Eliminating the creaking of the clutch pedal on a VAZ 2110. — logbook of the 2003 Lada 2110 PhiX on DRIVE2

Hi all! We continue to mock the car, and this time we will make the clutch pedal softer and quieter.

I think many owners of tens and other front-wheel drive VAZs have noticed that the clutch pedal becomes tighter over time and a squeak appears. There may be several reasons for this, and I want to talk about the fight against one of them. In search of the cause of the tight pedal and creaking, I took the easy way and first tried to lubricate the cable and boss, which naturally did not bring any effect. Having eliminated the cable, I moved on. The reason for the tight pedal and squeaking is the friction that occurs between the bushings and the axis of the clutch release fork. This happens because over time the lubricant loses its properties. The main source of the problem is the lower bushing, because it is metal, and as you know, metal slides without lubrication with great reluctance, with the risk of scuffing, i.e. with excess friction. The upper bushing is plastic and even without lubrication the axle glides well in it.

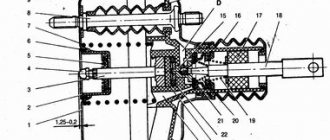

This is what these bushings look like.

Thus, the main task is to lubricate the lower bushing. Ideally, you would have to remove the box, replace both bushings with new ones and fill them with fresh grease. But since we have enough more important things to do, throwing away the box in vain was not part of my plans. I decided to implement an improvement that I learned about a long time ago, but as always, I never got around to it.

The essence of the modification is to drill a hole in the plastic bushing of the clutch fork axis, and then lubricate both bushings through this hole.

It all sounds very simple, and in reality the same thing happens. Next in order: We remove the air filter box so that it does not interfere.

We find this very bushing. And it is located at the checkpoint, strictly under the thermostat.

We drill a hole in it with a diameter of about three millimeters so that the nose of the syringe can fit through. By the way, in order to reach the bushing, you will need a fairly long drill. You can probably try to drill a short one, but the wiring harness and CO pipes will get in the way. You need to drill until the drill rests on the fork axis.

Then we fill the syringe with oil, I used transmission oil, and slowly pour it into the hole. The oil will not go away quickly, because... The bushing fits tightly to the axle.

To speed up the process, you can slightly lift the bushing (as far as the latches will allow) by prying it around the perimeter with a screwdriver.

You need quite a lot of oil so that it flows along the axis and properly lubricates the lower bushing. I poured about thirty cubes, there is no need to be afraid of overdoing it, the excess will simply flow out.

You can plug the hole using a screw.

If you suddenly need to lubricate the bushings again, this can be done by simply unscrewing the screw.

After the procedure has been completed, we get behind the wheel, squeeze the clutch and almost have time to get upset, because nothing has changed. But We don’t give up, we press the clutch five or ten times again, and on the next press the pedal falls down with less effort and without the nasty squeak.

Conclusions: After lubrication, I finally got rid of the annoying squeaking noise and the clutch pedal became much softer. The feeling can be compared to replacing the clutch with a new one.

PEACE to everyone, like, share the post with friends, this is another modification for the VAZ from the MUST HAVE category!

Price: 50 ₽ Mileage: 179,800 km

Clutch adjustment

If you notice even one of the listed signs, it means that the KamAZ clutch basket requires adjustment. If this is not done in time, problems may spread to the gearbox and other transmission parts. In general, proper adjustment of the Kamaz clutch can be divided into 3 main stages:

- Adjusting the pedal free play. The standard value for free play is in the range of 6–12 mm. It should be measured from the middle part of the plate at the moment when the pedal is lowered until you feel resistance when pressing. The free play is adjusted with an eccentric finger - it connects the pusher eye with the pedal lever. The pin should be rotated until the gap between the upper stop and the piston pusher reaches 6–12 mm. Once the desired value is reached, tighten and cotter the castle nut. Afterwards, be sure to measure the full pedal stroke, it should be 185–195 mm.

- Adjusting the clutch free play. The free play should be 3.2–4 mm. Measuring it is not difficult at all. We move the fork shaft lever away from the adjusting spherical nut of the pusher. Don't forget to remove the spring and note that the lever should move a maximum of 4-5mm. If discrepancies with the standards are noticed, the situation can be corrected using a spherical nut. As soon as the lever stroke reaches 4–5 mm, the free stroke of the clutch will automatically take on the desired value.

