The content of the article:

- Where is the pump located?

- How to understand that the pump has failed

- What to do if a breakdown occurs

- Pump diagnostics

- For what reasons does the pump break down?

- Replacing the pump on the "nine"

When operating a vehicle, various situations may arise. Some components can be repaired, but most require replacement (full or partial). The oil pump on the VAZ-2109 is repairable; if it fails, it can be fixed quite simply. One thing to remember is that operating a car with a damaged oil supply pump is prohibited. This will lead to destruction of the valve mechanism, crank and connecting rod. But you can repair the unit yourself, and you will spend a small amount of money and effort on it.

Where is the pump located?

You will be interested:How dangerous is the new coronavirus?

On the VAZ-2109 it is installed at the bottom of the engine. And more specifically, on the side of the gas distribution mechanism, near the crankshaft pulley. Actually, it is from this that the drive gear of the pump is driven.

Access to the mechanism is closed; to dismantle it, you will have to remove the plastic protection, the generator drive pulley, and the timing belt. The pump housing is secured using six bolts. In order to clean and suck oil from the pan, an oil intake of a special design is installed.

What to do if a breakdown occurs?

If such a malfunction occurs to you, then you need to perform the following manipulations:

- Stop and turn off the engine.

- Wait until all the oil that is poured into the engine flows back into the sump. Check the level. If it is below normal, then you need to top it up.

- Start the engine.

- Pay attention to the control lamp - if it still lights up and extraneous noise appears, then this is clearly a breakdown of the oil pump.

In some cases, the oil receiver mesh may become clogged. To be fair, it is worth noting that the pump is a mechanism in which there is nothing to break - it is the body and two steel gears. They will be able to “survive” even a tenfold increase in loads and long-term operation without lubrication. But the oil receiver often gets clogged, and lubricant simply does not flow into the pump.

Checking the pressure sensor

Oil pump cover VAZ 2109

If there is no unusual noise coming from the engine and the oil level is normal, the warning light may still sound indicating low oil pressure. Then, most likely, the problem will be with the oil pressure sensor. This sensor is usually located on the motor block. Inside the device there is a spring-loaded diaphragm, as well as an automatic switch diaphragm, which is highly sensitive to pressure. This switch is designed to close the low pressure warning lamp circuit when it drops below a certain level. Reasons for sensor failure:

- if the diaphragm stops moving;

- when the switch is jammed;

- if the hole through which oil gets inside the sensor is clogged;

- in case of unsatisfactory connection, which may be caused by corrosion, connector or wiring failure.

Attention! If the car is equipped with an electronic pressure gauge, a small rheostat will be placed inside the sensor, which, when this diaphragm moves, sends a variable voltage signal.

Pump diagnostics

But you still need to test the unit so as not to remove it in vain. The first step is to check the pressure in the system. Install any suitable pressure gauge and record the pressure. If it is low, then the unit will need to be repaired. The second step is to check the condition of the oil intake screen. To do this, you need to place the car on an inspection hole, completely drain the oil and remove the pan. To dismantle it, you will have to unscrew all the bolts using a “10” key. When installing, it is recommended to use a new rubber gasket.

Symptoms of a faulty oil pump

The first thing that will indicate problems with the oil pump is the oil pressure light coming on. In this case, the element indicates that there is a problem with the engine lubrication system. How serious they are remains to be determined by the car owner. In addition to checking the pressure, attention should be paid to oil consumption. If the pressure in the lubrication system of the power unit decreases, the vehicle should not be operated until the cause is determined and repairs are made. The main symptoms of problems in the system are a light coming on or a knocking sound in the engine.

Actions to be taken in the event of a breakdown:

- stop and turn off the engine;

- wait a while for the oil to drain into the engine crankcase, then check its level using a dipstick. If the level is minimal, you need to top it up to normal;

- start the engine;

- If the oil pressure lamp continues to light and extraneous noise is still heard from the engine, this may indicate a possible problem with the oil pump.

One of the reasons why the oil pressure light comes on may be a low level of lubricant in the engine.

How to check the oil pump

To test the mechanism, it is not necessary to dismantle it. For diagnostic purposes, it is necessary to measure the pressure in the lubrication system and compare it with the readings that correspond to the norm for a particular car. Based on the results obtained, we can draw conclusions: is there any cause for concern or not. If it is necessary to replace the oil pump on a VAZ 2108/2109, it is recommended to use only original parts. This is explained by the fact that many people today produce components for cars in the domestic automobile industry. However, their quality leaves much to be desired.

When replacing the oil pump, it is recommended to purchase an original part to avoid problems due to poor workmanship

Checking the oil pump on the stand

If possible, you can check the performance of the oil pump on a special stand. The essence of such a test is to evaluate the performance and pressure generated by the device, as well as the pressure at which the pressure relief valve operates. When testing the pump using a stand, special oil with a temperature of +20 ˚С is used. For an oil pump for a VAZ 2108/2109 engine, the flow rate should be within 34 l/min, the back pressure should be 5 kg/cm². The pressure relief valve should open at a pressure of 5.5–7.5 kg/cm². If the valve is checked on the engine using a pressure gauge, which is installed instead of an oil pressure sensor, the valve must operate at a pressure of at least 4.5 kg/cm².

