Engines

Replacing the timing belt on an AGU engine (rus.)

Photo report

Replacing the timing belt on an AEH engine (rus.)

Photo report We have a 1.6 AEH engine. I finally decided to replace the timing belt, the mileage was 130 thousand km, I opened the cover, there was an original, apparently original. I'm 90 percent sure that they didn't change it. I also ordered the original and the SKF video through exist. I received it the other day and was upset, a DAYCO belt arrived, albeit with VW AUDI badges. Without icons it costs 3 times cheaper!

ASZ engine, preheating repair, glow plugs, temperature sensors (rus.)

Photo report

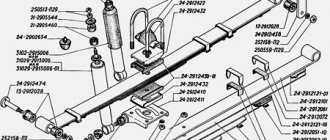

We tighten the oil pump chain on engines: AER, AEX, AEE, ALL. Replacing the timing belt and oil seal KV (rus.)

Photo report

Replacing intake manifold gaskets on an AKL engine (rus.)

Photo report

Skoda Octavia 1.9 TDI AGR engine, do-it-yourself service (rus.)

Photo report There are many reasons for the need to service any car on your own. Maybe the photos posted will help someone with this. And so, we have a Skoda Octavia 1.9 TDI engine letter code AGR. We change the oil and all filters. At the same time, we try to fulfill the requirements of the service instructions known to us, and especially regarding cleanliness, since dirt catastrophically reduces the service life of any engine, especially a diesel engine, and even one with a turbine...

Loss of power during acceleration, underblowing of the turbine, description of problems, removal of logs and diagnostics (rus.)

If problems arise related to loss of power during acceleration, both constant and variable loss of traction while driving. Loss of traction in the “full throttle” mode or the engine goes into emergency mode (it moves, but does not pull or pulls weakly), read this entire text carefully, and 9 out of 10 that this will help you establish the exact cause of the problem...

Repair of intercooler Skoda Octavia, AGU engine (rus.)

Photo report

Skoda Octavia 1998-2004: Repairing a SOHC petrol engine without removing it from the car (rus.)

Engines considered are AEE, AEH, AKL, AVU, BFQ, AEG, APK, AQY, AZH, AZJ.

Skoda Octavia 1998-2004: Repairing a DOHC gasoline engine without removing it from the car (rus.)

Engines AXP, BCA, AGN, AGU, ARX, ARZ, AUM, AUQ are considered.

Skoda Octavia 1998-2004: Repairing a diesel engine without removing it from the car (rus.)

Engines considered are AGP, AQM, AGR, ALH, AHF, ASV, ASZ.

Skoda Octavia 1998-2004: Engine removal and overhaul. (rus.)

The engines considered are AEE, AEH, AKL, AVU, BFQ, AEG, APK, AQY, AZH, AZJ, AXP, BCA, AGN, AGU, ARX, ARZ, AUM, AUQ, AGP, AQM, AGR, ALH, AHF, ASV, ASZ.

Information on VAG engine repair / Engines repair

This engine repair information applies to all VAG vehicles. To quickly find documentation for your engine, simply press Ctrl-F on your keyboard and type the letters of your engine. For example: 2E or BSE (English only!)

Malfunctions

The VW 1.6 bfq engine is considered to be quite reliable, allowing you to drive more than 300 thousand km without major repairs, however, it also has a number of typical malfunctions, some of which are shown in the table.

| FAULT | CAUSE |

| The engine is unstable (the crankshaft speed floats in idle mode). | The injectors, throttle valve, and idle air control may be faulty. |

| Increased engine oil consumption. | Worn piston rings. Oil seals are damaged. |

| Extraneous knocking noises during operation of the power unit. | The intake manifold has failed. Faulty hydraulic valve compensators. |

An unpleasant feature that owners of cars equipped with a bfq engine often encounter is the strong vibration of the engine during operation. You can eliminate this defect:

- flashing the electronic engine control unit;

- increasing the crankshaft speed in idle mode.

Injection, ignition systems

Replacing spark plugs on a BFQ engine in a Skoda Octavia (rus.)

Photo report Replacing spark plugs is a simple operation, but on this engine everything turned out to be quite difficult. The fact is that the spark plugs are located under the intake manifold so that it is not possible to disconnect even the high-voltage wires...

Replacing spark plugs on AGU, ARX engines (rus.)

Photo report Replacing spark plugs in AGU and ARX engines on Skoda Octavia and VW Golf 4. Remove the plastic engine protection and see 4 ignition coils, one is located under the plastic part (all shown by arrows). We unscrew it, the nut is 10, and tilt it to the side...

Repair of ECU number 06A 906 019 F of AKL engine - no idle, Simos injection system (rus.)

Photo report

Cleaning the throttle valve on the AKL engine, followed by adaptation (rus.)

Photo report

Replacing the contact group of the ignition switch on a Skoda Octavia (rus.)

Photo report I changed the ignition switch contact group for a Skoda Octavia Tour 2005, I decided to make a report, because... everything I haven’t seen is not suitable for this model, signs of illness - not everything the starter always starts working when you turn the key in the ignition, especially when it’s hot, I bought the part, all that remains is to change it. When replacing after removing the airbag (disconnecting the connector), it is advisable not to turn on the ignition, otherwise the computer will write an error, which will then have to be erased...

