Replacing the timing belt will extend the trouble-free life of the engine.

What is a timing belt

The main function of the timing belt, or timing belt, is to synchronize the operation of the engine's crankshaft and camshaft. In diesel units it is also connected to the high pressure fuel pump (HPF). Previously, in engines this role was performed by a chain. Today there is also a significant proportion of cars with chain synchronization. Why did the belt begin to be used in such a critical place in the engine?

To make it clearer, let’s look at the main differences between a belt and a chain in an engine timing belt:

- a timing belt system produces less noise;

- significant reduction in weight compared to a chain;

- reduction in the cost of repairs for components and labor;

- The structure of the timing belt itself is simpler;

- The belt should be replaced at least every 60,000 km under normal conditions. In harsh operating conditions, these periods are even lower.

The timing belt is an important component of the engine in terms of repairability in the event of a break. The consequences of failure of such a belt will, at best, lead to the replacement of part of the valves. In the worst case, all valves, pistons, camshaft and crankshaft will need to be replaced. The responsibility on a rubber product lies simply enormous. Therefore, it is best to replace it regularly and choose among the products of the most responsible manufacturers. And Gates (timing belts and other products) constantly deserves the best reviews.

Changing the timing chain

Many drivers wonder how to change the timing belt. This procedure can be carried out by contacting car service specialists, but it is quite possible to do it yourself. We will describe to you in detail the sequence of actions when replacing the timing belt with your own hands.

Removing the old belt

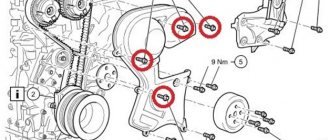

Before installing a new timing mechanism, you need to remove the old one. First you need to disconnect the negative terminal from the battery and remove the generator drive belt. After this, you should set the piston of the 1st cylinder to the “top dead center” (TDC). Take a 15mm wrench to unscrew the bolt that secures the roller. Turn the roller slightly to reduce chain tension. Now remove the timing belt from the pulleys of each element.

Have someone secure the crankshaft using a large screwdriver. Have your assistant hold it by touching the flywheel crown. At this point you can remove the plug securing the clutch housing. Use the key at “17” to unscrew the crankshaft pulley bolt and remove it. After this, you can remove the generator drive pulley. Carefully remove the timing chain drive washer. Then remove the mechanism itself from the crankshaft pulley.

Installing a new timing belt

Before installing a new chain, you must carry out preparatory work. They consist of cleaning the pulleys and tension roller from oil traces and dirt. In case of severe contamination, we recommend using white spirit or a piece of cloth soaked in gasoline.

Install a new timing belt in the reverse order of removal. When performing the procedure, follow some rules:

- the generator drive pulley must be installed in a special recess;

- when installing the belt, ensure optimal tension of the leading branch;

- use a special wrench to tighten the belt;

- the key must be inserted into the grooves of the tension roller and the latter must be turned counterclockwise. Rotate the roller until the notch on the outer disk aligns with the rectangular protrusion on its inner sleeve;

- to tighten the bolt fixing the roller, use a “15” wrench;

- If after the installation procedure you hear noise from the camshaft drive, this indicates a breakdown of the tension roller bearing. If you discover this, you should immediately replace the part.

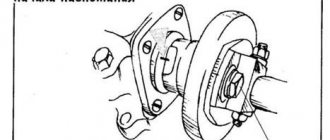

How to replace the tension roller yourself

Installing the roller with your own hands is easy. To do this, you need to buy the part in a specialized store and install it in the opposite order of installing the timing belt. When performing the procedure, make sure that the holes for the special key are located outward.

The video shows how to replace the timing belt and tension pulley:

Features of Gates timing belts

Gates has a century-long history of development. In 2020 it will be 100 years since the first V-belt rolled off the production line. The company survived such a long period of time for a reason. Just having our own research center speaks volumes. Today it is the largest supplier of belts for cars and agricultural machinery, not only for conveyors, but also for spare parts.