- Adjusting the full stroke of the booster pusher. It is measured very simply. Depress the clutch until it hits the floor. If the pushrod travel distance is less than 25 mm, first check the pedal free play and the fluid in the master cylinder. If everything is in order there, release the air from the hydraulic system and then everything will return to normal values.

Maintenance

If you periodically perform these procedures with additional adjustments, the device will last much longer.

- Tighten the bolts that secure the clutch air booster.

- device for leaks. If found, find and repair the leak, then bleed the system to remove air.

- Evaluate the operation of the pedal springs and shaft lever. If faulty ones are found, replace them.

- Lubricate the clutch bearing and the fork shaft bushing of the device.

- Assess the liquid level in the compensation tank. Top up if necessary.

Adjusting the Kamaz clutch

It is very difficult to cope with all this work for the first time. If you are not confident in your abilities. Entrust the adjustment to specialists and monitor the progress of the work. Having memorized all the steps in practice, in the future you will be able to adjust the device yourself without any problems.

Hard clutch pedal

If you own a car with an automatic transmission, then this article may not seem interesting to you, because now we will talk about an indispensable part for vehicles with a manual transmission. Of course, we mean the clutch pedal, which serves as the main link between the driver’s desire and the “obedience” of the car. To engage or disengage the clutch, a certain force must be applied to the pedal, but if excessive loads are required from the driver, then this is a clear sign of the presence of some problems in the system.

Causes of a hard clutch pedal

Why do we sometimes have to encounter such a phenomenon as a “hard clutch pedal”? In fact, there are several most common reasons. Firstly, the pedal lever itself often jams or the cable gets jammed, and secondly, the source of such problems can be too much wear on the clutch fork bearing, which is why it also begins to move slowly. In some cases, a stiff clutch pedal is due to a blockage in the hydraulic system or wear on the release bearing.

Naturally, to restore the clutch pedal to normal operation, you will have to take a number of necessary actions, but first, let’s try to understand the various signs of various malfunctions. For example, if the stiffness of the clutch pedal is the result of wear on the fork bearing, then when you press the pedal you will hear some characteristic rumbling, indicating that the release bearing has already served its allotted time, and it is time to replace it with a new part.

The mechanisms produced today are designed to cover fairly long distances (more than 1,300 km), but the driver would do well to carry out regular diagnostics and timely elimination of emerging problems (including replacing broken parts). In those cases where the system is treated negligently and inattentively, the clutch pedal will last you at most 50,000 kilometers, and in large trucks problems can be caused by poor grinding in of new elements.

The problem of incomplete engagement of the mechanism should not be excluded from the possible causes of “hard clutch”. In such situations, when changing gear, the driver of the vehicle will hear a characteristic grinding noise. This is due to the inability of the driven disk to come off the pressure plate normally. To fix this problem, it is best to immediately contact professionals.

Incomplete shutdown of the device also has its reasons. These include:

– incorrect adjustment of the cable;

– jamming of the driven disk;

– incorrect assembly of the system unit;

– severe wear of the switching mechanism.

The problem of a “hard” clutch pedal occurs in different cars, and hydraulically driven vehicles are no exception. If you are the owner of just such a car, then you should know that a tight clutch pedal can be explained by several reasons: a bent fork, coked splines of the input shaft along which the driven disk slides, contamination of the bushing along which the release bearing moves, as well as damage to the internal parts of a flexible hose of the hydraulic drive system. These are the most common explanations for the problem of a stiff pedal, but they are far from the only ones.

For example, on old hoses a piece of rubber may peel off, which will ultimately play the role of a kind of valve, so if you look for the reason without dismantling the gearbox, you can replace the flexible hose yourself and bleed the clutch, and if this does not help, then contact service specialists.

What to do if the clutch pedal is hard?

If the clutch pedal on your vehicle suddenly becomes tight, and the gears are switched with a certain effort (and it also happens that the speed does not turn on at all), first of all it is necessary to establish the exact cause of this phenomenon. It is likely that the clutch cable will need to be completely replaced and adjusted. This process has its own characteristics, and before installing a new element, it is necessary to lubricate it thoroughly with a special liquid. For this purpose, WD-40 is often used.

How to know when it's time to change your clutch

There are cases when adjusting the clutch cannot correct the problem. Perhaps you missed a moment when you could get by with little effort, or maybe the device failed for some objective reason. So, it’s time to change the MAZ clutch if you notice the following signs:

- The device turns on abruptly, the car jerks and abruptly pulls away.

