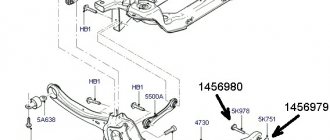

To fully understand the picture and due to the limit of 20 photos, I had to create a post with pictures and part numbers of the front pillar parts.

If you use original Matiz springs (soft), then we will need spring ties.

Let's start the assembly process, take the shock absorber, pump it, the algorithm is as follows:

1. Turn the shock absorber upside down and slowly compress it; 2. Wait 5 seconds; 3. Hold the rod in the retracted position (I used the support cover for this), turn the shock absorber over with the rod up; 4. We wait 5 seconds, release the rod, on gas-oil ones it will extend itself, on oil ones it must be smoothly pulled out by hand until it stops, again we wait 5 seconds; 5. We repeat points 1-4 8 times in a circle, we finish the operation stopping at point 4. 6. Holding the shock absorber in a vertical position, with the rod up, we check. We push in and out the shock absorber rod, it should move smoothly and without dips, without there should be extra gurgling and crunching sounds. If everything is OK, then the shock absorber will work well and for a long time. After pumping, keep the shock absorber only vertically, with the rod up; if it suddenly turns over, pump it again.

If you install the shock absorber without pumping or turn it over after pumping, then after a short period of time you will get a dead, leaking shock absorber, and until it dies during “work” on bumps, it will rattle, it will seem like the ball joints are rattling and the entire suspension will generally fall apart.

We will assume that the shock absorber is pumped and in good condition.

We fix the shock absorber vertically, you can, of course, hold it in your hands, but this is not particularly convenient, it is better to clamp it in a vice (do not squeeze it too hard, so as not to damage it)

In this case it is a Billstein B4, the lower cup for the spring is slightly modified, in the original the grip is not so high.

We install the spring (If the spring is original or long, first compress it with spring ties; if the spring is cut, then with the cut part down), in the picture the spring is not original.

Chevrolet Lacetti Removing the shock absorber strut and disassembling it

We remove and disassemble the shock absorber strut when it is necessary to replace its upper support, bearing, spring, compression stroke buffer, or the efficiency of the telescopic strut has decreased.

If the telescopic strut or spring is faulty, both struts or springs must be replaced so that the performance of the shock absorber struts on both sides of the vehicle is the same.

In the engine compartment, remove the cover of the upper pillar mounting.

Holding the shock absorber rod with a “9” head and a “17” z-shaped wrench, loosen the tightening of the nut of the upper strut fastening. We hang and remove the wheel. We securely fix the car on a factory-made stand. We disconnect the ball joint of the stabilizer bar from the bracket on the shock absorber strut body (see Removing the stabilizer bar). Remove the bracket securing the front wheel brake hose coupling to the bracket on the shock absorber strut body and remove the coupling from the hole in the bracket (see Replacing the front wheel brake hose).

We remove the rubber bushing of the wheel speed sensor wiring harness from the bracket hole on the shock absorber strut body.

Using a 17mm socket, unscrew the nut of the bolt securing the strut housing to the steering knuckle, holding the bolt from turning with a spanner of the same size. Similarly, unscrew the nut of the other bolt.

Using a punch we knock out the bolts.

We remove the steering knuckle from the strut housing bracket. Completely unscrew the nut of the upper mounting of the strut to the body...

...and remove the stand.

Remove the thrust washer from the mudguard cup. To disassemble the rack, clamp it by the bracket in a vice. We install two ties on the spring diametrically opposite each other so that they tighten at least four turns of the spring.

Why do you need a support bearing?

