In everyday life, quite a lot of terms remain unsolved for us. Highly specialized, they are simply of no use to us anywhere. However, there are times when a new word must be understood.

A simple example: a car service center told you that the clutch actuator needs to be replaced. This term in the automotive field has its own interpretations, which differ from the interpretation of other areas of technology. This article will sequentially examine the definition of “actuator”, its varieties in the field of automobiles, as well as its features and applicability.

Definition of the concept

So, an actuator - what is it? The word itself is very similar to another similar one - “activator”. The concept of both is almost the same. An actuator is a technical device or trigger mechanism that transmits force from the controller to the controlled object. The impact itself can be varied: from linear to rotating. At the same time, depending on how the force is applied, the variety of devices is determined.

View gallery

In automotive specifics, the actuator can be represented by a central locking drive. The force from the control circuit is transmitted here into linear movement by a worm gear. But the simplest automobile actuator is a mechanical jack. Here the node manager is a person. And the actuator transmits the rotational action into the vertical movement of the jack platform. This refers to the simplest mechanical device made in the form of a trapezoid.

Variety of actuators

The mysterious concept of “actuator” hides many already known devices. If you don't take the jack into account, you can start with the central lock - a linear device. Also among the famous ones is the turbine actuator. This is a vacuum regulator that protects it from stress at high speeds. There is also a clutch actuator on robotic automatic transmissions.

If we take the field of construction electromechanics, the most common would be the drive for opening and closing wickets and gates. That's what it's called - a door actuator. With the help of such a device, automatic garage doors and gates at entrances to the territory are driven.

Satellite dishes, so popular among the population, are also driven by actuators. This may be necessary when there are several positions for receiving information. In order not to install several antennas, they make do with one. Its actuator rotates to the required angle. Let's look at the car options in more detail.

Error correction

Improper disassembly of the device may cause some problems. One of the most common problems is mutual misalignment of the mounting locations of the actuator gears. As a rule, information on troubleshooting the problem is not described in the technical documentation. So now let’s take a closer look at this problem ourselves. There is nothing complicated here; all you need is skillful hands and a certain level of ingenuity.

So, let's begin. Before assembling the actuator, it is necessary to dismantle both sensors for selecting and engaging gears. After removing them, it is necessary to check the state of fastening of the sensor drives to the shafts of the gear sectors. You should make sure of the following:

- We check whether the drive rotors are unscrewed - if there is such a problem, then tighten them;

- We check the rotors for play - if there is any, it also needs to be eliminated.

The rotors should be securely fixed. As a rule, a special thread sealant is used for this, which will securely fix the axles in their places. The photo below shows the location of each of them.

The main reason for the inability to synchronize the gearbox on a car, as well as the cause of an actuator error - in the on-board computer may be a drive rotor that is not properly attached to the gear sector shaft.

If everything is in order, then we move on to the next step. We open access to the gear sector and install them clearly according to the marks on the gears. In the photograph, these marks are circled and indicated by arrows.

After setting the marks, you should scroll the gear sectors to the engagement positions of the middle parts of the sectors; when this point is reached, it must be marked with a marker.

Next, you should scroll the gear sector of the shaft counterclockwise from the rotor side, to the position - teeth up before installing the selection shaft, as well as gear shifting.

After completing these steps, we install the gear selection shaft into the actuator itself until the splines enter the intermediate gear sector, approximately 5 millimeters. We turn the rotor of the gear selection sensor drive counterclockwise until the plastic gear stops and finally slide the shaft into the actuator. Here, the sensor drive rotor must, simultaneously with the movement of the shaft, rotate through an angle of exactly 90 degrees counterclockwise. Let's look at the photo.

After completing all these actions, we check the correct installation of the selection shaft and gear shift, and also check the position of the gear sector. The latter must be aligned with the protrusion of the shaft housing. Everything is very clearly visible in the photo.

We make sure that there is no mutual displacement of the marks applied earlier. This is very easy to do; the photos below indicate places that should be checked.

Next you need to install the gear selection sensor. For correct installation, you should move the gear selection shaft 15 millimeters out of the actuator, after which you just install the sensor and insert the shaft until it stops. We scroll the sensor to the right all the way - you should turn it clockwise until the mounting holes coincide. We fix the sensor.

We check the position of the neutral mark and install the actuator back in its place. After installing it correctly, attach the battery terminal and conduct a test drive. If there is any malfunction in gear shifting, as well as in their selection, we check everything again.