- Noise in the mechanism, perhaps a loud cracking sound when the gear is engaged.

- The car starts moving late, even if you release the clutch on time.

- A characteristic burning smell in the cabin (this is a clear sign that the clutch has burned out).

There is no need to delay replacing the clutch. As a result, everything may end in damage to the gearbox or in the fact that one fine day the car simply will not be able to move.

You should take on the work yourself only if you know exactly the sequence of actions. Otherwise, it is better to contact specialists.

However, if you are confident in your abilities or the KamAZ clutch basket is familiar to you, you can get down to business.

What you need

Before starting work, you need to stock up on a certain set of tools. So, you will need:

- A set of wrenches or socket heads.

- Emphasis.

- A ruler to later measure the free play of the pedal.

- Pliers and pliers.

Replacing the Kamaz clutch

If you have all this, it's time to get to work. The main thing is to strictly follow the entire sequence of actions:

- First of all, remove the gearbox. KamAZ has it very heavy, so you will need the help of several people.

- Next, next is the clutch basket, remove it too.

- Then remove the driven, middle and driving clutch discs.

- Then install new parts of the device in their place. Start by installing the first driven disk and then install the parts in the reverse order of disassembly.

- Make sure once again that the device is assembled correctly and that’s it – you can put the gearbox in place.

If the clutch is single-plate, the process is similar and even easier. It may seem that everything is quite simple, but this is far from the case. Replacing and adjusting the MAZ clutch will require a lot of physical effort and time. Perhaps it makes sense to trust specialists who will do everything correctly and without mistakes. By observing the process, you will be able to remember the entire sequence in practice, and next time you will be able to adjust or replace the device yourself.

How to use the clutch to make it work as much as possible

There are several simple rules to extend the life of the KamAZ clutch. Unfortunately, not all drivers use them and often the device has to be changed much earlier than provided by the manufacturer.

- Do not keep the mechanism depressed for too long. Using clutch slipping at traffic lights and to reduce speed is very harmful to the device.

- And, most importantly, check the free play of the pedal as often as possible and lubricate all accessible components of the clutch mechanism. This is probably the most important guarantee that you won’t have to think about replacing the mechanism for at least several years.

«>

The clutch pedal creaks on a VAZ-2110

Car: VAZ-2110. Asks: Dmitry Aksyonov. The essence of the question: the clutch pedal on the VAZ-2110 began to creak, what should I do?

Damn, bad again! The clutch pedal on the VAZ-2110 began to creak. At first it creaked quietly, but now it’s getting stronger. I looked there in the pedal assembly, tried to lubricate it, but I can’t find where. What to do if the pedal squeaks more and more?

Why does the clutch pedal on a VAZ-2110 squeak?

Experts note that the clutch pedal on the VAZ-2110 is not tight compared to other domestic cars. This is even noticeable when the lubricant on the rubbing parts of the squeezing force transmission dries out.

The following two tabs change content below.

Causes

In the diagram, red arrows indicate places where squeaking may occur due to lack of lubrication.

When you drive a car for a long time and do not have it inspected, this will cause the driver to feel discomfort when driving, for example, a creaking sound when pressing the clutch pedal.

- Typically, modification and elimination of such a problem is carried out by drilling a larger diameter hole on the shaft attaching the pedal to the body bracket. You can do this yourself.

- Before work, it is important to find a shaft of suitable diameter that will be placed in the socket.

- After installing the new shaft, you will need to drip 4-6 drops of oil onto it every day until it breaks in.

- The oil will get into the gap between the bushing and the bracket, which will prevent the pedal from squeaking when pressed.

Other possible sources of squeaking

conclusions

After such an event, the pedal will be squeezed easier. This does not require repairing the box. Such modifications can be made not only on the VAZ 2110, but also on other cars of new domestic models.

Video about lubrication of the clutch fork without disassembling the box

The clutch on the VAZ 2110 was changed two weeks ago. At first the clutch pedal was pressed softly, but now it became hard. They installed a new cable, what was the reason? And the most interesting thing is that the basket remained the same, so that’s not the reason

- Which side should I put the clutch disc on? – 3 answers

- Extraneous sound when starting VAZ 2110 - 3 answers

- Clutch housing VAZ 2110 – 2 answers

- What is the best clutch to install on a VAZ-2110? – 2 answers

- How to tighten the clutch basket of a VAZ 2110? – 2 answers

So what next? Tell us about how the clutch works. How does the car start, how do the gears change? There is also a clutch fork there. There is a release bearing there. And plus a clutch pedal in the cabin. In addition, something could also happen in 2 weeks (rust, warp, break, etc.).