Diesel engine air flow meter (MAF) - Pierburg, insert into the flow meter housing LMM 7.22684.08 (rus.)

Photo report

Fault detection program for Skoda Octavia A4 (1U) (rus.)

Factory repair manual. The troubleshooting program is an extremely useful text flowchart for identifying problems in a particular vehicle, taking into account the specifics of the factory equipment installed on it. Actually, this is a text version of what later became part of VAG diagnostic tools under the name “Guided Fault Finding”. 49 pages. 1 Mb.

Skoda Octavia 1998-2004: Ignition system - models with gasoline engines (rus.)

Skoda Octavia 1998-2004: Preheating system - models with diesel engines (rus.)

Skoda Octavia: Repair of the ignition system.

Engine 1.6 55kW (rus.) Skoda Octavia: Ignition system control. Engine 1.6 74kW (rus.) Skoda Octavia: Ignition system repair.

Engine 1.8 92kW (rus.) Injection and ignition systems

This information on injection systems is suitable for all VW, Skoda, SEAT, Audi cars.

General information on ignition systems

Suitable for many VW, Skoda, SEAT, Audi cars

Dimensions

Models with an MPI injection system, such as the A5, are medium in size, which makes the driving process comfortable and easy for the driver and passengers. The length of the car reaches 4507 mm, the width and height are respectively calculated as 1731 * 1431 mm, the ground clearance is 134 mm. This slightly distinguishes the A5’s ground clearance from other models, but is optimal. The curb weight of the device is 1205 kilograms.

The characteristics of the Octavia model make it clear that it is comfortable and convenient. To improve movement, there is an armrest located in the cabin, as well as a host of other amenities. The ground clearance on the 1.6 MPI model ensures a comfortable and quiet ride on any type of road, as evidenced by numerous reviews from satisfied owners of this car.

The Skoda 1.6 MPI model, for example the A5, is a real find for anyone who wants to ensure driving comfort.

Fuel System

Replacing the fuel filter on the Skoda Octavia AEE engine (rus.)

Photo report

Skoda Octavia 1997 ->: Engine 1.9L / 50kW SDI (AGP, AQM) Repair manual (rus.)

Technical data, Removal and installation of the engine, Crank mechanism, Cylinder head, valve timing, Lubrication system, Cooling system, Power system, Exhaust system. (8 Mb.)

Skoda Octavia / Octavia Tour 1996-2009: Engine power system 1.6 (AKL / AEH) (rus.)

Repair and maintenance in color photos.

Skoda Octavia 1998-2004: Power system - models with gasoline engines (rus.)

Skoda Octavia 1998-2004: Power system - models with diesel engines (rus.)

Installing a fuel pump from a VAZ on a Skoda Octavia AGU engine (rus.)

Photo report

General information on fuel systems

Suitable for many VW, Skoda, SEAT, Audi cars

Car dimensions 1.4

In terms of dimensions, the machine is quite optimal and convenient; in length, width and height, respectively, the parameters reach 4513, 1731, 1457 mm. Ground clearance – 134 mm. The wheelbase has a size of 2512 mm, the front and rear tracks are 1513/1494 mm, respectively. The curb weight with which this car is equipped is 1230 kilograms, the total weight is 1750 kg. The front-wheel drive engine is equipped with a 5-speed gearbox.

The 2008 model with a 1.4 engine is distinguished by high-quality technical parameters and a relatively low price, which makes it preferred among many motorists in Russia and the CIS.

If you doubt the quality of the car, you can read numerous reviews from owners, evaluate photos and take into account the main technical characteristics of the car.

Exhaust system

Skoda Octavia: Exhaust system.

Engine 1.6/55kW (rus.) Skoda Octavia: Exhaust system. Engine 1.6/74kW (rus.) Skoda Octavia: Exhaust system. Engine 1.8/92kW (rus.) Skoda Octavia: Exhaust system. Engine 1.9/50kW (rus.) Skoda Octavia: Exhaust system.

Engine 1.9/66kW (rus.) Skoda Octavia 1998-2004: Emissions control and exhaust system - models with petrol engines (rus.)

Skoda Octavia 1998-2004: Emissions control and exhaust system - models with diesel engines (rus.)

Skoda Octavia 1997 ->: Engine 1.9L / 50kW SDI (AGP, AQM) Repair manual (rus.)

Technical data, Removal and installation of the engine, Crank mechanism, Cylinder head, valve timing, Lubrication system, Cooling system, Power system, Exhaust system. (8 Mb.)

General information on exhaust systems

Suitable for many VW, Skoda, SEAT, Audi cars

Skoda Octavia engines. Official fuel consumption per 100 km.

