Options for 8-valve engines are well known to Lada Granta owners from previous AvtoVAZ models. These engines have indexes 11183 and (11186, 21116), their power is 82 and 87 horsepower, respectively.

Domestic consumers are very afraid of a broken timing belt. Therefore, this issue plays an important role when choosing a car modification.

In the event of such a situation, bending of the valves may occur, which has given rise to the popular saying “fist of friendship.” There is even slang that refers to motors that bend valves as “plug-in”, and motors that do not have this disadvantage as “plug-in”.

general information

Important information about the car 11189 is considered a logical continuation of the power unit labeled 11186, but improved and modified. To understand what we are talking about, let’s visually analyze the technical characteristics of the 11189 engine.

The 11189 power unit has been assigned the Euro-5 environmental standard, unlike other similar engine models. Due to the high technical characteristics and low cost of the engine, from 2020 it was decided to use the 11189 engine in the Lada Largus instead of the more expensive K4M and K7M engine models produced by Renault.

As practice has shown, many motorists liked the new modification of the engine. The main role in this was played by the advantages of the 11189 engine, such as a simple design and relatively cheap spare parts.

What cars are equipped with the VAZ 11186 engine?

The Lada Kalina 2 and Granta with manual transmission are equipped with the 11186 engine. The engine is found on Datsun cars built on the Granta and Kalina platforms.

| Automobile model | Body | Years of manufacture |

| Lada Granta | sedan | since 2011 |

| liftback | since 2014 | |

| hatchback | since 2018 | |

| station wagon | since 2018 | |

| Lada Kalina 2 | station wagon | 2013 — 2018 |

| hatchback | 2013 — 2018 | |

| cross | 2014 — 2018 | |

| Datsun on-Do 1 | sedan | since 2014 |

| Datsun mi-Do 1 | hatchback | since 2015 |

Not all of these car models are lucky. On some the valves bend, on others they don’t. It depends on the year of manufacture and configuration.

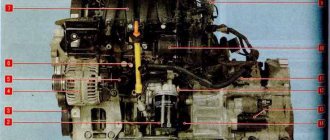

Briefly about the design of the 11189 engine

The cast-iron body for four cylinders is similar to the one that was equipped with the VAZ-2108. Their only difference is that the cooling jacket of the 11189 engine is considered more developed. The increased thermal load of the engine required not only an increase in the number of channels for fluid circulation, but also the use of special nozzles that spray the lower part of the pistons with oil.

The block head is made of durable aluminum alloy with good technical characteristics. In the process of its production, strengthening heat treatment began to be used. The intake manifold in this engine model is more developed with an E-gas electronic throttle. It is worth noting that the catalyst is built into the exhaust. The single camshaft is rotated by a durable Gates belt with a claimed service life of 180,000 km. Experts call a noticeable drawback the lack of hydraulic compensators.

Why does the belt break?

The valve bends when the timing drive breaks, so it is important to monitor its condition. On 11186 AvtoVAZ installs Gates belts art. 5670XS with automatic tensioner art. T43228. According to the manufacturer, the service life of the consumable is equal to the engine service life - 200,000 km. In reality, the belt runs about 50,000 km. Experts recommend checking the part during each maintenance, after 15,000 km.

In addition to the quality of the belt, how it is tensioned is also important. In engine model 11186, when backlash or jamming occurs in the pump or tension roller, the belt cuts off the teeth and the pistons bend the valve. It cuts teeth instantly, so it is rarely possible to avoid breakage.

Quality of spare parts

Gates has been cooperating with AvtoVAZ since 2003. The company's products are not cheap. A set of timing belt and tension pulley will cost at least 3,000 rubles. Is it worth saving and buying a cheap Chinese equivalent if there is a danger that if the drive breaks, the engine bends the valve?

However, even if you want to buy an original product, you can run into a fake. Under the name Gates there are counterfeits made from cheap material at a dubious price. You need to buy spare parts from official distributors. Addresses can be found on the company website.

The original timing belt is made of hydrogenated heat-resistant rubber with high resistance to various chemicals. The part has a rounded toothed profile. There are 113 teeth, 17 mm wide. Length - 1.076 m.

Similar article Where is the engine number on the Lada Granta

Belt wear is determined by the quality of the material, the presence of cracks and delaminations. The surface of the part should be elastic, not too hard. It is not permissible to stretch or shift the belt relative to the required position, otherwise it will fly off and a situation will occur in which the valve bends.

