Tips and ways to reduce engine noise

We figured out why the engine is loud, but what to do to reduce the noise level. First of all, the use of high-quality fuel and engine oil, they have a greater impact on the level of extraneous sounds produced by the power unit.

It is clear that to reduce the noise level , you need to determine the source. Often, after repairing an engine, the cause of noisy operation is a replaced part that is installed incorrectly or has some defects.

It happens that after changing the engine oil, flushing the system, using various additives, and performing decarbonization, the engine becomes louder.

Why is the engine noisy?

Before this, everything was fine - the engine had its own special noise, which you absolutely loved and you were even proud of it in front of your friends. But if you are already an experienced driver, then you are already beginning to understand that, first of all, the unpleasant squeal comes from belts and from other noise from worn bearings. But how can you accurately determine where the noise is coming from? First you need to completely remove all the belts from the power steering. Then listen to the engine. If this does not help, then you need to spray all the belts one by one with a syringe, and if the noise changes, then this belt will be to blame. You will need to pull it up or, conversely, let it go. But if you have already removed all the belts and the noise continues, this may mean that the bearings in the rollers along which the timing belt moves are making noise. If these bearings are properly lubricated, the noise will most likely simply disappear. Next on the list are bearings from a pump, generator, idler roller or tension roller.

If your belts are too tight (a lot of noise is guaranteed), this can lead to rapid destruction of the bearing. But how can this be determined?

First, remove all the belts and turn the desired roller (for example, a generator) with your fingers and listen carefully. If you feel a moderately rhythmic roar of the balls inside the bearing, then such a bearing needs immediate lubrication. If, during repeated rotation, you at least once feel a slight jamming or the rumble of the bearing is unrhythmic, then there is only one conclusion: you need to quickly replace the old bearing with a new one, because (this is clearly visible on the so-called tracks along which the balls roll) the working surface has already begun to crumble.

If the bearing has any noticeable play (you just need to rock the roller that is pressed into it, or move the outer race sideways relative to the inner race), then you need to look for a new one. You need to put new grease into the old “half-dead” bearing and drive it a little, but only in cases where such a bearing is located somewhere not in critical places: on a generator or on an air conditioner.

If such a bearing is installed, for example, in the tension roller of a toothed belt in the gas distribution of a diesel engine, then you should not take risks, it is better to just estimate how much it will cost you to repair the engine if the bearing with play suddenly falls apart or simply jams. It often happens that the drive belts begin to “squeak” (very often, the generator). You should not immediately rush and tighten this belt. It may happen that it “sings” only because some “dead” bearing is jammed or the belt has simply become unusable due to its age: the rubber on it has become hard, so the belt begins to slip. Naturally, in such force majeure cases, the belt can be tightened, but almost immediately the load on the generator bearing itself will sharply increase, which will in no way contribute to its longevity.

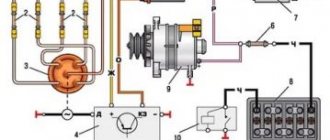

In gasoline engines, the cause of unpleasant noise, especially when the engine is not warmed up, is the ignition distributor and its drive. In this case, the distributor just needs to be removed, disassembled and cleaned properly. Then install it in the same way where the slider was previously “looking”.

Solving existing problems

In each specific case, the repair technology will differ, depending on the identified faults. If this is a problem with the engine mounts or various attachments have failed, then such breakdowns are relatively easy to fix. However, if there is wear on the crankshaft and problems with the piston group, then such repairs fall under the category of capital repairs, and accordingly the car owner’s expenses will be extremely high.

In such cases, when engine noise increases, the car owner should not delay contacting service. The sooner he contacts specialized workshops, the easier and cheaper it will be to eliminate existing faults. As a preventive measure, we can only recommend maintaining the car in technically sound condition, performing its routine maintenance in a timely manner, paying special attention to the quality of the oil used.

It is low-quality motor oil that most often causes such problems with a car engine. Lubricant can accumulate in hard-to-reach places, not providing high-quality lubrication of moving elements, and lead to increased wear. As a result, literally a few years after the start of operation, such a motor begins to operate at higher tones, and it is extremely difficult to solve such problems, since it is necessary to carry out a major overhaul of the engine.

Let's sum it up

There may be many reasons why the engine began to run louder. This is the use of low-quality fuel, improper operation of the lubrication system, problems with injectors, timing chain, wear of valves and camshafts. In such a case, it is extremely difficult to correctly identify faults and carry out repairs on your own; the car owner needs to contact workshops where specialists, using the appropriate equipment, will carry out diagnostics, identify characteristic breakdowns and restore the car.

29.07.2019

How everything works

Let's start with the fact that there are two types of such hinges.

These are internal ones, which work directly in the gearbox, where they force the axle shaft to move, and also external ones - they can be found on the hubs. They transmit torque to the wheels of the car.

Sometimes it seems that both internal and external hinges can work for a very long time and will fail in one day. However, it is wrong to think so. As a rule, internal components can work for a very long time, but external ones wear out more often. And then the car makes a popping sound from a faulty CV joint. Among the main reasons are the high loads that occur while moving. Also among the reasons is the higher rotation angle of the external product. These parts are also different in appearance - the internal ones are much larger in size than the external ones.

The design consists of a cup body with grooves on the inside and an axle shaft on the outside. The inner race resembles a spherical fist with grooves and there are 6 balls between the cup and the race.

Squealing noise when pressing clutch pedal

Squealing noise when pressing clutch pedal

If your car is equipped with a manual transmission and when you press the clutch pedal you hear a squealing sound (a prolonged squeal), then most likely the clutch release bearing in your car has worn out. If you observe this similar strange sound, which is not typical for the normal operation of all car systems, then be sure to check the condition of the clutch itself.

