Like any other part in a car, regardless of quality, shock absorbers fail, have their own service life and require replacement. Many car owners understand their purpose and functional characteristics, but not everyone can determine what kind of shock absorber malfunction is present on the car.

It is worth noting that shock absorbers are used not only as additional suspension elements that improve comfort. The correct choice affects safety, handling, braking distance and speed performance. Do not neglect the diagnostic services of specialized service centers and adhere to the regulated maintenance and replacement periods.

About shock absorber manufacturers

At this stage of development of the auto industry, car owners have to deal with the replacement of shock absorbers and their repair. There are a huge number of places where you can buy car parts. Car owners have a wide choice of different shock absorbers.

It is necessary to choose the right shock absorbers for your car. But this is not easy to do, since there is a wide range of companies on the market that produce different shock absorbers, including many different characteristics, properties, types and types.

The most popular shock absorber manufacturers: SACHS, KYB, MONROE, Koni, Bilstein, Boge, TOKICO (HITACHI), Al-KO, DELCO, Fenox, Fox, Plaza, Bilstein, SAAZ, LYNXauto, ZEKKERT, RANCHO, PATRON, AMD, Arirang, Asam, Finwhale, Miles, Ashika, Stellox, BORT, Mando, Avantech, KORTEX, SAT, FEBI, Optimal, PILENGA, PARTS-MALL, TRIALLI, Japanparts, TRW.

The first ten of them top the rating of shock absorber manufacturers.

The seller, as a rule, always has one goal - to sell. In order for the buyer to return, the seller focuses on opportunities and acts according to the following scheme:

- offer the most popular brands;

- offer the cheapest or most expensive;

- focus on the product that is in stock;

- make a choice regarding the buyer’s price category;

- motivate the buyer by the fact that these are the shock absorbers that are installed on his car from the factory.

Despite this, the buyer himself can determine and select the spare parts that are suitable for him, having the necessary knowledge. So which ones are better, gas or oil? Let's try to understand this complex issue and give comprehensive answers.

Which shock absorbers are better: oil or gas-oil?

Many car owners believe that a gas-oil shock absorber is a third, separate type of device. In fact, it is the same gas one. It is impossible to create a device with an exclusively gaseous environment. Gas models are essentially devices with a mixed medium, in which both gas and oil are present. Based on the technical characteristics, oil types should be more rigid, since the compensation fluid is practically not compressed. In practice, everything turns out to be exactly the opposite.

It's all about the factory settings of the device itself, its size and other design features. Before choosing shock absorbers for a car, you should read the recommendations of the manufacturer of a particular vehicle. This is due to the fact that the car’s suspension is carefully calculated, and the standard shock absorbers fully comply with all the necessary requirements for a specific modification of the car.

Installing any mechanism, even the most expensive one, with different characteristics, as a rule, leads to an increase in the load on the chassis. If it is necessary to replace standard devices, you should purchase models with identical or similar characteristics, and which shock absorber is better - oil or gas-oil - is up to the owner of the car to decide. If the car is used more in off-road conditions, softer models can be installed, but if the car is used on good surfaces, it is permissible to install harder models.

Types of shock absorbers

To correctly select the right parts, you do not need to be a car mechanic and have knowledge of all the mechanisms in the car. Shock absorbers are an important spare part and you don’t want to change them often, so you need to choose exactly what suits the technical characteristics best.

The following types of shock absorbers exist:

- single-pipe gas;

- two-pipe oil;

- two-pipe gas;

- gas with an external chamber;

- shock absorbers with automatic electrical adjustment.

Depending on the operating conditions of the car, the most appropriate type is selected.

Main characteristics of different types of shock absorbers

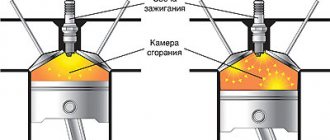

Monotube gas shock absorbers

These shock absorbers are gas-oil shock absorbers, filled with hydraulic oil, with gas support, the working fluid is hydraulic fluid. Mainly used for sports driving. They help to achieve maximum stability of the car on the track by increasing its grip characteristics with the road surface, increasing the rigidity of the suspension as a whole, while, of course, comfort is lost.