Sources used:

- https://portalvaz.ru/zamena-maslyanogo-nasosa-na-vaz-2109-2108/

- https://carnovato.ru/zamena-maslyanogo-nasosa-vaz-2109/

- https://masteravaza.ru/dvigatel/maslyanyj-nasos/vaz-2109-maslyanyj-nasos-772

For what reasons does the pump break?

There are several reasons why the pressure reducing valve and oil pump on a VAZ-2109 fail:

Please note that it is necessary to remove and clean the pan - this will avoid blockages. Malfunction of the pump can be caused by the following breakdowns:

repair of the oil pump on VAZ 2108, VAZ 2109, VAZ 21099 cars

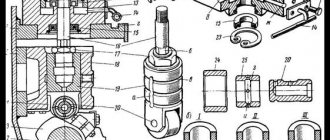

1. Remove the oil pump from the VAZ 2108, VAZ 2109, VAZ 21099 (see “Removing and installing the oil pump”).

2. Remove the six bolts securing the oil pump cover.

3. Using two screwdrivers, lift the oil pump housing so that the dowel pins on the housing come out of the holes in the oil pump cover, and remove the oil pump housing from the cover.

4. Remove the drive and... from the oil pump cover.

5... driven gear.

6. Remove the pressure reducing valve plug. Please note that an aluminum O-ring is installed under the pressure reducing valve plug. Replace a badly compressed ring.

7. Remove the pressure reducing valve spring.

8. Remove the relief valve by gently tapping the body on a clean wooden board. If the oil pump relief valve does not come out, remove the relief valve using a sharpened wooden stick.

9. Inspect the aluminum oil pump cover. In the contact area of the gears on the oil pump cover there should be no noticeable signs of wear, scuffs or deep scratches. Otherwise, replace the oil pump cover.

10. Inspect the oil pump housing. There should be no noticeable signs of wear, scuffs or deep scratches on the working surfaces of the oil pump housing. Otherwise, replace the oil pump housing.

11. Measure the diameter of the driven gear socket on the oil pump housing. The maximum permissible diameter is 75.1 mm. If the size is larger than the specified size, replace the oil pump housing.

12. Measure the width of the oil pump housing segment in the middle part. If the width is less than 3.4 mm, replace the oil pump housing.

13. Measure the thickness of the oil pump drive gear. If it is less than 7.42 mm, replace the gear.

14. Measure the thickness of the oil pump driven gear. If it is less than 7.35 mm, replace the gear.

15. Check the axial clearances of the oil pump gears. To do this, install the drive gear into the oil pump housing, place a metal ruler on the housing and measure the gap between the ruler and the gear with a feeler gauge.

16. In the same way, measure the axial clearance of the oil pump driven gear. The maximum permissible axial clearance is 0.12 mm for the drive gear and 0.15 mm for the driven gear. If the clearances exceed the specified values, replace the oil pump gears.

17. More accurately, the axial clearances of the oil pump gears can be obtained by calculation. To do this, measure the thickness of the oil pump housing with a micrometer along the outer surfaces and...

18... the thickness of the oil pump housing in the area of the gear socket in several places (along milled surfaces). Calculate the axial clearance as the difference between the arithmetic mean of the socket depth and the thickness of the oil pump gears.

19. Inspect the oil pump relief valve seat. There should be no burrs or deep scratches on its inner surface. Otherwise, replace the oil pump cover.

20. Replace the relief valve if the relief valve has nicks or deep scratches.

21. Replace a bent, broken or cracked relief valve spring. The height of the pressure reducing valve spring in the free state should be 44.72 mm, and under load (4+0.24) kgf ~ 31.7 mm. Otherwise, replace the pressure relief valve spring.

22. Install the driven gear into the oil pump housing. In this case, the chamfers on the gear teeth should face the oil pump housing.

23. Install the drive gear into the oil pump housing. In this case, the chamfers on the gear teeth should face the oil pump housing. 24. Install the cover on the oil pump housing and tighten the cover bolts.

25. Lubricate the oil pump relief valve with engine oil and install the pressure relief valve in the seat with the bottom down. Then install the pressure relief valve spring and tighten the plug with the O-ring.

26. Fill the oil pump with engine oil through the hole under the oil receiver.

27. Rotate the oil pump gears a few turns to lubricate their working surfaces.

- Author: admin

Rate this article: Share with friends!

Related posts:

Do-it-yourself repair of the VAZ 2106 engine oil pump

Removing and installing the oil pump on a VAZ 2106 car

Removal and installation of the oil pump from VAZ 2108, VAZ 2109, VAZ 21099 cars