminal connection and release the shock absorber strut.

- We remove the steering knuckle by pulling out the constant velocity joint of the front wheel drive from the hub.

- The ABS sensor can be pulled out if you are afraid of damaging it. The bearing is equipped with a red seal. When replacing a bearing, buy the same one. The fact is that the wheel rotation sensor ring is combined with a bearing, and if there is a bearing without this red seal, the ABS will not work.

- Using a puller, press out the hub together with the bearing and press in a new one.

- We collect everything and go to do the wheel alignment.

Replacing the front lever Ford Focus 2

It is advisable to replace the entire front control arms on a Ford Focus if they have been damaged or are already quite worn out (they have exhausted their service life). Car owners should take into account that after replacing the levers, it is necessary to check and adjust the wheel angles at the wheel alignment stand.

We replace the lever as follows:

- Place the car on a level surface, jack it up and remove the wheel;

- Using an 18mm wrench, unscrew the ball joint nut and use a puller to disconnect the support from the steering knuckle;

- first unscrew the front bolt that secures the lever to the subframe;

- then unscrew the two bolts from the bottom at the back;

- we remove the lever, if it is necessary to change both, we similarly dismantle the second one;

- install new parts in place.

As you can see, changing the levers is very simple and quick; almost any driver with minimal metalworking skills can perform such work.

Ford Focus rear suspension repair

The rear suspension of the Ford Focus is a multi-link independent system with telescopic shock absorbers and anti-roll bars. Unlike the front suspension, the design of the rear suspension on the “focus” is more complex. That is why it is better to entrust rear suspension repairs to professionals, since a non-standard design can raise a number of questions for inexperienced craftsmen.

The Ford Focus rear suspension system includes shock absorbers, stabilizer bars, trailing arms, springs and other elements. The rear suspension, although expensive, is characterized by increased durability. For example, silent blocks can last up to 110,000 km, while stabilizer struts can confidently “go” 150,000 km without the need for replacement. The rear shock absorbers are designed for 130,000 km. In this case, it is worth taking into account the condition of the roads on which the car is driven. An important factor is driver accuracy.

Pressing in the rear silent block of a Ford Focus 2

It is difficult to press out the rear silent block on the Focus, and since it has already served its purpose and is not needed, it can be removed in any way. We do this:

- we knock down the outer ring; if you apply force, it should move out of its place;

- We cut off the inner ring with a grinder; here it is important not to cut down the lever itself;

- we clean the seat under the s/b from dirt, sand it, and lubricate it with lithol;

- we heat the inner race of the sales block and cool the lever pin in ice water;

- Until the s/b has cooled down, quickly put it in place, while aligning the marks. The marks on the silent block are two slots in its body; they need to be aligned with the “edge” of the lever (see the figure below);

- Having installed the s/b, we finish it in place with a hammer.

- We put the lever on the car and go to adjust the wheel alignment.

Ford Focus 3rd generation suspension repair

Despite the fact that most 3rd generation cars have not yet passed the 100,000 km mark, specialists involved in servicing American brand cars already have experience in terms of repairing the front and rear suspension. The suspension design is largely the same as the previous generation cars. And since the craftsmen have experience in repairing the rear and front suspension of Ford Focus 2, then experienced craftsmen do not have any difficulties with servicing 3rd generation cars. Station wagon cars have the same suspension design as sedan or hatchback cars - the only difference is in the mounting method.

Step-by-step replacement instructions

Now let's move on to replacing the battery in the key. As noted above, these devices come in two types - a key fob with a flip key and a chip key. Let's consider both options.

Switchblade key

We throw away the mechanical key. At the side end of the key fob body, under its (key) seat, we find a hole.

Lock hole

We insert a small screwdriver into it and twist it counterclockwise until a wide gap forms between the two halves of the key fob. This is about three turns of a screwdriver.

After this, the keychain is easily separated into 2 parts.

We also disassemble the part with the buttons and logo into 2 halves, like a nut, using a suitable plastic object or, in extreme cases, the same screwdriver or knife.

Opening the electronic part

In the cover of the key fob we see a compartment with a CR2032 battery installed in it. Please note that the element is inserted minus side up.

We pry the battery with the tip of a knife and remove it. We install a new one in its place, observing the polarity, and push it in until it clicks. We close, snap the cover of the electronic part and install the unit with the mechanical switch key in place.

Important! When replacing the battery, make sure not to damage or lose the spring contact petals connecting the plus batteries to the electronic board.

Who should I entrust the repairs to?