Generation 1 (1996-2000)

Gasoline:

- 1.4, 60 l. p., manual, front, 18 sec to 100 km/h, 10.5/5.7 l per 100 km

- 1.6, 101 l. p., manual/automatic, front, 11.7 sec to 100 km/h, 10.7/5.9 l per 100 km

- 1.6, 75 l. p., manual, front, 14.4 sec to 100 km/h, 10.8/5.8 l per 100 km

- 1.8, 125 l. p., manual, front, 10.4 sec to 100 m/h, 11.9/6.3 l per 100 km

- 1.8, 125 l. p.s., automatic, front, 8.4 sec to 100 km/h, 12/6.4 l per 100 km

- 1.8, 150 l. p., manual, front, 12.4 sec to 100 km/h, 13.4/6.8 l per 100 km

- 1.8, 150 l. p.s., automatic, front, 9.9 sec to 100 km/h, 12.8/6.9 l per 100 km

- 2.0, 115 l. p.s., automatic, front, 12.6 sec to 100 km/h, 12.6/6.8 l per 100 km

- 2.0, 115 l. p., manual, front, 10.8 sec to 100 km/h, 11.2/6.1 l per 100 km

Diesel:

- 1.9, 68 l. p., manual, front, 18.3 sec to 100 km/h, 7.2/4.2 l per 100 km

- 1.9, 90 l. p., manual, front, 13.7 sec to 100 km/h, 6.8/4.3 l per 100 km

- 1.9, 90 l. p.s., automatic, front, 15 sec to 100 km/h, 6.6/4.8 l per 100 km

- 1.9, 110 l. p., manual, front, 11.3 sec to 100 km/h, 6.6/4.1 l per 100 km

- 1.9, 130 l. s, manual, front, 9.7 sec to 100 km/h, 7/4.3 l per 100 km

Restyling generation 1 (2000-2010)

Gasoline:

- 1.4, 60 l. p., manual, front, 18 sec to 100 km/h, 10.5/5.7 l per 100 km

- 1.6, 101 l. p., manual/automatic, front, 11.7 sec to 100 km/h, 10.7/5.9 l per 100 km

- 1.6, 75 l. p., manual, front, 14.4 sec to 100 km/h, 10.8/5.8 l per 100 km

- 1.8, 125 l. p., manual, front, 10.4 sec to 100 m/h, 11.9/6.3 l per 100 km

- 1.8, 125 l. p.s., automatic, front, 8.4 sec to 100 km/h, 12/6.4 l per 100 km

- 1.8, 150 l. p., manual, front, 12.4 sec to 100 km/h, 13.4/6.8 l per 100 km

- 1.8, 150 l. p.s., automatic, front, 9.9 sec to 100 km/h, 12.8/6.9 l per 100 km

- 2.0, 115 l. p.s., automatic, front, 12.6 sec to 100 km/h, 12.6/6.8 l per 100 km

- 2.0, 115 l. p., manual, front, 10.8 sec to 100 km/h, 11.2/6.1 l per 100 km

Diesel:

- 1.9, 68 l. p., manual, front, 18.3 sec to 100 km/h, 7.2/4.2 l per 100 km

- 1.9, 90 l. p., manual, front, 13.7 sec to 100 km/h, 6.8/4.3 l per 100 km

- 1.9, 90 l. p.s., automatic, front, 15 sec to 100 km/h, 6.6/4.8 l per 100 km

- 1.9, 110 l. p., manual, front, 11.3 sec to 100 km/h, 6.6/4.1 l per 100 km

- 1.9, 130 l. s, manual, front, 9.7 sec to 100 km/h, 7/4.3 l per 100 km

Generation 2 (2004-2008)

Gasoline:

- 1.4, 80 l. p., manual, front, 14.2 sec d 100 km/h, 9.6/5.6 l per 100 km

- 1.6, 102 l. p.s., automatic, front, 14.1 sec to 100 km/h, 11.2/5.9 l per 100 km

- 1.6, 102 l. p., manual, front, 12.3 sec to 100 km/h, 9.7/5.7 l per 100 km

- 1.8, 160 l. p., manual, front, 8.1 sec to 100 km/h, 10.1/5.9 l per 100 km

- 1.6, 115 l. p.s., automatic, front, 12.4 sec to 100 km/h, 10.6/5.8 l per 100 km

- 1.6, 115 l. p., manual, front, 11.2 sec to 100 km/h, 8.7/5.4 l per 100 km

- 2.0, 150 l. p.s., automatic, front, 10.1 sec to 100 km/h, 11.8/6.3 l per 100 km

Diesel

- 1.9, 105 l. s., robot, front, 12.2 sec to 100 km/h, 7.7/4.7 l per 100 km

- 1.9, 105 l. p., manual, front, 11.8 sec to 100 km/h, 6.5/4.3 l per 100 km

Restyling generation 2 (2008-2013)

Gasoline:

- 1.4, 80 l. sec., manual, 14.2 sec to 100 km/h, 9.6/5.6 l per 100 km

- 1.6, 102 l. p.s., automatic, front, 14.1 sec to 100 km/h, 11.2/6.1 l per 100 km

- 1.6, 102 l. p., manual, front, 12.3 sec to 100 km/h, 10/5.8 l per 100 km

- 1.4, 122 l. p., manual, front, 9.7 sec to 100 km/h, 8.5/5 l per 100 km

- 1.4, 122 l. s., robot, front, 9.7 sec to 100 km/h, 8/5.3 l per 100 km

- 1.8, 152 l. p., manual, front, 8.1 sec to 100 km/h, 9.5/5.5 l per 100 km

- 1.8, 152 l. p.s., automatic, front, 8.8 sec to 100 km/h, 10.8/5.9 l per 100 km

Generation 3 (2013-2017)

Gasoline:

