The era of carburetor technology is long gone. Today, fuel enters the car engine under electronic control. However, there are still cars that have carburetors in their fuel system. In addition to vintage cars, there are also quite workhorses - UAZs, as well as classics from the Togliatti Automobile Plant. This means that the ability to understand the device, carry out maintenance, and repair the carburetor remains valuable.

This article will focus on the K126G carburetor. Adjusting the K126G carburetor is a delicate undertaking that requires certain skills and good knowledge of its composition and operating principles. But first, let’s remember a little about what a carburetor actually is.

About carburetor systems

So, what is a carburetor? Translated from French, carburation means “mixing.” From here the purpose of the device becomes clear - to create a mixture of air and fuel. After all, it is the fuel-air mixture that is ignited by a spark from a car’s spark plug. Due to their simplicity of design, carburetors are now used on low-power engines of lawn mowers and chainsaws.

There are several types of carburetors, but in all cases the main components will be a float chamber and one or more mixing valves. The principle of the float chamber is similar to the valve mechanism of a toilet cistern. That is, the liquid flows to a certain level, after which the shut-off device is activated (for a carburetor this is a needle). Fuel enters the mixing chamber through a sprayer along with air.

A carburetor is a fairly delicate device to configure. The K126G carburetor must be adjusted with every maintenance and any problem. A correctly configured fuel-air mixture supply unit ensures uniform engine operation.

GAZ 3110 fuel consumption reviews

GAZ 3110 "Volga" is a Russian middle-class rear-wheel drive sedan, the production of which started at the Gorky Automobile Plant back in 1997. This car was a modernized version of Volga 31029. Serial production of the car was discontinued in 2005 due to low demand. The car is the only passenger car that the Gorky plant has ever created, since the enterprise's activities were mainly aimed at creating working trucks.

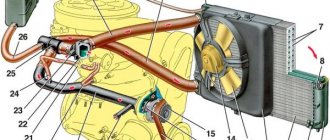

K126G carburetor design

The K126G carburetor is a typical representative of the two-chamber version. That is, the K126G contains a float and two mixing chambers. And if the first one works constantly, then the second one starts to work only in dynamic modes with sufficient load.

The K126G carburetor, the device, adjustment and repair of which are described in this article, is quite popular for UAZ cars. The device is very unpretentious in operation and is resistant to debris.

The K126G float chamber has an inspection window from which you can determine the fuel level. The carburetor has several subsystems:

- idle move;

- starting a cold engine;

- accelerator pump;

- economizer.

The first three operate only in the primary chamber, and for the economizer system a separate nozzle is provided, which is discharged into the air channel of the second chamber of the carburetor. General control of the device is carried out using the “choke” system and the accelerator pedal.

The procedure for connecting pipes to the K151D carburetor

The carburetor unit (CU) in the K151D modification is identical in appearance, design and many components to the K151S model, which was installed on ZMZ-402 engines. The device itself is not very complicated, moreover, it is easy to install, but some drivers (car owners) have difficulties connecting the hoses, since there are quite a lot of them.

Let's dwell on this issue in more detail, consider with the help of diagrams (photos) where the pipes are connected, and what each of the fittings is needed for:

Applicability of K126G

A carburetor marked “K126G” was installed and is still serviced on Gaz-24 “Volga” and UAZ vehicles, with mainly UMZ-417 engines. UAZ car owners especially love this model for its unpretentiousness and ability to work even with clogged fuel.

With minor modifications (drilling a hole), the K126G is installed on UMZ-421 engines. And this could be either a UAZ or a Gazelle. The predecessor of the K126G can be considered the K151, and the next model is the K126GM.

Adjusting the K126G carburetor is the most popular question among carburetor technicians. But first, let's look at various problems that can happen with the K126G.

Modifications of K126 carburetors

Carburetors of the 126th series have been produced for decades; the first models were manufactured at the Leningrad plant (Lenkarz), later renamed PEKAR. They began to be used on GAZ-53 and GAZ-66 trucks starting in 1964 (K126B), in 1977 the GAZ-52-03 was equipped with the K126I model, and the “Gazonchik” 52-04 began to be equipped with the K126E. The K126D version was also developed for Lawns and PAZ buses; later GAZ trucks began to be equipped with a K135 carburetor, which, in fact, is an analogue of the “one hundred and twenty-sixth”.