Turbine actuator

It is known that there are two types of turbocharger systems: low and high pressure. So, the actuator is used only for the second type of turbines. Otherwise, it is simply not needed. Its main function in this case is protective. The turbine actuator controls a special valve that opens or closes the path to the exhaust gases. When closed, they spin the impeller, which gradually increases the pressure. At a given point in time, the actuator opens the valve. Then it releases exhaust gases into the vehicle's exhaust manifold, which immediately reduces the permissible pressure. If this is not done, the entire system can simply be disabled.

View gallery

The turbine actuator operates on the principle of a pump. It converts pressure into linear movement of the rod. Next to it there is a spring and a diaphragm in a metal case, to which the adjustment hose is attached. If the actuator fails, it must be replaced and adjusted.

Subtleties of setting up the turbine actuator

Why is actuator adjustment necessary? The fact is that the original device is initially configured for a specific turbine at the factory. In case of replacement, you need to configure a new actuator. Adjustment is also required in case of problems in the turbine. There are several ways to configure:

- Changing spring stiffness.

- Loosening or tightening the actuator itself along the thread.

- Installation of a special computer-controlled controller.

The easiest option is to loosen the fastening. This is regulated by thread turns. The more weakening occurs, the softer and faster the valve will open. If the actuator, on the contrary, is tightened, its activation will be harsh. It will open longer.

In the case of adjusting the device by the spring stiffness, the spring in the actuator is simply changed to one that is suitable for the particular case in terms of stiffness. The difficulty here is only in the selection itself, and replacement is not difficult. Installing a controller in front of the actuator is the most expensive option, but also the most promising. Indeed, in this case, it becomes possible to fine-tune and control the valve according to the conditions programmed in this controller.

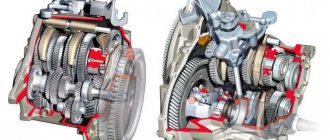

ACTUATOR manual transmission

A manual transmission actuator is a device that contains many parts, and repairing it without knowledge, special tools and exactly the right parts can cause a lot of difficulties and lead to more serious damage. The TOR MOTORS service center always has spare parts for repairing robotic gearbox actuators, such as:

- Complete actuators

- Manual transmission actuator electric motor

- Actuator motor bearings

- Motor brushes

- Manual transmission actuator gears

- Actuator bushings

Linear actuator

This concept implies a whole group of devices that convert control energy into linear movement. Most often we are talking about the transformation of electrical energy into mechanical energy. In another way, a linear actuator can be called a linear actuator. Widely used in car central locking system. Most often it is a plastic body with a retractable rod. Power and control are supplied through wires or connectors. There are both 12V and 24V options depending on the application on a car or truck.

View gallery

Each linear actuator is also a gearbox. After all, the initial energy applied to the actuator is an order of magnitude higher than the output impact. The transmitted force can also be multidirectional. That is, in relation to the electric motor shaft, the movement of the rod is possible both perpendicularly and parallel.

Depending on the purpose, a linear actuator can be manufactured for harsh climatic and aggressive conditions. That is, if desired, it works at subzero temperatures and with protection from aggressive environments. Due to their simplicity of design, linear drives require virtually no maintenance or repair.

Reviews from car enthusiasts about clutch actuator repair

- You don't always need to replace it, you can repair it

“I would like to tell you about my experience in repairing a servo drive on a Toyota Yaris 2007.” I got stuck in the snow, and after it started slipping, the transmission went into neutral and refused to engage any further. The service station diagnosed a breakdown of the actuator. Officials offered to replace the servo drive assembly for $380. I decided to repair it and found a repairman. The cause turned out to be a burnt-out motor winding. They rewound it and installed bearings instead of bushings. A miracle happened - the car drove off. For everything about everything – $65!”

Do not disassemble the actuator with the rod extended

“I ran into the same problem. After installing the servo drive back on the Corolla 2008RS box (and before that I moved the rod to the maximum extended position, although in the case of Peugeot, as it turned out, it was necessary to do the opposite), I took the minimum gap and tightened the fastening (18 N * m according to the “manual” "), that is, I did not catch the previous fit of the rod. I completed the clutch initialization process and... the box did not adapt. The renovation continued.

In the end, everything turned out to be much more trivial - the servo motor jammed. We came upon it by accident, the reverse gear was poorly engaged. “R” blinks and beeps, but the car doesn’t move for about the first 5 seconds. after switching on. There are no errors on the scanner.