- 1.4, 150 l. p.s., manual, front, 8.1 sec up to 100 km/h, 6.9/4.9 l per 100 km

- 1.6, 110 l. p.s., automatic, front, 12.2 sec to 100 km/h, 9/5.3 l per 100 km

- 1.4, 150 l. s., robot, front, 8.2 sec to 100 km/h, 6.6/4.8 l per 100 km

- 1.8, 180 l. s., robot, front, 7.4 sec to 100 km/h, 7.6/5.3 l per 100 km

- 1.8, 180 l. p.s., manual, front, 7.3 sec to 100 km/h, 8.2/5.5 l per 100 km

Diesel:

- 2.0, 150 l. s., robot, front, 8.6 sec to 100 km/h, 5.8/4.6 l per 100 km

Restyling of generation 3 (2017-present)

Gasoline:

- 1.4, 150 l. p.s., manual, front, 8.1 sec up to 100 km/h, 6.9/4.9 l per 100 km

- 1.6, 110 l. p.s., automatic, front, 12.2 sec to 100 km/h, 9/5.3 l per 100 km

- 1.4, 150 l. s., robot, front, 8.2 sec to 100 km/h, 6.6/4.8 l per 100 km

- 1.8, 180 l. s., robot, front, 7.4 sec to 100 km/h, 7.6/5.3 l per 100 km

- 1.8, 180 l. p.s., manual, front, 7.3 sec to 100 km/h, 8.2/5.5 l per 100 km

Front and rear suspension

Skoda Octavia 1998-2004: Drive axle shafts (rus.)

Skoda Octavia: Chassis - Front suspension (rus.)

Repair manual for

Skoda Octavia: Chassis - Rear suspension (rus.)

Repair manual

Replacing CV joints on Skoda Octavia (rus.)

Photo report

Diagnostics and replacement of the Haldex clutch pump in Skoda Octavia 4×4 (rus.)

Report

Repair of 1st generation Haldex pump 02D 525 557, for Skoda Octavia Tour 1.8T ARX 4×4 (rus.)

Photo report

Skoda Octavia: 4×4 all-wheel drive. (rus.)

Device and principle of operation. Self-education program manual. All-wheel drive, Manual transmission, Rear axle final drive, Propeller shaft, All-wheel drive vehicle modification (Rear axle, Fuel tank, Underbody, Exhaust system), Haldex clutch (System description, Mechanical components, Multi-plate clutch) Hydraulic system, General description of the system, Sensors, Control unit, Drives, Self-diagnosis, Functional diagram, Driving modes.

General information on suspension

Suitable for many VW, Skoda, SEAT, Audi cars

Price in Russia

Unfortunately, there is no official information on the cost of the 2020 Skoda Kodiak all-wheel drive crossover in our country yet, but according to some rumors the price will be about 1,890,000 rubles. The main competitors can be considered:

- Kia Sorento price 1,594,900 – 2,154,000 rubles;

- Kia Sorento Prime price 2,249,900 – 2,609,900 rubles;

- Hyundai Santa Fe Premium price 1,844,000 – 2,397,000 rubles;

- Mitsubishi Outlander price 2,499,000 rubles;

- Nissan X-Trail price 1,409,000 – 1,999,000 rubles.

The advantages of Kodiaq include:

- practicality;

- spacious interior;

- comfortable seats;

- comfort;

- excellent touch display;

- dynamics;

- controllability;

- high quality of materials used;

- ergonomics.

Flaws;

- a cramped third row that can only accommodate children;

- controversial front design;

- high price.

To summarize, we can say that Czech manufacturers managed to create a good family car that is suitable for traveling long distances. To achieve this, the crossover has an economical and dynamic engine, a spacious interior designed for a large family and proper comfort. But unfortunately the car is not well suited for off-road use; the Kodiak has an excellent all-wheel drive system based on the 5th generation Haldex, but the overhangs and long wheelbase spoil everything. On the other hand, most potential owners buy such cars for driving in the city, for which the Kodiak is ideally suited.

edit this post

Brake system (ABS, EDS, ESP / Brake system)

Skoda Octavia 1998-2004: Brake system (rus.)

Skoda Octavia: Anti-lock braking system ABS - ITT Mark 20 IE (rus.)

Skoda Octavia: Mechanical part of the brake system (rus.)

Calipers, drums, etc.

Skoda Octavia: Vacuum brake booster, brake master cylinder (rus.)

Skoda Octavia Tour - Security systems (rus.)

Device and principle of operation. Self-education program manual. ABS, ABS+EBD, EDL, Electronic stabilization system ESBS, EBC. Engine braking control, CAN information bus, ABS self-diagnosis, ABS service, ABS/EDL functional diagram, Pedal assembly, Side airbags, Alarm system.

Replacing the vacuum booster for Skoda Octavia 1U (rus.)

Photo report

ESP repair - soldering of the lateral acceleration sensor G200 (rus.)

Photo report ESP unit number 1J0 907 657 A / acceleration sensor 1J0 907 651A installed on cars: VW Golf 4 / Bora (1J), VW New Beetle (1C, 9C), VW Lupo (6X, 6E), VW Polo 3 (6N) , VW Sharan (7M), VW Transporter T5 (7H), Skoda Octavia (1U), Audi A2 (8Z), Audi A3 (8L), Audi TT (8N), SEAT Alhambra (7V), SEAT Ibiza / Cordoba (6K ), SEAT Leon / Toledo (1M). It is likely that this information will also apply to other cars.

Skoda Octavia: Security systems (rus.)

