A proven method for pressing out a bearing using bread

There are situations when it is necessary to press a bearing out of a blind hole. The most budget option is to use bread.

- We fix the product in a vice so that the seat is at the top.

- We select the required diameter of the bolt for pressing out.

- Take a soft piece of bread.

- Place the bread in the center, take a hammer and hammer the crumb inside using a bolt with the required diameter.

- We repeat the process of placing bread inside until the used crumb with its mass does not displace the bearing from the seat.

- We clean the bearing seat and carry out the work of pressing the new part into its seat.

There is a possibility of using plasticine or clay, but it will take longer to clean the nest, lubricate it, and carefully put it into operation before updating the product. And the bread is soft, so it does not damage surfaces or scratch walls. Plasticine or clay can leave “traces” and get into small cracks and threads, and this lengthens and complicates the process of cleaning the bearing seat.

Thus, you can use the proven method of pressing out a bearing using bread without fear of consequences. Just do the preparatory work and prepare the tools for repairs. Go for it and you will succeed! The main thing is to believe in the success of the business.

Pressing out the wheel bearing

| Attention Bearing Buyers Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: +74956460012 Delivery of bearings throughout the Russian Federation and abroad. Bearing catalog on the |

Attention Bearing Buyers

Dear customers, send your questions and requests for the purchase of bearings and components by mail or call now: +74956460012 Delivery of bearings in the Russian Federation and abroad. Bearing catalog on the website

Attention Bearing Buyers

Dear customers, send your questions and requests for the purchase of bearings and components by email or call now:

+7 Delivery of bearings throughout the Russian Federation and abroad. Bearing catalog on the website

A car is a means of transportation and there are no main or secondary parts in it, but there are parts that carry the main loads. In the chassis this is the wheel hub. This part ensures the connection of the wheel and chassis into a single whole. Thanks to this part, it is possible to replace and repair wheels, brake drums, and failed chassis parts; it is an integral part of the steering system.

The design of the hub depends on the types of vehicles, driving or driven axle. Additional sensors, additional systems (ABS) and others that improve the performance of the vehicle can be installed on the wheel hub. is the transmitter of movement of the suspension - wheel.

One of the parts that takes the load from the wheel onto the chassis is the bearing, which is subjected to extreme variable loads in all directions because The hub is installed on the axle through clips and rollers onto a pin, which is rigidly attached to the frame.

When installing products, mainly two options are used, which are considered “classic” - the part is installed on two roller cages, which can be angular contact conical or double-row cylindrical. Product type - with separators closed with a lid, which is additional protection for difficult operating conditions of the chassis. Also, the reliability of the unit is greatly influenced by the quality of the manufacturers.

The installation of two angular contact products is determined by the operating conditions of a variable load; here, two angular contact products operate in different load directions.

For reliable operation of the rollers, they must be protected from aggressive environmental conditions, which is ensured by installing additional protective devices:

- protective cone washers;

- rubber seals - oil seals;

- The operation of the separator in lubricant is ensured by a special type of product with closed cages.

The guaranteed operating life of “protected” units is 50,000 hours, after which they require replacement with new ones. Typically, such units are not maintained and are replaced by pressing out and pressing the wheel bearings with new ones during “large” types of maintenance, when complete disassembly and repair of the chassis is required.

Hub service

During the operation of the car, shafts, holders, rollers and fasteners are subject to wear, the reason for this is aggressive driving, treatment of the road with reagents that create an aggressive environment, and potholes that create additional load on the wheels. Therefore, it is necessary to periodically check and, if necessary, timely replace worn parts: oil seals, bushings, and sometimes the part itself. When installed correctly, double angular contact products work reliably, but during operation they also develop play that will require repair by pressing out the front or rear wheel bearing.

Determining the condition of parts

To determine the condition of the hub parts, it is necessary to lift the car wheel so that one or more wheels are above the ground. And shake them simulating vertical and horizontal load. Before checking the wheel, it is necessary to check the stability of the body; to do this, push the body from the side; the body must stand securely; if there are vibrations, it is better to shift the safety pad. If the wheel play is no more than 2 mm, then you can try to adjust the gap in the rolling elements of the product.

Eliminating backlash

To eliminate play of 1-1.5 mm, the procedure is almost the same for all cars:

- The bolts on the hub, which is being adjusted, are loosened;

- The protective cap covering the adjustment nut is knocked out; for this you can use a screwdriver and a hammer;

- The stopper is pulled out after squeezing it with pliers, or by pushing away the fixing tendrils;

- Using special keys or a screwdriver, tighten the hub nut until it stops, after which it must be loosened by one quarter of a turn;

- Next, the play is checked again, then the wheel is rotated in both directions. If humming, clicking, or other extraneous sounds remain, the clips need to be replaced.