When it comes to timing belts specifically, Gates offers products with strict requirements for quality and reliability. After all, timing belts operate at high speeds over a wide temperature range, while being exposed to oil. So, the features of Gates timing belts include:

- the use of nitrile in a synthetic material with increased wear resistance and protection against oil and aggressive environments;

- the use of fiberglass in the cord, spirally placed inside a rubber shell;

- a variety of tooth profiles that precisely align with the gears and ensure tight grip and silent operation;

- the availability of a variety of repair kits, including not only a tension roller, but also a special tool, and additional spare parts necessary for replacement, for example, pumps;

- good protection of products from counterfeiting.

Why do you need a timing belt and how does it work?

Thus, we can say that the timing belt is the part with the help of which the operation of the camshaft and crankshaft is synchronized. It should also be noted that in many models of modern internal combustion engines it also drives the water pump.

As a rule, designers of modern internal combustion engines place timing belts between the radiators and the cylinder block, that is, in the front part of the engine compartments of the cars. In some brands of cars, the timing belt is visible immediately after lifting the hood, in others they are hidden by covers, but in any case, mechanics have no problem getting to this part.

Visually, the timing belt of a modern car is a closed rim with teeth on its inner side. It is noteworthy that each engine model has its own timing belt, that is, universal parts of this type simply do not exist. As for the material of manufacture, if the very first rheniums were made of rubber reinforced with textile cord, now high-strength fiberglass and special polymer compounds are used, which are characterized by increased strength and resistance to significant temperature changes.

Manufacturers claim (and this is fully confirmed by practice) that modern timing belts, although significantly inferior in strength characteristics and wear resistance to timing chains, still have a significant resource. In most cases, the timing belt works properly for at least 60,000 kilometers. However, it often happens that it fails ahead of time and simply breaks off.

Types of timing belts

Considering that Gates produces timing belts for almost all types of cars, their number in the classification becomes clear. The manufacturer has developed detailed selection catalogs. For your car, you can easily and simply find the right timing belt, its reinforced analogue, as well as an installation kit, if necessary.

For passenger cars, Gates offers belts that are completely identical to their original counterparts:

- normal quality;

- enhanced quality;

- complete with roller or rollers;

- in an extended set with sealing elements and all important timing belt-related components.

In addition to belts with a standard tooth for a particular vehicle, there are varieties with teeth in the form of a trapezoid and complex shapes for different operating conditions.

If we consider the general types of Gates belts, the variety of shapes and models is even brighter. In addition to the standard type, designated Power Grip, there are:

- polyurethane belts;

- bilateral options;

- with conveyor type cord;

- resistant to paints and varnishes;

- open timing belts of all the above types.

Are there any disadvantages?

Positive reviews from Gates, whose timing belts have a long list of advantages, tell us that there are no product shortcomings. Is it really? The biggest disadvantage of products from a well-known and popular company is the large number of people who want to counterfeit them. And when there are negative reviews among the reviews, then with a 90% probability we are talking about counterfeit products.

The manufacturer's extensive experience in protecting products from counterfeiting allows the consumer to receive their Gates timing belt kit or any other product in proper quality. You can read about ways to protect products on the official website, in bulletins distributed with the product, and in this article.

What is timing belt

The timing mechanism is a gas distribution mechanism of an internal combustion engine and is designed to dose the cylinders with a certain amount of air-fuel mixture at specified intervals. The operation of the timing belt is clearly synchronized with the rotation of the crankshaft.

The gas distribution mechanism is represented by the cylinder head, on which all the necessary elements are located - these are valves, their bushings, seats, as well as springs, rocker, camshaft and bearing housing. Depending on the design and type of engine, the mechanism can supply air, either separately or together with fuel.

The valves themselves are located in special bushings installed in the cylinder head . The valves are fixed using special plates, two springs and locking “crackers”. Rockers with a return spring are mounted on top of them and there is a special surface that allows the camshaft cams to slide with a minimum of noise. The uppermost part is the camshaft, which is enclosed inside the bearing housing, and on older cars - liners.

How to distinguish an original Gates from a fake?

The popularity of a well-known company, together with high quality, and therefore good demand, has always attracted those who want to fake the same Gates timing belt. How to distinguish a fake? There are several ways to determine whether it is an original or a counterfeit, and the process of identifying the truth should be approached systematically.

