Removing and disassembling the cylinder head of the VAZ-21214 engine

We remove the cylinder head to replace the gasket, repair the valve drive mechanism and the head itself, as well as when completely disassembling the engine.

We carry out the work on an inspection ditch or a lift.

To replace the head gasket or connecting rod-piston group of the engine, remove the cylinder head from the engine complete with the receiver, intake pipe and exhaust manifold.

To remove the cylinder head:

— disconnect the negative cable of the battery;

— drain the coolant (see Replacing the coolant);

— remove the throttle assembly (see Removing the throttle assembly);

— disconnect the hoses from the outlet pipe of the cooling jacket;

— disconnect the hose from the inlet pipe of the heater radiator;

— disconnect the connector of the fuel rail injector wires (see Removing the fuel rail);

— disconnect the connectors from the coolant temperature sensor of the injection system and the coolant temperature indicator sensor;

— remove the tips of the high-voltage wires from the spark plugs;

— disconnect the fuel inlet and outlet pipes from the fuel rail;

— disconnect the exhaust pipe from the exhaust manifold (see Removing the exhaust pipe), the heat shield of the starter and the bracket for the heater radiator outlet pipe;

— remove the camshaft and valve drive levers (see Removing the camshaft and valve drive levers);

— remove the camshaft sprocket and tie the chain with wire.

1. Using a 13mm socket, unscrew the cylinder head bolt located next to the ignition module bracket.

2. Using a “12” socket, unscrew the ten bolts securing the head to the cylinder block.

We take out the bolts.

3. Remove the cylinder head assembly with the exhaust manifold, receiver and intake pipe with the fuel rail.

The cylinder head can also be removed from the engine by first dismantling the receiver (see Removing the Receiver), the intake pipe and the exhaust manifold.

4. Remove the cylinder head without the exhaust manifold and intake pipe

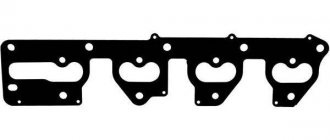

5. Remove the cylinder head gasket.

We install the cylinder head on the workbench.

6. Using a 10mm socket, unscrew the two nuts securing the heater radiator inlet pipe to the block head...

7. ...and remove it.

8. Remove the sealing gasket.

9. Using a 13mm socket, unscrew the two nuts securing the outlet pipe of the cooling system jacket..

10. ...and remove the pipe with the coolant temperature sensor of the injection system

11. Remove the sealing gasket of the pipe.

12. When disassembling the valve mechanism, we place a stop - a wooden block - under the plate of the valve being disassembled.

13. Dry the valve (see Replacing the oil seals of the gas distribution mechanism) and remove the valve from the guide sleeve of the cylinder head.

We dismantle the other valves in the same way.

We assemble and install the cylinder head in the reverse order.

Before installing the valves, clean them from carbon deposits and lubricate the valve stems with engine oil.

14. Having assembled the valve mechanism, we strike the ends of the valves with a hammer with a plastic striker for more reliable fixation of the crackers (the wooden stop must be removed from under the valve plate)

Before installing the cooling system pipes, we clean the mating surfaces of the pipes and the block head from the remains of old gaskets.

We install new pipe gaskets, applying a thin layer of sealant to them.

We clean the mating surfaces of the head and cylinder block from the remains of the old gasket, dirt and oil.

Using a syringe with a needle or a rubber bulb, remove oil and coolant from the mounting holes of the cylinder block.

15. Install the gasket and cylinder head using two centering bushings

16. When installing the head on the cylinder block, thread the chain by the wire through the hole in the head

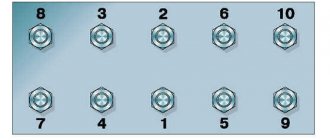

Having installed the cylinder head bolts, tighten them in the order shown in the figure.

To ensure a reliable seal and eliminate the need to tighten the bolts during vehicle maintenance, tighten the bolts in four steps:

1st step – tighten bolts 1–10 to a torque of 20 Nm (2.0 kgf.m);

2nd step - tighten bolts 1–10 with a torque of 69.4–85.7 Nm (7.1–8.7 kgf.m), and bolt 11 with a torque of 31.4–39.1 Nm (3.2– 4.60 kgf.m).

Then we turn bolts 1–10 by 90° (3rd step) and another 90° (4th step).

Niva cylinder head bolts, installation

To work with bolts, a special tool is required. E16 head, which is not always included in universal tool kits, and a torque wrench. To make the process logically complete, the price list includes an E16 head (Sata or Force) and a torque wrench ( JTK) .

I won’t invent anything about the installation technology, just completely follow the factory manual.

- Submerge the bolts in a container of engine oil.

- Let it drain. Exposure for at least 30 minutes.