As a result, we cleaned the servo motor, everything else (the bearings were a little loose) was in order. We put it back and the box became obedient again.

Plus, it was my mistake that I disassembled the servo drive with the rod extended. Under no circumstances do this! Remove the engine and use a screwdriver to “screw” the gear into a position corresponding to the minimum extension of the rod. I had not found the importance of this moment in any description before. In my case, in addition to the skew of the actuator cover, the spring also flew out...”

Linear motion actuators: do it yourself

We will not consider the reasons for wanting to make a linear actuator with your own hands. We'll just tell you how to do it. The easiest way to get, say, a door actuator is to use an electric motor. Now they are quite popular and affordable. Their cost can range from 50 to 200 rubles, depending on the parameters.

View gallery

The sequence of manufacturing work can be as follows:

- A threaded rod is attached to the motor axle.

- A nut with a rod attached to it is put on it. As the engine rotates, the nut moves along the stud. The rod moves with it.

- The thread pitch is selected. Thanks to this, you can adjust the speed of movement of the rod.

It's even easier to get a linear drive if you get a gear rack. The speed of force transmission will be the fastest. But there is one minus. Thus, the transmission force, on the contrary, will remain at its lowest level. M20 and larger diameter studs transmit maximum energy. Here is our homemade linear actuator and it’s ready. Door locks in most cars operate on this principle.

A number of malfunctions

Malfunctions in the functioning of the clutch actuator manifest themselves both in a sluggish start when moving away from a vehicle (slippage), and accompanied by jerking and jerking of the transmission gear shift. In addition, overheating of the clutch discs may occur.

But the listed deviations in the operation of the box only indirectly indicate the need to repair the clutch actuator. Don't jump to conclusions. By adapting the ECU, you can get rid of the described symptoms, since in this case the control unit will make adjustments to the operation of all sensors, drives and even the car engine based on a specific driving style.

Consequences of resetting the ECU

After initialization of the control unit, the reference point will be shifted in accordance with the factory parameter. If there is significant wear on the clutch discs, then when the gear is engaged, some gap will remain between the discs, which will lead to slipping and/or jerky gear shifting. At the same time, the speed of movement of the clutch disc will decrease, as evidenced by error code P0810.

Clutch actuator

Clutch actuator - what is this thing? Why is it needed? Simply put, this is an actuator for turning the clutch on and off. This also includes actuators for gear shifting. Such devices are used in robotic boxes of German and Japanese foreign cars. The actuator made in the Land of the Rising Sun is especially notorious. Toyota Corolla, which has a robotic gearbox, did not immediately achieve good work. Breakdowns began when the car did not even travel 60,000 km.

The problem was solved not only by modifying the actuator, but also by changing the software of the control unit. After all, it depends on the ECU at what point in time it is worth connecting the box to the engine. And the actuator serves as a simple actuator. It can be either electric, which is typical for Japanese and Korean manufacturers, or hydraulic. The latter are often used in WV and Audi gearboxes. Having a working engine ECU makes life much easier.

View gallery

As for gear shift actuators, they work as follows. The rod of the device acts on a specific synchronizer at a given time upon command from the head computer. Physically, the actuator is very similar to a regular clutch cylinder.

Reasons for failure of the clutch actuator

The most common actuator failure is jamming of the worm gear shaft bushings. As planned, they should ensure free rotation of the axes in the clutch release mechanism. The surface of the bushings is coated with Teflon to reduce the friction force, but after 80–100 thousand kilometers this layer is destroyed. This negatively affects the operation of the mechanism as a whole. Ultimately, at one “wonderful” moment, the friction forces in bushings without Teflon become insurmountable for the electric motor, and the servo stops functioning and jams. The result is that the mechanism requires repair.

During operation, the compensation spring, compressed by the worm shaft gear, exerts a large force on the actuator bushings. These values reach values of up to 150 kg each. And since the diameter of the bushings is relatively small, it is easy to guess that, experiencing such loads, sooner or later they may require repair and replacement.

In addition, the servo drive axis rotates only within specified limits (small angle). In this case, the lubricant accumulates in one sector, the rest of the friction pair (shaft/bushing) runs dry, which ultimately again leads to the need for repairs.

