General parameters of diesel fuel

There are three brands of such fuel, often called diesel fuel:

- winter: recommended for use at low ambient temperatures (up to -30 °C);

- summer: poured at positive temperatures;

- arctic: indispensable when the vehicle is operated at critically low temperatures.

The main characteristics that describe diesel fuel (summer, winter, arctic) include:

- Viscosity and density index. Their values determine the phenomena of formation and evaporation of mixtures in the internal combustion engine.

- Cetane number. The power of the vehicle’s engine and its noise level depend on it.

This parameter determines the knock resistance of the motor. The higher it is, the better the diesel fuel burns due to the short ignition period. At the same time, the exhaust is more environmentally friendly. The standard cetane number is in the range of 40–60. - Low temperature parameters. These include indicators of the pour point, filtration and cloudiness of diesel fuel.

Additional characteristics - ash content, iodine value, chemical stability, mass fraction of sulfur compounds and sulfur, kinematic viscosity, water content, coking ability, acidity, resin concentration. They are not so important, but diesel fuel manufacturers always take them into account, as required by GOST.

Biodiesel

This type of diesel product deserves special attention. This is an innovative development of European engineers. The technology for the production of biological diesel fuel involves the use and processing of vegetable oils. The main difference between biodiesel and conventional diesel fuel brands is environmental friendliness. Complete disintegration of its combustion products without harmful consequences in the natural environment occurs within 30 days after entering the soil, water or atmosphere.

The governments of industrialized countries and international organizations specially created on this issue are now forced to act in the fight for the environment. By this time, new standards were introduced in the production and operation of biofuels.

Biodiesel is intended, first of all, for use in internal combustion engines of passenger vehicles, then for trucks and industry. Summer brands of high-quality diesel fuel are usually made on its basis. The cetane number of biodiesel is 58 units, and the combustion temperature is 100°C; it has excellent lubricating properties and a reduced percentage of CO 2 emissions into the atmosphere. Thanks to the combination of such characteristics, product developers have provided car enthusiasts and enterprises with the opportunity to not only significantly increase the service life of internal combustion engines and reduce maintenance and repair costs, but also significantly reduce the risks of explosions and fires.

Read also: Removing the Kia Rio alternator belt tensioner

A feature of biological diesel fuel is the presence of vegetable and animal fats in the mass. The structure of biofuel is natural, and the product itself is the result of processing agricultural crops such as rapeseed, soybeans and other oil-containing plant species, and cattle fat. The distinctive characteristics of this type of diesel fuel are that it can be used as an additive to traditional types of fuel.

Biodiesel has special designations. For example, in the United States of America, biological fuel in the name includes the letter “B”, followed by a digital value indicating the percentage of bioadditive content in the total mass of the fuel. Cetane number not lower than 50 units.

Biodiesel is produced using a technology similar to the production of diesel fuel from oil. Today, there are brands of biodiesel not only for summer, but for off-season and winter conditions in temperate latitudes.

Summer diesel biofuel is used only at positive temperatures, intermediate grades - up to -10° below zero, winter biodiesel - up to minus 15-20°C. Frost resistance of winter grades is achieved through the use of special additives, originally developed to improve the properties of diesel fuel.

Summer diesel fuel - features

This type of diesel fuel is used in our latitudes from April to early autumn, when the air temperature is not recorded below -5 degrees Celsius. The fuel will freeze immediately if the outside temperature remains stable at -7–8 °C. This can lead to breakdowns and blockages in the pipes. Cloudiness of diesel fuel is observed at -6 °C.

In Russia, summer diesel fuel is marked with the letter “L”. It is produced by mixing hydrotreated straight-run fractions and secondary hydrocarbon fractions, which boil away at temperatures of 280–360 degrees. An increase in the final boiling point of secondary fractions is the cause of high smoke and coking of the injectors.

It is allowed to use summer diesel fuel for heating boiler rooms. And its high explosion resistance and low level of flammability make it possible to use the composition as fuel for the operation of diesel generators, military and agricultural equipment, and not just for passenger cars. The process of producing diesel fuel, compared to the production of gasoline, is less technologically advanced and costly, which leads to a lower cost of diesel fuel.

