Gear ratio

- a term often used in Russian-language technical literature from the Soviet GOST 16530-83 (16530-70). It means the amount by which a specific mechanical gearbox of two intermeshing gear wheels can theoretically change the torque and angular velocity in any direction, regardless of which wheel is the driving one and which is the driven one. In the general case, it is not equal to the gear ratio, although in half of the cases it may coincide with it. Unlike the gear ratio, the gear ratio is always greater than one. Notation: ( u {\displaystyle u} ).

Ksenia98 › Blog › About complex things in simple words. Gearbox gear ratio.

Each of us, when choosing a new car to buy, looks at the technical characteristics. If we are able to analyze them, then we can predict (albeit not very accurately) the nature of the car. This way, it will be easier for us to choose a “new thing for ourselves” (after all, we are all different, just like the cars offered to us). And the right choice will have a positive impact on both driving pleasure and safety. Often in the characteristics there are gear ratios, as well as the number of the main pair. What do they mean? Each gearbox has several gears, for example, in a manual transmission there are most often 5. Why are so many of them needed? Think of 1st gear as a sprinter. Powerful man, huge leg muscles. The 1st gear (sprinter) will run his 100-meter race the best. And 5th gear is a marathon runner who does not stand out with a powerful physique, but is wiry and durable. Over a distance of 42 km, 5th gear (marathon runner) will cope much better than a sprinter (1st gear). But a marathon runner (5th gear) may not have enough strength to move a heavy car. All other gears (2nd, 3rd, 4th) are runners for their own distances, each of them is also important.

One of the main characteristics of a car transmission is the gearbox ratio. The meaning of the term is the ratio of the number of teeth of two interacting gears, driven to drive. Or, what is the same, the ratio of angular velocities or rotational frequencies of both elements of a kinematic pair. The size of the teeth on both gears will be the same, but their diameters may differ. In the case of interaction of several gears, the total value is determined by the product of the numbers for all pairs. If the drive wheel has a smaller diameter and number of teeth than the driven wheel, the output speed is reduced and the torque is increased. The lower the speed, the higher the thrust. With the reverse ratio of gear diameters, the opposite is true: the speed is higher, but the thrust is less.

In any type of gearbox there are several stages. Transmissions of SUVs and tractors have additional reduction gears; they provide an increase in torque. The lower the stage, the higher its gear ratio and the “shorter” it is. The lowest stages in most manual transmissions are the first three. Providing greater traction, they are designed for starting, driving slowly, and accelerating. Then we switch to direct gear - fourth. Fifth, increased or “long” - for driving at high speed. However, it cannot provide the required torque when we are driving uphill or about to overtake the car in front. It is necessary to go to a lower level: fourth or even third. The gear ratios of the stages in gearboxes are selected taking into account the type of drive, vehicle weight, engine power, and wheel diameter. The calculation is carried out in such a way that, with decent dynamics, the driver does not have to frequently switch the lever and fuel consumption is moderate.

Mass-produced cars are equipped with “long” gearboxes. They are more convenient and have a wider range of speeds for each stage. In the city, with constant changes in traffic speed, this is of great importance.

Sports versions, designed for fans of fast driving, are equipped with “short” ones. It’s realistic to “rush” first from the intersection, but you’ll have to switch more often.

Domestic tuning is a legacy of the Soviet automobile industry, where three types of passenger cars were produced for the largest country in the world. A body kit, LED “BMW eyes” and a leaky straight-through muffler “Maserati sound” allow owners of domestic cars to at least somehow stand out from the faceless stream. “Advanced and handy” car enthusiasts go further and deeper, making design changes to the engine and transmission.

It is believed that “shortening” the box is very cool. Fans of fast driving can purchase instead of standard pairs (rows) of gears, alternative ones that increase the gear ratio. For example, the value for the main pair of VAZ 2107 in the factory gearbox is 3.9, for the VAZ 2108 - 3.8. Change to 4.1 or more, up to 5.1. Yes, this allows the car to “shoot” from a standstill, but it worsens other characteristics. Fuel consumption and engine wear increase, maximum speed decreases, and you have to switch frequently. Excessive gearbox tuning instead of thrills can lead to disappointment.

Transmission tuning. How to choose gear ratios for a gearbox?

Most of the technologies used in transmission tuning are proven in motorsports.

