The timing belt drives the camshafts, which control the opening and closing of the valves. Maintaining it in proper condition is extremely important for the stable and durable operation of the power plant. Excessive belt wear can cause the belt to jump one or more teeth. As a result, the motor will lose power, and extraneous noise will be heard during its operation. More severe consequences will arise if the timing belt breaks.

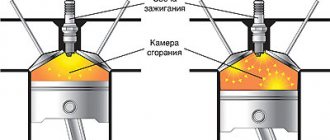

Timing drive structure

In this case, the pistons will hit the valves and the engine will completely lose its functionality. Repairs to eliminate the consequences of a broken belt are quite difficult to do with your own hands, and its cost can reach more than tens of thousands of rubles. Therefore, it is important to monitor the condition of the timing belt and change it before it completely runs out of service life.

Article number and cost of the original Chevrolet Lacetti timing belt and its analogues

On Chevrolet Lacetti cars with a 1.4 or 1.6 liter power plant, a timing belt manufactured by General Motors is used, the article number of which is GM 96417177. The cost of the product is more than 900 rubles. A direct analogue of the General Motors branded belt is Gates products with catalog number 5419XS. The cost of this consumable is from 700 rubles.

Identical to the original timing belt are products from Daewoo with article numbers:

- 96183352;

- 96814098;

Branded belt for 1.4- and 1.6-liter engines

The 1.8 liter engine has a different timing belt. The General Motors company produces it under the GM article number 96413861. The manufacturer of the consumable is Gates. It produces a direct analogue of the branded product with catalog number 5499XS.

The price of the original GM is more than 2,000 rubles, and a direct analogue can be purchased by paying about 1,000 rubles. General Motors also purchases timing belts from Contitech. The article number of these consumables is 24451895. The cost is similar to Gates products.

For the entire line of power plants, there are alternative versions of the original timing belts. The best brands are presented in the tables below.

Table - List of analogues of the original Lacetti timing belt with 1.4 and 1.6 liter engines

| Company manufacturer | Article number | Cost, ruble |

| BOSCH | 1987949403 | 450 |

| PARTS-MALL | 96183351 | 340 |

| LPR | 5133 | 500 |

| DONGIL | 127RU254 | 640 |

| CRB | 13110350 | 335 |

| DAYCO | 94241 | 540 |

Third Party Belt

Table - List of alternative options for the Lacetti 1.8 branded timing belt

| Company manufacturer | Article number | Cost, ruble |

| BOSCH | 1987949433 | 620 |

| DAYCO | 94787 | 615 |

| FLENNOR | 4388V | 550 |

| GOODYEAR | G1495H | 545 |

| OPTIBELT | ZRK1026 | 720 |

| ONNURI | 96413861 | 480 |

Analogue of a branded product

Main timing faults of the Chevrolet Lacetti

It also follows that the main danger to this system is the friction forces that arise during engine operation. Lubrication helps to reduce them to a minimum, which, according to the recommendations of the Lacetti manufacturers, should be changed at least every 15 thousand km. car mileage.

The second enemy of the timing belt is the imbalance of its components. In particular, two main nodes:

- cylinder-piston group;

- synchronization of rotation of the crankshaft and camshaft.

In the first case, when the thermal clearance of the valves is violated, the latter either gradually deform, colliding with the cylinder head at high speed, or become covered with soot, or even completely burn out under the influence of combustion of the air-fuel mixture. In the second, there is a serious desynchronization of the shafts, one of which is responsible for the timely opening/closing of the intake and exhaust valves, and the other controls the movement of the pistons; the valves collide with the pistons. As a result, the former are bent, the latter are deformed or broken, thereby disabling the cylinders themselves. The result is a complete replacement of the Chevrolet Lacetti timing belt with 16 valves.

Replacement frequency

According to the Chevrolet Lacetti maintenance plan recommended by the manual, replacing the timing belt is necessary every 60 thousand km. At the same time, regardless of the mileage, the drive belt should be changed if 4 years have passed since the previous installation of a new product.

Experienced car owners claim that the real life of the timing belt is much higher than that declared by the manufacturer.

The gas distribution drive can last 90-120 thousand km without owner intervention. It is not worth using up the entire service life of the belt, as this can lead to its breakage and cause the need for a major overhaul of the power plant.

Replacement frequency and location of timing drive elements

According to the service book regulations, replacement work should be carried out every 60,000 km or after 4 years (whichever comes first). Also, according to the requirements of the service book, every 30,000 km the timing belt must be inspected to identify defects, such as:

- peeling of fabric from rubber, obvious cracks and folds on the surface of the belt;

- the appearance of a bend on the back side of the belt, exposing the cord threads, as well as possible traces of burning;

- signs of leaking oil;

- trace of tooth wear.

When the following defects are found on the belt during inspection, then it is necessary to replace it. If you do not replace it in time, then this can lead to belt failure (whether it is a break or a cut of teeth), resulting in a collision between the valves and the pistons. As experienced motorists say, “the valve is bent.” A broken timing belt will lead to valve failure; in addition to them, replacement of pistons, internal combustion engine gaskets, etc. will be required. This type of repair is quite expensive and will also take a lot of time.

List of consumables required to replace the belt

If you are replacing the timing belt on a 1.6 or 1.4 liter engine, you must additionally purchase the following items:

- tension roller with article number GM 96350550 and cost from 750 rubles;

- deflection roller with catalog number GM 96350526, the price of which is more than 550 rubles.

There is a special repair kit that includes a proprietary timing belt and two rollers. The article number for this kit is GM 93744703.