Density of summer diesel fuel

This is the most important indicator that affects the functionality of the vehicle’s fuel and filter equipment. Density refers to the amount of mass of diesel fuel moved in one cubic meter. It can change as the temperature of the diesel fuel rises and falls (the lower the density, the higher the temperature).

To begin with, I would like to clarify what is meant by specific gravity (hereinafter referred to as SG) in physics and chemistry, and only then move on to the specific gravity of diesel fuel or, as it is also called, the specific gravity of diesel fuel.

Let's go over the theory.

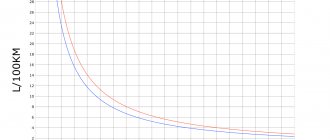

Reasons for increased fuel consumption in winter

Depending on the density of diesel fuel, not only the possibility of freezing or thickening is determined, but also the possibility of energy release. The increased value makes it possible to obtain more joules from each liter during combustion in the cylinders. This will entail an overall increase in engine efficiency.

As a result, the car will consume significantly less fuel for every 100 km of travel. You can drive further on one filled tank.

Winter and arctic fuel types have fewer kg per cubic meter. This means that after combustion, less energy is released from the engine than in comparison with the summer grade of hydrocarbons used.

However, the use of diesel fuel marked “L” to increase the performance of internal combustion engines in winter is unacceptable or undesirable. The composition of such a liquid contains a large percentage of paraffins in a dissolved state. A decrease in temperature affects fluidity, viscosity and geliness increase. Pipelines become dirty and clogged.

For each season you need to choose an acceptable type of fuel. This will allow you to operate your vehicle optimally and efficiently in any conditions.

“>

Fuel Specific Gravity

Specific gravity is the ratio of the weight [P] of any substance in question to its volume [V], namely weight, and not mass, as many people think. However, there is no particular difference for us here; these are only distinguishable concepts from a scientific point of view and cannot be confused in any way. It has become so common in everyday life that weight is mass.

The specific gravity of a substance [y] can also be expressed through its density [p]: y=p*g

where g is the acceleration of gravity at a specific point in space, it is usually considered equal to 9.81 m/s*s.

The unit of measurement for hydrocarbons is 1 N/m3 (Newton divided by cubic meter).

Formulas for calculating density, weight and volume of diesel fuel

Formula for determining the weight of diesel engines

The weight of the fuel is determined by multiplying the density of the petroleum product by its volume. 1850 liters of diesel fuel with a density of 0.840 kg/m3 will weigh 1554 kg. 1000 liters of diesel fuel with a density of 0.860 kg/m3 will weigh 860 kg.

Formula for determining the volume of diesel fuel

A pressing question for transportation, sales and accounting is: how to convert the weight of fuel into volume?

To find out the volume of diesel fuel, you need to divide its mass by its density. If there is 1 ton of diesel fuel, and its density is 0.840 kg/m3, the volume will be 1,190 liters 476 grams.

Fuel density

The density of a fuel is the amount of its mass in kilograms that fits in one cubic meter. This value is not constant and depends on the temperature of the diesel fuel, which has a bad effect on the operation of the car engine if the diesel fuel is of poor quality in terms of density. The higher the temperature of the liquid, the lower its density and vice versa. It is also a known fact that the higher the density of automobile fuel, the heavier its fractional composition. This leads to the fact that the processes of atomization and evaporation of gasoline or diesel fuel are significantly worsened, therefore, various types of deposits occur more intensively in the combustion chambers of the engine and in the fuel system, which over time increasingly complicates the movement of fuel through the system. This also contributes to the formation of carbon deposits on the engine valves.

contents .. 1 2 3 4 ..Performance indicators of diesel fuels

Density of marine diesel fuel

Fuel density is an indirect characteristic of its chemical properties and fractional composition. Density refers to the ratio of the mass of fuel at 20°C to the mass of the same volume of fresh water at 4°C.

Under operational conditions, density should be taken into account in the following cases:

A. When bunkering, to determine the mass of the remaining fuel in the tank, the mass capacity of the fuel received in the tank. Since the density of the fuel depends on temperature, and in the fuel passport this value is given at 20°C, when bunkering under different temperature conditions and determining the amount of fuel, its density should be clarified for these conditions.

B. When selecting the adjusting washer in the separator;

B. When replacing the fuel brand recommended for a given engine with another one, since the density affects the range of the fuel torch and its change can negatively affect the conditions of mixture formation and combustion.