How to adjust the KamAZ clutch

Maintenance is carried out regularly. Increasing the pedal stroke leads to incomplete disconnection of the flywheel and gearbox. This device causes the gears to come into contact, and the load on the teeth of the gears increases. If the accelerator stroke is insufficient, the drive disk does not engage, rotation is not fully transferred, and the machine stops.

Adjusting the clutch on a KamAZ allows you to eliminate faults that are diagnosed based on the following symptoms:

- at the beginning of departure - jerks;

- the friction pedal sticks;

- the accelerator is slow;

- if you check the drive fluid level, a leak is detected;

- extraneous sounds are heard.

The need to adjust the clutch on a KamAZ is checked by measuring the distance from the bottom of the pedal to the floor surface of the driver's seat - the indicator should be 16 cm.

Without removing the box

Adjustment of the clutch operation is carried out by removing the gearbox. But if adjustment is required under road conditions, then the work is performed without removing the structure.

You will need a homemade device in the form of a piece of wire, one side of which is 2 cm long and bent at an angle of 90˚. The thickness of the rod is at least 3-4 mm; this size is convenient for controlling the clearance between the disc release element and the contour of the legs.

The adjustment is made using the pneumatic booster nut. The legs are connected to the ring through a hole at the top of the crankcase. Elements are placed as equally as possible to the area.

The procedure is as follows:

- Unscrew the locking bolts.

- Remove stoppers and plates.

- The nuts are all loosened equally by 5 turns; ratchets are used for convenience.

- If a nickel protrudes beyond the surface of the ring, then it is recessed, first checking for the presence of ferodo underneath.

- The springs can be replaced at the same time.

- The paws are placed so that they touch the ring equally. Then the runout of the disc area is analyzed.

- The front bearing is lubricated. Select an adjustment gap of 29-30 mm.

Setting up the mechanism without removing the gearbox is done in the case of a double-disc clutch; single-disc clutches are not adjusted this way.

How to adjust pedal free play

Check the movement of the coupling by moving the axial shaft lever away from the pusher nut. If the free distance measured at 90˚ is less than 3 mm, then to adjust it, rotate the pusher screw so that the distance of free movement of the coupling is 3.1-4 mm.

The stroke of the amplifier pusher is checked when the accelerator is pressed - the indicator should be more than 2.5 cm. A smaller value does not ensure effective activation. If the pusher stroke of the pneumatic hydraulic booster is less than recommended, then:

- adjust the free play of the clutch pedal;

- control the amount of liquid in the main cylinder container;

- remove the atmosphere from the hydraulic device.

The pedal movement should correspond to the size of 6-15 mm, it is measured in the middle of the pedal. If it is exceeded, the clearance of the piston and pusher is set using an eccentric element connecting the hole at the top of the pusher and the accelerator.

How to adjust the cart

The basket's feet are adjusted on the removed disk or through a gap in the flywheel directly on the machine.

- When the machine is in the pit, remove the box using a winch.

- Inspect the release bearing, springs and collets.

- Unscrew the fastening of the disk to the engine flywheel.

- Remove the pressure mechanism while holding the drive disk.

- Inspect the surface and make adjustments to the paws relative to the area of the disk.

- Check the change in the position of the paws using a plate, taking into account that their round surfaces should touch the template located on the hub.

- After adjusting the clutch basket, the hardware is tightened until it stops. Clutch assembly is done in reverse order.

The clutch pedal creaks on a VAZ-2110

Car: VAZ-2110. Asked by: Dmitry Aksenov. The essence of the question: the clutch pedal on the VAZ-2110 began to creak, what should I do?

Damn, bad again! The clutch pedal on the VAZ-2110 began to creak. At first it creaked quietly, but now it’s getting stronger. I looked there in the pedal assembly, tried to lubricate it, but I can’t find where. What to do if the pedal squeaks more and more?

Why does the clutch pedal on a VAZ-2110 squeak?

Experts note that the clutch pedal on the VAZ-2110 is not tight compared to other domestic cars. This is even noticeable when the lubricant on the rubbing parts of the squeezing force transmission dries out.

