A rotary engine (RPD or rotary piston engine), unlike a traditional piston internal combustion engine, is simpler in terms of design. Also, this type of power plant has higher efficiency. Accordingly, even with a small displacement, the “return” from such a motor is quite high.

However, RPD is not widely used in the automotive industry. Unfortunately, even with all the advantages, the unit also has a number of disadvantages. Next, we will look at how a rotary motor works and works, as well as its strengths and weaknesses.

Rotary engine: design and principle of operation of the RPD

So, the rotary engine, which is also called the Wankel engine in honor of its creator, is a fairly separate type of internal combustion engine. At the same time, this type of engine was installed on different cars (for example, a VAZ rotary engine, a Mazda rotary engine, etc.), but it was Mazda that popularized the unit to a greater extent thanks to the Mazda RX‑8 sports car with a 13B-MSP rotary engine.

In short, in a conventional piston engine, the energy from the combustion of fuel in the cylinders is converted into reciprocating motion by a bulky piston group, after which further conversion occurs into rotational motion (rotation of the crankshaft).

In turn, there is no CPG in a rotary motor; energy conversion occurs virtually “directly,” that is, with virtually no losses. Of course, the Mazda rotary engine has become a fairly powerful “heart” with outstanding characteristics.

It is noteworthy that the gasoline atmospheric rotary engine with a displacement of only 1.3 liters (13B-MSP) with 2 rotors in the form of sections produced 192 horsepower. At the same time, its forced version made it possible to produce 231 “horses”.

- If we consider the design, the engine received 5 housings, resulting in 2 chambers. These chambers, like cylinders, are designed for combustion of the fuel-air mixture. The energy from fuel combustion rotates the rotors, which are mounted on an eccentric shaft, which resembles the crankshaft of a conventional internal combustion engine.

In this case, the movement of the rotor is complex, since the rotor does not rotate, but actually “rolls” its internal gear around a stationary gear, which is attached in the center of one of the side walls of the chamber. The eccentric shaft itself passes through all housings and stationary gears. The rotation of the rotor, or more precisely, its rotational movement occurs in such a way that for 1 revolution there are 3 revolutions of the eccentric shaft.

Another noteworthy thing is that although a rotary engine also has intake, compression, power stroke and exhaust cycles, the timing mechanism is simplified as much as possible. There is no drive for the gas distribution mechanism, there are no camshafts, and there are no valves themselves.

All necessary functions are implemented through inlet and outlet windows, which are made in the side walls. In fact, the rotor opens and also closes these windows during rotation. To make it clear, let's look at the principle of operation of a rotary engine using the example of a unit with one section.

- So, the sides of the rotor, together with the walls of the housings, form the working cavity. When the engine rotor is in the initial position, the cavity is small in volume (this is the beginning of the intake stroke). Then, as the rotor rotates, it opens the inlet windows, resulting in the working fuel mixture entering the chamber. When the cavity reaches its maximum volume, the rotor will close the intake ports, after which the compression stroke will begin (the cavity will begin to decrease).

At the moment when the volume of the cavity is again minimal, due to a spark from the spark plug, the mixture will ignite and the working stroke will begin. Next, the energy of fuel combustion rotates the rotor, after which the rotor will move to a position in which the exhaust windows open (exhaust gases are released). After release, the entire cycle repeats.

Other cavities will work the same way. Taking into account the fact that there are 3 cavities, 3 power strokes will occur per revolution of the rotor. Moreover, the eccentric shaft rotates 3 times faster than the rotor. The result is one power stroke per revolution of the motor shaft with one section. It is quite obvious that a piston four-stroke internal combustion engine with one cylinder has a ratio that is 2 times lower compared to a rotary engine.

It turns out that if we compare the number of power strokes per shaft revolution, then the two-section 13B-MSP resembles a conventional 4-cylinder piston engine, however, with a volume of 1.3 liters, the engine is as powerful as a piston unit with a volume of just over 2.5 liters. Let us also add that the rotary motor has a much higher detonation resistance, which makes it possible to turn this motor into a hydrogen engine.

Output shaft

The output shaft has rounded cam protrusions located eccentrically, i.e. shifted relative to the central axis.

Each rotor is associated with one of these projections. The output shaft is analogous to the crankshaft in piston engines.

As the rotor rotates, it pushes the cams. Since the cams are installed asymmetrically, the force with which the rotor presses on it creates a torque on the output shaft, causing it to rotate.

Design features of a rotary motor

Although the rotary motor has fewer parts, its operating principle is somewhat more complicated. Also, elements made of different materials (cast iron, aluminum) are used in the design of the rotary engine. There are also special coatings (for example, chrome).