Table

7

2

Temperature correction coefficient to fuel density value

Density p, g/cm3

| Coefficient Y, 1/deg | Density p, g/cm3 | Coefficient Y. 1/deg | River density g/cm | Coefficient Y. 1/deg | |

| 0,84-0.8499 | 0,000712 | 0,89-0,8999 | 0,000647 | 0,94-0,94991 | 0,000581 |

| 0,85-0,8999 | 0,000?99 | 0,90-0,9099 | 0,000633 | 1 0,95 0,9599 | 0,000567 |

| 0.86-0DO9 | 0,000686 — | 0,91-0,9199 | 0,000620 | 0,96-0,9699 | 0,000554 |

| 0,87-0,8799 0,000673 0.88-0,8879 0,00066 | 0,92-0,9299 | 0,000607 | 0,97-0,9799 J | 0,000541 | |

| 0,93-0,9399 | 0,000594 | 0,98-0,9899 | 0,000528 | ||

High-quality paraffinic straight-run distillates such as Gas Oil (diesel L) have a density of 830-860 kg/m3, while the density of aromatic distillate fuels is 880-910 kg/m3. Cracking distillates have an even higher density, and if they are obtained from aromatic oils, their density can reach 1000 kg/m3. The density of residual straight-run fuels from paraffinic oils is 870*930 kg/m3, with a high content of asphalt-resin, which makes up the density of heavy residual fuels, it increases to 950-970 kg/m3, cracked residues can have a density of 980-1030 kg/m3.

High density is evidence of the presence in the fuel of highly aromatized heavy asphalt-resinous hydrocarbons, which impair the self-ignition of fuels, increase the duration and incompleteness of combustion, and increase carbon formation. At a density of more than 991 kg/m3, fuel separation becomes difficult.

Due to the fact that fuel pumps dose fuel by volume, the mass of fuel supplied to the cylinder will depend on its density.

Fuel density affects the process of mixture formation and combustion. At low density, the speed of movement of fuel particles in a dense medium of compressed air decreases, the process of mixture formation worsens and the volume of air in the combustion chamber is not fully used. With a significant fuel density, the range of the torch increases, part of the fuel reaches the wall of the combustion chamber, worsening the mixture formation process. As a result, the efficiency of diesel operation decreases and the smoke of exhaust gases increases.

Viscosity

Viscosity is one of the most important physical indicators of diesel fuels, determining the quality of atomization, mixture formation and combustion of fuel.

As the viscosity of diesel fuel increases, the resistance of the fuel supply system, the range and size of droplets in the spray increase, the filling of the fuel pump decreases, and the atomization and mixing of fuel with air deteriorates. As a result, the combustion process is disrupted, the amount of products of incomplete combustion of fuel increases, scale deposits on parts, specific fuel consumption and the fuel pump delivery coefficient increase.

When using diesel fuels with low viscosity, their leakage through injectors and pumps increases, the flow rate and engine power decrease. Engine power decreases not only due to a decrease in feed, but also due to a decrease in the size and speed of sawn fuel particles.

Fuel viscosity is estimated by the coefficient of kinematic viscosity, which shows the amount of internal friction of liquid particles that occurs during their mutual movement, and is determined using U-shaped viscometers according to the formula:

In domestic practice, for marine diesel engines, viscosity is usually measured in scale degrees (°ВУ) or equivalent Engler degrees (°E), which is the ratio of the flow time under standard conditions of 200 ml of the test product at the test temperature through a calibrated hole with a diameter of 2.8 mm to flow time of the same volume of distilled water at a temperature of 20°C.

The relationships between existing viscosity units at different temperatures are given in Table. 1.3.

When pumping, the fuel temperature must be at least 15 - 20°C above the pour point. Reliable operation of fuel equipment when using high-viscosity fuels is ensured by heating them to achieve a viscosity in the range of 10-25 mm2/s (2-3.7°VU).

Nomograms of the dependence of fuel viscosity on heating temperature are shown in Fig. 1.4—1.6.

In Fig. 1.4 shows a diagram recommended by MAN-B&W (MAN - Burmeister and Wein) for determining the heating temperature of heavy fuel in front of the injection pump, depending on the required viscosity and initial viscosity (before heating). To avoid rapid contamination of the fuel heater, the heating temperature should not be higher than 135°C in an open type system; 150°C in a closed system.