Incorrect belt installation

On a Grant with engine 11186, the valves bend in case of any damage to the timing drive. Since the slightest loosening of the belt causes teeth to be cut off, the drive must be installed strictly according to the diagram, using a special key.

If you look at the drive tension, then on the right side from the camshaft to the crankshaft you get a long arm in a free state. The force is from 15 to 20 Nm. Next, the belt covers the crankshaft sprocket. It rises to the water pump, going around the gear on the left. It goes to the tension roller on the right and returns to the camshaft.

AvtoVAZ does not recommend tensioning the drive belt yourself. According to the manufacturer, for the service you need to contact specialized services, where the part will be installed in accordance with the requirements of the plant. This is especially important if there is warranty service.

The difference between motor 11189 and motor 11186

The main distinguishing feature of the earlier engine model is the 39% lighter connecting rod and piston group. The use of tandem parts made it possible to significantly reduce engine noise and vibration while the vehicle was moving. The new anti-friction inserts in the piston design and thinner rings have reduced the finishing process to a minimum. However, the new model abandoned the holes on the bottom.

Do the valves on the Grant bend?

Since different versions of the Lada Granta are equipped with different engines (more about engines), the answer to the question above will be different.

On the “standard” trim levels, 8-valve 1.6-liter engines are installed, which are also used on the Lada Kalina. Such engines have already passed the test of time and have shown themselves to work well - even if the timing belt breaks, the valves remain in normal condition.

The “norm” configuration is equipped with a modernized 8-valve valve with a lightweight piston group (these are also installed on Kalina). Here the problem of pistons and valves meeting when the timing belt breaks has not been solved. This happens because special recesses are made in the pistons of such engines, and with the lightening of the ShPG, the pistons became thinner and there was no room left for the recesses.

The owners of the “luxury” will also not be able to please - their 16-valve valves also encounter a valve and piston when the belt breaks. True, there are fewer cases with such engines, but there is a risk. The main cause of breakage on such engines is jamming of the pump, tension and support rollers.

Problems with the motor 11189

Despite all the advantages, with long-term operation of the 11189 engine, the following breakdowns may occur in Lada:

- Malfunctions in the operation of the indicators of the electronic throttle drive E-gas, which in most cases lead to the appearance of floating idle speed.

- Burnout of valves and malfunction of the ignition coil, which causes the engine to trip (1-2 cylinders of the engine stop working completely).

- Damage to the mass air flow sensor is considered the most common reason that the “iron horse” stalls while driving. A breakdown can lead to an accident.

- Overheating occurs, most often caused by an unreliable thermostat.

- Knocks and noises may be heard from under the hood. They appear mainly due to incorrectly set valve clearances.

- According to reviews, the 11189 engines have significantly reduced oil leaks compared to earlier engine models, but this problem has not yet been completely eliminated.

- Due to a design miscalculation, the occurrence of jamming of the water pump becomes inevitable for the engine. Experts recommend monitoring her condition with special attention.

Engine Features

Due to the design of the car's cooling system, the engine does not warm up above 80 degrees. The management of AvtoVAZ does not see anything wrong with this; they have an official information letter on this matter. You can read it in the material: What is the operating temperature of an 8 valve engine.

The engine design is as simple as an axe. There are no hydraulic compensators, no sores were noticed. Mostly problems can arise due to malfunctions in the engine management system.

Video of acceleration to 100 km per hour

I haven’t shot my video yet, it’s winter, so we’ll wait for the weather to warm up. That's when I'll post it on our YouTube channel. In the meantime, here's a video from Grantovodov.

Here's another interesting video. It is interesting because the measurement is made using an application with a navigator , which means that the speedometer readings are more accurate if the navigator is well calibrated. Everyone knows that the higher the speed, the more the car’s speedometer lies.

Oil and parts replacement schedule

The manufacturing plant of the 11189 Lada-Largus engine has outlined the following list, which indicates the replacement of consumable fluids and materials:

- engine oil and oil filters - once every 15,000 km;

- fuel and air filters, as well as spark plugs - every second technical control of the car’s condition;

- poly V-belt, wires and coolant - every 90,000 km.

Technical inspection and replacement of the above parts and fluids should only be carried out by an experienced car service specialist. According to reviews from car enthusiasts, valve clearances should be adjusted during each maintenance.

The most common problems of internal combustion engines 11186

VAZ 11186 borrowed the design from its predecessor. The engine is a cast iron block with 4 cylinders in line and a head with 8 valves. One camshaft. There are no hydraulic compensators, so the valve clearances have to be set manually. The timing belt is driven by a belt.