They maintain a constant high gas pressure. As a rule, the service life of these shock absorbers is long, but they are demanding on the quality of the road surface.

Gas under excess pressure (for example, nitrogen) passing through the bypass holes from one chamber to another impedes the movement of the rod, while the hydraulic oil poured into the shock absorber does not foam; a specialized valve is responsible for the rebound and compression stroke.

Different models use hydraulic oil of different viscosities and manufacturers, this affects both the temperature indicators of viscosity and the ability of the valves to pass hydraulic fluid. The passage of oil through channels of different diameters occurs with different foaming - compensated by an increase in gas pressure.

The most common system for assembling valves on a stem is the herringbone. Valve washers are selected from smaller to larger gradually, in increasing order. Thus, at the beginning of the shock absorber stroke (on small bumps) we have slight damping, but on large bumps large washers come into play and the suspension begins to work progressively. Thus, failures in operation disappear and stability is ensured.

Twin-tube oil shock absorbers

These shock absorbers are oil, with the exception of pneumatic ones, which are rarely used in the civilian version, without gas support.

Operating principle: the role of an expansion tank is performed by an external pipe; when the piston is lowered, the liquid in the external pipe rises, unlike single-pipe ones, in which compensation of the hydraulic fluid occurs due to a floating piston and gas pressure.

The oil bypass channels are larger in diameter, due to this there is less foaming and there is no need to compensate for the formed foam, as a result we get the most comfortable and soft ride, the car is more impressive, not fussy about the surface and quality of the roads.

The larger the diameter of the holes in the bypass valve, the less oil resistance the piston faces and the piston works easier - the shock absorber becomes softer. If the diameter of the holes is smaller, the stroke becomes stiffer accordingly.

They were mainly used on now outdated cars . Unfortunately, comfort and controllability are difficult to compatible things, so the use of oil shock absorbers is not suitable for active driving.

The oil shock absorber, which has the advantage of an affordable price, is designed for simple operating conditions. This type has a number of disadvantages: overheating of the oil due to slow cooling until the oil boils, frequent replacement of damping elements.

Twin-tube gas shock absorbers

They are gas-oil shock absorbers - a combined type of shock absorbers, created to combine all the positive characteristics of single-tube and double-tube shock absorbers. They are resistant to elevated temperatures due to better cooling and contact of the hydraulic fluid with the second tube.

Operating principle: Pressurized gas, instead of air in the outer cylinder, prevents oil from foaming inside the shock absorbers, which improves performance. In this position, the piston is pressed with gas; when overcoming bumps in the roads, the rigidity changes nonlinearly. The choice of such shock absorbers is necessary for those who prefer active driving.

They provide ideal road grip, even in unpredictable situations, and can be used in normal civilian, city driving. For those who prefer a mixture of active driving and everyday driving, it is better to install shock absorbers of this type.

It is worth considering that the price category of these shock absorbers is slightly higher than conventional oil shock absorbers; they will cost car owners approximately 15-20% more.

Gas with remote chamber

These shock absorbers use a remote chamber. Remote chamber - designed to increase the volume of oil and gas, with the same overall dimensions, which allows you to increase the stroke of the rod, install additional hydraulic valves to flow hydraulic fluid from the working chamber into the remote chamber and counteract the operation of the piston.

It is possible to set various adjustments for the stiffness and rebound of the rod; in some models, you can adjust the height of the shock absorber and even the ground clearance of the car.

Such products require more careful care and maintenance . Mainly used in sports. The Russian racing team KAMAZ-master, a multiple winner of the Dakar, uses shock absorbers with a remote chamber because there is a need for careful suspension settings for different types of tracks, weather conditions, and speed limits, which together allows you to save precious minutes of time.

Such shock absorbers are not installed on production cars because They are tuning components for sporty and aggressive driving. And the cost will not be cheap for car owners.

Shock absorbers with automatic electrical adjustment

They use hydraulic oil and gas, but in automatic modes. Automatic, electrical adjustment is the newest type. With this adjustment, there is no need to leave the car to adjust the shock absorber.