First of all, you need to pay attention to the packaging. Gates takes this issue very seriously. All timing belts are packed in cardboard packaging. If the product is not packaged, it is 100% fake. Only recyclable cardboard is used and the paint is solvent-free. That is, the cardboard should not be covered with a bright glossy picture. Information about the application and article number of the timing belt is made in the form of an adhesive label, and is not printed on the packaging.

What is the purpose of the belt?

The timing belt is a part whose purpose is to act as a connecting link.

Thanks to the timing belt, the camshaft and crankshaft work synchronously, which contributes to the proper functioning of the engine as a whole. This is the need for using a strap.

Markings on the strap

Let's look at a few examples of translating the timing belt decoding:

- ISO-58111x19. The first two numbers (58) encrypt a series of teeth used on the product. In this case, the pitch and profile will be without a groove, the shape will be semicircular, and the height will be 3.5 mm. Then there are three numbers (111), which indicate the number of teeth. By number 19 you can determine the width of the product. There are belts on sale whose teeth are made in the form of a rounded trapezoid.

- 58127x3/4 HSN. Here the first two digits also indicate a series of teeth. The numbers 127 indicate their number, but you need to take into account that in straps belonging to the 40 series, this number is conditional. The numbers 3/4 indicate the width of the product in inches. In this case it is also 19 mm. The HSN mark at the very end indicates that the product is made of durable, highly saturated nitrile. This material has proven its strength. If there are no such letters at the end, then the strap is made of neoprene rubber.

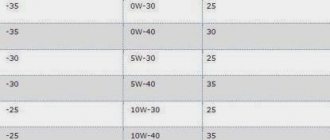

Table: Belt markings

Manufacturers may label their products differently. The table shows how to decipher the timing values.

The appeal of Gates timing belts

It's time to figure out why the reviews are so good. Gates (timing belts) creates products with many advantages, including:

- high wear resistance;

- production of the entire required period with a reserve in conditions of an aggressive environment and large temperature ranges;

- silent operation, thanks to precise selection of teeth and soft material;

- colossal tensile strength due to the fiberglass in the cord.

Fiberglass, which is used in the cord of timing belts, on the one hand, increases stability and tensile strength. But there is a downside, or rather a disadvantage. Such a belt has an increased risk of breaking during jerking. Therefore, for a car with such a belt, “starting” from a pusher is contraindicated.

Due to the high flow of goods turnover and the release of numerous batches, Gates allows itself to maintain reasonable prices for its products. And a Gates timing belt, the price of which can be 900 rubles, is a common picture on the market. And the product testing and quality control program maintains the brand of a worthy competitor.

Breakage of a new timing belt: common causes

- Incorrect operation.

A break in the new timing belt may result from improper operation of the entire assembly. For example, when driving, the tensioners, rollers or pump may jam, which will lead to a break in the new timing belt.

Despite the external quality of this part, when a high crankshaft rotation speed is reached, a sharp change in operating conditions can damage it.

To prevent the new timing belt from breaking, you need to carefully monitor its tension. Excessive tightening can also cause part failure. However, by loosening the drive too much, you can get a similar result due to the belt jumping off the pulley grooves.

This situation can also arise if there is existing pulley play. That is why, in order to prevent engine damage, it is necessary not only to change the timing belt in a timely manner, but also to monitor its tension and the proper operation of each element of the mechanism in order to prevent breakage.

Oil getting on the surface.

If you notice traces of oil or antifreeze on the new belt, this means that it needs to be replaced.

If you do not install a new belt, the entire gas distribution mechanism will not work efficiently. The drive will slip, be removed from the pulley, and eventually break.

Don't think that just by wiping off an oil stain you can continue driving without taking any action. It is not possible to completely remove traces of oil from a new drive. After technical fluid gets on it, it is absorbed, depriving the drive of the qualities necessary for proper operation. Only replacing it with a new drive will help here.

Low quality product.

If you saved money by buying a timing belt, then you need to be prepared for the fact that troubles may arise during its operation. This is a case where the stingy pays twice, because a broken new timing belt can lead to high engine repair costs. We recommend purchasing an original drive from a seller whose quality you are confident in.