The K126P modification was intended for four-cylinder MZMA engines, used on Moskvich-408 cars, production began in 1965. The K126N modification was already used on Moskvich-412, for the Volga 24 and 24-10 the K126G and K126GM (the modernized version of G) were intended, and for cars with gas equipment - the K126S. The model used regularly on UAZs is the K126GU version (UMZ-417 engine), often UAZ owners install a Volgov carburetor “G” or “GM”.

In fact, many variants of the “126” are interchangeable, differing mainly in the lower part of the body (“sole”) and the top cover (different mounts for the air filter housing). Of course, each of the carburetor units is equipped with its own jets, but they can be easily changed. The only thing that cannot be done is to install a carburetor from a truck to a passenger car, and also in the reverse order, here they have significant differences.

I came up with a theory (using my friend’s calculations www.drive2.ru/cars/gaz/31/3110/skyrider/ as a basis)

Everything is as it should be...

For example, compare the K-135 with the K-151s in theory

It is known that air speeds in the diffuser above 120 m/s are already beginning to negatively affect the filling of the cylinders with fresh charge. The “geometry” of a standard 402 engine is 92×92, which means that per revolution it consumes: 3.14*((9.2/2)^2)*9.2*2=1223 cc of air per revolution (per the intake revolution occurs in two cylinders). At a speed of 4500 (maximum power speed according to VSKh ZMZ402), the consumption will be: 1223*4500/60=91725 cc/s. Next, it is necessary to take into account the engine filling coefficient at high speeds due to the inertia of the mixture. Approximately 1.2. As a result, the air flow through the diffusers is: 91725*1.2=110070 cc/s. Next, it is not difficult to calculate the area of the diffusers of the 1st and 2nd chambers of the K-151s carburetor; it has diffusers 23+26: 1 - 3.14 * ((2.3/2)^2) = 4.15265 sq.cm 2 - 3.14*((2.6/2)^2)= 5.3066 sq.cm, respectively, for a total of 9.45925 sq.cm. Now we divide the flow rate by the area: 110070/9.0432 =11636.22909 cm/s We convert from centimeters to meters and get the flow rate in the diffuser (for drain): 11636.22909 /100=116.3622909 m/s. That’s why, after 4500 rpm, the power on any 402 stops growing, or rather, it drops and the engine begins to “twist” - losing power, although it spins further, up to 5500 rpm. This is due to a sharp decrease in the cylinder filling ratio. There is only one conclusion - the engine is tightly clamped by the carburetor! A similar calculation for the K-135 carburetor: the area of the diffusers of the 1st and 2nd chambers of the K-135 carburetor, its diffuser diameter (27x27mm): 1 - 3.14*((2.4/2)^2)= 5 .72265 sq.cm 2 - 3.14*((2.4/2)^2)= 5.72265 sq.cm, respectively, for a total of 11.4453 sq.cm. (which is 21% more than the standard K-151S)

Possible faults

All malfunctions of the described system are either visible visually or are easy to check. One of the main problems is unstable operation of the engine at idle, or there are no idle speeds at all. The K126G carburetor, whose fuel flow adjustment is normal, allows the engine to idle without any problems.

The second point that shows that the device is faulty and requires adjustment is an increase in fuel consumption. There may be several reasons, so adjusting and tuning the carburetor does not always help.

Planned regular cleaning of all components can solve the problem. Incomplete cleaning is also possible when the carburetor is not removed from the car, but it is undesirable. K126G, like any mechanical device, prefers good care.

Replacing a carburetor with an injector on a ZMZ-4063 engine

In order to improve technical characteristics, quite often Gazelle owners replace the carburetor system with an injector, although this pleasure is not cheap. For such a modification it will be necessary to purchase additionally:

- air flow sensor;

- electric fuel pump;

- other wiring for the engine;

- intake manifold (receiver) assembled with dampers;

- air pipes;

- DTOV (ambient temperature) and TPS (throttle position) sensors;

- fuel rail with injectors and fuel pressure regulator;

- the engine control unit;

- front small engine cover;

- both camshafts (differ in cam profile);

- fuel filter;

- air filter housing (“can”) assembled with a filter element;

- idle speed controller.