The transmission of any, especially a sports car, is the most important mechanism for realizing the dynamic characteristics of the engine. Even with a relatively weak engine, the car can be fast due to correctly selected gear ratios. In motorsport, synchronized (as on 'road' cars) and non-synchronized (cam) gearboxes are used. Based on the shifting principle, they are divided into conventional (H-pattern) and sequential (with sequential gear selection, like on motorcycles).

In cars of a fairly serious level of preparation, cam gearboxes are used. They have a number of advantages - they can withstand higher loads (due to the shape of the tooth and the gear-cam clutch engagement), allow experienced pilots to spend less time changing gears due to incomplete squeezing of the clutch or without squeezing the clutch at all, they do not destroy synchronizers (which are simply No).

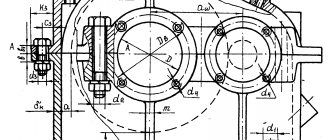

Gearbox ratio.

What is a gear ratio? Quite often you can hear the question “what is a gear ratio” from car owners. In this article I will try to briefly cover this topic. So, transmission mechanisms transmit the rotation of one shaft to another, i.e. force the second shaft to rotate through the rotation of the first. This question was explored by Leonardo da Vinci. Some of his inventions are still used today in the designs of bicycles and even cars.

Thus, based on his sketches of gears, globoid worm gears, bevel gears, spiral gears and roller chains, the current vehicle gearbox mechanisms were developed. The gear ratio is the ratio of the angular speeds of the drive to the driven gear (wheels, shafts) or the ratio of the radii of the driven to the drive gear. In particular, gear ratios of a gearbox are determined by the ratio of the number of teeth of the driven gear to the drive gear. If several pairs of gears are involved in the transmission, the total gear ratio is the product of the gear ratios of all pairs of gears participating in the transmission.

How does the gearbox work?

To obtain torque of varying magnitudes, which will allow the vehicle to operate in different conditions, the gearbox contains several pairs of gears that have different gear ratios. “Reverse” gear is obtained by placing another intermediate gear between the drive and driven gears, which will make the rotation reverse. Any gearbox, manual, automatic or robotic, ensures optimal engine operation in different road conditions by changing the gear ratio. Also, in any gearbox there are high and low gears. The higher the gear ratio, the more powerful (or shorter) the transmission is considered. This means that the more powerful the gear, the faster the engine revs. At the same time, however, the gear shift frequency also increases. This is a consequence of the fact that in a given gear the maximum speed at which it is necessary to engage a higher gear will be less

Gear ratio: what effect does it have?

The gear ratio is a parameter that you can calculate yourself. Its value is calculated by dividing the number of teeth of the driven gear by the number of the drive gear. Moreover, the larger the gear ratio, the more rapidly the power unit can reach the required number of revolutions. That is, with a large gear ratio, the car accelerates much faster. However, there is one important nuance here: the maximum speed in this case will be lower, and gear changes will have to be performed much more often. It is for this reason that most automakers consider the parameter value in the mid-range acceptable and create multi-stage gearboxes.

Gearbox ratio: what you need to know

In a car, a gearbox is a unit that allows you to change the torque developed by an internal combustion engine before transmitting such torque to the drive wheels of the vehicle. As you know, most gearboxes are stepped, and the gearbox is based on a gear drive.

Simply put, gears are actually pairs of gears that have different gear ratios (gear ratios). In this article we will look at what a gearbox gear ratio is, what this characteristic indicates and influences.

Read in this article

Determination of the final drive gear ratio.

The final drive ratio is determined based on the maximum vehicle speed in top gear, specified by the technical specifications for the vehicle being designed.

The final drive gear ratio is determined by the formula

Ur=3.6(wmaxrk)/VmaxUkUd

where vmax is the maximum speed of the vehicle, km/h; wmax — maximum angular velocity of the crankshaft, rad/s; rk—wheel radius, m; Uk is the gearbox ratio in top gear; id - gear ratio of the additional gearbox in top gear (id = 1).

It is believed that the gear ratios of the gearbox in top gear have the following values: IR = 1.0 - for direct transmission and IR = 0.9...1.0 - for overdrive transmission of passenger cars; IR - 1.0 - for trucks with no more than six gears; ik = 0.7...0.8 - for multi-stage transmissions of trucks.

The main gear ratio UT, determined by calculation, should have the following values: no more than 5.0 - for passenger cars; no more than 7.0 - for trucks with a carrying capacity of up to 8 tons; no more than 8.0 - for trucks with a carrying capacity of over 8 tons.

