Sometimes a car requires very minor repairs, just replacing the liners, but is it really necessary to remove the engine, look for a hoist or several assistants for such a simple procedure? When it comes to such a need, replacing the liners without removing the engine will help. This simple type of repair does not require a large number of tools, but it does require some skill, so you should immediately evaluate your skills.

Inside the engine on the crankshaft, the liners are attached to a tendril, which is responsible for fixing the bearing in the engine bed when it is running. And lubricant is supplied to them through a special groove; a lack of lubrication always leads to the appearance of snags and jamming. Due to such liners, the wear time of the part is reduced, so they must always work at one hundred percent, otherwise major repairs cannot be avoided in the near future. However, during the trip you may find:

- Rotating the liners. If the fastening tendril has jumped out of its place (sometimes due to lack of lubrication), then it begins to rotate. Due to its rotation, scuff marks will appear on the journal, leading to the need to grind the crankshaft.

- Backlash. This breakdown can be easily heard by the knocking sound of the crankshaft. As soon as you hear suspicious knocking noises, repairs should be made immediately, without the need to remove the motor from the mount.

Why does this happen and how to avoid it?

- The lubricant was too viscous or there was too little of it. Abrasive got into the lubricant and disrupted the smooth running. Lubricant cleanliness is one of the key parameters for preventing any breakdown; it is better to change it regularly every 60-80 thousand km. mileage

- The motor was constantly operating in overload mode. You should not constantly “strain” the engine at high speeds and drive the car for a long time without slowing down.

- When installing previous bearings, the interference was too low. Check everything yourself, tighten the bolts well, it is better to use special equipment.

What are earbuds?

Engine bearings are conventionally divided into connecting rod bearings (between the connecting rods and the crankshaft journals) and main bearings (between the crankshaft and the engine housing). They play the role of sliding bearings. The half-rings of the liners occupy places in special grooves, resting against the front parts of the block with special protrusions along the edges. The fit of the liner depends on its tension, which is set structurally and depends on the size of the half-ring and the diameter of its seat. If the plate loses its stop, it jumps out of the groove and “sticks” to the crankshaft, damaging the engine.

How to replace bearings without removing the engine?

Many car owners think and write on forums that it is impossible to get to the liners without removing or removing them from the engine hood. However, such operations are carried out by repairmen on ships, where the size of the parts is enormous and too much force is required to remove the engine. And if the technique exists, it can be used for simple cars.

- Park the vehicle on a ramp to gain easy access to the engine. If there is protection installed on it, it should be removed and the lubricant drained.

- Remove the box, front cover and loosen the camshaft chain in advance. If you're not too lazy, it's better to remove it entirely so it doesn't interfere.

- Remove the starter and pan (if the beam does not interfere). If it interferes with operation, you will have to lift the motor and pull out the pan from under it.

- You now have access to the crankshaft. The easiest way is to replace the connecting rod bearings. The old bearings are pulled out after unscrewing the head screws; it’s easy to put new ones in place, just don’t forget to lubricate them well with the same engine oil that is in your engine.

- It is more difficult to replace the main bearings without removing the engine. You will need to lower the crankshaft by loosening its fastening. You don’t need to lower it much, ten, maximum fifteen centimeters.

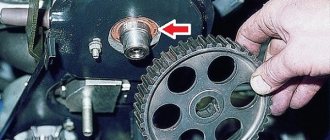

- Now it will be easier to pull out the earbuds. But you will need an aluminum rivet, which must be inserted into the lubrication hole, so it will push the bearing out. The main thing is that the size of the rivet is suitable and does not scratch the crankshaft.

View Queue

Queue

- delete everything

- Disable

Purpose of crankshaft bearings

These parts are sliding bearings that ensure acceptable operation of the connecting rods when they rotate the crankshaft.

At this very point, during the operation of the power unit, colossal loads arise on the parts. Imagine, the piston, after igniting the fuel-air mixture, gains a simply monstrous speed and at the same time, at the lowest point of its stroke, it encounters an obstacle in the form of a shaft elbow, which provides it with a reciprocating maneuver. It is this “return” that puts the greatest load on the connecting rod bearings. Of course, no one has yet canceled the laws of physics, therefore, due to friction, sooner or later the liners will fail, that is, they will no longer provide the contacting parts with minimal friction. As they wear out, the oil pressure will decrease and the so-called oil film will no longer provide the proper degree of protection.