Similar article 126 VAZ engine bends the valve or not

The modernization has made improvements to the characteristics of the engine: it has become less capricious, more reliable and economical. However, the engine is not without its drawbacks:

- While the engine is running, knocking noises are heard. Often the problem is solved by adjusting the valve clearances. If this does not help, install new pistons or crankshaft bearings;

- RPM fluctuates at idle. The cause of the malfunction is glitches in the automatic throttle and sensors;

- increased oil consumption. Observed when the main liners or piston rings are worn;

- misfire. The problem is in the ignition module. It is beyond repair and must be replaced.

Granta owners also complain about the unreliability of the Itelm ECU. The electronic unit fails when exposed to moisture. To prevent damage, the ECU can be moved into the interior to avoid getting wet during rains. It is not recommended to cover the module with film, as condensation will occur.

The most critical problem with the 8-valve Lada Granta is that the engine bends the valves. The damage can only be corrected by replacing it with new parts. It remains to find out why the valves bend and how to avoid trouble.

Maintenance

Carrying out inspection, maintenance and analysis of the characteristics of the 11189 engine is practically no different from the standard procedure for similar VAZ engines. Maintenance includes the following actions:

- Change the oil once a year, or every 15,000 km. The specialist must fill in at least 3.2 liters of oil.

- Inspect and replace spark plugs at every oil change.

- Periodic inspection of the “heart” of the car to determine transmission and engine oil leaks. If any problems are discovered, it is important to resolve them quickly.

- Change the drive belt after a mileage of 40-60 thousand km.

Specifications

Download .xls file

xls

Download picture

Send by email

| OPTIONS | VALUES |

| Engine displacement, l | 1.6 |

| Rated power, l. With. (5100 rpm) | 87 |

| Maximum torque, Nm (3800 rpm) | 140 |

| Number of cylinders | 4 |

| Valves per cylinder, pcs. | 2 |

| Total number of valves, pcs. | 8 |

| Cylinder diameter, mm | 82 |

| Piston stroke, mm | 75.6 |

| Compression ratio | 10.5 |

| Fuel supply system | Injector |

| Fuel | Unleaded gasoline AI-95 |

| Fuel consumption, l/100 km (city/highway/mixed) | 8,5/5,7/7,2 |

| Lubrication system | Combined |

| Engine oil | 5W-30, 5W-40, 10W-40, 15W40 |

| Engine oil quantity, l | 3.5 |

| Cooling system | Liquid, closed type |

| Coolant | Using ethylene glycol |

| Motor resource, hour. (manufacturer's data) | 200000 |

The engine was installed on Lada Kalina 2 cars (2004 - 2013); Lada Granta (1.6 l, 8-cl., manual transmission); Lada Priora.

Tuning

Literally all production engines that have eight valves are improved according to the same schemes. The VAZ-11189 engine is no exception, the characteristics of which make it possible to quickly modernize the engine.

Popular methods of tuning the power unit:

- Replacing the standard internal combustion shaft with a “Nuzhdin 10.93 (phase 282)” or “OKB Dinamika 108” shaft.

- Equipped with split gear.

- Forming the exhaust using a spider 4-2-1.4. Mounting on top of the receiver cylinder head 5.

- Setting the valve timing.

If the above steps are performed by an experienced specialist, then it is quite possible to increase the engine power to 100 hp. With.

Lada Granta engines 16 valves

VAZ 21126 - 98 hp. 145 Nm

This engine is also equipped with a lightweight piston group manufactured by Federal Mogul and a belt with an automatic tensioner from Gates. It is distinguished by a 16-valve head with a pair of camshafts and hydraulic compensators, due to which its power is significantly higher.

All the problems of its predecessors apply to this unit in full.

The engine often suffers from lubricant leaks, tripping, floating speed, sensor glitches and valve burnout. Plus, you can add hydraulic compensators that are very demanding on oil quality. Hatchback before restyling 2020 - 2019

| 1.6 l 21126 MKP5 | 1.6 l 21126 automatic transmission4 | |

| Type | injector | injector |

| Fuel | gasoline AI-92 | gasoline AI-92 |

| Location | transverse | transverse |

| Cylinders | 4 in a row | 4 in a row |

| valves | 16 | 16 |

| Working volume | 1596 cm³ | 1596 cm³ |

| Power | 98 hp | 98 hp |

| Torque | 145 Nm | 145 Nm |

| Acceleration to 100 km/h | 11.2 s | 13.3 s |

| Speed (max) | 182 km/h | 173 km/h |

| Ecological Class | Euro 5 | Euro 5 |

| Consumption city | 8.8 l | 9.9 l |

| Flow track | 5.6 l | 6.1 l |

| Mixed flow | 6.8 l | 7.2 l |

VAZ 21127 - 106 hp. 148 Nm

The updated engine received an adjustable intake tract with dampers in the receiver channels. Also here, the mass air flow sensor gave way to a combination of absolute pressure and air temperature sensors, thanks to which the frequent problem of floating speed at idle has finally gone away.