The calculated final drive ratio must be compared with the existing final drive ratios of vehicles of similar type and purpose. If a drive axle is being designed for a new car model, then this value of the gear ratio is specified taking into account the number of teeth of the final drive gears.

Determination of the gear ratio of the first gear of the gearbox. Determination of gear ratios of intermediate gearbox stages.

When determining the gear ratios of the gearbox, you need to remember that 1st gear is designed to overcome maximum road resistance. Intermediate gears of the gearbox are used when accelerating the car, overcoming increased driving resistance, operating the car in conditions that do not allow moving at high speed (ice, broken road, delay by vehicles ahead, etc.), as well as when braking the engine on long, flat roads. descents

When calculating gear ratios, first find the gear ratio of first gear according to the maximum road resistance coefficient ψmax specified by the technical conditions or the maximum dynamic factor of the vehicle in terms of traction Dmax in first gear.

This gear ratio is determined using the expression obtained from the formula for the dynamic factor, neglecting the force of air resistance, since it is insignificant at low speeds:

u1=(Gaψmaxrk)/Mmaxηtrigud

where Ga is the weight of the vehicle with a full load, N; Mmax—maximum engine torque, N • m.

The resulting gear ratio of the first gear of the gearbox does not guarantee the absence of slipping of the driving wheels of the vehicle. To avoid slipping of the drive wheels when driving in 1st gear, the following inequality must be met:

(Mmaxηtrigudu1)/ Gark≤Dsc=(mp2Ga2φx)/Ga

where Dsc is the dynamic factor of the car in terms of adhesion; tР2 -= 1.20…1.35 - coefficient of change in reactions on the rear drive wheels; Ga2—weight attributable to the rear wheels of the vehicle at full load, N; fx = 0.6...0.8 - coefficient of wheel adhesion to the road.

From this ratio, a new gear ratio of first gear is determined, at which there will be no slipping of the drive wheels:

u1= (mp2Ga2φxrk)/ Mmaxηtrigud

After checking the gear ratio of the first gear for the absence of slipping of the driving wheels of the vehicle, the smaller one is selected from the two found gear ratios of the first gear of the gearbox for further calculations.

Based on this value of the first gear gear ratio and the known value of the top gear gear ratio, the gear ratios of the intermediate gears are determined.

If the top gear is direct (ip = 1), then to calculate the gear ratios of intermediate gears use the following expression:

Uk=

where n' is the number of gears, not counting overdrive and reverse gears; k - transmission number.

If the top gear is an overdrive (uk < 1), then the value of its gear ratio is selected in accordance with the type of car, and the remaining gear ratios of the intermediate gears are calculated using the above expression.

Reverse gear ratio

Uzk=(1.2…..1.3)u1

The final value of the reverse gear ratio is determined when configuring the gearbox.

The calculated gearbox ratios are indicative only and may change slightly when designing a new gearbox.

What is gearbox ratio

The gear ratio is the main characteristic of a gear drive. This transmission transfers torque from the engine (in the case of a car to the drive wheels). Also, the gear drive allows you to both reduce and increase the torque coming from the engine. The change is made possible by increasing or decreasing the number of teeth on the gears.

So, the gear ratio (automatic transmission, manual transmission) is the ratio of the number of teeth of the driven gear to the number of teeth of the drive gear in the gearbox, gearbox, etc. Simply put, for example, the drive gear has 30 teeth, and the driven gear has 60. In this case, the gear ratio of such a gear pair will be 2, that is, 60:30.

- The gear ratio in the gearbox and gearbox directly affects the dynamics of acceleration, as well as the maximum speed. Step transmissions have several gear pairs with different gear ratios. The higher the number, the more traction the gear provides. At the same time, the engine picks up speed faster, the car actively accelerates, but the maximum speed is not high in this gear. To increase speed, it becomes necessary to switch to a higher level.

In higher gears (4, 5, 6), the gear ratio decreases, which increases the maximum speed of the car. At the same time, acceleration in such gears is less intense than in lower gears.

Let us also add that the acceleration dynamics are also affected by the gear ratio of the main gearbox pair. The larger the indicated number, the better the car’s dynamics, in all gears. At the same time, the maximum speed is lower. For example, let's take the VAZ models. If you put on a car a main pair that has a number of 4.1 or 4.3 instead of 3.9, the car will be more dynamic, but the maximum speed will also be reduced.