Car service workers know well how an attempt to save a couple of hundred rubles can result in repairs costing tens of times more. There is nothing surprising here, since a low-quality new timing drive can break without traveling even a couple of tens of thousands of kilometers. Constantly expecting a catch from such an important detail, you worry, which leads to driving mistakes and uncertainty in your own car.

External damage.

If the drive has served you for a long time or it was of poor quality to begin with, it may develop external damage, such as cracks, grooves, loose threads, and the like. These shortcomings cannot be eliminated. If such damage is present, a new drive must be installed as soon as possible.

Ignoring wear can lead to the fact that under load the defect will intensify and a breakage will occur. It is better to anticipate and prevent this situation than to blame yourself later and pay for expensive repairs and a new drive.

Harsh climate and active driving.

In many regions of Russia, the climate is such that the car is regularly exposed to too high or low temperatures. Therefore, car repair and maintenance must be approached with special care. Sudden changes in temperature can affect the wear of the new timing belt, which increases the likelihood of it breaking. In such conditions, it is better to use only original components for repairs and change the drive at the first signs of wear, without waiting for the expiration of the service life declared by the manufacturer.

Failed rollers very quickly lead to abrasion of the surface and the new timing belt breaks.

The purpose of the rollers is to support the drive in a tense position. It is thanks to them that the timing belt does not slip and does not fly off the teeth. If the rollers malfunction, they jam and the new drive quickly fails or breaks.

We recommend

Gates Achievements

Among the most popular achievements is the story of the almost century-long production of the first belt, as well as the presence of its own scientific center. The company constantly accumulates information, as well as searches for and resolves issues with the quality and reliability of materials. Thus, developments in the field of rubber products brought Gates to the rubber goods market in the areas of refrigeration and air conditioning systems.

The company successfully patents all its developments and inventions. A consistent approach to the development and implementation of technical solutions has led to the expansion of production to 70 factories around the world. Thousands of jobs and global recognition are what Gates deserves. Almost every 2nd timing belt replacement occurs with Gates products.

Reviews of Gates timing belts

Most users of Gates products express a general opinion of high quality and low price. On the well-known “Otzovik” there was only one opinion about the short service life. At the same time, no one checked whether they were talking about Gates, or whether the person simply came across a fake.

Many people like simple but functional packaging. Others are attracted by the company's huge range of products. What’s interesting is that such a large selection of Gates timing belts for passenger cars represents only a small portion of the company’s total products presented on the world’s markets. A much larger volume falls on belts for agricultural machines and various industries.

Applicability of Gates timing belt

In order to occupy the maximum niche in sales, Gates produces timing belts and kits for the entire range of cars, both cars and trucks. Products are supplied to conveyors of such well-known brands as:

- Ford;

- Audi;

- Volkswagen;

- General Motors;

- Chrysler;

- Toyota;

- Nissan;

- Opel;

- Renault;

- Fiat and a number of others.

The popular Scania, MAN, Iveco and, of course, Mercedes-Benz are not left out of attention. Thus, replacing the timing belt with a Gates kit will work like clockwork for models of the above-mentioned car manufacturers.

Complete set of timing belts

Along with just timing belts, Gates offers the consumer options for a comprehensive system replacement, which includes one or more rollers and mounting bolts. This Gates timing repair kit is designated PowerGrip and is packaged, like all products, in an individual box indicating the article number and application. The kit necessarily contains assembly instructions and a sticker to indicate the mileage.

There is also an option for extended timing replacement. Such kits are called PowerGrip Plus and may contain, in addition to the belt and rollers itself, various o-rings and seals required for replacement, and sometimes a water pump assembly. The pump is included in such a kit only if the car manufacturer recommends replacing the timing belt. It is worth noting that the tension roller can be included either as part of the tensioner assembly or separately, again, according to the recommendation of the equipment manufacturer.

What is timing belt?

Before we look at how the timing belt abbreviation is translated and deciphered, let’s consider what the engine gas distribution mechanism in a car is intended for and its operating principle. The timing belt is a distribution device of the car's power unit, used to dose the cylinders with a specified amount of the combustible mixture. The dosing procedure is carried out at certain time intervals.