Stators (rotor housings) have metal inserts made of special steel integrated into an aluminum housing. In fact, the stator is more like a cylinder with a honed sleeve. In turn, the side buildings are made of cast iron and have inlet and outlet windows. Gears are attached to the outer stators.

The rotor itself is a piston and connecting rod, made of lightweight cast iron. Each side of the rotor has a combustion chamber and seals to maintain tightness. In the inner part of the rotor there is a rotor bearing, reminiscent of a crankshaft liner.

- On a regular piston of a traditional internal combustion engine, the piston has 3 rings - a pair of compression rings and an oil scraper ring. In turn, the rotor has apexes (sealing the tops of the rotor). Apexes act as compression rings. These elements are pressed against the stator wall by a spring, and they are also pressed due to centrifugal force.

The function of the second belt of compression rings is performed by side and corner seals. They are also pressed by springs. These side seals are made of cermet, while the corner seals are cast iron. Additionally, there are seals for isolation so that exhaust gases do not enter the intake ports through the gaps that are formed between the rotor itself and the side housing, respectively.

On two more sides of the rotor there are special oil seals (similar to oil scraper rings), which retain the oil entering the internal cavity of the rotor for cooling.

By the way, the lubrication system of a rotary internal combustion engine is complex; it includes an oil cooling radiator, as well as a whole group of several types of oil nozzles. The nozzles are integrated into the eccentric shaft to cool the rotors, and they are also installed in the stators.

Oil is also supplied to the working cavity, mixing with the combustible mixture and burning out along with the fuel charge. In fact, a rotary engine is very demanding on the quality of oil. If you fill in the wrong lubricant, the unit will coke, detonation will occur, etc.

We also add that the power system is simple, there are several injectors (a pair of injectors in front of the intake windows, as well as in the intake manifold). As for ignition, two spark plugs are used per rotor. This was done due to the fact that the combustion chambers themselves turned out to be long. As a result, in order to achieve uniform and complete combustion of the mixture, two spark plugs are used, and their electrodes are different. When replacing spark plugs, it is important to pay attention to this.

Release

As the rotor passes through the exhaust port, high pressure combustion gases exit into the exhaust system. As the rotor rotates further, the volume of the chamber decreases, pushing the remaining exhaust gases into the exhaust port. By the time the chamber volume approaches minimum, the tip of the rotor passes through the inlet port and the cycle repeats.

It should be noted that each of the three sides of the rotor is always involved in one of the cycle strokes, i.e. For one full revolution of the rotor, three power strokes are performed. For one full revolution of the rotor, the output shaft makes three revolutions, because There is one stroke per revolution of the shaft.

Disadvantages of a rotary engine

Currently reading

Device, repair of muffler resonator

How often to change the timing belt on a car: what you need...

At the start of sales, the Mazda rotary was in active demand, as the car attracted car enthusiasts with its unusual and powerful engine (especially forced versions with a power of about 500 hp). However, a little later, the owners, already on relatively short runs, encountered the first problems and disadvantages of this type of internal combustion engine.

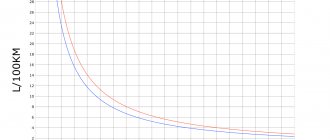

The main disadvantages are high fuel consumption and the relatively low service life of the 13B-MSP rotary engine. Under ideal conditions, a power plant of this type is capable of operating for about 100 thousand kilometers. As for actual operation, engines often became unusable by 50-60 thousand km. mileage

Rotor seals are usually the first to fail. The reason is quite obvious, since the seals are under high loads and become very hot. Detonation and wear of eccentric shaft bearings, rotors, etc. also make themselves felt.

- It is noteworthy that the apexes (seals at the ends) are the first to fail, while the side seals take much longer. As a result of wear of the apexes, as well as their mounting locations on the rotor, compression in the engine drops, and the corners of the seals can fall off, damaging the stator surfaces.

It should also be noted that the main bearings of the eccentric shaft quickly fail. Taking into account the fact that the shaft rotates 3 times faster than the rotors, the rotors are slightly displaced in relation to the stator walls, and the tops of the rotors should always be the same distance from the walls.

We also recommend reading the article about what a hybrid car engine is. From this article you will learn how a hybrid engine works and works, as well as what you need to know about a hybrid engine before buying a car with this type of power plant.

As a result, when the apex corners fall out, scoring will inevitably appear on the stator surface. At the same time, diagnosing a rotary engine is very difficult, since, unlike a conventional motor, a rotary engine does not knock if the liners wear out.

At the same time, we note that on supercharged versions of this engine, running the unit on a lean mixture leads to overheating of the apex. Next, the spring pressing the apex simply bends it and the compression is greatly reduced. Even forced ones (supercharged rotary engines) are characterized by uneven heating of the housing.