It is also worth knowing that liners are divided into two groups: connecting rod and main. To see the difference between them, look at the image below to see which ones are located and where:

Factors influencing the price of the service - replacing the crankshaft without removing the engine in Kirov

It is common knowledge that the cost of car repairs depends on several aspects. Among them are the following:

- cost of spare parts (original, China, alternative manufacturers);

- personnel qualifications;

- level of equipment of the service station (availability of painting booths, lifts, special tools and equipment, etc.).

For example, the price of the service - replacing the crankshaft without removing the engine in Kirov will also depend on factors such as the age, make and model of the car. We are confident that car services will compete for your order and offer the best conditions. The centers have a system of discounts for regular customers.

General information

When repairing an engine, a number of operations can be performed without removing it from the car. As a rule, the following operations can be performed without removing the engine:

- removal and installation of the cylinder head;

- removal and installation of the camshaft (after removing the cylinder head);

- removal and installation of toothed drive belt and sprockets;

- removal and installation of the oil pan and oil pump;

- removal and installation of pistons, connecting rods and connecting rod bearings;

- replacing engine mounts;

- replacing crankshaft seals;

- removal and installation of the auxiliary shaft;

- Removing and installing the flywheel.

Removing the engine from the car is necessary to perform the following operations:

- replacing the crankshaft main bearings;

- removal and installation of the crankshaft;

- replacing cylinder liners (when installing them).

Before starting repairs, it is necessary to drain the liquid from the cooling system and the oil from the engine crankcase and gearbox. The liquid is drained through three drain valves. When disassembling the engine, it is recommended to place small parts in separate containers, and when disconnecting wires from electrical equipment, return the screws and nuts to their previous position and tighten them by hand.

Before disassembling, the engine must be cleaned of dirt and oil, washed with kerosene or a degreasing solution, and then blown with compressed air. It is advisable to remove instruments and assemblies from the engine on a stationary rotary stand. Parts removed from the engine should be placed in specially prepared containers in which they are sent for washing, testing and troubleshooting operations.

Professional crankshaft alignment!

The crankshaft should be adjusted when, as was written above, the runout of the middle crankshaft journals exceeds 0.1 mm relative to the outer ones.

Specialists know several methods for straightening the crankshaft, but most of them have various disadvantages, which were taken into account when developing a unique method called the “element-by-element cold straightening method” or Buravtsev’s method.

This method allows you to straighten crankshafts that had an initial journal runout of more than 1 mm with the final result being only 0.01 mm! None of the previously known methods for straightening crankshafts gave such a result. Moreover, high-quality straightening can replace grinding, especially for new “factory” crankshafts, which often have unacceptably large runout (from 0.05 mm or more).

Achieving high quality crankshaft repairs is possible only if all technological techniques are correctly performed during grinding and finishing of the working surfaces of the crankshaft journals and haptics.

Autopride specialists will qualitatively perform the necessary work on repairs and grinding of crankshafts of engines of any foreign-made cars not older than 2000. Engine overhaul requires a serious approach.

Removing crankshafts

| Engine overhaul | 3 cyl. | 4 cyl. | 5 cyl. | 6 cyl. | 8 cyl. |

| Passenger car (gasoline) | 1 p | 40 000 p | — | — | — |

| Minibus (petrol) | — | 50 000 p | — | — | — |

| SUV (petrol) | — | 60 000 p | — | — | — |

| Cylinder head repair, in-line engines | 3 cyl. 6th grade | 3 cyl. 12th grade | 4 cyl. 8th grade | 4 cyl. 12th grade | 4 cyl. 16th grade | 4 cyl. 20 grades | 5 cyl. 10 grades | 5 cyl. 20 grades | 6 cyl. 12th grade | 6 cyl. 24 grades |

| Valve seat machining | — | 2p | — | — | — | — | — | — | — | — |

| Cylinder head repair, V-shaped engines | V6 12 cl. | V6 24 cl. | V6 30 cl. | VR6 12 cells | VR6 24 cells | V8 16 cl. | V8 32 cl. | V8 40 cl. |

| Valve seat machining | — | 2p | 3p | — | — | — | — | — |

| Engine repair | Domestic cars | Foreign cars small class | Foreign cars middle class | SUVs | Minibuses |