Repairing the Ford Focus suspension can be expensive, since replacing some parts requires disassembling the entire suspension. In this case, the specialist must have enough experience in servicing Ford Focus 1st and 2nd generations.

Practice shows that it is better to entrust Ford Focus suspension repairs to the professionals of our technical center. The special design of the front and rear suspension can cause a number of difficulties for an inexperienced craftsman. At the same time, a qualified professional who is well acquainted with the specifics of the Ford Focus will quickly and efficiently repair or replace failed elements of the chassis system.

Ford Focus 2 front suspension repair

Front suspension repair Owners of a Ford Focus 2 can complain about malfunctions of their car that occur in any vehicle, but no one has the right to say anything bad about the quality of both the front and rear suspensions. The developers of the Ford Focus 2 really did a great job in this category. However, over time, Focus car owners will one way or another be faced with the question of what to do with the car: take it to a car repair shop for repairs or try to fix everything themselves. And also the rear suspension.

front suspension ford focus 2

In any case, the restoration of such an important part as the front suspension of the Ford Focus 2, be it restyling or repair, is inevitable - everything, sooner or later, becomes unusable and everything has its own expiration date. For suspension, similar terminology is measured in kilometers traveled. Most of the components of the front suspension are capable of “carrying” you about 80-100 thousand km.

Characteristic signs of a faulty Ford Focus 2 battery

- Cloudy consistency of the electrolyte in the jar(s). In its natural form, the electrolyte is colorless;

- Lead falls off the plates;

- When charging, one can boils or does not boil at all;

- Abundant boiling of all cans. Most likely, strong sulfation, you need a diagnostic device - a multimeter;

- During the charging process of the battery, the current does not decrease, but increases. Most likely there is a current leak between the lead plates, the electrolyte is of poor quality;

- When the plug is loaded with a current of 100A, the voltage drops to 10 Volts;

- When loaded with a 100A plug, the electrolyte boils in several jars;

- Check the condition by activating the low beam for 4 - 5 minutes. In good condition, the voltage shows at least 12.2 V. If the reading is below 12.0 V, the battery must be recycled;

- Checking the time until complete discharge using a 100 Watt light bulb;

- Checking the battery for self-discharge: charge it to the maximum, and then carry out a control measurement. If the indicator is above 0.4 V, the power source needs to be changed;

- The battery becomes excessively hot during charging;

- There is a crack, dent, or other defects in the plastic case, which led to electrolyte leakage;

- Near the battery you can smell rot and hydrogen sulfide;

- Electrolyte leakage from under the plug (cap);

- The voltage on the current leads is below 9.0 V;

- A light came on on the dashboard - an indicator indicating a lack of battery charge.

How to check the suspension

Ford front suspension repair diagram

We should not forget about the errors that occur in our realities: we are talking about the quality of domestic roads: I really didn’t want to raise the topic of Russian roads again and again, but, in this case, they directly affect the service life of the entire suspension, reducing the “period » use for 20-30 thousand km - the amount is not so small, is it? Let us briefly recall the main characteristics of the front suspension of the Ford Focus: it is a lever-spring, independent MacPherson-type suspension. "Composition" of the front suspension.

shock absorbers and springs for ford focus

According to its “physiological” structure, the suspension consists of the following undoubtedly important parts, the total number of which hardly reaches one dozen: a lever together with a ball joint, as well as silent blocks; shock absorber strut and anti-roll bar; anti-roll bar; bracket for attaching the stabilizer bar to the subframe; hubs; steering knuckle; subframe

New front lever assembly

Tie rod end

front brake pads

As one might guess, the parts are connected into a common chain, creating the very concept of a front suspension. The front suspension arm of the Ford Focus 2, for example, in this symbiosis plays the role of an organ that perceives braking and traction forces while the car is moving.

Steering rod Spain

We are convinced that the front suspension is faulty. We should probably start with the shock absorber. Why it is advisable to lift the car either with jacks or with a suspension mechanism. Next, you need to grab the wheel and “shake” it away from you and towards you. Having noticed free vibrations of the wheel (play), we will receive information about the need to replace the shock absorber. The brake will allow us to finally verify the situation. Having pressed on it and noticing the loss of play, we conclude that the front wheel bearing is most likely faulty. Of course, the initial “sampling” should be a visual inspection of the shock absorber for external damage and oil leaks.

unscrew the shock absorber tip and check the shock absorber

Even earlier, you can verify that the shock absorber is faulty in the following way: without lifting the car off the ground, you only need to press on one side of the car and watch what happens. If the car has returned to its original state with complete or almost complete absence of repeated vibrations, it is reasonable to draw a conclusion about the general serviceability of the shock absorber and only then proceed to longer checks. This is exactly how our advice is distributed; the best should be read from the end, gradually moving to the beginning.