Design and description of work. Self-education program manual. Active safety systems are constantly being improved and, in combination with passive safety systems, help prevent or reduce the consequences of accidents more than ever. Contents: ABS - Anti-lock braking system, ABS+EBD - Electronic brake force distribution, ABS sensors, ABS power drive, Anti-lock braking system braking, EDL, Electronic stabilization system ESBS, EBC, Engine braking control, CAN information bus, ABS self-diagnosis, ABS service, ABS/EDL functional diagram, Pedal assembly, Side airbags, Task and functioning, Maintenance work, Self-diagnosis, Block diagram, Alarm system.

Braking and stabilization systems (rus.)

Device and principle of operation. Self-study program Over the past thirty years, car manufacturers and brake system suppliers have been developing braking and stability systems that help drivers cope with certain critical situations. These systems, together with seat belts and airbags, are among the most important elements of the active safety system. Myths about safety systems Due to poor awareness of the principles of operation of auxiliary systems, there are many rumors among amateurs. The most frequently heard myths include the following incorrect statements: • the ABS system increases the braking distance; • with the help of fast, intermittent braking, the ABS system can be replaced; • the ESC system intervenes in vehicle control prematurely and inaccurately; • the ESC system is capable of eliminating any critical situation for the driver while driving

Contents: The importance of braking and stabilization systems, Increasing the active safety of a vehicle, Facilitating travel and increasing driving comfort, Elements of active vehicle safety, Braking and stabilization systems as structural elements of active safety, The place of braking and stabilization systems in ensuring road safety, Categories of braking systems and stabilization: Overview of braking and stabilization systems, Hierarchy of braking and stabilization systems, Application of systems depending on the driving mode, Fundamentals of driving dynamics: Friction circle, Tire slippage, Braking process, Sensors: Logic of the sensors of braking and stabilization systems, Sensors used in circuits braking and stability systems, Data exchange protocol, Anti-lock braking system (ABS): Functional requirements for the ABS system, Behavior of a car without ABS, Behavior of a car with ABS, ABS system components, ABS hydraulic circuit, ABS operating principle, Electronic brake force distribution (EBV) ), Cornering Brake Control (CBC), Yaw Moment Reduction (GMB), Anti-Slip Control (ASR): Layout, How ASR works, Engine Brake Torque Control (MSR): Description of principle operation, Electronic Stability Control (ESC): Principle of vehicle stabilization with ESC, Hydraulic circuit of ESC system, Electronic Differential Lock (EDS): Operation principle of EDS, Extended Differential Lock (XDS): Layout, Operation principle, Hydraulic Brake Assist (HBA): Layout, Description of the operating principle of the HBA, Overboost Brake Compensation (FBS), Hydraulic Brake Boost (HBV), Trailer Stability Assist (TSA), Active Steering Assist (DSR): Description of the principle functions, Hill Start Control (HHC), Brake Wet Control (BSW), Tire Pressure Monitor (TPM): Description of the operating principle, Hill Start Control (off-road): Activation conditions, Deactivation conditions, Drive Assist on a descent - activation of the function, Downhill assist - driving around bends in the terrain, ABS-Offroad function, EDS-Offroad function, ASR-Offroad function, Braking assistants and legislation, Glossary.

General information on brake systems, ABS, EDS, ESP, etc.

Suitable for many VW, Skoda, SEAT, Audi cars

Engine Skoda Octavia A5

Skoda Octavia cars are equipped with transversely mounted four-stroke four-cylinder petrol injection 8-valve engines with a displacement of 1.6 liters. as well as 16-valve engines with a displacement of 1.4 liters with turbocharging and 2.0 liters with direct injection. The engines are highly efficient and meet the requirements of the Euro-5 standard.

The operation of a piston internal combustion engine is based on the use of thermal expansion work of heated gases during the movement of the piston from top dead center (TDC) to bottom dead center (BDC). Heating of gases in the TDC position is achieved as a result of combustion of fuel mixed with air in the cylinder. At the same time, the gas temperature and pressure increase. Since the pressure under the piston is equal to atmospheric pressure, and in the cylinder it is much higher, the piston will move downward under the influence of the pressure difference, and the gases will expand, doing useful work. In order for the engine to continuously produce mechanical energy, a mixture of air and fuel must be periodically supplied to the cylinder through the intake valve. The products of fuel combustion after their expansion are removed from the cylinder through the exhaust valve. These tasks are performed by the gas distribution mechanism, which controls the opening and closing of the valves, and the fuel supply system. The engine operating cycle is a periodically repeating series of sequential processes occurring in each cylinder of the engine and causing the conversion of thermal energy into mechanical work. Car engines typically operate on a four-stroke cycle, which is completed in two revolutions of the crankshaft or four strokes of the piston and consists of intake, compression, expansion (power stroke) and exhaust strokes.

Features of the design of the 1.6 liter engine The design features of the engine are considered using the example of a 1.6 liter engine as the most common.

The engine is mounted transversely at the front of the car.

