CVT history

A car whose speed depended solely on the engine speed would be extremely inconvenient to use. Imagine that the car has only one gear, for example, first or third. In one case, you would be able to drive quite fast, but the car would take a long time to accelerate and slowly drive uphill. In another, everything would be exactly the opposite - an easy start, but an extremely slow speed. Because of such difficulties, the first manual transmission was developed.

Time passed, and every automaker tried to make driving a car easier (everyone is well aware of the difficulties that manual transmission causes for some drivers). In the course of such research, first an automatic transmission was developed, then a robot, and, finally, a variator with an infinite number of gears.

What is a variator?

If the robot, in fact, is the same mechanics with the only difference that the electronics handle squeezing the clutch and shifting gears, then the CVT gearbox (also known as a variator) is radically different from its counterparts.

The main feature of the CVT is that it adapts to the required conditions and continuously calculates the desired gear ratio. Thus, in a car with a CVT installed, there is an infinite number of gears. This feature allows you to significantly save fuel and optimize energy costs.

There are two types of continuously variable transmissions:

- V-belt (installed on 90% of cars with this type of box);

- Toroidal.

Operating principle of V-belt gearbox

In simple terms, the device works as follows. There are two pulleys: one driving, connected to the power unit, the other - driven, connected to the wheel drives. The shafts are connected by a belt or chain.

The pulleys are not cast, but made of two conical halves that can converge and diverge, changing the diameter of this structure.

The principle of operation is quite simple: let’s say our car is “moving away” and needs more power. To reduce the load on the motor, the cones on the drive shaft diverge, and it decreases in diameter. The driven pulley, on the contrary, must have a maximum diameter, so its cones are brought together. Thus, the engine makes the optimal number of revolutions in each specific case, which reduces the load on it.

As the speed increases, the diameters of the pulleys change accordingly - the driving one increases, and the driven one decreases. All this is necessary to stabilize the operation of the power unit, as well as to reduce traction effort.

Changing the diameters on each of the pulleys is carried out by an electronic system that receives data from the on-board computer and ECU.

The advantages of this option are its lower cost and simplicity of design, which is why the price of the transmission is slightly lower than for other types of CVTs.

V-belt variator and its structure

The V-belt variator is the most famous, so I suggest starting with it. It is equipped with a driven or V-belt and a pulley. This type of stepless gearbox does not respond to loads, and its operation depends on the speed of the device. For example, if you go uphill, the load on the rear wheel will automatically increase, however, the emergency situation will not change. Most experts consider this parameter to be a disadvantage of the V-belt variator.

This type of belt is called V-shaped belts due to the fact that they are trapezoidal in cross section and are wedged into the pulley with side pieces. When these sidewalls wear out, the belt is able to wedge even deeper into the pulley, which makes the coupling of the same quality.

On a V-belt variator, the gear ratio is modified through the coupled operation of the drive and driven pulleys. In other words, the elements of the drive pulley, rotated by the crankshaft, are compressed plastically and evenly, thereby pushing the belt further from the center. With this procedure, the driven pulley is able to unclench and the belt, gently sinking into it, approaches the center. Consequently, the gear ratio changes away from the crankshaft and towards the rear wheel.

The driving and driven pulleys differ in that the first one has a spring installed instead of rollers.

As for the operating principle of the V-belt type variator, it can also be explained by the method of two pencils of the same type. To do this, you need to place them on the table parallel to each other. Next, you should tighten them with an elastic band, and then twist one of them. Undoubtedly, the second object will begin to spin simultaneously with it and, interestingly, at the same speed. However, if the cross-sectional diameters of the pencils are different, the situation will not repeat.

Pencils of different diameters will still rotate, but a little differently. While a large pencil will make one revolution, a smaller one will have time to make two.

The principle of operation similar to pencils is also used by various variators. However, as mentioned above, V-belt types of devices have two pulleys, which are made in the form of cones, which is why the diameter of the pencils in the variator constantly changes. Typically, the pulleys have their ends facing each other, and the belt is clamped between them.

With relative mutual movement, pulleys are very similar to pencils, which constantly change their diameter. These pulleys are often equipped with a hydraulic system, although sometimes a servo drive is also connected. As a result of this, the halves of both pulleys move apart and move synchronously. If one is located on the drive shaft coming from the engine, and the second of them is located on the driven shaft, which goes to the wheels, the change in the frequency converter will occur much more widely.

In addition, variators of this type are sometimes equipped with a device responsible for changing the direction of shaft rotation when reverse gear is engaged.

CVT V-belt box device

Since the toroidal version is quite expensive to produce and is used only on premium cars, it makes sense to talk about only the V-belt type device.