The reliability of the new unit has increased, although it is not flawless.

The thermostat also often fails, the injectors become clogged, and the ignition system malfunctions. But the main threat is the water pump, because of the wedge of which the timing belt breaks and the pistons meet the valves. Update: In July 2020, the manufacturer equipped this engine with plugless pistons. Hatchback before restyling 2020 - 2019

| 1.6 l 21127 MKP5 | 1.6 l 21127 AMT5 | |

| Type | injector | injector |

| Fuel | gasoline AI-92 | gasoline AI-92 |

| Location | transverse | transverse |

| Cylinders | 4 in a row | 4 in a row |

| valves | 16 | 16 |

| Working volume | 1596 cm³ | 1596 cm³ |

| Power | 106 hp | 106 hp |

| Torque | 148 Nm | 148 Nm |

| Acceleration to 100 km/h | 10.9 s | 12.3 s |

| Speed (max) | 183 km/h | 180 km/h |

| Ecological Class | Euro 5 | Euro 5 |

| Consumption city | 8.6 l | 9.0 l |

| Flow track | 5.6 l | 5.2 l |

| Mixed flow | 6.5 l | 6.5 l |

Additional materials

Installation of the turbine on the engine

The simplest option for turbocharging 11189 engines is considered to be the use of kits based on the Garrett 17 turbine. Using this kit, it is quite possible to increase the power of the “heart” of the car to 130 hp. With.

Today, there are other methods for installing a turbine, but they require large investments and labor costs. In addition, such engines, when turbocharged, are considered very sensitive to detonation, which as a result leads to a decrease in engine life and the need for expensive repairs in the future.

Increase engine power 11189 to 180 hp. With. it is quite possible by replacing the 8-valve cylinder head with a 16-valve one. After carrying out such actions, you can use any of the above methods to tune the engine.

The risk is especially great if...

If you don’t look after the car, it will force you to take a closer look at it with large and costly repairs. At AvtoVAZ they advise changing the timing belt more often, monitoring the condition of the rollers, tensioners, etc., i.e. Carry out periodic maintenance. Although the factory gives a 120,000 km guarantee on the belt, testing this is a big risk. It is better to monitor it more often and change it in advance, before you have to spend money on a major engine overhaul.

In the fall of 2020, the Lad family of passenger cars was replenished with a top model - the Vesta car, produced in a sedan body. When asking the question “do the valves bend on the Lada Vesta,” you need to clearly imagine what kind of engine we are talking about: a 1.6-liter Russian or Nissan, or maybe the latest VAZ development with the name “21179”.

Here we consider options related to cars currently being produced or those that will begin to be produced in the near future. An 8-valve engine was also developed for Vesta - it definitely does not bend the valves and will definitely not be installed on top-end sedans in 2016.

Read more about the engines equipped with the Lada Vesta line in the material: !

ICE VAZ-21129, 106 “hp” (valve bending)

Under the hood of the 106-horsepower Lada Vesta

A little history. Motor 21129 is a modified version of another engine, namely 21127. The last of them, when the timing belt broke, successfully bent its valves, although grooves were made on the pistons (Fig. 1). The point is that the depth of the grooves was not sufficient: if certain conditions were met, the valve “met” the piston with all the ensuing consequences.

With the transition to a new generation of internal combustion engines, that is, 21129, the design of the pistons was modified. But the external shape has not changed much, and although the recesses remain, their depth is still insufficient.

Here we considered the question of whether the Lada Vesta valves with the “21129” engine are bent. And the answer was clear: yes, oppression.

In theory, the problem with valve bending is typical for all VAZ engines equipped with 4 valves per cylinder. Each new 16-valve engine “inherits” it. The exception is one rarity - the VAZ-2112 internal combustion engine, the volume of which is 1.6 liters.

There, the recesses are made conscientiously (Fig. 2).