Engine (front view in direction of travel): 1 - oil sump; 2 - oil filter; 3 — auxiliary drive pulley; 4 - generator; 5 — thermostat housing; 6 — knock sensor; 7 — intake manifold; 8 — oil filler neck; 9 - bypass valve; 10 — additional air pump; 11 — automatic transmission selector position sensor; 12 — oil pressure sensor; 13 - starter; 14 — crankshaft position sensor; 15 — gearbox sensors

Engine displacement (displacement) is one of the most important design parameters of an internal cropping engine (ICE), expressed in liters (l) or cubic centimeters (cm3). The engine displacement largely determines its power and other operating parameters. It is equal to the sum of the working volumes of all engine cylinders. In turn, the working volume of the cylinders is determined as the product of the cross-sectional area of the cylinder and the length of the piston stroke (from BDC to TDC). According to this parameter, a distinction is made between long-stroke engines with a piston stroke length exceeding the cylinder diameter, and short-stroke engines with a piston stroke less than the cylinder diameter.

Engine (rear view in direction of travel): 1 — gearbox; 2 — automatic transmission heat exchanger; 3 — mounting area for the left suspension support of the power unit; 4 - water distributor; 5 - bypass valve; 6 — throttle assembly; 7 — oil filler plug; 8 — adsorber valve; 9 — intake manifold receiver; 10 — timing belt flap; 11 — bracket for the right suspension support of the power unit; 12 — control oxygen concentration sensor; 13 — cylinder block; 14 — crankshaft pulley; 15 — oil drain plug

The engine cylinder head is made of aluminum alloy according to a transverse cylinder blowing pattern (intake and exhaust channels are located on opposite sides of the head). Valve seats and guides are pressed into the head. The intake and exhaust valves have one spring each, fixed through a plate with two crackers.

The separation plane between the head and the cylinder block is sealed with a gasket, which is a plate molded from thin sheet metal.

The cylinder block is a single casting that forms the cylinders, cooling jacket, upper crankcase and five crankshaft bearings designed as crankcase baffles. The blocks are made of aluminum alloy with cylinders bored directly into the body of the block. The main bearing caps are machined together with blocks and are not interchangeable. The cylinder blocks have special bosses, flanges and holes for fastening parts, assemblies and assemblies, as well as channels for the main oil line.

The crankshaft rotates in main bearings that have thin-walled steel liners with an anti-friction layer. The axial movement of the crankshaft is limited by two half-rings installed in the grooves of the middle main bearing bed.

The flywheel is cast iron, mounted on the rear end of the crankshaft and secured with six bolts. A toothed rim is pressed onto the flywheel to start the engine with a starter. In addition to it, the flywheel has a gear ring that ensures the operation of the top dead center sensor of the engine control system.

The pistons (Fig. 5.3) are made of aluminum alloy. On the cylindrical surface of the piston head there are annular grooves for the oil scraper ring and two compression rings.

The piston pins are installed in the piston bosses with a gap and pressed with interference into the upper heads of the connecting rods, which are connected by their lower heads to the crankpins of the crankshaft through thin-walled liners, similar in design to the main ones. The connecting rods are steel, forged, with an I-section rod.

The camshaft is driven from the crankshaft by a toothed belt. The camshaft support covers are combined into a monolithic frame structure. The intake and exhaust valves are closed using coil springs and move in guide bushings pressed into the cylinder head. The camshaft cams drive the valves through roller oscillating arms supported by hydraulic lash adjusters.

Combined type lubrication system. Lubricant enters the engine from an oil pump driven through a chain and a sprocket from the toe of the crankshaft. The pump takes oil from the oil pan through a strainer and forces it through a full-flow replacement oil filter mounted outside the engine. Next, the oil flows through the channels into the cylinder block, from where it is distributed to the support (main) bearings of the crankshaft and the camshaft to the cylinder head. Oil is supplied to the connecting rod journals through drillings in the crankshaft; oil is supplied to the camshaft bearings and hydraulic compensators under pressure. Cams and valves are splash lubricated, just like all other moving engine components. To cool the oil, an oil-liquid heat exchanger is built into the lubrication system.

The closed crankcase ventilation system does not communicate directly with the atmosphere, therefore, simultaneously with the suction of gases, a vacuum is formed in the crankcase under all engine operating modes, which increases the reliability of various engine seals and reduces the emission of toxic substances into the atmosphere.

The system consists of two branches, large and small.

When the engine is idling and at low loads, when the vacuum in the intake pipe is high, crankcase gases are sucked into the intake pipe through a small branch of the system.

At full load conditions, when the throttle valve is open to a large angle, the vacuum in the intake pipe decreases, and in the air supply hose it increases, and crankcase gases through the large branch hose connected to the fitting on the cylinder head cover mainly enter the air supply hose, and then through the throttle assembly into the intake pipe and engine cylinders.

The engine cooling system is sealed, with an expansion tank, and consists of a cast cooling jacket surrounding the cylinders in the block, combustion chambers and gas channels in the cylinder head. Forced circulation of coolant is provided by a centrifugal water pump driven from the crankshaft by a timing belt. To maintain the normal operating temperature of the coolant, a thermostat is installed in the cooling system, which closes a large circle of the system when the engine is not warmed up and the coolant temperature is low.

The engine power supply system consists of an electric fuel pump installed in the fuel tank, a throttle assembly, a fine fuel filter installed under the tank, a fuel pressure regulator installed in the fuel pump module, injectors and fuel lines, and also includes an air filter.

The engine ignition system is microprocessor-based and consists of an ignition module, high-voltage wires and spark plugs. The ignition module is controlled by the electronic engine control unit. The ignition system does not require maintenance or adjustment during operation.