A hydromechanical adaptive system with an additional valve, together with various sensors, is capable of determining the vibration frequency of the suspension, analyzing the data, driving style, determining how much it is necessary to open or close the bypass valve, making the shock absorber softer or stiffer. In some cases, you can manually select operating modes.

On a flat surface, the shock absorber does not lose rigidity, which allows you to quickly take turns, and on bumps and paving stones, the valves in the shock absorbers open, providing softer suspension operation to improve ride comfort.

Another automatic control option changes the gas pressure. This option uses shock absorbers with remote chambers and pneumatic lines to them. The compressor changes the pressure in the receiver and supplies it through a reducer to the remote chamber, which allows you to adjust the stiffness of the shock absorbers, and sometimes the vehicle's ground clearance.

An electromagnet in the rod allows for a lightning-fast reaction; shock absorbers can change stiffness instantly, depending on the speed and operation of the suspension, on each wheel in automatic mode, transmitting data from the sensors to the controller and to the solenoid valve. The technology is not durable, due to its complexity, and is not stable to various temperature changes, but it is very promising and developing.

Which shock absorbers are better: gas or oil?

BOGE Shock Absorber Kit

Strictly speaking, both modifications are popular. But the advantage still remains with gas models. They are more reliable, rarely leak or break. They can withstand temperature and pressure loads better. But if you ask yourself which struts are softer, gas or oil, then the answer will remain with the second option. Oil dampers are also more elastic, which gives better car controllability. Due to the fact that they use only oil, they are much softer and more energetic. What is the difference between a gas shock absorber and an oil shock absorber? First of all, the design. In addition, the gas damper is designed for high-speed driving on a flat road. And oil ones are more suitable for moving on broken roads, but at low speeds. When deciding this question: which shock absorber struts are better, gas or oil, first of all it is worth remembering the recommendations of the car manufacturer. The best shock absorption will be standard.

Oil shock absorbers are more suitable for traveling on rough roads, but at low speeds.

Many motorists prefer gas shock absorbers. It is worth considering the difference between a gas shock absorber and an oil shock absorber:

- the presence of a rigid suspension for fast driving;

- perfect grip;

- protecting the car from aquaplaning;

- and with all these advantages there will be shaking on uneven roads.

So which shock absorbers are better: gas or oil? Still, drivers do not like oil shock absorbers. And the reason is that in the cold the oil takes a long time to warm up, which makes the trip completely uncomfortable. In addition, during long and fast driving, the oil may become airy and lead to.

Useful tips

Shock absorbers are always replaced in pairs! It is not permissible to use different types and brands on the same axis! It is possible to install several shock absorbers on one wheel. It is not allowed to use a standard size other than the factory one.

After a long period of inactivity (for example, on store shelves, transportation, etc.), before installing the shock absorber on a car, regardless of whether it is new or not, it must be bled.

Bleeding allows you to get rid of air pockets that may be in the bypass channels. During pumping, you can check the part and understand how the flowing liquid sounds, whether there are knocks at the end of the stroke of the rod, determine the absence of play at the end of the stroke, the presence of oil smudges on the rod - all this can be done when purchased in a store.

To pump, it is necessary to install the shock absorber with the rod up and make several movements of the rod (5-10 times) down and up with little movement to the lower and upper points. The air lock goes into the outer pipe. When pumping, smooth operation should appear and noise should disappear. All shock absorbers need to be bled!

Relationship between repair of springs and shock absorbers

Since the operating mode is considered to be only the functioning of the entire spring-shock absorber combination, the failure of one of these elements provokes the occurrence of excessive force load on the other. Both components are completely interconnected. For example, if significant subsidence of the springs has occurred, then additional work of the shock absorber strut will seriously reduce its service life. In the same way, a failed shock absorber is not able to effectively dampen the vibrations of the springs, which provokes its breakdown. Based on this, the ideal repair would be one in which the springs are replaced along with the shock absorbers. We understand that this is expensive and not always practical, but it should be understood that the investment is compensated by the increased service life of this assembly. In practice, it is quite acceptable to replace car springs every two shock absorber replacements. This is usually enough.