122-horsepower engine “21179” (valve bending)

In terms of its design, the internal combustion engine of the VAZ-21179 is not very different from its predecessors. The working volume was increased to 1774 ml, which was achieved by changing the piston stroke length: it was 75.6 mm, it became 84.0 mm.

Elements of the connecting rod and piston group

The piston itself is now better fitted to the cylinder than in engines 21127 and 21129. The distance from the piston pin to the piston bottom has increased by 1.3 mm - to 26.7 mm.

But deeper grooves in the bottom never appeared. The timing mechanism still drives the belt, and if it breaks, the possibility of bending the valves has not been canceled.

Now we know whether the valves bend on a Lada Vesta with a 1.8-liter engine. The answer will be the same as for all 16-valve VAZ internal combustion engines (with the exception of 2112). The problem with the transition to a new generation remains the same. But VAZ does not intend to return to “heavy” pistons.

The timing drive on 21179 engines is equipped with not one, but two tension rollers. What was done to make the design less susceptible to timing belt stretching.

Engine cost 11189

Buying such a used engine is not as easy as it might seem at first glance. This model of power unit is not very common in domestic car dismantling yards. Almost always, the only option for purchasing it is to contact an official dealer. It is quite rare to find offers to sell a used engine for 27 thousand and a new one for 70 thousand rubles.

Owners of Lada Largus cars with such an “iron heart” praise their unit for its excellent traction even at low speeds, safety, durability and efficiency. In addition, the price of car servicing and spare parts is affordable.

The 11189 engine is a very common engine that is equipped in many vehicles produced by. The quality and technical parameters of the product are not inferior to many domestic analogues, which are sold on the car market at a high price.

Pros and cons of the motor

The main feature of the ICE 21127 remains the insufficient safety of the valves, which can be bent by the pistons if the timing belt breaks. The second disadvantage is the expensive overhaul, even if you do it yourself:

- the timing belt complete with automatic tensioner and pulley is expensive, as it is produced by the foreign company Gates;

- The ShPG kit also has a high price, since it is manufactured by another foreign manufacturer, Federal Mogul.

Damper control valve

The advantages of the design are:

- attachments are conveniently located, which reduces labor costs for maintenance and repairs;

- increased torque and power of the internal combustion engine.

On the one hand, the manufacturer AvtoVAZ has expanded its line of engines with version 21127. On the other hand, it has provided a new spare part - an improved receiver with an inertial charging system, which is a definite plus:

- owners of Grant, Prior and Kalin of the second generation, equipped with 21126 engines, can buy this unit;

- install it yourself instead of the standard receiver of the previous configuration;

- remove the mass air flow sensor, install DBP and DTV sensors to get a power of 106 hp. With. instead of the factory 98 hp. With.

Error codes

Using error codes, you can diagnose malfunctions in the power unit system, which will help you eliminate them quickly.

Of course, if there is a breakdown, it is mechanical in nature, then diagnosing the electronic engine control unit will not help much, except perhaps pointing to the location of the fault.

Let's look at decoding error codes for the Lada Granta 87 hp ECU:

- P0030 Oxygen sensor to the converter, checking the heater circuit for open circuit

- P0031 Oxygen sensor before the converter, checking short circuit of the heater circuit to ground

- P0032 Oxygen sensor to the converter, checking the short circuit of the heater circuit to the on-board network

- P0036 Oxygen sensor after the converter, checking the heater circuit for open circuit

- P0037 Oxygen sensor after the converter, checking the short circuit of the heater circuit to ground

- P0038 Oxygen sensor after the converter, checking the short circuit of the heater circuit to the on-board network

- P0101 Mass air flow sensor, signal out of acceptable range

- P0102 Mass air flow sensor, low output signal

- P0106 Intake manifold absolute pressure sensor circuit, signal out of acceptable range

- P0107 Manifold absolute pressure sensor circuit low signal

- P0108 Intake manifold absolute pressure sensor circuit, high signal level

- P0103 Mass air flow sensor, high output level

- P0112 Intake air temperature sensor, low output signal

- P0113 Intake air temperature sensor, high output level

- P0115 Incorrect coolant temperature sensor signal

- P0116 Coolant temperature sensor, signal out of acceptable range

- P0117 Coolant temperature sensor, low output signal

- P0118 Coolant temperature sensor, high output level

- P0122 Throttle position sensor, low output (sensor No. 1)

- P0123 Throttle Position Sensor, High Output (Sensor No. 1)