Heating that is not appropriate for the type of fuel (high viscosity) not only worsens the combustion process, but can also cause increased wear of cylinder liners and compression rings, destruction of exhaust valve seats, increased injection pressure and a high level of stress in the high-pressure fuel system.

For distillate fuels, the viscosity is in the range of 2–10 mm2/s at 20°C.

Cloud point and pour point

Cloud point is the maximum temperature at which phase heterogeneity appears in the fuel; the fuel begins to become cloudy due to the release of microscopic droplets of water, micro-ice crystals or hydrocarbons. Use fuel only until it becomes cloudy.

Pour point is the temperature at which the fuel loses its mobility under standard conditions (in a test tube inclined at an angle of 45°, the fuel level remains motionless for 1 minute). Fuel washout is associated with the crystallization of paraffin dissolved in it. Therefore, the pour point depends on the chemical composition of the fuel. In operation, the pour point is taken into account when storing fuel, choosing a heating mode and pumping fuel. The cooling temperature of domestic fuels ranges from -5 to 10°C; some heavy fuels with a high paraffin content can reach 30°C.

contents .. 1 2 3 4 ..

Specific gravity of diesel fuel

The density of the fuel and, therefore, its specific gravity is measured with a special device called a hydrometer.

According to the current GOST, the following values are accepted for the specific gravity of diesel fuel (for diesel fuel temperature +20C):

the specific gravity of summer diesel fuel must be within 8440 N/m3; the specific gravity of winter diesel fuel is 8240 N/m3

Or in density:

Density of summer diesel fuel – 860 kg/m3 Density of winter diesel fuel – 840 kg/m3 Density of Arctic diesel fuel – 830 kg/m3

In practice, if we take into account only high-quality diesel fuel, it turns out that when the temperature of diesel fuel changes by one degree Celsius, its density changes by 0.00075. This coefficient can be used to recalculate the density of diesel fuel under different temperature conditions. But it is worth remembering that at most gas stations the quality of the product leaves much to be desired, and no one knows what impurities are present in it. While the density of pure fuel can be recalculated using this coefficient, the density of impurities in it is not always true.

How many kilograms are in a liter of diesel fuel?

Mass is a characteristic of a body, which is a measure of gravitational interaction with other bodies.

Volume is a quantitative characteristic of the space occupied by a body, structure or substance.

Density is a physical quantity defined as the ratio of body mass to body volume.

The relationship between liters and kilograms of diesel fuel is determined by a simple mathematical formula:

V – volume; m – mass; p – density.

In the calculation, the density of diesel fuel was taken = 840 kg/m3.

The density of diesel fuel can vary depending on temperature and pressure. You can find the exact density of diesel fuel in reference books.

See also the universal program for converting liters to kg for any substance depending on its density.

If you need to convert m3 to tons, then see the program for converting tons to m3.

If you need to convert kg to m3, then see the program for converting kg to m3.

Question: How many kg are in a liter of diesel fuel?

Answer: 1 kg of diesel fuel is equal to 1.19 liters.

Question: How many liters are in a kilogram of diesel fuel?

Answer: 1 liter of diesel fuel is equal to 0.84 kilograms (kg).

You can quickly solve this simple mathematical operation using our online program. To do this, enter the initial value in the appropriate field and click the button.

This page presents the simplest program for converting kilograms of diesel fuel into liters. Using this online calculator, you can convert liters of diesel fuel to kg and back in one click.

To begin with, I would like to clarify what is meant by specific gravity (hereinafter referred to as SG) in physics and chemistry, and only then move on to the specific gravity of diesel fuel or, as it is also called, the specific gravity of diesel fuel.

Let's go over the theory.

Weight of 1 liter of diesel fuel (diesel fuel)

Based on the density values of diesel fuel given above, it is easy to calculate the weight of 1 liter of diesel fuel. It will vary from 830 grams to 860 grams, that is, the higher the temperature of the diesel fuel, the lighter 1 liter of it will weigh.