If during the operation of the car you begin to observe problems that are most likely associated with the clutch release drive, then you can try replacing the servo with a new one or, if you have some skills, risk repairing the clutch actuator yourself.

But before repairing the clutch drive, you need to know exactly what causes the problems in its operation and how it manifests itself.

Features of gearbox actuators

How can you tell if something is wrong with the actuator in your car's automatic transmission? This will be clear from the jerks at the moment of switching. It is necessary to figure out the problem in time by looking at the actuator. What is happening to him? If you see a serious problem, you may have to replace other clutch parts later.

View gallery

To select parts for a robotic box, the vehicle's VIN is required. This is especially important if you have a Japanese actuator (Corolla still treats parts for its robot boxes with trepidation). When replacing parts of such units, it is best to contact only qualified specialists. Dealerships selling and servicing cars have both competent craftsmen and the necessary equipment.

how to understand that the manual transmission ACTUATOR is broken

Appearance of the indicator on the instrument panel

Reasons: An indicator in the form of a gear on the instrument panel indicates the need for diagnostics and repair of the manual transmission, including the reason for the appearance of the indicator may be a malfunction of the manual transmission actuator.

It is worth noting that often if the actuator malfunctions, the indicator may not light up, so you should be guided by other signs described below. Solution: Diagnostics and repair of the actuator of a robotic gearbox.

Kicks when changing gears, the gear does not engage

Causes: Wear of the gear or actuator lever leads to unstable operation of the system.

A malfunction of the manual transmission clutch actuator also leads to similar symptoms. Solution: Diagnostics and repair of the actuator of a robotic gearbox.

The gear is flashing, the car does not move

Reasons: Malfunction of the servo drive of the manual transmission actuator.

Solution: Diagnostics and repair of the actuator of a robotic gearbox.

The car won't start

Reasons: Malfunction of the electric motor of the manual transmission actuator leads to the fact that the transmission does not switch to neutral, the protection system is triggered and the car cannot be started in gear.

Solution: Replacement or repair of the actuator electric motor (motor).

Manual transmission shift to neutral position

Reasons: Wear of the bushings leads to wear on the shafts and a large gap, as a result the shaft jams and the manual transmission switches to the neutral position.

Solution: Replacement of bushings and shafts of the manual transmission actuator.

Actuator Manufacturers

A large number of applications directly affects the choice of manufacturer. For automotive turbine and clutch actuators, you should pay attention to original parts or those recommended by the manufacturer. But that is not all. If you have a Toyota Corolla, you need to look for the same device. The Kia Sorento turbine actuator will be Kia brand. And this applies to all other brands. Saving in such parts is fraught with further investment in repairs, but in more expensive spare parts.

When it comes to linear actuators, there is so much choice that there is no point in recommending any specific manufacturer. The main thing you should pay attention to when choosing is positive reviews from real buyers and verified sellers. It is worth remembering that an actuator, the price of which will differ upward, is not always of higher quality. By the way, the average cost of the device fluctuates around 2-3 thousand rubles. You can find a very cheap actuator for 500 rubles, or you can buy an expensive one that costs 10 thousand rubles.

Methods for restoring the performance of the clutch actuator

The simplest and most easily accessible way to repair a clutch actuator is to replace damaged bushings with similar ones, machined from soft metals - bronze or brass.

Another option for repairing the clutch actuator may be to purchase Chinese analogues “to match the original”. Experience shows that the quality of the latter in repairs is extremely low. They don't last long. Repairing a servo drive means restoring the wear of its shaft and installing new bushings. At the same time, free and smooth sliding of these parts relative to each other is achieved.

Experienced craftsmen recommend a radical repair of the actuator - replacing the bushing with bearings (ball). This will give two advantages at once: durable bearings with lubricant inside the housing will allow you to forget about problems with this unit for a long time; the low rolling resistance of these elements will reduce the operating current consumption of the servo drive by half. This will delay the possible time of repair until the sale of the car.

Application of actuators

Actuators are most widespread in the automotive sector and in the development of both industrial and residential facilities. In transport, the use of devices starts from simple drives for closing doors and trunks (also don’t forget about jacks), ending with complex systems of turbo units and robotic gearboxes. With all this, the actuator is a fairly reliable device due to the ease of manufacturing of the actuating parts.

View gallery

In everyday life, the work of actuators is most easily seen on automatic doors and shutters. To receive satellite transmissions, it is also more convenient to use a controlled device and one dish rather than several at the same time.