- P0130 The oxygen sensor before the converter is faulty

- P0131 Oxygen sensor before the converter, low output signal level

- P0132 Oxygen sensor before the converter, high output signal level

- P0133 Oxygen sensor before the converter, slow response to enrichment or depletion

- P0134 Oxygen sensor to the converter, open signal circuit

- P0135 Oxygen sensor to the converter, heater is faulty

- P0136 Oxygen sensor after the converter, open signal circuit

- P0137 Oxygen sensor after the converter, low signal level

- P0138 Oxygen sensor after the converter, high signal level

- P0140 Oxygen sensor after the converter, open signal circuit

- P0141 Oxygen sensor after the converter, heater is faulty

- P0171 Fuel supply system too lean

- P0172 Fuel system too rich

- P0200 Injector control circuit is faulty

- P0201 Cylinder No. 1 injector control circuit, open

- P0202 Cylinder No. 2 injector control circuit, open

- P0203 Cylinder No. 3 injector control circuit, open

- P0204 Cylinder No. 4 injector control circuit, open

- P0217 Engine overheating, engine temperature above the threshold value

- P0222 Throttle position sensor, low output (sensor No. 2)

- P0223 Throttle Position Sensor High Output (Sensor No. 2)

- P0261 Cylinder No. 1 injector control circuit, short to ground

- P0262 Cylinder No. 1 injector control circuit, short to +12V

- P0264 Cylinder No. 2 injector control circuit, short to ground

- P0265 Cylinder No. 2 injector control circuit, short to +12V

- P0267 Cylinder No. 3 injector control circuit, short to ground

- P0268 Cylinder No. 3 injector control circuit, short to +12V

- P0270 Cylinder No. 4 injector control circuit, short to ground

- P0271 Cylinder No. 4 injector control circuit, short to +12V

- P0300 Random or multiple misfires detected

- P0301 Misfire detected in cylinder 1

- P0302 Misfire detected in cylinder 2

- P0303 Misfire detected in cylinder 3

- P0304 Misfire detected in cylinder 4

- P0325 Knock sensor break

- P0326 Knock sensor, signal is outside acceptable limits

- P0327 Knock sensor, low signal level

- P0328 Knock sensor, high signal level

- P0335 Crankshaft position sensor, no signal

- P0336 Crankshaft position sensor, signal is outside acceptable limits

- P0337 Crankshaft position sensor, circuit short to ground

- P0338 Crankshaft position sensor, open circuit

- P0340 Camshaft position sensor is faulty (Phase sensor error)

- P0342 Camshaft position sensor low signal level

- P0343 Camshaft position sensor high signal level

- P0346 Phase sensor circuit, incorrect signal

- P0351 Ignition coil, open circuit check, primary circuit current is less than threshold value

- P0352 Ignition coil, open circuit check, primary circuit current is less than threshold value

- P0353 Ignition coil cylinder 3, control circuit open

- P0354 Ignition coil cylinder 4, control circuit open

- P0363 Random or multiple misfires detected to protect the converter

- P0422 Neutralizer efficiency below threshold

- P0441 Incorrect air flow through the valve

- P0443 Control of the canister purge valve is faulty

- P0444 Canister purge valve, open circuit check

- P0445 Short circuit to ground in the canister purge valve circuit

- P0458 Canister purge valve, checking short circuit to ground

- P0459 Canister purge valve, checking the short-circuit circuit to the on-board network

- P0480 Fan relay control circuit 1; open circuit, open circuit check

- P0481 Fan relay 2 control circuit; open circuit, open circuit check

- P0485 Cooling fan, supply voltage check

- P0500 Vehicle speed sensor, no signal

- P0501 Vehicle speed sensor error

- P0503 Vehicle speed sensor, intermittent signal

- P0504 Brake pedal sensor, sensor signals change inconsistently

- P0505 Idle air control error

- P0506 Idle speed control blocked, low speed

- P0507 Idle speed control blocked, high speed

- P0522 Oil Pressure Sensor Circuit Low Signal

- P0523 Oil Pressure Sensor Circuit High

- P0560 On-board voltage is below the system operability threshold

- P0562 On-board voltage is low

- P0563 On-board voltage is high

- P0601 Control unit ROM malfunction

- P0603 Control unit RAM malfunction

- P0604 Controller internal RAM checksum error

- P0606 Controller, ADC faulty

- P0607 Invalid controller detonation channel signal

- P0615 Starter relay control circuit, open

- P0616 Starter relay control circuit, short to ground

- P0617 Starter relay control circuit, short to +12V

- P0627 Fuel pump relay, open circuit check

- P0628 Fuel pump relay, checking short circuit to ground

- P0629 Fuel pump relay, checking the short-circuit circuit to the on-board network