The question of why a support bearing is needed is asked by many novice car enthusiasts, but before you figure it out, you need to understand how shock absorber struts work and are installed. Shock absorbers in a car are designed to ensure a smooth ride, smooth out shocks and vibrations when driving on uneven roads, bumps and potholes. On front-wheel drive cars, the struts are attached to the body at the top, to the so-called “glasses”, and at the bottom they are connected to the steering knuckles. The support bearing (PU) is often called the upper shock absorber support; this generally simple device plays a very important role in the suspension of the car, and if it is faulty, it will become difficult to drive the car. It is necessary to monitor the condition of the supports and replace them in a timely manner - we must not forget that traffic safety depends on them.

A typical OP consists of three parts:

- an upper metal plate with fasteners (most often these are three studs);

- lower base;

- directly to the bearing itself.

The lower and upper plates are rigidly connected to each other, the bearing itself is usually pressed into the body of the support, and the design options for the OP can be different; each automaker uses its own design solutions. With the help of a support, the shock absorber strut is fixed to the body; due to the OP, the shock absorber rotates smoothly relative to the body, with no play.

What types of support bearings are there?

The upper shock absorber mounts on different car models can differ significantly in design and mounting;

- with two or three studs;

- with threads in the body of the cup for screwing in bolts.

To dampen oscillations and vibration, shock absorber cups often have a rubberized surface or separate elastic elements, and the bearing itself can be pressed out and replaced.

What other support bearings are there? There are car models on which the upper support is not attached to the body “glass” with studs or nuts; the shock absorber is held in place by the upper steel plate. A wide metal washer is secured here with a nut screwed onto the shock absorber rod; to ensure a soft connection, a rubber spacer is placed under the plate (a similar design is found on the Chery Amulet car).

What is a support bearing and a front shock absorber strut support?

The basis of a MacPherson-type spark plug suspension combines a shock absorber and a spring, that is, one telescopic spark plug is capable of both acting as an elastic element and absorbing the vibration energy of the body relative to the road.

In other words, this assembly is called a "suspension strut" or "telescopic strut".

The strut is attached from below through a ball joint to the positioning lever, and a bearing support is installed on top, allowing the strut body with the spring to rotate about its own axis under the influence of the steering rod.

The upper support directly includes the rolling bearings, housing, damping rubber elements and mounting pins.

On the one hand, the body is rigidly connected to the body shell, and on the other, the shock absorber rod and spring support cup are attached to it. Rotation occurs between them.

Bearings according to their structural organization can be divided into:

- by the nature of the rolling body - ball and roller;

- bearings with removable outer or inner races;

- integrated angular contact bearings of non-separable type;

- bearings without cages, which are a powerful cage with built-in rolling elements; the support flanges act as tracks.

During assembly, a supply of lubricant is placed in the bearing, but its operating conditions are such that it is not enough for a long time.

Front shock absorber support bearing faults

Like any parts in a car, OPs wear out and break over time; these suspension elements have their own service life. For each car model, the shock absorber supports have their own service life; on average, parts can last from 50 to 100 thousand kilometers without replacement. But for various reasons, support bearings can fail prematurely; the main causes of failure are:

- driving a car on bad roads;

- poorly performed repairs (for example, during installation the nuts were not fully tightened);

- low quality of spare parts or defects, most often non-original parts are of poor quality;

- destruction of the OP as a result of an impact (when hitting an obstacle or due to an accident);

- ingress of dirt and moisture onto the parts of the “support”; on many car models these parts are not protected in any way.

To make sure that the upper support is faulty, it is necessary to carry out diagnostics; in general, checking the support bearing is not difficult, but it is better to diagnose the suspension together.

Symptoms of malfunction

The bearing design itself is simple. But this does not prevent him from performing important tasks. It was mentioned above that the part is subjected to heavy loads. Meanwhile, she has to withstand the weight of the entire front part of the car.

When the car enters turns, lateral loads occur, which also leads to bearing wear. Frequent travel on broken roads adds fuel to the fire.

Characteristic signs will help you understand that it is time to check the condition of the supporting part:

- Body knocks - there is a purely mechanical connection between the part and the cups, and therefore, even with slight play, extraneous sounds will be heard.