When replacing the timing belt of a 1.8 liter engine, you need to purchase more rollers. Required:

- tension roller, article number GM 55567191, and cost more than 2000 rubles;

- right bypass roller with article number GM 96413864 and a price of about 1,100 rubles;

- left parasitic with catalog number GM 96413863 and costing more than 700 rubles.

To facilitate the process of servicing the timing drive, General Motors produces a special kit with GM part number 93745368. It includes all three rollers and a belt.

How long does it take to change the timing belt, what signs indicate the need to replace the timing belt

- Wear of material. A timing belt can wear out in the same way as, for example, a tire. If the belt material is worn out, it may break or slip. This happens especially often under heavy loads on the car engine. For example, when pulling a caravan or trailer, as well as in wet weather conditions.

- Belt abrasion. This usually happens when the pulley and tensioner roller deviate from the rear position, as well as when the bearing is faulty and the temperature is elevated. Upon inspection, you can notice wear on the belt teeth - its fabric base is revealed (fleecy fabric fibers and uneven texture).

- Peeling or cracks. This sign of wear and tear is obvious. It is necessary to examine the back and front surfaces of the belt. The presence of cracks, especially if there are many of them, indicates severe wear.

- Hardening of the opposite surface of the timing belt - the opposite surface of the belt is hard, non-elastic and shiny. In this case, the belt becomes inflexible, as a result of which it no longer provides the required contact with the pulley.

- Elongation. Wear of the material can lead to a strong elongation of the belt, as a result of which the tension roller moves beyond the permissible limits. This reduces the rigidity and overall tension of the belt, and, consequently, the overall performance of the mechanism.

- Deviation from the designated position. This sign indicates that the internal elements of the tension roller are quite close to failure. If the roller fails, it will result in increased noise, temperature and vibration.

Required Tools

To replace the timing belt and related parts, you need the tools shown in the table below.

Table - List of tools required to replace the Chevrolet Lacetti timing belt

| Name | Note |

| Socket wrench | "at 15", "at 17" |

| Head | "at 10", "at 12" |

| Key "41" | This special wrench is designed to tension the belt by turning the pump. |

| Screwdriver | Flat blade |

Tweet

It is recommended to replace the timing belt on a Chevrolet Lacetti with a 1.4/1.6 engine every 60 thousand km.

To replace the timing belt yourself, you need the following tools: a standard set of sockets, a standard set of keys, and a special key -J424992

You can make a special key yourself from an open-end wrench on <<41>>

- First of all, remove the negative terminal from the battery

- remove the air filter

- Using the key to <<14>>, turn clockwise the bolt of the automatic tensioner of the auxiliary drive belt, loosen the belt and remove it

- Using a <<10>> wrench, unscrew the three bolts securing the upper timing belt cover

- remove the hose supplying coolant to the throttle body from the holders on the top cover of the timing belt, and remove the cover

- Using a jack, lift the right side of the car and remove the wheel

- remove the plastic protection

- install a jack under the engine oil sump

- unscrew the crankshaft pulley mounting bolt

- Using a <<10>> wrench, unscrew the three bolts securing the lower timing belt cover and remove the cover

- screw the crankshaft pulley mounting bolt into the crankshaft threaded hole

- Using the head on <<14>>, unscrew the three nuts and one bolt securing the engine mount bracket

- turn the crankshaft clockwise using the crankshaft pulley mounting bolt until the timing marks align

- Using a key on <<14>>, unscrew the bolt securing the timing belt guide roller, and remove the belt

- Using a <<10>> wrench, unscrew the four bolts securing the engine support bracket to the cylinder block

- Using a wrench on <<12>>, unscrew the three bolts securing the automatic timing belt tensioner

- using a hex wrench <<5 mm>> loosen the tightening of the coolant pump mounting bolts until the coolant pump is turned using a special wrench (do not loosen the bolts too much to avoid coolant leakage)

- turn the coolant pump counterclockwise

- screw on the new automatic timing belt tensioner

- screw on the new timing belt guide roller

- put on the timing belt, starting from the crankshaft sprocket, counterclockwise, make sure that the belt is tight between the sprockets, and the timing marks are aligned

- turn the coolant pump clockwise with a special wrench until the marks on the automatic timing belt tensioner align

- turn the crankshaft clockwise two turns until the marks align

- check the marks on the automatic timing belt tensioner (if necessary, turn the pump until the marks align)

- tighten the coolant pump mounting bolts to a torque of 10 N.m

- turn the crankshaft clockwise two turns again and check the marks again

- install the remaining parts in the reverse order of removal

- tightening torque of the crankshaft pulley bolt - (95 N.m + 30 degrees + 15 degrees)

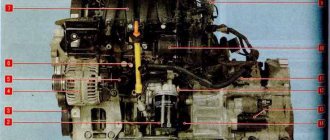

Photos of the engine and attachments

- View of the Chevrolet Lacetti engine with attached units 1 - oil pan; 2 — auxiliary drive pulley; 3 — oil pressure sensor; 4 — generator bracket; 5 - generator; 6 — adsorber purge valve; 7 — block of throttle position sensor and idle speed regulator; 8 — throttle assembly; 9 — hose for supplying coolant to the throttle body; 10 — upper front timing drive cover; 11 — cylinder block bracket for attaching the right support of the power unit; 12 — thermostat cover; 13 — lower front timing drive cover; 14 — power steering pump pulley; 15 — auxiliary drive belt; 16 — roller of the automatic tensioner of the auxiliary drive belt; 17 — air conditioning compressor pulley; 18 — bracket for auxiliary units; 19 - oil pump.