- Also, when creating a gearbox, designers try to achieve an optimal balance between acceleration dynamics and efficiency. If, by changing the gear ratio, it is necessary to achieve better acceleration dynamics of the car, efficiency will definitely suffer.

By the way, often in 5-speed gearboxes the fifth “overdrive” gear is not the gear for achieving maximum speed, as many people mistakenly believe. As a standard, this transmission allows you to achieve maximum fuel economy, as well as significantly reduce noise and load on the power unit when driving at high speeds or speeds close to the maximum for a given vehicle.

Definition

This gear train has a 28-tooth wheel and a 10-tooth gear. Due to the fact that it is not clear from the figure which of the two elements is the leading one and which is the driven one, the gear ratio ( i ) of this transmission is not obvious and can be equal to either 2.800 or 0.357. The gear ratio in either of the two cases is 2.800

Formally, it is calculated as the ratio of the number of wheel teeth to the number of gear teeth

[1].

the driven and driving gears

in a gear drive N

ambiguity of the term

In fact, based on the meaning of the definition, the digital value of the gear ratio clearly shows only the following facts: how many times the linear dimensions (radius, diameter, circumference) of both gears differ; by what amount can a given gear train change the two components of rotational motion - torque and rotational speed. However, there is no indication from which of the two gear elements the rotation should be transmitted. According to the same GOST, the “gear” is not necessarily the driving element[2], and the “wheel” is not necessarily the driven element[3]. The footnote to the definition of the terms “wheel” and “gear” indicates only one case of one-to-one correspondence - the driving element can be called a “gear” only if the number of teeth is equal to the driven one.

The introduction of the term “gear ratio” by GOST 16530-83 is not very clear: in a sense, this term duplicates the international term “gear ratio”[4]. The fact that most gears in various units have a gear ratio greater than one has led to the fact that the terms “gear ratio” and “gear ratio” are often perceived as synonyms in everyday life. But in reality this is a mistake. Given the specific formulation of the term “gear ratio”, it should always be understood that the gear ratio is not necessarily equal to the gear ratio. It can coincide with the absolute value of its value, if it is greater than one (the leading one is the gear): ( u = i {\displaystyle u=i} ) if ( i > 1 {\displaystyle i>1} ) Or be equal to its inverse value, if it is less than one (the wheel is driving): ( u = 1 / i {\displaystyle u=1/i} ) if ( i < 1 {\displaystyle i<1} )

Changing the gearbox ratio: gearbox tuning

As you know, the best dynamic performance is achieved in the speed range of maximum torque, and not power. In fact, at the lower and upper values of the crankshaft speed, the engine torque is less than the maximum.

It turns out that the more the revolutions differ from the maximum torque revolutions, the slower the car accelerates. In standard gearboxes, the gear ratio of each stage is selected so that the driver can comfortably accelerate the car in low gears, after which in higher gears the selected speed can be maintained while saving fuel.

In practice, the engine in this case quickly reaches maximum speed in a lower gear, but after switching to a higher gear the speed does not drop, for example, 3500 rpm. at 1800, but remain at around 2500. In fact, after shifting up, the speed still remains in the maximum torque range.

To solve this problem, you can use wheels with a smaller radius, and you also need to install another main gearbox pair with a changed gear ratio (for example, 3.9 or 4.1 instead of 3.7). Let's start by using "stock" parts.

As a rule, if a car model is produced with different engines (for example, 1.2, 1.4 and 1.6 liter engines), then the main pair for the gearbox paired with a 1.6 liter engine is used from the version whose engine is less powerful (in this case, a 1.2 or 1.4 engine ).

At high speeds, the engine will spin up to maximum speed at 5th, which can cause discomfort to the driver and passengers. For this reason, a number of gearbox ratios must be selected taking into account specific tasks and goals, taking into account engine power, vehicle weight, and driver preferences.

If you make more serious modifications, then you can assemble a gearbox with a modified set of gears. Naturally, this is expensive, but it manages to bring the rows closer together in all gears, and not just 4th and 5th.

We also add that the standard 5-speed gearbox is sometimes converted into a 6-speed gearbox (especially when paired with a tuned forced engine). In fact, a sixth gear kit is integrated into the transmission. It is important to understand that in addition to the high cost of such modification, the overall reliability of such a box is reduced.