On a note! Cylindrical wheel bearings are not adjustable.

Let's take an example of replacing the wheel hubs of a VAZ-2110 car.

To press out the wheel bearing you will need the following tool:

- special clamps or bench vice;

- kit for pressing and pressing wheel bearings;

- set, screwdrivers and thin pliers;

- wrenches, bushing puller, hammer;

- torque wrench;

- Litol lubricant or foreign equivalent

The hubs of front-wheel drive and rear-wheel drive cars are different. Therefore, the operations for the change are also different. The similarity of the designs is that there are two products - internal and external. The outer bearing is always located in the hub, but the internal ones have a different design, for example, in a front-wheel drive car the inner one is located in the steering knuckle. If you have the skills to replace clips, you won’t have any problems with these either. Also, for a rear-facing car, a special puller will most likely be required. All devices are needed in order not to damage the seating surface under the internal and external bushings.

To change it is necessary to carry out operations in the following sequence:

- The front cap is removed from the disc. When removing it, you need to pay attention to the tightness of the fit in the socket. The tight fit protects the inside of the bushing well from dirt;

- Using a screwdriver, remove the stopper of the hub nut, which protects it from unwinding;

- Then the nut is slightly loosened with a wrench, but not completely unscrewed;

- Unscrew the nuts securing the desired wheel. To do this, first loosen the nuts on the unjacked wheel;

- The brake disc caliper is removed by unscrewing the bolts securing them. It is better to immediately hang it on wire loops so as not to interfere with further work;

- The brake disc is removed by unscrewing the fastening of the disc to the hub;

- The hub nut is unscrewed completely and the washer is removed;

- A special puller is used to remove the hub from the steering knuckle;

- For rear-wheel drive VAZ cars, this procedure will not take time. Front-wheel drive cars require a little more effort: the fastening of the ball joint to the steering knuckle is unscrewed; the CV joint is removed;

- The steering knuckle is clamped with special clamps or yews, the locking ring is removed, and the clips are removed using a special device;

- For rear-wheel drive cars, the bearings are pressed out of the bushing part; a puller may be needed for this;

- The surfaces of the bushings are cleaned of dirt;

- The inner bearing is installed in the steering knuckle using a special kit for pressing out and pressing in wheel bearings;

- On rear-wheel drive VAZ cars, the bearings are pressed into the hub. It is better to replace existing sealing seals with new ones;

- Lubricate the seating surfaces of the bushings with lithol;

- The hubs are assembled in the reverse order;

- The hub nut is tightened with force in accordance with the repair manual for this brand. Control is carried out with a torque wrench.

Some recommendations for choosing a wheel bearing

When choosing a product for the hub, you need to keep the following in mind:

- Original parts from the manufacturer are always preferable, this applies to Russian cars and foreign cars;

- If it is not possible to purchase an original part, it is always better to choose trusted suppliers;

- Before purchasing, you need to look at the markings on the packaging and on the clips of the products, they must match. If there is a discrepancy, the purchase must be refused;

- To ensure that the purchased product fits correctly, it is better to use paper or electronic spare parts catalogs before purchasing.

- If there is an original catalog number and article, it is necessary to select products with nominal values according to the original.

Hub repair kit

The principle of operation of the kit for pressing out wheel bearings is quite simple; to do this, just select the diameter of the thrust ring to match the outer diameter of the ring, install the thrust sleeve and tighten the threaded screw and tighten the nut to pull the outer race out of the sleeve. Using a device for pressing out a wheel bearing helps to avoid inevitable defects in the seating surface of the bushing for the outer race when knocking out the race manually with a chisel or other devices. When landing on a defective surface of the bushing, uneven compression of the inner and outer races occurs - this can lead to their ellipse, which accelerates the development of roller defects. Using the device will help you avoid the big troubles and costs of replacing the entire part due to incorrect installation of the clips.

Manufacturers of the most popular and high-quality components

Products and components: TIMKEN, ZKL, FAG, SKF, URB, INA, Craft.Russian, Minsk OJSC MPZ, OJSC SPZ-group, Rostov-on-Don OJSC GPZ-10, Vologda OJSC VPZ , Kursk OJSC KPK, Samara OJSC SPZ-4.

themechanic.ru

Replacing the wheel bearing with your own hands; rear, front, video

Replacing a wheel bearing is a routine job that all car enthusiasts can do. In this publication we will look at how to replace the front and rear wheel bearings with your own hands.

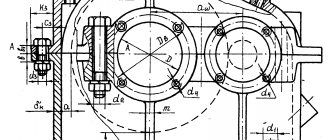

Hub unit

You cannot change a wheel bearing without understanding this component of the chassis.