The power unit (engine with gearbox) is mounted on two supports with elastic rubber elements on the right and left side, which absorb the bulk of the power unit. The lower jet thrust compensates for torque from transmissions and loads that occur when the vehicle starts, accelerates, and brakes.

Steering

Steering rack overhaul for Skoda Octavia A4, rack number 1J1 422 105 DE (rus.)

Photo report

Repair of the Airbag “spiral”, restoration of the airbag contact ring (rus.)

Photo report I beg to differ with the statements regarding the non-repairability of the “Airbag spiral”. As they say, “the collective farm was a success for me...” So we will need: a soldering iron, a tester, a cross-head screwdriver, a thin slotted screwdriver, flux, tin, sandpaper or a mini-drill, accuracy, patience...

Skoda Octavia: Repair Manual - Power Steering (rus.)

General information on steering

Suitable for many VW, Skoda, SEAT, Audi cars

Transmission, clutch

Removal and repair of gearbox type 02K (DUU, DUW), typical factory defect of rivets (rus.)

Photo report

Self-repair of valve body of automatic transmission 01M (rus.)

Photo report, suitable for cars: Automatic gearbox 01M, installed on cars: Skoda Octavia A4 / Skoda Octavia A4 (model code: 1U2, 1U5), etc.

Repair of hydraulic plate of automatic transmission 01M (rus.)

Photo report

Replacing speed sensor G68 on automatic transmission type 01M (rus.)

Photo report symptoms: shifting to 4th gear is delayed. After a few seconds (10-15) at a speed of about 80 km/h, a sharp gear change occurs with an impact. Error: 00281 - Vehicle Speed Sensor (G68).

Automatic transmissions (rus.)

Skoda technical manual. Training of service station specialists. Currently, automatic transmissions are installed on Skoda Fabia models: 001 (Jatko), on Skoda Octavia models: 01M, on second-generation Skoda Octavia models: 09G and 02E (DSG), on Skoda Superb models: 01V.

Replacement of gearshift lever housing (1J0711061A), Audi A3, Skoda Octavia, VW Golf IV / VW Bora, etc. (rus.)

Photo report

Information on repair of VAG gearboxes / Transmission repair

This transmission repair information applies to all VAG vehicles.

Body

Water gets into the backlight of the Skoda Octavia Tour A4 (rus.)

Photo report.

Repair of the central door lock and installation of a window lift repair kit for VW Golf 4 / Bora, VW Passat B5, etc. (rus.)

Photo report A common occurrence in all VW Golf 4, VW Passat B5, Skoda Octavia A4, etc. - these are problems with the central locking - we press close, the lock closes and immediately opens. Sometimes you have to struggle for a long time to lock the machine... The culprit is a cracked solder on the circuit board inside the lock. I hope this article will help many people save some money on repairs on their own...

How to properly assemble the glove box lamp (glove compartment) (rus.)

Photo report When disassembling the interior or replacing a light bulb, the glove compartment light often fell apart when pulled out. Assembling it is a non-trivial task, not everyone can do it. I had to remove my flashlight from the glove compartment in order to disassemble it and show how it is then assembled. We have 8 structural elements (one contact consists of two elements)…

Replacing the cabin filter on Skoda Octavia Tour 1.4 (2007) (rus.)

Photo report

Door handle repair for Skoda Octavia (rus.)

Photo report

Replacing the mics in the door locks with limit switches for VW Passat B5, VW Golf 4, Skoda Octavia (rus.)

Photo report

Eliminating the rattling of the driver's glass on the Skoda Octavia (rus.)

Photo report

Replacing the flexible rod of the driver's door Skoda Octavia (rus.)

Photo report

Resuscitation of the rear wiper on the Skoda Octavia (rus.)

Photo report

Replacing the turn signal lamp on the wing of a Skoda Octavia (rus.)

Photo report

DIY armrest in Skoda Octavia A4 (rus.)

Photo report

Removing minor body corrosion (rus.)

Photo report

Repairing bumpers on your own (rus.)

Photo report.

Skoda Octavia 1998-2004: Body and body equipment (rus.)

Repair manual.

Body check points Skoda Octavia I 1U2 (rus.)

Skoda Octavia: Body, assembly work (rus.)

Repair manual.

Skoda Octavia: Body - tin work (rus.)

Dimensions of all parts of the body. Skoda Octavia, Skoda Octavia Combi, Skoda Octavia RS, Skoda Octavia Combi 4x4.

Skoda Octavia: Air conditioning, heating system (rus.)

Repair manual.

Skoda Octavia: Wheels, tires, car measurements (rus.)

Repair manual.

General information on the body, tires and wheels

Suitable for many VW, Skoda, SEAT, Audi cars

Body

The car appeals to several of the latest styling trends, meaning a fairly neutral design. There are no fireworks, but it's also hard to talk about boredom - everything is made to order and looks very good. The lighting that looks best is made up of tiled headlights with dark filling and taillights that span the tailgate. The headlights are also covered with plastic covers that run along the lower edges of the housing.

Skoda Karoq 1.5

Electrical equipment

Repair of the Skoda Octavia A4 instrument panel - arrows fell (rus.)

Photo report

Replacing a generator pulley with a freewheel (rus.)

Photo report

Replacing Bosch generator bearings (rus.)