Gear ratio values

For a manual transmission operating in five-speed mode, the gear ratios are in the following ranges:

· 1st gear – from 3 to 4;

· 2nd gear – from 2 to 2.9;

· 3rd gear – from 1.2 to 1.9;

· 4th gear – from 0.9 to 1.2;

· 5th gear – from 0.7 to 0.9;

Reverse gear – from 3 to 4.

In automatic transmissions the ranges of values are somewhat wider. This was done so that the power unit operates more dynamically and smoothly in various modes. In addition, if the automatic gear ratios are set incorrectly, then driving the car will become uncomfortable with periodic jerks and impressive fuel consumption. Therefore, gear ratios located close to each other are considered optimal for automatic transmissions. With these parameters, the car will accelerate without unpleasant jerks when changing gears.

More details about the gear ratio will be discussed in this video:

What's the result?

As you can see, the gear ratio has a serious impact on the dynamic performance and characteristics of the car. As part of the design of a gearbox, engineers separately take into account engine power, the intended purpose of the vehicle, etc., based on which gear ratios are selected for the entire range of gears.

It is also possible to make changes only to the transmission, which in itself gives noticeable improvements. When tuning a transmission, it is necessary to take into account the feasibility of certain modifications, as well as take into account the modes in which a particular car will be operated.

The design and principle of operation of a manual gearbox. Types of mechanical boxes (double-shaft, three-shaft), features, differences

Gearbox differential: what is it, differential design, types of differentials. How does a gearbox differential work in a car transmission?

How does the gearbox work?

As you know, a manual gearbox (MT) is nothing more than a multi-stage gear reducer, the functions of which include changing torque. At the same time, changing gears (speeds) can only be done manually, which is why it is often called a manual gearbox.

Absolutely any gearbox consists of a set of shafts and gears located on them. The drive shaft is connected to the flywheel through a clutch, and the driven shaft, in turn, has a rigid connection to the driveshaft. Between them there is an intermediate shaft, which directs rotation from the drive to the driven shaft. Moreover, all three of these nodes interact with each other through gears located on them. In order to reduce noise, these gears are made helical.

Thus, the principle of operation of the gearbox can be reduced to the kinematic connection of the drive and driven shafts, caused by various combinations of gears with different gear ratios (RG).

We calculate the gear ratio of the gearbox

IF is the ratio of the number of teeth of the driven gear to the number of teeth of the drive gear. Thus, it is calculated quite simply. Let’s say if the first has 50 teeth, and the second has 25, then dividing the first by the second number (50:25), we get 2. The last digit will be the IF value of this pair. But if you have no idea what the IF value of your transmission is, then you can calculate it quite easily. To do this you will need an inspection hole and a jack.

After placing the car on the inspection hole, install a wheel chock to avoid various unpleasant moments. Then place the gearshift lever in neutral and slightly raise one of the drive wheels using a jack. Next, you need to make chalk marks on the floor and the wheel so that they clearly coincide. Similar marks must be placed on the housing and flange of the gearbox.

In further steps, you will need an assistant; someone (for example, you) must rotate the wheel and count the number of revolutions made, while a partner (your friend) counts the number of revolutions of the driveshaft. As soon as the marks match again, you must stop counting. As a result, you will get two values, the number of wheel revolutions is divided in half, and then the cardan revolutions must be divided by the resulting value. The result will be the desired gear ratio.

How are gearbox ratios calculated?

Algorithm for determining the gear ratio of the box:

- We take the formula K = Kvm/Kvsh as the base one, where Kvm is the number of teeth of the driven gear, Kvsh is the number of teeth of the drive gear. If, say, it is necessary to determine the frequency of torque to the wheels from the transmission, it is necessary to take as the initial data the number of teeth of the differential gear that will be driven, and the number of teeth of the gearbox secondary shaft. The resulting value is called the IF of the main pair;

- So, let there be 15 teeth on the box located on the secondary shaft, and 53 teeth on the differential gear. Substituting these values into our formula, we obtain an IF value for this pair equal to 3.5. This means that the differential shaft will rotate 3.5 times slower than the secondary shaft of the box;

- In the same way, the IF is calculated for each pair of gears present in the transmission. The closer they are, the smoother the car will accelerate if the gears are switched sequentially one after another. Using the gearbox ratios, you can calculate the engine rotation speed, or rather, the speed difference between high and low gears, by dividing the first gear drive by the highest gear drive;

- An increase in the gear ratio leads to faster acceleration of the car, but you will have to switch more often. The smaller the inverter, the higher the maximum achievable speed, but it will take longer to accelerate.