The front axle hub assembly is also called the steering knuckle, since it transmits the desired direction of movement to the wheels through the steering rods. The latter, in turn, are required to rotate. The role of the wheel bearing is in the articulation of the steering knuckle and the hub to which the wheel is directly attached. There are many types of bearings (tapered, spherical, roller, radial ball, etc.), but this is not of fundamental importance for replacement.

Novice DIY repair enthusiasts will be interested in learning how this part works. The product consists of an outer ring, a rolling body, a cage and an inner ring. For lubrication, the insides are filled with grease.

The essence of the work is to transmit rotation through rolling bodies. In this case, the outer and inner cages are not connected to each other. In our case, the inner race is articulated with the hub, and the outer race with the steering knuckle.

Inside the hub there are teeth that serve to engage the hub with the drive shaft. It is these splines that allow torque to be transmitted from the gearbox to the wheels of the car.

Support mechanisms

It’s worth noting right away that replacing the wheel bearing is possible in two ways:

Universal puller

- canonical, which is the only option if you want the part to go happily ever after;

- artisanal. In this case, the service life of the new spare part depends entirely on your skill.

The first method involves the use of specialized tools: a hub and bearing puller, tools for pressing and pressing. You can build such a mechanism with your own hands. A hydraulic bottle jack can be used to force the bearing in and out. To successfully press out, you need a mandrel whose diameter will be larger than the outer diameter of the hub. One edge of the mandrel will rest against the steering knuckle, and the second against the plane pushed by the jack. Another attachment will be used for extrusion. Its diameter should correspond to the outer diameter of the bearing or be 1-2 mm smaller.

Another type of design involves using the threaded joint between the bolt and nut as a force to push out the bearing. The principle of selecting attachments is the same as for the previous puller.

The second replacement method involves using various attachments and a hammer. They knock out and then drive the wheel hub and bearing back in.

We change it with our own hands

Using the Daewoo LANOS as an example, let's look at how to replace the front wheel bearing.

- Install wheel chocks.

- Remove the retainer and “tear off” the hub nut.

- Raise the car, securing the position using a log or other type of support.

- Unscrew the brake caliper and remove the pads. The caliper itself can be secured with a rope. Be careful not to damage the brake hose. Remove the brake disc.

- Unscrew the stabilizer link, steering linkage and ball joint.

- Using a ball joint remover, remove the end and ball from their seats.

- Unscrew the bolts securing the shock absorber strut under the hood of the car.

- Pull the steering knuckle off the drive shaft splines.

- Remove the brake disc protection. Move the stand to a convenient place for working.

- Install the puller and separate the hub from the steering knuckle.

- Using special curved pliers, squeeze the corkscrew ring. While holding it compressed, pry it out using a flathead screwdriver. Remove the second one in the same way.

- Now, on the reverse side, install an extension that will press out the bearing. Remove it from the front wheel steering knuckle.

Press-fitting

Whether replacing the front wheel bearing will be successful depends entirely on proper installation. Before pressing, be sure to clear the surface of dirt and clean the grooves of the retaining rings. The edges of the seat in the steering knuckle can be wiped with sandpaper. Be sure to lubricate the bearing itself and the cavity inside the “fist”. Of course, the first step is to install a new retaining ring.

Place the hub strictly in the center of the mounting hole. You can try to fill it a little with light blows of your hand. Place the unit under the press or mount a puller for pressing. Be careful that the part is not distorted. Otherwise, replacing the front wheel bearing will be in vain. Soon a hum or play will appear again.

When you feel that the bearing has stopped, you can stop. Install the second retaining ring. Press the hub into the steering knuckle. We can say that the bearing replacement was successful.

What to do if part of the bearing remains on the hub

Oddly enough, but often replacing bearings does not happen without incidents. When pressing out the hub, the inner race of the front hub may remain in its seat. The best solution in this case is to tighten the clip using a special puller. Unfortunately, its cost is quite high, so only service stations can afford such a tool.

Folk craftsmen recognize two ways out of this situation:

- file the remains with a grinder and then cut them with a chisel;

- knock off the clip using a chisel.

Both of these methods are dangerous because there is a risk of damaging the front bearing seat on the hub. If you use the second method, be careful not to damage the mating plane.

If you cut through the landing site, it is better to replace the part immediately. Experience shows that new bearings on such hubs “run” very little.

We recommend trying to use a hub puller. And only in case of “dead” sticking of the clip should resort to emergency measures.

Rear axle

The principle of pressing out and pressing in the rear wheel bearing is no different from the work done on the front axle.

Working without a puller

If you are changing the front wheel ball bearing using a makeshift method, pay attention to the following tips:

- a socket head of a suitable diameter can be used as a clip for pressing out;

- The old bearing can be used as a press-fit race.

The clip should be struck with even force. You need to hit on opposite sides or evenly moving in one direction. The main thing is that there are no distortions.

autolirika.ru