- P0642 Sensor power bus, low signal level

- P0643 Sensor power bus, high signal level

- P0645 Air conditioning clutch relay, open circuit check

- P0646 Air conditioning clutch relay, checking short circuit to ground

- P0647 Air conditioning clutch relay, checking the short-circuit circuit to the on-board network

- P0660 Intake length control valve, open circuit

- P0661 Intake length control valve, circuit short to ground

- P0662 Intake system duct length control valve, on-board circuit short circuit

- P0691 Fan relay control circuit 1; open circuit, checking short circuit to ground

- P0692 Fan relay control circuit 1; open circuit, checking the short-circuit circuit to the on-board network

- P0693 Fan relay 2 control circuit; open circuit, checking short circuit to ground

- P0694 Fan relay 2 control circuit; open circuit, checking the short-circuit circuit to the on-board network

- P0830 Clutch pedal switch circuit faulty

- P1102 Low oxygen sensor heater resistance

- P1115 Faulty oxygen sensor heating control circuit

- P1123 Additive component corr. by air the composition of the mixture exceeds the threshold. The composition is “rich”

- P1124 Additive component corr. by air the composition of the mixture exceeds the threshold. Composition "poor"

- P1127 Multiplicative the mixture correction component exceeds the threshold. “Rich” composition

- P1128 Multiplicative the mixture correction component exceeds the threshold. Composition "poor"

- P1135 Malfunction of the oxygen sensor heater circuit to the converter

- P1136 Additive component corr. fuel exceeds the threshold. “Rich” composition

- P1137 Additive component corr. fuel exceeds the threshold. Composition "poor"

- P1141 Malfunction of the oxygen sensor heater circuit after the converter

- P1171 Low signal level from CO correction potentiometer

- P1172 High signal level from CO correction potentiometer

- P1301 Misfire detected to protect the converter in the 1st cylinder

- P1302 Misfire detected to protect the converter in the 2nd cylinder

- P1303 Misfire detected to protect the converter in the 3rd cylinder

- P1304 Misfire detected to protect the converter in the 4th cylinder

- P1335 Monitoring throttle actuator control, throttle position out of range

- P1336 Monitoring the control of the throttle valve drive, checking the mismatch of signals from the throttle position sensors, sensor voltages differ by the threshold value

- P1384 Monitoring throttle actuator control. Engine torque out of range

- P1385 Monitoring throttle actuator control. Engine load signal is out of range.

- P1386 Knock detection channel, internal test error

- P1387 Monitoring throttle actuator control. Injection time is out of range.

- P1388 Monitoring throttle drive control, checking the accelerator pedal position, sensor voltages differ by the threshold value

- P1389 Monitoring throttle actuator control, engine speed outside the permissible range

- P1390 Monitoring throttle actuator control, no response to a malfunction in the system

- P1410 Canister purge valve control circuit, short to +12V

- P1425 Canister purge valve control circuit, short to ground

- P1426 Canister purge valve control circuit, open

- P1500 Open circuit in the electric fuel pump relay control circuit

- P1501 Fuel pump relay control circuit, short to ground

- P1502 Fuel pump relay control circuit, short to +12V

- P1509 Idle air control control circuit, overload

- P1513 Idle air control control circuit, short to ground

- P1514 Idle air control control circuit, open or shorted to +12V

- P1541 Fuel pump relay control circuit, open

- P1545 Throttle valve drive, deviation of the actual throttle valve position from the desired one is greater than the threshold value

- P1558 Throttle actuator return spring faulty

- P1559 Throttle actuator, throttle position at rest out of range

- P1570 Immobilizer, no positive response or open circuit

- P1578 Throttle valve actuator, adaptation value out of range

- P1558 Throttle valve drive, valve return time to limp home position above threshold value

- P1559 Throttle valve actuator, valve position out of range

- P1600 No connection with immobilizer

- P1602 Voltage failure on-board network

- P1603 Control unit EEPROM fault

- P1606 Rough road sensor, incorrect signal

- P1612 Processor reset error

- P1616 Rough road sensor, low signal

- P1617 Rough road sensor, high signal

- P1620 Control unit ROM malfunction

- P1621 Control unit RAM fault

- P1622 Faulty EEPROM of the control unit

- P1640 Court controller, error reading-writing EEPROM memory

- P1689 Error memory failure

- P2070 Control valve for the length of the intake system channels, constantly open