The following two tabs change content below.

All my life I have been surrounded by cars! First, in the village, already in the first grade, I was rushing around on a tractor through the fields, then there was JAVA, then a penny. Now I am a third-year student at the Polytechnic Faculty of Automotive Engineering. I work part-time as a car mechanic and help repair cars for all my friends.

Causes

In the diagram, red arrows indicate places where squeaking may occur due to lack of lubrication.

When you drive a car for a long time and do not have it inspected, this will cause the driver to feel discomfort when driving, for example, a creaking sound when pressing the clutch pedal.

- Typically, modification and elimination of such a problem is carried out by drilling a larger diameter hole on the shaft attaching the pedal to the body bracket. You can do this yourself.

- Before work, it is important to find a shaft of suitable diameter that will be placed in the socket.

- After installing the new shaft, you will need to drip 4-6 drops of oil onto it every day until it breaks in.

Other possible sources of squeaking

The “grandmother” on the bushing may creak.

The clutch cable holder can also be a source of squeaking noise.

Pin for fastening the clutch cable to the pedal.

Lubricating the brake pedal mounting pin.

Lubricate the clutch fork shaft through the side hole.

Lubricating the clutch fork axle through the hole in the plug.

conclusions

After such an event, the pedal will be squeezed easier. This does not require repairing the box. Such modifications can be made not only on the VAZ 2110, but also on other cars of new domestic models.

Hard clutch pedal

If you own a car with an automatic transmission, then this article may not seem interesting to you, because now we will talk about an indispensable part for vehicles with a manual transmission. Of course, we mean the clutch pedal, which serves as the main link between the driver’s desire and the “obedience” of the car. To engage or disengage the clutch, a certain force must be applied to the pedal, but if excessive loads are required from the driver, then this is a clear sign of the presence of some problems in the system.

Causes of a hard clutch pedal

Why do we sometimes have to encounter such a phenomenon as a “hard clutch pedal”? In fact, there are several most common reasons. Firstly, the pedal lever itself often jams or the cable gets jammed, and secondly, the source of such problems can be too much wear on the clutch fork bearing, which is why it also begins to move slowly. In some cases, a stiff clutch pedal is due to a blockage in the hydraulic system or wear on the release bearing.

Naturally, to restore the clutch pedal to normal operation, you will have to take a number of necessary actions, but first, let’s try to understand the various signs of various malfunctions. For example, if the stiffness of the clutch pedal is the result of wear on the fork bearing, then when you press the pedal you will hear some characteristic rumbling, indicating that the release bearing has already served its allotted time, and it is time to replace it with a new part.

The mechanisms produced today are designed to cover fairly long distances (more than 1,300 km), but the driver would do well to carry out regular diagnostics and timely elimination of emerging problems (including replacing broken parts). In those cases where the system is treated negligently and inattentively, the clutch pedal will last you at most 50,000 kilometers, and in large trucks problems can be caused by poor grinding in of new elements.

The problem of incomplete engagement of the mechanism should not be excluded from the possible causes of “hard clutch”. In such situations, when changing gear, the driver of the vehicle will hear a characteristic grinding noise. This is due to the inability of the driven disk to come off the pressure plate normally. To fix this problem, it is best to immediately contact professionals.

Incomplete shutdown of the device also has its reasons. These include:

– incorrect adjustment of the cable;

– jamming of the driven disk;

– incorrect assembly of the system unit;

– severe wear of the switching mechanism.

The problem of a “hard” clutch pedal occurs in different cars, and hydraulically driven vehicles are no exception. If you are the owner of just such a car, then you should know that a tight clutch pedal can be explained by several reasons: a bent fork, coked splines of the input shaft along which the driven disk slides, contamination of the bushing along which the release bearing moves, as well as damage to the internal parts of a flexible hose of the hydraulic drive system. These are the most common explanations for the problem of a stiff pedal, but they are far from the only ones.

For example, on old hoses a piece of rubber may peel off, which will ultimately play the role of a kind of valve, so if you look for the reason without dismantling the gearbox, you can replace the flexible hose yourself and bleed the clutch, and if this does not help, then contact service specialists.

What to do if the clutch pedal is hard?