You may also need various small things, such as gasoline hoses, clamps, fuses, gaskets, fuel filter bracket, etc. The work here is labor-intensive, but the end justifies the means. The advantages of an injector over a carburetor are significant:

- the engine receives a significant increase in power;

- no need to constantly struggle with adjusting and cleaning the carburetor;

- You can install HBO of almost any generation, except the first.

Some injector spare parts are expensive, but it is not necessary to purchase them at the store. Excellent quality used parts can be found at car dismantling yards or through advertisements from private traders, especially since you can almost always bargain. Definitely, it is better to buy a used collector (receiver), since it almost never wears out, and there is no point in overpaying here.

Video on repairing the Gazelle ZMZ 406 engine:

From the very beginning of production, the Gazelle was equipped only with the ZMZ 402 engine, but since 1996, the ZMZ 406 engine began to be installed on the car as a series. The internal combustion engine was equipped with an electronic ignition system, but unlike the Volga, which already had an injector, the Gazelle had an injector. decided to leave the carburetor.

Adjusting the K126G carburetor

The need to adjust the carburetor may arise for various reasons. This could be routine maintenance or troubleshooting issues. Moreover, simple adjustments according to the instructions are quite easy to perform. The downside is that it does not always help in solving. Experienced mechanics with extensive experience in carburetor repair do not begin work without adjusting the valves.

In order for the fuel-air mixture mixing device to function without interruption and not require constant adjustment, timely maintenance is necessary. It is enough to carry out a basic inspection for leaks and tightness and flush the carburetor at least partially. Sometimes it is necessary to check the fuel level in the float chamber, as well as the flow rate of both fuel and air jets.

If we approach the issue systematically, then it is necessary to highlight the following types of carburetor settings:

- idle move;

- fuel level in the chamber with a float;

- economizer valve.

Adjusting the K126G carburetor on an UAZ most often involves adjusting the idle speed specifically. So, let's consider the sequence of actions to restore auto stability at idle.

Carburetor for Volga. DAAZ 4178-40 Brief impressions.

I’ll briefly talk about the two carburetors that were on the car. Which carburetor is best for the 402 engine? Which thermostat is better to install on a Chevrolet Niva:. Tags: gaz-24, gas-24 carburetor. Please tell me which carburetor is better to install on the gas-24, ZMZ-4021 engine. DAAZ 4178.1107010-40 and Solex 41-1107010-10.

When installing something like this on a Volga (or UAZ), it will provide excellent gas savings, but will reduce the engine's agility and throttle response - you won't be able to drive it much anymore. 21083

– more accurately produces dosage in different modes. So, we draw conclusions: if there is a very big need for savings, then we install DAAZ, and if we want to get a more powerful car, then K-151.

Since probably only a few people dream of racing cars like the Volga, it would be advisable and practical to think about installing a Zhiguli carburetor on the 402 engine. In the old days, some happy owners of old Volgas, which absolutely shamelessly consumed gasoline that had become more expensive in the post-Soviet space, installed eight Zhiguli carburetors, and were very pleased with the results obtained. This was done exclusively for economic purposes, although some problems arose during installation (for example, with the length of the studs or the choke).

On Solex ( DAAZ-21083

) the holes are slightly shifted (a millimeter inward).

For final finishing, you also need to make a jet correction. Solexes already modified specifically for the Volga also appeared in the offer (labeling DAAZ-3110

). Automotive forum Wroom.ru: discussion of the topic Which carburetor is better to install on a GAZ-3110 with 402 doors. This greatly simplifies the task of a car driver planning to carry out reconstruction. Help me choose which carb is better; at 100 for gas 31029 but set the case to 151. Which thermostat is better to install on a VAZ 2114 Thermostats that are supplied from the Middle Kingdom are a metal case that looks like stainless steel, but in. You only need to choose the unit (the kit also includes an adapter for old air filters), and the rest is a matter of technique. To install a new one in place of the old one, you will need to spend very little time and physical effort.