- P2071 Intake system channel length control valve, constantly closed

- P2100 Throttle valve actuator, open circuit check

- P2101 Electric throttle actuator, control circuit faulty

- P2102 Throttle valve actuator, checking short circuit to ground

- P2103 Throttle valve actuator, checking the short-circuit circuit to the on-board network

- P2105 Controller, monitoring module faulty

- P2122 Pedal Position Sensor A Circuit High Signal

- P2123 Pedal Position Sensor A Circuit High Signal

- P2127 Pedal Position Sensor B Circuit Low

- P2128 Pedal Position Sensor B Circuit High

- P2187 Fuel supply system too lean (idling)

- P2188 Fuel system too rich (idling)

- P2135 Throttle position sensors “A”/”B”, signal mismatch

- P2138 Sensors “A”/”B” accelerator pedal position, signal mismatch

- P2176 Throttle valve actuator control system, throttle zero position adaptation not performed

- P2178 Throttle valve actuator, adaptation has never been carried out

- P2187 Fuel system too lean at idle

- P2188 Fuel system too rich at idle

- P2270 Oxygen sensor after the converter, no response to enrichment of the mixture

- P2271 Oxygen sensor after the converter, lack of response to lean mixture

- P2301 Ignition coil of cylinder 1, short circuit of the control circuit to the on-board network

- P2304 Ignition coil of cylinder 2, short circuit of the control circuit to the on-board network

- P2307 Ignition coil of cylinder 3, short circuit of the control circuit to the on-board network

- P2310 Ignition coil of cylinder 4, short circuit of the control circuit to the on-board network

- P2500 Alternator excitation (LT) control circuit low

- P2501 Generator excitation (LT) control circuit high

List of automatic transmission error codes

- Error code Error description

- P0720 "Output shaft speed sensor faulty"

- P0717 “Turbine speed sensor”

- P0706 “Automatic transmission selector. No signal"

- P0705 ″ Automatic transmission selector. Several signals at the same time"

- P0974 “On-off solenoid. Open circuit"

- P0973 “On-off solenoid. The circuit is shorted to ground"

- P0963 “Pressure control solenoid. Open circuit"

- P0962 “Pressure control solenoid. The circuit is shorted to ground"

- P0740 "LOCK UP SOL(Open)"

- P0743 "LOCK UP SOL(GND short)"

- P17AB "L/C SOL(Open)"

- P17AA "L/C SOL(GND short)"

- P17AE "2-4/B SOL(Open)"

- P17AD “2-4/B SOL(GND short)”

- P17B1 "H/C&L&R/B SOL(Open)"

- P17B0 "H/C&L&R/B SOL(GND short)"

- P1735 "INTER LOCK FUNCTION(1st)"

- P1736 "INTER LOCK FUNCTION(2nd)"

- P1737 "INTER LOCK FUNCTION(3rd)"

- P1738 "INTER LOCK FUNCTION(4th)"

- P0744 "LU CLUTCH(Lock-up)"

- P1744 "LU CLUTCH(Slip Lock-up)"

- P0731 “Incorrect automatic transmission gear ratio in 1st gear”

- P0732 “Incorrect automatic transmission gear ratio in 2nd gear”

- P0733 “Incorrect automatic transmission gear ratio in 3rd gear”

- P0734 “Incorrect automatic transmission gear ratio in 4th gear”

- P17A1 "NEUTRAL FUNCTION(1st)"

- P17A2 "NEUTRAL FUNCTION(2nd)"

- P17A3 "NEUTRAL FUNCTION(3rd)"

- P17A4 "NEUTRAL FUNCTION(4th)"

- P17A0 "NEUTRAL FUNCTION(Rev)"

- P0712 "Oil temperature sensor low reading"

- P0713 "Oil temperature sensor, high reading"

- P0711 "Oil temperature sensor stuck"

- P0863 “CAN bus connection (initialization)”

- P062F "BACKUP MEMORY"

- P1701 “Controller supply voltage”

List of data transmission error codes

- U0001 CAN bus faulty

- U0009 CAN bus circuit short circuit

- U0073 “CAN bus connection (bus disabled)”

- U0100 “CAN bus receiver (ICE ECU)”

- U0155 No communication with cruise control control module

- U0305 Software incompatibility with cruise control control module

If the Lada Granta has error P0504 Error P0504 stands for “mismatch of brake pedal sensors”.