If the clutch pedal on your vehicle suddenly becomes tight, and the gears are switched with a certain effort (and it also happens that the speed does not turn on at all), first of all it is necessary to establish the exact cause of this phenomenon. It is likely that the clutch cable will need to be completely replaced and adjusted. This process has its own characteristics, and before installing a new element, it is necessary to lubricate it thoroughly with a special liquid. For this purpose, WD-40 is often used.

In addition, often the clutch pedal simply cannot be depressed. This is often preceded by excessively light pressure or complete “failure.” Such breakdowns are often associated with improper adjustment of the cable or its breakage. In such cases, it would be useful to check the condition of the release bearing, which may be damaged, which is why it becomes difficult to press the pedal. You should also check the diaphragm spring located on the pressure plate for damage.

If you are used to repairing your vehicle yourself and are well familiar with the features of its design, then such a check can be performed independently, but in most cases, car owners prefer to seek help from service station specialists.

How to fix it?

The easiest way to “soften” the clutch pedal is to lubricate the release bearing guide and clutch fork support. Of course, this method will help fix the problem only if more serious malfunctions and component defects are excluded. To perform this task it is not at all necessary to dismantle the gearbox. Simply remove the cable from the fork, then the protective rubber, and then secure the fork so that it does not slip out of the support bearing. After completing these tasks, take a flashlight and see if the mechanism has enough lubrication.

If it is missing, then carefully clean the dirt with a wire and lubricate the part. Move the fork in different directions so that the lubricant is better distributed over the entire surface. Also, do not forget about the support located behind the fork; it must also be well lubricated. Of course, due to the limited engine compartment space, it is quite inconvenient to perform all of the above actions, but if desired, nothing is impossible. Therefore, be patient and confidently begin the task.

Subscribe to our feeds on Facebook, Vkontakte and Instagram: all the most interesting automotive events in one place.

Was this article helpful?Yes No

Diagnosis of clutch faults VAZ 2110 2111 2112

Cause of malfunction

Elimination method

The clutch slips (does not fully engage) When you sharply press the gas pedal, the engine gains speed, but the car hardly accelerates - this is especially noticeable when driving uphill; the smell of overheated friction linings may be felt; fuel consumption increases

Oiling of the flywheel, pressure plate, friction linings of the driven disk

Thoroughly wash oily surfaces with white spirit or gasoline and wipe them dry. Replace the heavily oiled driven disk. Eliminate the cause of oiling (oil leakage through the cuffs (oil seals) of the engine or gearbox)

Severe wear or burning of the friction linings of the driven disk

Replace the driven disk assembly

Damage or jamming of the clutch drive

Remove jam. Replace drive if necessary

The clutch moves (does not disengage completely) It is difficult to change forward gears, the reverse gear is engaged with noise. Gearbox is OK

Incorrect clutch drive adjustment (full pedal travel is too small)

Adjust the drive. Replace the deformed clutch fork

Clutch cable jamming

Lubricate the cable with engine oil. If this does not help (the cable wires are frayed, the sheath is damaged) - replace the cable

Loosening of rivets or breakage of friction linings, warping of the driven disk (end runout more than 0.5 mm)

Replace the drive

Severe and uneven wear, scoring on the working surfaces of the flywheel or pressure plate

Replace flywheel. If the surface of the pressure plate is damaged, replace the housing with the pressure plate assembly (“clutch basket”)

Jamming of the driven disk hub on the splines of the input shaft of the gearbox

Clean the splines from dirt, remove minor damage with a file. If there is significant wear or damage to the splines, replace the transmission disc and/or input shaft. Before assembly, apply CV joint grease to the splines

Distortion or warping of the pressure plate

Replace the housing with the pressure plate assembly (“clutch basket”)

Wear of the diaphragm spring blades at the point of contact with the release bearing

Replace the housing with the pressure plate assembly (“clutch basket”)

Jerks when starting off

Clutch cable jamming

Lubricate the cable with engine oil. If this does not help (the cable wires are frayed, the sheath is damaged) - replace the cable

Jamming of the driven disk hub on the splines of the input shaft of the gearbox

Clean the splines from dirt, remove minor damage with a file. If there is significant wear or damage to the splines, replace the transmission disc and/or input shaft. Before assembly, apply fresh CV joint grease to the splines

Driven disk deformation

Replace the driven disk

Loose fastening of the friction linings of the driven disk, severe wear or cracks on the linings

Replace the driven disk

Loss of elasticity of the spring plates of the driven disk

Replace the driven disk

Significant settlement or breakage of torsional vibration damper springs, wear of windows for springs