Device and principle of operation

The assembly itself is represented by the cylinder head of the machine's engine, on which all the structural components of the system are installed - valves, bushings, seats, springs, rockers, camshaft, as well as the housing of bearing devices. Depending on the features and type of power unit, the unit can supply air to the cylinders both with fuel and separately.

The valves are installed in bushings specially designed for their installation, located in the BC head. They are secured using so-called plates, spring elements and locking parts. Rockers with a return spring are mounted on top. There is also a working surface along which the camshaft cams slide, while emitting a minimum of extraneous sounds. The upper structural component is the camshaft installed in bearing devices. On older cars it is mounted in the bearing housing.

Timing belt device

The principle of operation begins with the rotation of the camshaft sprocket, which starts a certain stroke. As a result, the shaft itself comes into operation. It has cams in a certain order, which must correspond to the beat.

When, at startup, the power unit starts working from the first cylinder, cam 1 hits the rocker. The latter overcomes the force of the spring part and lowers the valve to the very bottom. As a result of rotation, the cam jumps off the surface of the rocker, and under the pressure of the spring it moves to its original position. This causes the valve to return, which ultimately closes the combustion chamber. The same happens with other cylinders.

The entire procedure is synchronized with the operation of the crankshaft of the power unit. If one of the valves opens at the wrong time, this will make it impossible to start the engine.

Therefore, the crankshaft is used as a drive for the gas distribution mechanism.

From the video of the channel “Made in a Garage” you can learn about the consequences of a broken timing belt.

Gas distribution mechanisms may differ from each other according to the location of the camshaft in the car:

- The camshaft is installed inside the cylinder head, and the valves are located on the top of the head. This allows the elements to trigger the movement of the so-called rocker arms and push rods. The main advantage of such a mechanism is the simplicity of the design and reliability of the system as a whole. The downside is high inertia, as a result of which the power unit is not able to quickly gain speed, which leads to a loss of power.

- The valves can be located in the lower part with the plates facing up. The camshaft is installed at the bottom, the drive comes from it. The advantage of this mechanism is the absence of noise. The main disadvantage is the fuel system, which is complex in design. As a result of poor saturation of the combustion chamber with the air-fuel mixture, engine power is reduced.

- The camshaft can be installed directly in the cylinder head with valves. The elements are located on the sides of the camshaft and begin to work as a result of the influence of rocker arms located on the same axis. These parts rock the cams on the camshaft. The disadvantage of such devices is their high noise level, as well as the difficulty of adjusting valve clearances. In addition, the device operates under high load at the contact point.

- In some power units, the camshaft is installed above the valves, and the plates of these elements are located below. The shaft itself in such motors actuates the valves through pushers located in a cylindrical housing. The main disadvantage of this design is the low elasticity of the unit and the difficulty of adjusting the gaps.

Installation nuances

Replacing the timing belt on most cars requires different timing. If, for example, Renault Logan recommends changing the belt at 60 thousand km, then for many Volkswagens this period is 120 thousand km. Sometimes the manufacturer limits the service life to a time frame, which also makes sense. Therefore, Gates’ recommendations in this regard do not contradict car manufacturers. Even if a Gates reinforced timing belt with a large margin of safety is used, its maximum service life should not be checked.

In any case, replacing the timing belt is recommended as an assembly with its associated elements, that is, at a minimum, rollers and tensioners. Gates kits always come with replacement instructions. If you follow all the recommendations and have experience or skills, you can easily replace the timing belt.

What to pay attention to when replacing a belt

Not only the belt will have to be replaced. The tension roller also requires replacement, and if the engine is 16-valve, then the support roller as well. Rollers can be made entirely of metal or made of plastic and metal. They all have pros and cons; some will argue that metal is eternal and difficult to break. Difficult, but quite possible.

And just imagine what will happen if such a roller jams. The most important thing is that the belt will break immediately. This is why it is better to use metal rollers with a plastic insert. If it breaks, at least it won't jam. Also try to change the coolant pump together with the belt. Its resource is not much greater than the resource of the roller and belt.

However, you can change the pump with every second timing kit. But if you notice that the edge of the belt is starting to eat away, then blame it on the pump bearing, which has some play. But the most important thing is to monitor the belt tension. Its service life depends on this. If the tension is insufficient or excessive, the teeth will wear out and the load on the belt will increase.