Every year, automakers try to improve not only the design, but also the technical characteristics of their cars. Improvements affect all aspects, including the engine. Nowadays, for several decades now, various types of superchargers have been installed on many cars. They are designed to improve engine power and torque. There are two types of superchargers. This is a compressor and a turbine. What's better? The difference, pros and cons of both units are in our article.

Compressor Features

This is a mechanical supercharger, which comes in several types:

- Screw.

- Rotary.

- Centrifugal.

Compressors began to be installed on cars long before the advent of turbines - approximately in the 50-60s of the last century. Now such units are practically not used. The latest manufacturers to install compressors are Mercedes and Range Rover.

Turbocharger

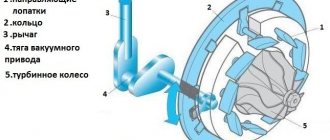

A turbocharger (popularly known as a turbine) is a very complex mechanism, difficult to manufacture and repair, which is designed to compress air and pump it into the engine. Its main distinguishing feature from compressors, as mentioned above, is the drive method. The turbine converts the kinetic energy of the exhaust gases leaving the cylinders into mechanical energy due to the rotation of the rotor.

Attempts to create a working production model of a turbocharger began a long time ago, but for success, engineers lacked the quality of materials and level of processing (creating an impeller requires great precision). However, a lot has changed over the past hundred years. The creation of such a complex unit not only became possible, but over the years the development of turbocharging has gone far ahead. Initially, quite a few types of turbines appeared, but in the process of refinement and modernization they acquired a very standardized appearance, becoming very similar in appearance.

Today, turbines are widely used and are used in various vehicles (cars, motorcycles, ships and aircraft) and generators.

To improve the quality of its operation, an intercooler is used with it, which cools the air before it enters the turbine. This makes it denser and protects the turbine from overheating.

Advantages and disadvantages

Which is better - a compressor or a turbine? Cars with a compressor have several advantages:

- Reliability. The design of such a mechanism is very simple, and therefore breakdowns are practically excluded.

- No dips during hard acceleration.

- No need for additional cooling and lubrication.

- Low chance of overheating.

- Long engine life.

When answering the question of which is better - a compressor or a turbine, it is worth considering the disadvantages of the first mechanism. The main disadvantage is the low performance of the compressor. So, the unit can increase power by no more than 10 percent. Today this is a very small indicator, for the sake of which manufacturers do not dare to complicate the design of the car and make it more expensive.

And all because the mechanism is driven by the crankshaft pulley. That is, the efficiency of the compressor directly depends on the rotation of the pulley. And since the speed of each engine is limited, the efficiency of a mechanical supercharger will not be too high.

Definition

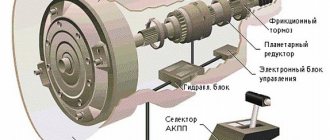

A turbine is a rotary engine, the peculiarity of which is continuous operation. The rotor converts the kinetic energy of steam, gas or water into mechanical energy. Today, turbines are actively used as the main element of the drive of a wide variety of vehicles (land, sea and air). No matter how incredible it may seem, an attempt to create a mechanism similar to a modern turbine was made before our era. And only at the end of the 19th century, with the development of thermodynamics and mechanical engineering, steam turbines began to appear, characterized primarily by high functionality. Turbine Compressor can be different and used in a wide variety of industries. It is necessary for compressing and supplying gases (including air) under pressure. This device was invented in order to significantly increase the maximum engine power, because more air is pumped into the combustion chamber. As a result, more fuel enters the cylinder, which in turn means that the final goal has been achieved. For clarity, here are some numbers: on average, a compressor can add about 46 percent of power (plus 31 percent of torque). Now these devices are actively used to increase engine power in both cars and trucks. Today, compressors are the most optimal and economical option for those who want to increase engine power and add a certain amount of horsepower to it. Compressor

Turbocharger Features

Which is better - a compressor or a turbine? Now let's look at the features of the turbocharger. Such a mechanism does not depend on the crankshaft. It works on a different principle.

The impeller rotates due to the flow of exhaust gases. The turbine has a cold and a hot part. Gases move through the latter, forcing the impeller of the cold part to work. Its number of revolutions per minute is many times greater than that of a mechanical supercharger. Hence the productivity. As practice shows, due to supercharging, it is possible to increase power by up to 40 percent, with virtually no loss of service life.

Thus, the main advantage of the turbine is its performance. In addition, there is the possibility of chip tuning, which allows you to increase the engine power by another couple of percent. But the shortcomings are obvious.

As engine power increases, the load on the crank mechanism also increases. It follows from this that the parts must be reliable. But this is not always the case, especially on chipped internal combustion engines. Often the crankshaft cannot withstand such loads, and therefore the service life of the motor is reduced significantly.

The norm for turbocharged engines is considered to be a resource of 150 thousand kilometers (if we take into account modern TSI). Also, the turbine often likes to eat up oil. Its consumption is from one liter per 10 thousand kilometers (and this is on a working engine). In addition, the oil must be of high quality. Otherwise, the engine life will be even less.

Engines with a compressor do not have such problems. They do not require oil and put less strain on the engine. Accordingly, any compressor engine will have more resource than a turbocharged one.

But, as statistics show, more and more manufacturers prefer to use the second type of supercharging. This is especially true for diesel units. They have a more durable structure, and the operating speeds are not as high as those of gasoline engines. However, after 250 thousand kilometers, problems occur with them.