- Difficulty turning the steering wheel - this can be clearly felt on cars without power steering.

- Crunches or squeaks usually occur in the area of the support cups when the car makes turns.

- Deviation from a given course.

The appearance of extraneous sounds from the suspension should under no circumstances be ignored! Otherwise, all this threatens with more serious consequences, due to which the safety and comfort of using the car will be significantly reduced. It is worth considering that a vehicle with existing malfunctions (especially suspension components and other important mechanisms) poses a potential danger not only to the driver and his passengers, but also to other road users. Therefore, each owner must treat his own car responsibly and repair any breakdowns in order to avoid any complications, including sad ones.

How to check the serviceability of the front strut support

The OP check is performed when the car is parked on a level surface; there is no need to hang the wheels. Diagnosis is carried out as follows:

- one of the inspection participants in the front rocks the car up and down;

- another person performs a visual inspection to see if there are any gaps.

Additionally, you can turn the steering wheel and observe the behavior of the shock absorbers, put your hand on the upper support while rotating the steering wheel or rocking the car - if there is play, you will feel it with your hand; clicks and squeaks may also be heard. Another diagnostic option is to grab the top cup protruding above the glass and try to rock it from side to side, in this case the play will also be noticeable.

Signs of a faulty support bearing may include:

- knocking in the front suspension while the car is moving;

- periodically occurring creaking while turning the steering wheel;

- crunching, knocking from the front when driving on an uneven road, for example, when driving at a railway crossing;

- tight turning steering wheel;

- instability of the car on the highway.

It is possible to accurately identify the fault only by disassembling the shock absorber struts and performing a visual inspection of the parts.

How to properly check the support bearing in a car

If any malfunction appears in the front suspension of a car, the first thing any motorist must check is the support bearing. It is located between the upper spring cup and the support itself. To do this, just grab the “cup” of the rack with your hand and shake the car a little.

Constantly sharply changing loads, as well as shock loads and abrasive dust particles, contribute to bearing wear. Ultimately, all this can cause complete failure. As a result, the shock absorber rod begins to deviate from its axis, and the bearing will creak, knock, play and squeak. Wear of the support bearing leads to a violation of the wheel alignment angles. As a result, vehicle controllability decreases and tire wear accelerates.

Support bearing cost

The upper support of the front strut is a relatively inexpensive part; the cost of a spare part depends on the car model, brand, design features; it is no secret that car shops can sell the same spare parts at different prices. The approximate price of a shock absorber bearing is from 150 to 2200 rubles; for prestigious foreign cars, parts usually cost significantly more; you can buy cheaper ones from non-original production. As you can see, the range in prices for these spare parts is quite large; the most expensive bearings are sold for cars:

- Mazda 3;

- Toyota 4Runner/ Avensis;

- Nissan Juke;

- Honda CR-V;

- Mercedes W204;

- Lexus RX300;

- BMW X6.

At a very affordable price you can purchase support bearings for such car models as:

- Chevrolet Lacetti;

- Daewoo Matiz;

- Honda Fit;

- Nissan Almera;

- Chery Amulet;

- Hyundai Accent.

Support bearings for Chinese and Korean cars are generally inexpensive; spare parts for brands such as BMW, Audi, Lexus, and many purely American cars are almost always more expensive.

Device

The front shock absorber support consists of several parts:

- top plate, which has fastening elements;

- a bearing that smoothes out the beating of the shaft, taking on the load during movement;

- the base of the bowl, which is often pressed into the top plate.

The types of execution are varied. This depends on the model and manufacturer. There are cars that do not have locking nuts. This mount rests through a rubber gasket on the bowl itself, on which a plate is installed on top. The shock absorber shaft, in turn, rests against it.

Some models of the front shock absorber support are made with welded or pressed-in lock nuts. Thanks to the use of special bearings, this design can withstand heavy loads.