In the end, if you yourself are not a great carburetor specialist, then the easiest way is to turn to the craftsmen who live at the service station for help. Which thermostat is better than the VAZ 2115 is that the thermostat will fit any of the. There, for a certain amount of money, they will change everything for you and check how the system works. Although, of course, there is no 100% trust in the masters either. There were cases when, during installation, the difference in the structure of the native and VAZ EPHH block - forced idle - was ignored. As a result, the engine operated at idle with interruptions and flaws when driving.

You should try to avoid such nuances and properly set up the newly installed unit right away, so as not to mess around with breakdowns in the middle of the road. And then the question of which carburetor to install on the 402 Volga engine will be resolved by itself. From experience: as a result of a journey of 850 km, the GAZ-24 consumed only 80 liters of gasoline, that is, less than 10 per hundred!

Instructions for adjusting idle speed K126G

The stability of the engine is adjusted using two screws. One determines the quantity of the fuel-air mixture, and the second determines the quality of its enrichment in the K126G. Adjusting the carburetor, the instructions for which are given below, is carried out in stages:

- With the car turned off, tighten the mixture enrichment screw until it stops, and then unscrew it 2.5 turns.

- Start the car engine and warm it up.

- Use the first screw to achieve neat and stable engine operation at approximately 600 rpm.

- The second screw (enrichment of the mixture) gradually depletes its composition so that the engine continues to operate steadily.

- With the first screw we increase the number of revolutions by 100, and with the second we reduce them by the same amount.

The correctness of the adjustment is checked by increasing the speed to 1500 and then closing the throttle valve. The revolutions should not fall below the permissible values.

GAZ 3110 in detail about fuel consumption

When buying a car, any driver first of all pays attention to its technical characteristics. Their relationship with each other determines the final quality of the machine. The use of gasoline is important in this list. That is why, let’s consider the fuel consumption of the GAZ 3110 per 100 km, how economical it is considered and how to reduce this vehicle consumption.

Adjusting the fuel level in the float chamber

Over time, it may happen that the level of gasoline in the float chamber changes. According to the norm, it should fluctuate within 18-20 mm from the bottom surface of the connector, which is determined through the carburetor inspection window. If visually this is not the case, then adjustments need to be made.

Changing the fuel level in the K126G chamber is carried out by bending the tongue of the float lever. This is done very carefully, trying not to damage the seal washer made of special gasoline-resistant rubber.

see also

Comments 24

put it on! Just bore the accelerator nose to 0.6-0.7. so that there is no failure and turn it (the spout so that the stream hits evenly between the wall and the chamber damper

Place it and don’t worry. Normal carb. cold start with half a kick, fuel consumption is normal and everything is OK with traction. In the summer, you can sand it on the 2nd place without any problems.

I have one like this, after a visit to the master the car became very lively, the consumption was A92 13.4 liters in the city in traffic jams and 10 on the highway (it was all on a regular ignition, now it is contactless and the head is polished for A95, the consumption is not yet I measured that it eats no more than before - that’s for sure) the second chamber was disconnected by the previous owner, I can’t find spare parts to connect it to other carbs, I haven’t driven, so I won’t say anything bad about them) I’m happy with mine

Tell me the calibration of the jets on your engine

I had this on the old engine (now 4062f). normal. was taken when the native 151 began to completely fall apart. I took it because The quality of the 151s at that time was not at all impressive, and they cost twice as much. worked great.

I've had this one for 4 years now and it's been flying normally on both gas and gasoline.

I have a question, for gas - are the chambers drilled or is a spacer installed?

In the air there is a round mixer like this. I purchased it from one of the offices that install HBO.

I read somewhere that with such a mixer the consumption is increased (and you are unlikely to find such a thing in our province), it is better to “drill” or put a spacer under the carb

Consumption 13. And the mixer can be ordered online. As a last resort, you can make a homemade one by inserting a tube with a diameter of about 20mm into the air vent, cut the tube at an angle and turn the cut towards the diffusers, I had this design when I had the K126.

I have one, it runs great, but I need to select jets to reduce consumption. The Volgov ones were eating 25, now the Niv ones are 20, I bought 1.3 engines from a penny and haven’t moved them yet. Starts the car when cold at the drop of a hat!