The upper part of the internal combustion engine, where the intake and compression strokes occur, is colder. At the same time, the lower part, where the process of combustion of the mixture and the release of hot gases takes place, heats up much more. The result is deformation of the body of the forced versions.

- We also note that problems with the lubrication system also appeared separately. In practice, the oil nozzles in the stator often become dirty and stop working. In this case, it is not possible to wash the injector valves, which means they need to be replaced. If the problem is not identified in time, oil starvation causes severe wear of a number of elements of the rotary engine.

Moreover, in all cases and regardless of the reason, in practice it is practically impossible to restore the stator, and it should also be noted that there are no repair parts. This means that if the stator is damaged, it is very difficult and expensive to rebuild the engine. The same applies to the rotor. If the grooves for the apexes are damaged, it is almost impossible to repair the part.

All this means that the motor is actually “disposable” and there is no way to properly repair it. The only way out is to purchase and install a new engine, since contract options in most cases will also be worn out and will not last long. Of course, you can buy a rotary engine without mileage, but the price of a rotary engine will be high.

Tips and tricks

First of all, the rotary engine must be “fed” only with high-quality high-octane gasoline (not lower than AI-98). Only high-quality fuel avoids detonation and also slows down the process of carbon accumulation on the spark plug electrodes.

It should also be remembered that this engine is extremely sensitive not only to the quality, but also to the type of oil. For example, it is not recommended to pour synthetics, as carbon deposits quickly accumulate on the apexes and compression drops. Such a motor should only be filled with oil recommended by the manufacturer itself or a mineral water that meets all the tolerances.

Also, oil changes need to be done frequently; the oil in a rotary engine is changed every 4-5 thousand km. It is also important to change the engine air filter in a timely manner, since its contamination can lead to coking of the oil nozzles of the lubrication system. As for spark plugs, it is better to replace them every 10-15 thousand km.

- As a rule, the main symptom of rotary engine problems is loss of compression, which manifests itself in difficult cold starts. Further, the problems progress, the engine starts to run poorly and even “hot”. Usually in this case, wear at the apexes, accumulation of deposits on the spark plug electrodes, etc. are obvious.

In such a situation, it is necessary to urgently go for diagnostics to specialists in the repair of internal combustion engines of this type. In practice, although repairs are complex and expensive, several centers have recently appeared in the CIS, specializing in the troubleshooting and repair of rotary engines with a guarantee.

As a rule, as part of the repair, stators, rotor seals, rotors themselves, etc. are replaced. Of course, repairs are not cheap, but they are definitely more affordable compared to buying a new power unit.

Finally, we note that, like a piston engine, a rotary engine needs to be warmed up before driving. In this case, until the motor reaches operating temperatures, the unit should not be loaded. With this approach, as well as in combination with high-quality gasoline and oil, as well as timely maintenance, there is every chance that the Mazda RX-8 rotary engine will last about 80 or even 100 thousand km without repair.

Let's sum it up

Taking into account the above information, it becomes clear why the rotary engine is not widely used, even taking into account a number of advantages. First of all, the short service life, the need for frequent and costly maintenance, as well as the difficulty of repairing the RPD are serious disadvantages of power plants of this type.

We also recommend reading the article about what a hydrogen engine is. From this article you will learn what features a hydrogen engine has, as well as what prospects a hydrogen engine has.

For this reason, you should separately study all the nuances discussed above, especially if you are considering a car with a rotary engine for purchase. For example, a Mazda RX-8 on the secondary market may seem like an excellent option, since these cars are sold at an attractive price compared to competitors with similar characteristics.

However, in practice, such a car may require replacement or serious and expensive repairs to the power unit. Moreover, even if everything is in order with the engine, you should not count on a long service life, and potential owners should prepare for higher costs for routine maintenance of a rotary engine compared to forced piston internal combustion engines (both naturally aspirated and supercharged).

Smooth operation

All parts of a rotary engine rotate continuously in one direction, rather than constantly changing direction like pistons in a conventional engine. Rotary engines use balanced rotating counterweights to dampen vibrations.

Power delivery is also smoother. Due to the fact that each cycle cycle occurs during a 90-degree rotation of the rotor, and the output shaft makes three revolutions for each rotor revolution, each cycle cycle occurs during a 270-degree rotation of the output shaft.

This means that a single rotor motor delivers power at ¾ of a revolution of the output shaft. In a single-cylinder piston engine, the combustion process occurs at 180 degrees of every second revolution, i.e. ¼ of each revolution of the crankshaft (piston engine output shaft).