Ford Focus 2 front suspension: fault diagnosis, repair diagrams

The front suspension of the Ford Focus 2 is lever-spring, independent, MacPherson type. Consists of a subframe, a steering knuckle with a hub, a lever with a ball joint and silent blocks, a shock absorber strut and a stabilizer bar with a strut.

Most of the front suspension design elements are designed to last approximately 100 thousand kilometers without repair, except for the wheel bearing, which must be changed after 50-60 thousand kilometers. In this case, the hub bearing, the hub itself and the steering knuckle are not disassembled and the entire assembly is replaced. Due to the unsatisfactory condition of roads in our country, the mileage of the front suspension is halved. After every 20 thousand kilometers or impact when driving through particularly deep holes at high speed, it is necessary to check the condition of the front suspension. The problem that most often arises with the front suspension of the Ford Focus 2 is the noise effect (knock) when driving over bumps.

Signs of faulty spark plugs

An experienced driver will always pay attention to the following symptoms:

- There is a burning smell.

- During operation, fuel consumption increases.

- The engine and its satellites begin to wear out intensively.

- There are problems with starting, the starter rotates, but the car does not start.

- The engine “troits”, hums unevenly, “sneezes”, and spontaneously stalls at idle.

- Throttle response deteriorates, the vehicle accelerates slowly with a decrease in the active power threshold and cruising speed.

In such a situation, a detailed visual inspection often reveals:

- Abundant black-brown carbon deposits on the walls or central electrode are a sure sign of the presence of an enriched combustible mixture in the cylinder; Partial combustion with a high CO content leads to the formation of soot and its further release into the exhaust manifold. Gray color – normal operation, yellow-white – lean mixture.

- An uncharacteristic shine and oiliness on the surface of the spark plug is evidence of splashing and filling it with oil, which is a consequence of the use of fuels and lubricants with additives, damage to the cylinder block gasket and piston rings, as well as problems with the valves.

- Erosion, other defects from thermal or mechanical effects in the housing and electrode (unnatural wear, oxidation, melting).

Why do Ford Focus 2 spark plugs still fail? Preconditions that provoke a breakdown may include:

- Refueling with fuel of questionable origin.

- Constant movement at low and medium speeds.

- The type of spark plugs does not match the given model of the foreign car.

- Frequent overheating, radiator boiling, low amount of antifreeze in the system.

- Defects in the battery, bromine wire, ignition coil and electrical equipment in general.

Moreover, the most unpleasant thing is that the mentioned factors can act both individually and in combination. That is why it is very important to carry out timely prevention, that is, a routine preventive examination.

Preliminary diagnosis of front suspension faults

Shock absorbers

- The function of a shock absorber is to dampen spring vibrations. If, when pressing on one side of the machine, it returns to its original position and there is no repeated vibration, the shock absorber is working.

- We grab the wheel and swing it towards and away from us. If we feel play, it means the shock absorber is faulty. If the play disappears after pressing the brake, there is a very high probability that it is time to change the front wheel bearing.

- Upon visual inspection, there should be no damage or oil leaks in the lower part of the shock absorber and the springs should be intact.

Steering rods

It's best to check when the car is raised.

We swing the wheel left and right. If play is felt, it means the ball joint, tie rod or tie rod is faulty.

Anti-roll bar joints

- No external damage to the ball strut covers.

- We move the stabilizer bar up and down by hand or using a pry bar. If we feel play, then the struts need to be changed.

Rear silent block for subframe mounting

- Visually there should be no delamination of rubber.

- We are trying to move the lever ear by inserting a screwdriver between it and the subframe. If it moves, then the silent block needs to be changed.

Ball joints

Take a screwdriver and carefully insert it between the lever and the steering knuckle. We move up and down. If there is play or knocking, the ball must be replaced.

Having completed the preliminary diagnostics, it is advisable to go to a service station and make sure your conclusions are correct. In most cases, the problem will be in the wheel bearing or one of the parts of the control arm.

Repair schemes for the two most common problems with the front suspension of Ford Focus 2

Front wheel bearing replacement diagram

It is advisable to replace both bearings at the same time.

- Jack up the car, unscrew the hub bolt, unscrew and remove the wheel.