| Cleaning the injectors (rinsing the “injector”) | 1 800 p | 1 800 p | 1 800 p | 1 800 p | 1 800 p |

| Coolant temperatures | — | 800p | 800p | 1 000 p | 1 000 p |

| Replacing the air filter | 200p | 200p | 200p | 200p | 200p |

| Replacing spark plugs | 400p | 500p | 500p | 1 500 p | 2 000 p |

| Replacing, adjusting, washing the throttle pipe | 400p | 500p | 600p | 700p | 700p |

| Replacing the timing belt or chain | 1 000 p | 3 500 p | 4 500 p | 5 000 p | 5 000 p |

| Replacing the water pump | 800p | 1 000 p | 1 000 p | 1 500 p | 1 500 p |

| Changing the engine oil | 500p | 500p | 500p | 600p | 700p |

| Engine flushing | 500p | 500p | 500p | 600p | 700p |

| Engine radiator replacement | 1 000 p | 1 500 p | 1 500 p | 2 000 p | 2 000 p |

| Muffler replacement | 500p | 700p | 700p | 1 000 p | 1 000 p |

| Starter replacement | 500p | 650p | 650p | 1 000 p | 1 200 p |

| Generator replacement | 1 000 p | 1 000 p | 1 000 p | 1 000 p | 1 000 p |

| Coolant replacement | 800p | 800p | 800p | 1 000 p | 1 000 p |

| Replacing the engine assembly | 4 000 p | 6 500 p | 6 500 p | 10 000 p | 10 000 p |

| Adjustment of valves | 1 000 p | — | — | — | — |

| Installing crankcase protection | 150p | 150p | 150p | 150p | 150p |

Acting as a motion converter in the crankshaft system, the crankshaft rotates in the engine structure on main journals (5 bearings in a 4-cylinder engine). High dynamic load explains the wear of the journals (main and connecting rod), the corresponding bearings, and sometimes damage and bending of the entire part. These are the main reasons for removing the crankshaft, except for the forced necessity when disassembling the engine.

Many models of modern foreign cars with reduced engine designs do not provide for the dismantling of the crankshaft or other components of well-coordinated car mechanisms, promising a resource reserve of 200 thousand km. and more. However, the peculiarities of repairing a crankshaft are well known to the domestic service industry thanks to the local automotive industry.

It is only possible to safely remove the crankshaft, repair it and install it back on a dismantled engine. At a minimum, to do this you need to disassemble the cylinder head and then remove the crankcase and gasket. Next, you need to remove the timing drive sprockets (upper and lower), remove the timing chain, unscrew the rear oil seal cover and, if necessary, remove the liners with the piston group.

Key points for removing the crankshaft

- For all engines without exception, it is initially recommended to carry out a procedure for measuring the axial play. An exceeding value (over 0.3 mm) is “treated” by correct installation of new thrust rings (half rings).

- It is also important to put the appropriate marks on the connecting rods with caps so that later you can install each one in its place.

- After this, you can begin to unscrew the bolts and remove the covers and steel-aluminum liners one by one. It is important to place the marked parts in an orderly manner for easy installation of the crankshaft.

Next, the main bearing caps are dismantled, the thrust half-rings are removed, and the remaining fastening bolts are unscrewed.

As a result, you can remove the crankshaft and easily carry out operations with the liners. Car enthusiasts who have little interest in major repairs are often occupied with another question:

Is it possible to replace the liners without dismantling the unit?

The approach to repair, taking into account the characteristics of engines, may be different.

Simply by removing the pallet and overcoming difficult access to the liners, there is a risk of getting even more work. The point is that in order to replace the last of a number of parts, you need to lower the shaft considerably, guaranteed to damage the seals. But first you will have to “move” the gearbox by unscrewing the fasteners. Leaking and replacing the camshaft oil seal after such intricate manipulations becomes a regular occurrence.

The next “surprise” is the difficult dismantling of the flywheel, which is securely secured using a hard-to-reach flange on the crankshaft being removed.

In addition, it is more effective to carry out the necessary check of the crankshaft after grinding (sometimes multiple times) on an inverted block. At the same time, it doesn’t hurt to clean the combustion chamber with valves and carry out preventive maintenance.