TheDifference.ru determined that the difference between a compressor and a turbine is as follows:

The compressor ensures proper operation of the engine (uninterrupted combustion of impurities). The turbine does not contribute to horsepower loss (total power output of the power unit). The degree of complexity of installing and configuring the device. In this regard, the compressor has an advantage. The turbine requires an oil supply, which affects the entire operation of the car. The turbine will have to be constantly maintained and diagnosed. The turbine is installed directly into the engine, and the compressor is an independent device. The compressor has a fixed power, and the operation of the turbine depends on the vehicle speed. A turbine is capable of accelerating a car at a higher speed than a compressor. The compressor consumes more fuel with lower efficiency than the turbine. The compressor can be selected for any car model, but the turbine has a small selection. The cost of the turbine itself and its installation is higher than the price of the compressor.

Which is better to choose?

So let's summarize. Which is better - a mechanical compressor or a turbine? There is no clear answer to this question. Everyone chooses based on their requirements and preferences. If resource is a priority, you should limit yourself to a compressor and be content with 10 percent of additional power. But if you want maximum efficiency, the choice here will be obvious - only a turbine. However, you should always remember that such an engine can suddenly “end” - it will require repair of the turbine or parts of the crankshaft.

Let's consider the choice from a tuning point of view. What is better on a VAZ - a compressor or a turbine? Many choose the second option, since the resource of VAZ engines is already insignificant.

Compressor

So what is this mechanism? The compressor is a mechanical air blower that is installed near the engine. There are several types of mechanisms: centrifugal, rotary and screw. Unlike turbines, compressors appeared much earlier.

You may be interested in: How to restore a battery terminal with your own hands in a garage

They became widespread in the 60-70s of the last century in the USA. At that time, American muscle cars were universally equipped with these superchargers. In 2000, the installation of a compressor was practiced. A striking example of this is the Mercedes C-Class car. Such cars were distinguished by the “Compressor” nameplate on the rear of the body.

Turbine

Turbine operating principle

Unlike a compressor, a turbine is “built” into the engine, uses its oil and operates from exhaust gases, that is, it “interferes” with the exhaust system.

The principle of operation of the turbine is as follows: gases enter the engine exhaust, then go to the hot turbine wheel (spinning it), the rotational energy is transferred to the cold wheel, which begins to rotate quickly and pump air into the engine intake.

Turbine advantages:

- higher operating efficiency;

- uses the energy of exhaust gases;

Disadvantages of the turbine:

- works efficiently at high speeds;

- there is so-called turbo lag or a delay between pressing the gas pedal and increasing engine power;

- uses engine oil for lubrication, and therefore the engine requires more frequent replacement;

- increased oil consumption;

- short service life, in the best case - up to 200 thousand kilometers;

- high cost of repairs;

- installation difficulties;

In fact, the main and only advantage of the turbine is the impressive increase in engine power; then there are only disadvantages.

What is better, a turbine or a compressor?

In fact, it all depends on what kind of effect the car owner needs, and this is always strictly individual. The following conclusions can be drawn.

Turbine.

Gives a huge increase in engine power, up to 40%. Relevant for rally races or for fans of street racing. True, you will have to spend a lot of money both on the purchase of the device itself and on its installation, configuration and maintenance. Plus you have to put up with high oil consumption, lag and frequent repairs.

Compressor

. Suitable for drivers who do not need such an impressive increase in engine power. At the same time, the car owner does not want to have problems with servicing the equipment, since the compressor is used according to the “install, configure and forget” principle - its service life is enough for the entire period of using the car. And the cost of the device itself is several times lower.

The end of the working day, nothing foreshadowed trouble. How a dispute broke out among the mechanics in one of the boxes. The age-old topic, long overgrown with moss, once again revealed a heated confrontation between adherents of the compressor and turbine. It must be said that in our service there are constantly clashes between fans of German and Japanese cars, fans of Apple gadgets and supporters of Android devices, and now it’s the turn of air blowers. Why really be surprised, each device is good in its own way, has a number of advantages over each other, but is not without its drawbacks. There was only one way out of this situation; each side had to provide compelling arguments in favor of their device and oppose the other side with the help of the disadvantages of their “gadget.” I acted as the arbitrator, because for me there is nothing better than a huge displacement “aspirated” engine without additional superchargers.

Turbine operating principle

The operating principle of the device is as follows: during the exhaust stroke, all exhaust gases exit through a special channel to the muffler. These gases spin the hot turbine wheel, which is located on the same shaft as the cold one. In turn, the cold wheel begins to spin strongly and this way you can get about 200-240,000 revolutions per minute.

Advantages of a turbine over a turbocharger:

- High level of performance compared to a compressor;

Flaws:

- Uses engine oil, which is designed to lubricate and remove excess temperature;

- Low resource. Often after 300,00 km it needs repairs;

- High oil consumption. In normal condition, turbines on gasoline engines consume up to 1 l/10,000 km;

- The use of a turbine quite often causes chain stretching;

- It is quite difficult and risky to install yourself if it is not provided by the manufacturer.

Turbine or compressor - what's the difference? The compressor operates on a belt drive from the crankshaft of the unit, the turbine - from exhaust gases, crashes into the muffler and is lubricated with oil.