- To avoid damage, we release the stabilizer bar link.

- Disconnect the ABS (anti-lock braking system) sensor terminal.

- Release the tie rod end.

- Remove the brake caliper. We do not disconnect the brake system hose. We secure the brake caliper in such a way as not to damage the hose. We knock down the brake disc.

- We unscrew the ball fastening nut and press it out using a puller or knock the pin out of the lever with a hammer. Please note that under no circumstances should you hit the ball, we hit the bottom of the steering knuckle.

- Unscrew the bolt connecting the shock absorber and steering knuckle. Using a chisel and hammer, loosen the terminal connection and release the shock absorber strut.

- We remove the steering knuckle by pulling out the constant velocity joint of the front wheel drive from the hub.

- The ABS sensor can be pulled out if you are afraid of damaging it. The bearing is equipped with a red seal. When replacing a bearing, buy the same one. The fact is that the wheel rotation sensor ring is combined with a bearing, and if there is a bearing without this red seal, the ABS will not work.

- Using a puller, press out the hub together with the bearing and press in a new one.

- We collect everything and go to do the wheel alignment.

Replacing a ball joint for Ford Focus 2

The front suspension arm (FSL) is sold in car dealerships assembled with silent blocks and a ball joint, but if the FAL itself is still in good condition and the ball joint is loose, there is no point in changing the entire arm. Changing the support on the RP is not difficult; we perform this work in the following order:

- remove the lever from the car;

- take an electric drill with a 9 mm drill, drill out the rivets approximately halfway, there is no need to drill out the rivets to the end;

- using a chisel and a hammer we knock down the rivets;

- remove the ball joint from the lever;

- We install the new part on bolts and nuts.

Separately, a ball joint can be purchased in auto stores at a price from 650 to 1350 rubles; spare parts are produced by the following companies:

- TRW;

- NK;

- Sidem;

- Fenox;

In the package, along with the part itself, there are three nuts with three bolts securing the support to the lever, as well as a nut securing the support to the steering knuckle. This is very convenient - you don’t need to look for fasteners when replacing a part.

Ford Focus 2 Manual

Front suspension Ford Focus 2

: 1 — lever; 2 — ball joint; 3 — steering knuckle; 4 — hub; 5 — shock absorber strut; 6 — stabilizer bar; 7 — bracket for fastening the stabilizer bar to the subframe; 8 — anti-roll bar; 9 — subframe

Elements of the front suspension on a Ford Focus 2 car

: 1 — lever; 2 — ball joint; 3 — steering knuckle; 4 — shock absorber strut; 5 — stabilizer bar; 6 — anti-roll bar; 7 — subframe

The front suspension is independent MacPherson type, providing high levels of smoothness of the car's ride, its stability and controllability, with telescopic shock absorber struts that serve to dampen vibrations, absorb shocks and shocks acting on the car through its wheels. Shock absorber struts include elastic elements - springs, which prevent the wheels from lifting off the road, providing constant grip on the road and preventing the body from swaying, which consequently affects the safety and comfort of driving. A hub assembly is attached to the bottom of the shock absorber strut, which is the basis for attaching the wheels and brake mechanisms. The hub assembly is connected to the subframe through a ball joint and a wishbone, and the subframe is connected to the car body. The front suspension is also equipped with a stabilizer designed to increase stability and reduce body roll angles when cornering and uneven roads by transferring compression or tension forces from one strut to another.

Shock absorber strut elements

: 1 — telescopic stand; 2 - spring; 3 - thrust bearing; 4 - nut; 5 — upper support of the rack; 6 — upper spring support cup; 7 — compression stroke buffer; 8 — dirt cover; 9 — adapter sleeve of the dirt protection cover

The basis of the Ford Focus 2 suspension is two shock absorber struts that allow the front wheels to move up and down when driving over uneven surfaces and at the same time dampen body vibrations. The steering knuckle is attached to the lower part of the strut housing, and a bracket for attaching the stabilizer bar is welded to the middle part. A hydraulic gas-filled shock absorber is installed in the strut housing. A polyurethane foam compression buffer is located on the shock absorber rod, designed to limit the upward movement of the wheel when the vehicle moves over uneven surfaces. The helical cylindrical spring of the shock absorber strut with its lower coil rests on the lower cup welded to the strut body, and with its upper coil (reduced diameter) on the centering sleeve mounted on the shock absorber rod together with the upper support of the strut. The upper support of the strut, which rests against the mudguard cup of the body, due to its elasticity, allows the strut to swing during suspension movements and does not transmit high-frequency vibrations to the body. A thrust bearing located between the upper spring seat and the upper strut mount allows the strut and spring to rotate with the steering wheel.