Replace the driven disk

Seizures on the working surfaces of the flywheel or pressure plate

Replace the flywheel or clutch housing with pressure plate assembly (clutch basket)

Oiling of the working surfaces of the friction linings of the driven disk

Thoroughly wash oily surfaces with white spirit or gasoline and wipe them dry. Replace the heavily oiled driven disk. Eliminate the cause of oiling (oil leakage through the cuffs (oil seals) of the engine or gearbox)

Rattling, knocking or noise when engaging the clutch

Significant settlement or breakage of torsional vibration damper springs, wear of windows for springs

Replace the driven disk

Driven disk deformation

Replace the driven disk

Loose fastening of the friction linings of the driven disk, severe wear or cracks on the linings

Replace the driven disk

Increased noise when disengaging the clutch

Worn, damaged or leaking clutch release bearing

Replace bearing

Why is the clutch on the VAZ 2110 tight?

Best site news

:: Author Message Val69

15 years on the forum

Added: 06 May 2004 08:03 The clutch pedal has become tight. What is the treatment? two months ago I lubricated the high pressure cable, it helped, but not for long. nm78

14 years on the forum

Added: 06 May 2004 10:01 Val69 wrote: The clutch pedal has become tight. What is the treatment? two months ago I lubricated the high pressure cable, it helped, but not for long. I had the same garbage at one time on nine. It was cured only by replacing the cable. Zlobniy DAg

13 years on the forum

Car: Hyundai Coupe 2002

Added: 06 May 2004 11:25 Val69 wrote: The clutch pedal has become tight. What is the treatment? two months ago I lubricated the high pressure cable, it helped, but not for long. Isn't this a sign of a dying clutch? Does he take it high? Dim Dimych

13 years on the forum

Added: 06 May 2004 11:38 Val69 wrote: The clutch pedal has become tight. What is the treatment? two months ago I lubricated the high pressure cable, it helped, but not for long. The clutch cable is definitely due for replacement. There was such a problem - until I changed it, it was not cured _________________ Well secured. The patient does not need anesthesia! NName

13 years on the forum

From: I come from Urals. Southern Urals

Added: 06 May 2004 12:21 maybe the cable - if somewhere the inner braid has already worn out - lubricant will not help here, replace it. but most often the cable is a consequence, not a cause. I encountered this myself - the clutch became tight - due to the release valve running without lubrication along the guide sleeve (when there was no lubrication there at all). then the cable broke (replaced), until the release assembly was replaced, the clutch remained tight. The metal of the bushing was worn on one side. You can try to lubricate the bushing where the release lever goes without removing the box, but it’s almost like “fucking a mouse in a hole” Victor P.

15 years on the forum

From: Krasnodar

Added: 06 May 2004 13:23 NName is absolutely right! I bought a new 12th, after 1000 km. the pedal began to feel heavy, an unpleasant feeling appeared on the pedal, especially when you drive for a long time. I disconnected the cable from the plug, it fits perfectly in the sheath. I went to TO-1, told the foreman, the verdict was unequivocal - it is necessary to lubricate the bushing on which the release valve runs. They removed the box, and it was as dry as a tank, he lubricated it, and at the same time boiled the fork. Lubricating without removing the gearbox is like a mouse. NName

Why is the clutch on the VAZ 2110 tight?

here someone in my review wrote that after replacing the entire clutch, the pedal becomes weightless, apparently very light, but mine is very tight right now, so I was thinking of changing it, maybe something is faulty or has already worn out? Tell me what can affect the tightness of the clutch release? What might not be working correctly?

pws-nsk.ru Products for Martial Arts and Crossfit, tel.: 2-123-123

maybe change the fluid? what else besides e-liquid maybe, I was recently on a hundred, about a month ago, with the device they looked at all the liquids for replacement, everything was within the normal range, i.e. replacement is not coming soon they said

pws-nsk.ru Products for Martial Arts and Crossfit, tel.: 2-123-123

When all the components of the clutch are new - the petals of the basket are even, the basket is easy to push through. As the disc/basket/flywheel wears out, the basket becomes more humpbacked and it becomes more and more difficult to “break” it

Last edited by igor vm; 01/13/2012 at 20:55.

Professional repair of Subaru electric racks

What is the correct name for the return spring or what? does she have anything to do with it?

pws-nsk.ru Products for Martial Arts and Crossfit, tel.: 2-123-123

Message from 8eTeR

What is the correct name for the return spring or what? does she have anything to do with it?