The main consumers of diesel fuel are trucks, construction and agricultural equipment, as well as railway transport. However, recently, passenger vehicles can also be found using diesel fuel. For all drivers, the worrying question has always been its price. It is very profitable and convenient to use in car engines, as it is cheaper than gasoline. The power and efficiency of engines running on diesel fuel is quite strong, since its high compression ratio leads to significant savings.

The density indicator is currently the most common one used in the characteristics of all petroleum products. The higher it is, the more energy is generated during the combustion process, and this allows you to increase the efficiency of the engine. It affects not only the quality of the fuel, but also its use in winter. When purchasing diesel fuel at gas stations, drivers are often not interested in its density, especially in the summer. And as long as the car is moving normally, they don’t think about anything.

But the density of diesel fuel plays a big role in the fate of the car, and, as a rule, it is always remembered in winter. When severe frosts set in, diesel fuel is waxed and turns into a mushy mass that can clog the whole. Winter diesel fuel should be 840 kg per cubic meter. If it is summer, having 860 kg per cubic meter, then with a sharp change in temperature the consequences may not be very pleasant. In addition to winter and summer, there is also Arctic diesel fuel. It has the lowest density of 830 kg per cubic meter and can easily withstand frost.

Of course, it is difficult to visually determine what kind of fuel is being poured into the tank. All that remains is to believe the documents on him. But at home, you can find out the density of diesel fuel. To do this, you need to pour it into a three-liter jar and place it in a room where the temperature does not exceed twenty degrees. In the morning, use a hydrometer to measure the density. However, it should be taken into account that in this way you can only find out whether it is summer or winter, but a qualitative indicator cannot be determined in this way.

If the temperature outside is down to minus ten degrees, you can analyze the density of diesel fuel right at the gas station. To do this, you need to pour a small amount of it onto the metal and observe whether its structure changes. If it drains normally, then there will be no doubt that it is winter. If it becomes cloudy and solidifies slightly, this means that the diesel fuel is summer, and in severe frost it solidifies completely. To do this, you just have to look at the refueling nozzle and be convinced of this.

Therefore, if the driver knows for sure that diesel fuel was produced under factory conditions, he, based on knowledge of its density, can himself determine its identity, as well as its freezing point. Well, if it is low-grade, then there will be no point in visually analyzing it.

High-quality winter diesel fuel becomes cloudy at forty-five degrees and solidifies at forty-eight. If we talk about the Arctic, then its freezing point is generally sixty-five degrees.

You can be completely confident in the quality of the fuel only after laboratory tests using fractional distillation. There are other methods for determining quality, more modern ones.

Every driver should know that it is best to refuel a car at those gas stations that have been tested repeatedly. And although the density of diesel fuel plays an important role, there are many other indicators that affect engine performance.

The largest consumer of diesel fuel today is railway transport. All agricultural vehicles are also fueled with diesel fuel. There are also quite a few passenger cars equipped with a diesel engine. Therefore, the issue of diesel fuel is always hotly discussed among drivers. What is summer diesel? Why and when should you switch to it? We will talk about all this today.

What you need to know when switching to winter diesel fuel

Diesel fuel consists of heavy hydrocarbons of the paraffinic group, which can precipitate and crystallize when the temperature drops. The diesel fuel simply thickens and does not pass through the filters or through the power supply system and pumps. In this case, the fuel becomes cloudy, viscous until completely solidified. In this regard, there are three types of fuel for diesel engines, which must correspond to the ambient temperature:

- summer diesel fuel, which can only be used at temperatures from 0°C;

- winter fuel, the use limit of which ends at -30°C;

- Arctic diesel fuel is used when the temperature is -50°C.

Diesel fuel has remained virtually unchanged over the past hundred years.

Moreover, all types of diesel fuel can turn into plasticine, but at different temperatures. According to GOST 52368-2005, summer fuel becomes cloudy at a temperature of -5°C, at 7 degrees below zero the filterability limit is reached, and at -10°C it is completely waxed. Cloud point, even short-term and at night, is the main signal to start switching to winter fuel. But, unfortunately, gas stations cannot always offer winter fuel on time, and even if they offer it, it is not a fact that it is winter. It is not possible to check the fuel at a gas station, so many people use depressant additives - antigels - during the transition period. In principle, oil refineries in the middle zone use exactly the same method. Winter fuel is prepared from summer fuel by introducing depressant additives into it. But this is not the most important indicator of fuel quality.