- Wrap and tighten according to the diagram.

Stage 1 – tightening torque (12…20) N.m [(1.2…2.0) kgf.m];

Stage 2 – tightening with torque (50…70) N.m [(5.0…7.0) kgf.m];

Stage 3 – turning the bolts by 90-110 degrees;

Stage 4 – turning the bolts 90-110 degrees.

Tightening torque of bolt 11 (at the cylinder head tail): preliminary – (14…16) N.m [(1.4…1.6) kgf.m]; final – (32…40) N.m [(3.2…4.0) kgf.m].

Alezhikk › Blog › Tightening torques for main threaded connections of VAZ

Tightening torques for various main threaded connections of vehicle components. These tightening torques can only be ensured using special equipment (torque wrench) Part Thread Tightening torque, N•m (kgf•m)

Engine Cylinder head mounting bolt M12x1.25 cm. Note 2 Stud nut securing the intake pipe and exhaust manifold M8 20.87–25.77 (2.13–2.63) Tension roller mounting nut M10×1.25 33.23– 41.16 (3.4–4.2) Nut of the camshaft bearing housing stud M8 18.38–22.64 (1.87–2.31) Bolt of the camshaft pulley M10 67.42–83.3 ( 6.88–8.5) Bolt for fastening the housing of auxiliary units M6 6.66–8.23 (0.68–0.84) Nut for the stud fastening the outlet pipe of the cooling jacket M8 15.97–22.64 (1.63– 2.31) Bolt for fastening the main bearing caps M10x1.25 68.31–84.38 (6.97–8.61) Bolt for fastening the oil sump M6 5.15–8.23 (0.52–0.84) Nut connecting rod cover bolt M9x1 43.32–53.51 (4.42–5.46) Flywheel mounting bolt M10x1.25 60.96–87.42 (6.22–8.92) Coolant pump mounting bolt M6 7, 64–8.01 (0.78–0.82) Crankshaft pulley mounting bolt M12x1.25 97.9–108.78 (9.9–11.1) Coolant pump supply pipe mounting bolt M6 4.17– 5.15 (0.425–0.525) Nut for fastening the exhaust pipe of the muffler M8×1.25 20.87–25.77 (2.13–2.63) Nut for fastening the flange of the additional muffler M8×1.25 15.97–22, 64 (1.63–2.31) Nut securing the clutch cable to the engine bracket M12x1 14.7–19.6 (1.5–2.0) Bolt securing the front engine mount bracket M10x1.25 32.2–51, 9 (3.3–5.5) Nut of the bolt securing the front engine mount M10 41.65–51.45 (4.25–5.25) Nut of the bolt securing the left mount of the power unit suspension M10 41.65–51.45 (4.25–5.25) Nut securing the left suspension support of the power unit M10 31.85–51.45 (3.25–5.25) Bolt securing the rear suspension support of the power unit M10x1.25 27.44–34 ( 2.8–3.47) Nut of the bolt securing the rear suspension support of the power unit M12 60.7–98 (6.2–10) Bolt securing the oil receiver to the main bearing cover M6 8.33–10.29 (0.85– 1.05) Bolt for fastening the oil receiver to the pump M6 6.86–8.23 (0.7–0.84) Bolt for fastening the oil pump M6 8.33–10.29 (0.85–1.05) Bolt for fastening the housing oil pump M6 7.2–9.2 (0.735–0.94) Oil pump pressure reducing valve plug M16x1.5 45.5–73.5 (4.64–7.5) Oil filter fitting M20x1.5 37 .48–87.47 (3.8–8.9) Oil pressure warning lamp sensor M14x1.5 24–27 (2.45–2.75) Carburetor mounting nut M8 12.8–15.9 (1.3 –1.6) Nut securing the cylinder head cover M6 1.96–4.6 (0.2–0.47) Clutch Nut securing the clutch housing to the engine block M12x1.25 54.2–87.6 (5.53– 8.93) Bolt securing the clutch housing to the engine block M12x1.25 54.2–87.6 (5.53–8.93) Bolt securing the guide sleeve flange of the clutch release bearing M6 3.8–6.2 (0. 39–0.63) Bolt securing the clutch housing to the flywheel M8 19.13–30.9 (1.95–3.15) Nut securing the clutch housing to the gearbox M8 15.7–25.5 (1.6–2 ,6) Bolt securing the bottom cover to the clutch housing M6 3.8–6.2 (0.4–0.6)