Important to know: Signs of a faulty transmission and what to do

Remember, friends, that failure of the release bearing can lead to the inoperability of the manual transmission clutch element.

7) Whining sound of the power steering pump

If you hear a hum coming from a wheel while driving, then the likely cause is bearing wear. If this is indeed the case, then remember that the bearings must be replaced in pairs. That is, if the hum in one wheel is associated with a malfunction of the hub bearing, then when replacing it, it is necessary to change the bearing in the other wheel.

Remember that worn bearings can produce a whine or hum that should come from the car's wheel. Also note that the higher the speed of the car, the louder the hum or howl.

In order to distinguish a hum or howl from the noise of wheels, you need to change lanes several times. If the howling sound does not change somewhat during maneuvering, then most likely the cause is a strange sound in the hub bearing.

How to find out which CV joint is faulty?

How to determine which CV joint is crunching? Unfortunately, it can be quite difficult to make the most accurate diagnosis due to the fact that failures of grenades are very similar to failures of ball joints, steering joints, and others. Therefore, it is worth checking their condition again.

Carrying out diagnostic procedures is very simple. To do this, you just need to turn the steering wheel to any extreme position and start driving the car. When there is a maximum angle between the axle shafts, you can clearly hear a popping sound from a faulty CV joint. If you hear sounds when turning to the right, you need to change the right one, if it crunches when turning to the left, then, accordingly, the left one.

However, the internal mechanism also has some peculiarities.

They sometimes crunch when moving straight. To check their performance, you don’t even have to have any special car diagnostic skills. It is enough to take a short trip to where there are no roads. You will hear sounds when entering pits.

But you can find out which of the mechanisms has failed even more precisely. For this you will need a lift. When the car is suspended, engage first gear. Let the wheels spin fairly slowly. In this position, a crunching sound will be clearly audible. If you move the shaft, you can again feel the play.

If everything is as described, you are on your way to the store for a new mechanism.

Where is this strange noise coming from?

So. There are two such parts on each drive wheel. Internal ones transmit rotational energy from the differential to the axle, external ones - from the axle to the hub. With the same design, these hinges have different sizes.

To independently diagnose where this nasty popping sound from a faulty CV joint comes from, you can use one of two methods.

So, if the car is stationary, you can try to tug the axle on each part in turn.

If everything is fine, you will not feel any play. If the CV joint is knocking, then there is wear, and quite a lot at that.

If you are on the move, it is very advisable to listen to the sounds that the car makes.

We change the inner CV joint ourselves

It seems strange, but the internal mechanism changes much easier than the external one. All replacements are also performed either in a pit or using a lift. This unit can only be removed from below.

The first step is to unscrew the bolts of the product. Now the part is held in the socket only with the help of a flange. By turning the steering wheel to one of the extreme positions, you can ensure that the mechanism falls out on its own. Well, then everything is the same as in the case of the external CV joint.

Different kits may be equipped differently. Often, the package may contain a different number of washers, retaining rings, and other additional elements. Don't forget to install them, even if you didn't find them in the previous kit.

When purchasing spare parts, pay attention to the parameters.

Like most other elements of a car, this mechanism requires a certain amount of attention. After all, a car is an expensive toy. Unplanned repairs of this kind can cause serious damage to the budget. And these are just the smallest possible problems.

Always ensure that the vehicle is in good condition. This will save both your life and the lives of your family and friends.

So, we found out how to identify the faulty one and replace it with our own hands. We hope you find the information above helpful.

Read the article for examples of sounds from a faulty hard drive and how to identify them

. Sounds of clicking or rustling, vibration or whistling that were not there before. A working hard drive is a fairly quiet device that can only be heard by a soft click when accessing it or turning on/off the computer. But if, over time, clicking or rustling sounds are heard from the hard drive, as well as vibration or whistling that were not heard before, then the hard drive may have failed.

Western Digital

The dull sound of faulty hard drive heads.

Faulty disk heads click slowly several times, after which the disk spins slower.

Slowdown of the rotation of the hard disk platters after the failed heads produce several clicking sounds.

A hard drive with a jammed spindle cannot spin up.

Clicking sounds of a hard drive with a failed preamp chip.

A disk with unstable heads that stops after several clicks.

A laptop hard drive with a jammed spindle that tries to spin up, making a sound similar to a siren.

The computer hard drive cannot spin up due to faulty bearings.

Seagate

Rustling and clicking sounds made by a disk with inoperative heads.

The sounds that a disk with damaged heads makes during startup (plate spinning).

Clicks of faulty laptop hard drive heads.

A disk with a jammed spindle is trying to unwind.

The drilling sound of broken disk heads.

Maxtor

A computer hard drive with a non-working or broken head unit.

Clicks of inoperative heads.

The sound made by a disk with a jammed spindle.

Samsung

A fast clicking sound indicates the failure of the hard drive heads.

Same as with the previous disc.

The sound of damaged hard drive heads.

A worn-out computer disk that makes a scratching sound when accessing bad sectors.

Hitachi/IBM

A laptop hard drive with damaged heads clicks during startup and then beeps.

A worn-out computer drive that makes a scratching sound when accessing an area with bad sectors.

A disk with worn plates and head block makes wheezing and howling sounds.

The whirring of a laptop disk with a jammed spindle that is trying to unwind.

Toshiba

The sound of failed laptop hard drive bearings.

The sound of worn-out laptop hard drive bearings.

The sound of the laptop hard drive bearings seizing.

Fujitsu

Worn laptop hard drive heads.

Faulty laptop hard drive heads.

The sound of worn-out computer hard drive platters.

Quantum

Faulty head block.

Squealing noise when pressing clutch pedal

Squealing noise when pressing clutch pedal