Photo report.

Replacing slip rings on a Bosch 70A generator (rus.)

Photo report It all started with the fact that the car began to start worse. The battery seems to be normal, it’s not cold outside. Having measured the charge with a tester, I saw 14.3-14.4. I calmed down, but in vain. Symptoms of undercharging continued. I decided to measure the charge not after starting the car, but after 30-40 minutes of driving and everything became clear - the tester showed 13.78-13.85. And this is not enough. If it's a short trip and I turn off the car several times, it's already difficult to start. Solution: generator analysis...

Repair of the steering column switch if your turn signal is “ticking”, platform A4 / PQ34 (rus.)

Photo report

Starter, overhaul with troubleshooting, 02A 911 023 T / 02A 911 023 TX (rus.)

Photo report

Repair, overhaul of starter 020 911 023 M (Bosch 0 001 112 038 (039)) (rus.)

Photo report

Repair of a gearbox (bushless) starter (rus.)

Photo report

Converting a Bosch starter from conventional to bushless (rus.)

Photo report

Repair of front windshield wipers, relay 389, wipers do not stop (rus.)

Photo report The other day the windshield wipers stopped stopping in the “Off” position (you could hear the double click of the relay and the passenger wiper didn’t go completely into place), they were rushing across the glass as if in second speed, the other modes worked fine, I had to drive for a day with the windshield wipers flapping at a minimum. . Everyone advised to look at the relay first, then the steering column, and then the trapezoid - I listened to them and was not mistaken...

Repair of electrical wires and connectors for Skoda cars (rus.)

Self-study program 091 Skoda. The purpose of this self-study program is to support Skoda service personnel in correctly carrying out repair work on the electrical wiring of Skoda vehicles. It brings together all the basic principles and recommendations on proper methods and procedures when performing work, using recommended tools and accessories in accordance with the current service documentation, including references to the relevant sections in the current service literature. In addition, examples of typical, most common cases of incorrect performance of individual works are given, indicating their consequences and recommendations on how these works should be performed correctly. Contents: Preface 1. Skoda service documentation: procedure for performing repair work with electrical wiring 2. Use of recommended tools and equipment 3. List of current TPI reports regarding repair work with electrical wiring in Skoda vehicles 4. Common errors when performing repair work with electrical wiring 5. Repair of connectors/contacts.

Skoda Octavia 1998-2004: Starting and charging system (rus.)

Skoda Octavia: Repair Manual - Troubleshooting (rus.)

Skoda Octavia: Repair Manual - Electrical equipment assembly points (rus.) Skoda Octavia: Repair Manual - Starter, alternator, battery (rus.) Skoda Octavia: Repair Manual - Dashboards, instruments (rus.) Skoda Octavia: Repair Manual - Radio, telephone, navigation system (rus.) Skoda Octavia: Repair Manual - Windshield wipers and washers (rus.) Skoda Octavia: Repair Manual - Lights, lamps, switches - external (rus.) Skoda Octavia: Repair Manual - Lamps, switches - internal, immobilizer (rus.) Skoda Octavia: Repair Manual - Wires, cables, fuse box (rus.) Skoda Octavia: Repair Manual - Relay panel, fuse box (rus.)

Skoda Octavia: Schematic diagram of electrical equipment (rus.)

8 MB

Skoda Octavia 1998-2004: Electrical equipment of the body, electrical diagrams (rus.)

Repair manual.

Skoda Octavia: Electronic comfort system (rus.)

Self-education program manual. Comfort system, Functions, Operating principle of the system, Central locking, Functional diagram, Electric windows, Interior lighting, Remote control, Mirror adjustment, mirror heater, Central control unit, Self-diagnosis, Special functions, Actions in case of an accident, Emergency operating modes of the system, System operation in sleep mode, Current central locking settings, Mechatronics, Door lock, Microswitch in the door lock actuator, Lever switch, CAN bus, Glossary.

Comfort system (rus.)

Device, description, diagnostics. We are considering Skoda Octavia, Skoda Octavia II, Skoda Fabia, Skoda SuperB.

Skoda cars: Dashboards - service (rus.)

History of control panels, their differences, diagnostic functions, block coding, panel fault table, etc.

Replacing the contact group of the ignition switch, for Skoda Octavia Tour (rus.)

Photo report

Installing cruise control on a Skoda Octavia 1U TDI with AGR, AHF, ALH engines (rus.) Skoda Octavia A4 speedometer does not work, replacing sensor 191 919 149 E (rus.)

Photo report

Installation of bi-xenon in Skoda Octavia Tour (A4), in standard reflector optics (rus.)

Photo report

Replacing the license plate lamp socket on a Skoda Octavia (rus.)

Photo report

Electrical System - general notes (eng.)

Edition 12.2014. Repair manual for electrical equipment of Skoda cars: Octavia 1997 -> Contents (repair groups): 27 — Starter, current supply, CCS, 92 — Windscreen wash/wipe system, 94 — Lights, bulbs, switches — exterior, 96 — Lights, bulbs, switches - interior, 97 - Wiring 73 pages. 2 Mb.

General information on electrical equipment

Suitable for many VW, Skoda, SEAT, Audi cars

Radios and radio navigation systems for Volkswagen, Audi, Skoda, Seat

Documentation for car radios and navigation Volkswagen, Audi, Skoda, Seat