In principle, this method of calculation is used when developing a transmission, but here a lot depends on the accuracy of the selection of gear ratios - this affects not only the maximum speed of the car, but also its dynamic characteristics.

You can find out the inverter for a specific car model by looking at its technical characteristics in the user manual. If you couldn’t find any, you can calculate the ratio for each pair of manual transmissions yourself.

This is done as follows:

- the car is driven into the pit, all wheels except one drive wheel are secured with wheel chocks;

- set the gearshift lever to the neutral position;

- We use chalk to record the current position of the wheel, placing marks on the tire and floor (ensuring their alignment);

- We perform a similar operation with the flange and gearbox housing;

- Let the assistant rotate the wheel, and you count how many revolutions the gearbox shaft makes. The assistant ensures that the marks match again by counting the number of wheel revolutions;

- divide the resulting value in half, and then by the number of revolutions made by the driveshaft. The resulting value will be the desired gear ratio.

The influence of the gear ratio on the dynamics of the car

A correctly selected gearbox ratio is the key to coordinated operation of the entire transmission. When selecting it, you should be guided, first of all, by the power and torque characteristics of the engine, as well as the size of the wheels and, of course, the personal wishes of the driver. By changing the inverter, you can reduce or increase the amount of redirected torque. This is done by changing the number of teeth on each gear.

The higher the value of this number, the more “powerful” and “shorter” the transmission will be, which means that the engine will turn out the required number of revolutions much faster, while the speed is picked up just as quickly, but there is a need for more frequent gear changes, and, consequently , the maximum speed value at each stage will be slightly reduced. Higher IF results in faster acceleration.

Reducing the gear ratio results in an increase in maximum speed, but this is only good if the engine has sufficient power reserves. But this negatively affects the acceleration dynamics of the car. The closer the IF values, the faster and smoother the acceleration will be when changing gears. During normal driving, the number of revolutions should be in the range of 2-2.5 thousand, this value can be seen on the tachometer, as soon as the revolutions exceed this value, and you still need to pick up speed, you need to switch to a higher gear. Of course, gear shifting should only be sequential.

Gear Ratio - What is Gear Ratio?

What is the gear ratio of the gearbox and final drive?Sergey Krovovyaz, Kirovograd

The gear ratio is nothing more than the ratio of the number of teeth of the driven gear to the number of teeth of the drive gear (gearbox or gearbox). In practice it looks like this. If one (driven) gear has 60 teeth, and the other (drive) has 30, then the gear ratio of this pair is 2 (60:30).

Gear ratio is one of the main characteristics of gears, which ensure the transmission of torque from the engine to the drive of some other device (unit). Moreover, this mechanism allows you to increase or decrease the amount of transmitted torque. For example, by changing the number of teeth on both gears, you can increase or decrease the torque transmitted from the engine to the “consumer”. In conventional cars, the torque transmitted from the internal combustion engine to the drive wheels through the gearbox (except 4th, 5th and 6th gears) and the drive axle gearbox increases. In many SUVs, the amount of torque transmitted is additionally changed by a transfer case with a low range of gears.

The gear ratio in the gearbox and gearbox affects such characteristics as acceleration dynamics and maximum vehicle speed. In relation to gearbox stages with different gear ratios, it looks like this: the larger this number, the “shorter” and “more powerful” the transmission, that is, when accelerating, the engine spins up faster to maximum speed, and the car accelerates more intensely. True, this reduces the maximum speed in this gear. Consequently, there is a need for more frequent switching.

The acceleration dynamics are influenced to the same extent by the gear ratio of the main gearbox pair. The higher it is, the more dynamic the car is, the better it pulls in all gears, but the maximum speed is lower. By reducing the gear ratio, they increase the maximum speed (if the engine has a so-called power reserve), but lose in the acceleration dynamics of the car. For example, installing the main pair 4.1 or 4.3 instead of 3.9 makes the VAZ-2107 more dynamic, but less fast.

It is worth noting that transmission gear ratios are selected depending on the power and torque characteristics of the engine, wheel size, braking system capabilities, and if the car is tuned, the wishes of the car owner are also taken into account.

Prepared by Yuri Datsyk, Sergey Ivanov Photos of manufacturing companies