Don't bet on a penny! I’ve already set it...sneezes...farts and barely drags along)

What else will reduce consumption?

I don’t want a Lada. But do all Volgas really eat 20?

Well, she grabs my 11L and what’s the point? It's impossible to drive! In 1st and 2nd gears it stalls a little, and in 3rd gear it stalls, but it barely accelerates. In a big city you will stall at every traffic light.)) My motorcycle (Ural) runs much faster than it does with these jets))

Gas to the floor and stalls, it's the carb that doesn't work. I have 12 l. City and 9.5 highway, but it doesn’t stall, even if you start in 2.

I don’t want a Lada. But do all Volgas really eat 20?

No, not all! There are and they perform well relative to the Volga with the 402nd and the consumption is within 11-13 in the city and 8-10 outside the city

There was such a carb, but when switching to gas I had to install K 151

Why ? what is the reason ?

They made an insert into it, but they couldn’t adjust it. On gas it worked only with a slightly extended suction, and on gasoline it began to work completely differently, but before the insertion it worked perfectly on gasoline.

I understand, thanks for the answer, in general, as I understand it, this carb should not be installed under the LPG

Read more: Checking fines online

a good carb does not heat like a child! but I achieved the ideal from 151 to a cold one, it goes well, not like 4178

I have one like this, but the numbers are different, I really don’t remember them, but the first ones on it are definitely 3110. But I can’t get around to putting it on) I had this on my gazelle, and the most positive impressions were!

I came across this device on the Internet. What can you say about him? How does it actually compare to other Volga carburetors? More interested in economic and power characteristics.

Advantages and disadvantages of K126G

The K126G carburetor is quite popular among UAZ owners. It is valued for a number of advantages that are missing from more modern models:

- stable operation in the presence of clogging;

- unpretentiousness to fuel quality;

- sufficient economy.

The K126G carburetor, the mixture quality of which is adjusted regularly, will work without any problems. Simplicity of design is a guarantee of reliability. In this case it will comply, but subject to scheduled maintenance.

The K126G has one unpleasant drawback. If overheated, the device body may become deformed. This occurs when the carburetor threads are over-tightened.

Compatibility

But what about such an important indicator as compatibility, you ask? Almost all carburetors (two-chamber), both domestic and many foreign, can be interchangeable and coincide in many of their parameters and connection sizes. DAAZ-2107) can also function successfully on the Volga

), and gas (

K-151

and

156

), and azlkash. There will, of course, be a difference in performance, and the diameter of the jets will need to be adjusted. So, the VAZ unit has a smaller diffuser.

When installing something like this on a Volga (or UAZ), it will provide excellent gas savings, but will reduce the engine's agility and throttle response - you won't be able to drive it much anymore. 21083

– more accurately produces dosage in different modes. So, we draw conclusions: if there is a very big need for savings, then we install DAAZ, and if we want to get a more powerful car, then K-151.

Installation

First of all, we dismantle the air filter. Next, we remove one by one:

- damper drives;

- hoses (fuel supply and vacuum corrector vacuum extraction).

The K-126GU carburetor is simple, reliable and easy to maintain.

The unit is mounted on the flange of the engine intake pipe. Secure the carburetor with four nuts. Additionally, spring washers are used. We check the integrity of the rubber gasket and, if necessary, change it. At the final stage, we attach the damper drives and pipes.

Setting procedure:

- We check the tightness of the unit (special attention to the areas where hoses are attached, plugs and gaskets). If we find a fluid leak, we fix the problem;

- pump in fuel (6–8 times using a manual fuel pump);

- close the air damper, start and warm up the engine;

- as the engine warms up, gradually open the damper;

- at the moment when the antifreeze temperature reaches +40 °C, fully open the damper;

- screw in the screw that regulates the quality of the fuel mixture until it stops;

- unscrew the “quality” screw 5 turns;

- bring the liquid temperature to 90 °C;

- increase the crankshaft speed to the maximum possible amount;

- smoothly tighten the screw for adjusting the amount of fuel mixture until interruptions in engine operation begin;

- unscrew the “quantity” screw half a turn;

- We check the performance of the engine. We press the gas pedal and then sharply release it. If the engine stalls, increase the speed.