Gearbox Conical screw fastening the drive rod joint M8 16.3–20.1 (1.66–2.05) Bolt fastening the gear selection mechanism M6 6.4–10.3 (0.65–1.05) Bolt fastening the housing gear shift lever M8 15.7–25.5 (1.6–2.6) Nut securing the drive rod and torque rod clamp M8 15.7–25.5 (1.6–2.6) Nut of the rear end of the primary and secondary shaft M20x1.5 120.8–149.2 (12.3–15.2) Reverse light switch M14x1.5 28.4–45.3 (2.9–4.6) Bolt securing the forks to the rod M6 11.7–18.6 (1.2–1.9) Differential driven gear mounting bolt M10x1.25 63.5–82.5 (6.5–8.4) Speedometer drive housing mounting nut M6 4.5– 7.2 (0.45–0.73) Bolt securing the gear selector lever axle M6 11.7–18.6 (1.2–1.9) Nut securing the rear cover to the gearbox housing M8 15.7–25, 5 (1.6–2.6) Reverse fork clamp plug М16×1.5 28.4–45.3 (2.89–4.6) Conical screw fastening the gear selector rod lever М8 28.4–35 ( 2.89–3.57) Clutch housing and gearbox mounting bolt M8 15.7–25.5 (1.6–2.6) Drain plug M22x1.5 28.7–46.3 (2.9– 4.7)

Front suspension Nut securing the upper support to the body M8 19.6–24.2 (2–2.47) Nut securing the ball pin to the lever M12x1.25 66.6–82.3 (6.8–8.4) Eccentric nut bolt for fastening the telescopic strut to the steering knuckle M12x1.25 77.5–96.1 (7.9–9.8) Bolt for fastening the telescopic strut to the steering knuckle M12x1.25 77.5–96.1 (7.9–9. 8) Bolt and nut for fastening the suspension arm to the body M12x1.25 77.5–96.1 (7.9–9.8) Nut for fastening the brace M16x1.25 160–176.4 (16.3–18) Bolt and nut mounting the stabilizer bar to the arm M10x1.25 42.1–52.0 (4.29–5.3) Nut securing the stabilizer bar to the body M8 12.9–16.0 (1.32–1.63) Bolt fastening the brace bracket to the body M10x1.25 42.14–51.94 (4.3–5.3) Nut securing the telescopic strut rod to the upper support M14x1.5 65.86–81.2 (6.72–8.29 ) Bolt securing the ball joint to the steering knuckle M10x1.25 49–61.74 (5.0–6.3) Nut of the rear wheel hub bearings M20x1.5 186.3–225.6 (19–23) Nut of the front wheel hub bearings M20x1.5 225.6–247.2 (23–25.2) Wheel bolt M12x1.25 65.2–92.6 (6.65–9.45) Rear suspension Nut securing the lower end of the shock absorber M12x1, 25 66.6–82.3 (6.8–8.4) Nut for fastening the rear suspension arm M12x1.25 66.6–82.3 (6.8–8.4) Nut for fastening the brackets for the suspension arms M10x1.25 27 .4–34 (2.8–3.46) Nut securing the upper end of the shock absorber M10x1.25 50–61.7 (5.1–6.3) Brakes Bolt securing the brake cylinder to the caliper M12x1.25 115–150 (11 ,72–15.3) Bolt for fastening the guide pin to the cylinder M8 31–38 (3.16–3.88) Bolt for fastening the brake to the steering knuckle M10x1.25 29.1–36 (2.97–3.67) Bolt mounting the rear brake to the axle M10x1.25 34.3–42.63 (3.5–4.35) Nut securing the vacuum booster bracket to the bracket booster M8 9.8–15.7 (1.0–1.6) Nut mounting the main cylinder to the vacuum booster M10 26.5–32.3 (2.7–3.3) Nut securing the vacuum booster to the bracket booster M10 26.5–32.3 (2.7–3.3) Nut of brake connections pipelines M10 14.7–18.16 (1.5–1.9) Front brake flexible hose end M10x1.25 29.4–33.4 (3.0–3.4)

Steering Nut for fastening the steering gear housing M8 15–18.6 (1.53–1.9) Nut for fastening the steering shaft bracket M8 15–18.6 (1.53–1.9) Bolt for fastening the steering shaft bracket M6 Tighten until the head comes off Bolt securing the steering shaft to the gear M8 22.5–27.4 (2.3–2.8) Steering wheel mounting nut M16x1.5 31.4–51 (3.2–5.2) Bolt tie rod end M10 19.1–30.9 (1.95–3.15) Rod ball pin fastening nut M12x1.25 27.05–33.42 (2.76–3.41) Steering rod fastening bolt to rack M10x1 70–86 (7.13–8.6) Steering gear bearing nut M38x1.5 45–55 (4.6–5.6) Electrical equipment Spark plug M14x1.25 30.67–39 (3.13 –3.99) Generator mounting bolt nut M12x1.25 58.3–72 (5.95–7.35) Generator mounting stud nut M10x1.25 28.08–45.3 (2.86–4.62) Notes :