Which is on the fork in the gallery - you can pull it into a string with your foot and you won’t feel it. It only moves the release fork away from the basket. By the way, another important point is that the release fork should slide easily along the box guide; the edges and steps will have an effect. Well, you need high-quality lubricant.

Professional repair of Subaru electric racks

nope, the pedal moves smoothly back and forth, without any jerks, smoothly up and down, I think the steering is normal, the pedal doesn’t stick anywhere, it throws it off well) it’s just tight, the leg actually sometimes gets tired of holding the pedal in a traffic jam, you have to hold it with your foot pedal, namely with your foot =))

pws-nsk.ru Products for Martial Arts and Crossfit, tel.: 2-123-123

Yes, it’s clear, especially in traffic jams. Most likely the disc is already thin. Well, take off the box and you will see what I’m talking about. After installing the new hitch, pay attention to how the petals are located on the basket - almost exactly...

Professional repair of Subaru electric racks

Message from 8eTeR

here someone in my review wrote that after replacing the entire clutch, the pedal becomes weightless, apparently very light, but mine is very tight right now, so I was thinking of changing it, maybe something is faulty or has already worn out? Tell me what can affect the tightness of the clutch release? What might not be working correctly?

If the year is 2005 and higher, then this is true, direct turbo squeezing is very difficult compared to reverse. It's good for your health, don't worry.

It's better to do it and regret it than not to do it and still regret it

I have a 2004 model, the turbo dore-restyle fluid and clutch are good, the squeezing is tight, in comparison let’s say a Lacetti or a Focus. So nothing has changed for a long time, I thought that’s how it should be until I read this topic.

Message from Mondeo

I have a 2004 model, the turbo dore-restyle fluid and clutch are good, the squeezing is tight, in comparison let’s say a Lacetti or a Focus. So nothing has changed for a long time, I thought that’s how it should be until I read this topic.

Tight means it’s suitable for replacing the clutch assembly, you don’t have to look at the mileage, it depends on the driving style. I had experience, a friend had an Impreza WRX 220pony, he was the second owner and the car was still under the dealer’s warranty, so they also compared its clutch with mine, mine was many times easier, even though the mileage was 125t.km. I changed everything in the Impreza assembly and everything turned around!

Forester EJ201 MTX2 01 Japan - yes Impreza EL154 SS 08 Euro - yes BRAT EA81 MTX2 89 Euro - yes

Well, I don’t know, everything is always new, and since 2005, with direct squeezing on all cars it was tighter than with the opposite one. I notice this now when I drive old cars.

It's better to do it and regret it than not to do it and still regret it

I had a slipping clutch, I changed the entire set, along with the flywheel, and the squeezing force felt the same on both the old one and the new one. So maybe it also depends on the kit itself.

Subaru Legacy MY08 EJ204

Hello everyone, guys, tell me, I have a legacy, born in 1995. I’ve had it for four years now. The clutch was tight once every half a year. I change the cables, they break; I didn’t do anything; but still this is not a way out

Today I tried where the clutch pedal straightened out the bend, it becomes easier (but I couldn’t straighten it, I didn’t have enough strength and was afraid to break it, and when I hold the clutch with my hand, it’s much easier to squeeze out.) where the clutch pedal is where the casing ends, that is, there is a bend in the cable when it comes out from the casing. and it got dark, I didn’t have time, I’ll repeat it tomorrow :)

Install hydraulics the next time you change the disc.

It's better to do it and regret it than not to do it and still regret it

Posted by anatoly1983

I had a slipping clutch, I changed the entire set, along with the flywheel, and the squeezing force felt the same on both the old one and the new one. So maybe it also depends on the kit itself.

Forester 2007 manual transmission purchased, Forester '2000 S/20 manual transmission given to dad, Impreza 2.0 '97 HX20S manual transmission sold.

There was such a problem as a “traffic jam” so “turn out the lights”, I pressed the pedal with my heel, I was thinking about selling the car. The clutch began to slip. I threw off the box and saw: the disk was in rags, the basket was some kind of Korean, the release NTN. With all this, according to the previous owner, the car covered 20 thousand km and I drove 20. I installed the basket and disk from EXEDY, the NTN roller. Put it back together, operating time 5 hours. My happiness knew no bounds, how soft it could be. BE-5 EJ-204.