How to change the support bearing on a VAZ-2115 car

To replace the OP without a lift, the car will have to be jacked up; before starting work, stops should be placed under the rear wheels. Next we perform the following steps:

- unscrew the hub nut, for this purpose you will need a 30mm head with a wrench or pry bar (depending on the design of the head);

- remove the front wheel on the side where the bearing will be replaced, hang the car on a jack, and install a stand under the threshold to secure it (you can use a wooden block);

- Having pulled out the cotter pin with pliers, unscrew the nut holding the steering tip, using a puller, disconnect the tip from the shock absorber strut;

- unscrew the two caliper bracket bolts (13 wrench), if necessary, hold the caliper guide with the “17” wrench;

- move the caliper to the side on the brake hose;

- disconnect the ball joint (two bolts) from the steering knuckle, move the assembly with the axle toward you, freeing the hub from the CV joint splines;

- from above, under the hood, tighten the three nuts of the upper support (13 wrench);

- Having removed the rack assembly, use zip ties to compress the spring evenly on both sides;

- Having fixed the shock absorber rod in a stationary position with a special wrench, use a 22 mm head to unscrew the nut that holds the entire structure, including the support bearing;

- Next, remove the old bearing from the rod, install a new bearing without removing the couplers, tighten the nut to 22 until it stops;

- loosen and remove the ties and assemble.

Some car owners recommend using a gas wrench instead of a special wrench to hold the shock absorber rod, but this is not recommended; you can scratch the mirror surface, and then the shock absorber will leak.

Since many VAZ models have an identical suspension design, exactly the same as on the VAZ-2115, replacement is carried out on cars 2108-09-099, 2110-11-12, 2113-14. Due to the fact that with this sequence of operations the steering knuckle is not disconnected from the shock absorber strut, wheel alignment is not necessary after repair.

What types of malfunctions are there?

Most often, the first signs of problems with the support bearings will be knocking sounds in the suspension. A heavily worn and loose bearing will make this sound at every significant bump.

Depending on the design, the shock absorber rod can either be connected to the inner race of the bearing, or secured through a bushing and a rubber damper on the body.

In the first case, bearing wear will more significantly affect the car's handling, camber and caster angle settings, and therefore can be noticed even before knocking occurs.

As already mentioned, the sealing of the unit from road dirt and moisture leaves much to be desired. As all this accumulates in the bearing, it intensively corrodes and begins to make sounds of a different kind, reminiscent of creaking and crunching.

If such a part is disassembled, the picture will be characteristic - the cavity between the clips is occupied by rusty fragments of former balls or rollers.

Some Tips for Replacing the Front Shock Absorber Upper Mount

- When disassembling, the hub nut should be loosened before you remove the wheel; if the car is already suspended on a jack, it will not be easy to move it.

- If you do not have a ball joint and tie rod remover, the steering tip can be knocked out by hitting the joint joint with a heavy hammer, the blows must be sharp and precise. Even if the tip seriously “boils” in the connection, after several attempts it will still come off.

- To make it more convenient to disassemble the shock absorber strut after removal, you can immediately (while the shock absorber is still on the car) loosen the shock absorber rod nut.

- To make the nuts and bolts easier to turn off during the next repair, it is recommended to treat the fasteners and threads with graphite lubricant during assembly.

- When removing the shock absorber assembly with the hub and steering knuckle, it is a good idea to check the condition of all suspension parts on this side of the wheel. Such diagnostics will save your money and time, because it is often discovered that along with a defective support bearing, for example, a shock absorber is also faulty, or the outer CV joint has a large amount of play.

- You need to compress the spring with ties gradually, squeezing the coils little by little on one side and the other. The spring is compressed until the upper support begins to rotate freely; too much compression of the coils is not required, and in general it is unsafe.

In general, replacing the support bearings on the front struts is quite simple; to make a replacement, you don’t have to go to a car service center; you can do the work yourself.