Front suspension arm Ford Focus 2

: 1 — ball joint; 2 — silent block for front mounting to the subframe; 3 — silent block rear mounting to the subframe

Braking and traction forces when the car is moving are perceived by suspension arms connected through ball joints to the steering knuckles, and through silent blocks to the suspension subframe. The subframe is attached to the side members at four points through silent blocks (pressed into the subframe holes).

The ball joint housing is riveted to the arm with three rivets, and the ball joint pin is attached to the steering knuckle using a tapered joint.

.

Steering knuckle assembly with bearing and hub

: 1 — tie rod end mounting eye; 2 — mounting hole for the wheel speed sensor; 3 — hole for attaching to the shock absorber strut bracket; 4 — eye for fastening the brake pad guide; 5 — hub bearing; 6 — hole for fastening the ball joint pin; 7 - hub

The hub bearing, hub and steering knuckle are a non-separable unit, so if it malfunctions, replace the entire unit.

Anti-roll bar

: 1 - stand; 2 — rod; 3 — bracket; 4 - pillow

The anti-roll bar is made of spring steel. The rod in its middle part is attached to the suspension subframe with brackets through two rubber pads. Both ends of the rod are attached to the shock absorber strut housings through the ball joints of the anti-roll bar struts.

To ensure good stability and controllability of the car, the front wheels are installed at certain angles relative to the body and suspension elements.

B–A — front wheel toe-in

;

A and B - distance (mm) between the edges of the wheel rims at the front and rear

;

δs is the toe angle of the front wheels

;

S - track

Wheel toe - the angle between the plane of rotation of the wheel and the longitudinal axis of the car. Wheel toe ensures the correct position of the steered wheels at various vehicle speeds and turning angles. Signs of deviation of the wheel toe angle from the norm: severe sawtooth wear of tires in the transverse direction, increased fuel consumption due to high rolling resistance of the front wheels. Toe-in is adjusted by rotating the tie rods with the lock nuts of the tie rod ends unscrewed.

t — angle of longitudinal inclination of the wheel turning axis

The casting angle of the steering axis is the angle between the vertical and the line passing through the centers of rotation of the ball joint and the bearing of the upper support of the shock absorber strut in a plane parallel to the longitudinal axis of the vehicle. It helps stabilize the steered wheels in the direction of straight motion. Symptoms of deviation of the angle from the norm are the car pulling to the side when driving, different forces on the steering wheel in left and right turns, one-sided tire tread wear.

γ — camber angle

Wheel camber is the angle between the plane of rotation of the wheel and the vertical. It promotes the correct position of the rolling wheel during suspension operation. If this angle deviates greatly from the norm, the vehicle may deviate from straight-line motion and one-sided wear of the tread may occur.

Only the wheel toe angle is adjustable. The camber angle and the longitudinal inclination angle of the wheel's turning axis are specified structurally by the geometry of the suspension and body parts. These angles cannot be adjusted in operation. It is recommended to check and adjust wheel alignment angles at a service station. Before adjustment, the wheels must be set to the straight-ahead position of the vehicle. The car must be placed on a horizontal platform. Fuel tank, windshield washer reservoir, etc. must be full, the spare wheel is in its original place. There should be no foreign objects in the passenger compartment or trunk. Wheel alignment angles are given in table. 1.

Table 1. Wheel alignment angles Ford Focus 2

Replacing the front silent block of the suspension arm of a Ford Focus 2

To repress the small silent block of the front RP, it is more convenient to use a puller, but if you don’t have one at hand, you can try to repress the s/w using improvised means. To do this, you will need a piece of pipe of the appropriate diameter and a bolt (stud) with a nut and washers.

To make the block move easier from its place, treat it with WD-40 and let it sit for some time (15-20 minutes).

We place a thick wide washer under the piece of pipe, turn the nut with a wrench, and begin to press out the steel.

We take a new sales block and press it into the lever.

The new s/b may be difficult to fit, so you need to be patient and take your time. The sales block is pressed in in the same way as it is pressed out. It is necessary to install the rubber seal so that the rubber flanges protrude from the iron.

To make the salenblock fit into place more easily, it would not be superfluous to treat the outside with silicone grease. The lubricant will not corrode the rubber, but it will be easier to press in the s/b.