Like the robot, the variator is installed either longitudinally or transversely. Its main components:

- Clutch system. The simplest device designed to connect the engine to the transmission and, if necessary, turn it off (the so-called “neutral”).

- A torque converter, also used in a conventional automatic transmission.

- Shafts with variable cones.

- A belt or chain to connect them. By the way, both components are made only from durable metals, since they bear a large load.

- Oil used to reduce friction between shafts, as well as to build up pressure.

- A pump that creates the same pressure. It is necessary for the correct operation of the cone parts. Sometimes it may be absent (in such cases, either hydraulics or a spring are responsible for changing the diameter of the pulleys).

- A hydraulic unit that performs the function of supplying oil through various channels to both pulleys. By the way, if various shocks or slipping occur during operation of the variator, most often this indicates a breakdown of the valve body.

- A filter system that prevents oil channels from becoming clogged with deposits and metal debris.

- Radiators that remove heat from the gearbox. Unfortunately, without them, such a transmission overheats quite quickly, especially when slipping or driving off-road.

- An electronic control system that receives commands from the ECU and changes the diameter of each shaft depending on speed and load.

- A device responsible for turning on reverse motion.

Toroidal variator, device and principle of operation

This variator is equipped with rollers and wheels instead of pulleys and belts. This system is slightly different, but, in fact, all its elements perform exactly the same functions as the V-belt type of variator, and also give one result - a constant change in the transmission.

The toroidal variator works according to the following scheme. One disk is connected to the motor, and the second to the cardan shaft. The first disk is the drive shaft, and the other is the driven shaft. Between the discs there are rollers and wheels (not a belt) that transmit power to each other.

The wheels rotate around two shafts - horizontal and vertical. As a result, the wheels come into contact with the rims in a variety of areas. When the wheels near the center come into contact with the drive disk, they contact the driven disk near the rim, this increases torque and reduces speed. This is called high gearing or overdrive.

What is a toroidal variator?

The operation of the toroidal variator gearbox is carried out by rollers clamped between the shafts. Such wheels have a toroidal shape (in fact, that’s why the gearbox is called that).

Toroidal variator device

The gear ratio is changed by increasing and decreasing the contact surfaces between the shafts and rollers. At maximum thrust, the clamps face the driven shaft, which increases friction and, accordingly, reduces the number of revolutions. If speed is needed, the rollers are moved to the other side.

The advantages of this type are higher reliability and wear resistance.

A few words about oil and filters

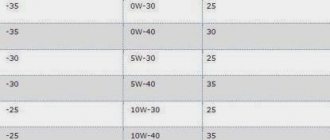

Most manufacturers assure that oil is poured into the variator gearbox forever. However, this fact is fundamentally incorrect. Our roads and weather conditions (snow, rain, severe frosts, bad roads and traffic jams) create an increased load on the device, so it is recommended to change filters and oil every 40,000 kilometers.

If this is not done, oil deposits will begin to accumulate on the structural elements, and the filter will become clogged with various debris. As a result, the pressure in the pump will drop, which will lead to shocks and jerks while driving, and in especially severe cases, the variator will simply stop working.

What belts are used in V-belt variators?

Let's say a few words about belts. Of course, ordinary rubber belts installed on the generator drive cannot be used. They are designed for lower loads and will wear out quickly.

The belt is a steel belt with a special coating, or several of these belts with a complex cross-section and strung plates.

Such properties allow the pushing force to be transmitted not only by the part that faces the drive shaft (otherwise such a belt would simply fold).

Some cars use a steel chain lubricated with a special fluid to reduce the sliding effect. This design is capable of transmitting greater force and is designed for high loads, however, its cost is slightly higher.

CVT - principle of operation, types of CVTs

Design improvements have led to the emergence of several operating principles for this device:

V-belt design. The rotation of the crankshaft is transmitted to the propellers using one or two durable belts. Manufactured using special technology to ensure a high working life. This belt drive is mounted on two pulleys consisting of pairs of conical disks.

The trick to this design solution is the variable diameter of the pulleys. Reduction and increase in the size of the cones occurs with the participation of the hydraulic system, centrifugal force and spring supports. The cones are placed at an incline to minimize the friction force.

Some of the first such transmissions often failed due to belt wear. The modern automotive industry produces belt drives using innovative technologies that provide a service life of up to 2,000,000 kilometers traveled. Belts are made by weaving special wire, assembling and fastening steel plates together. Moreover, this transmission has good flexibility. It was these technical solutions that made it possible to classify such a gearbox as a separate type of transmission.

Variators with wedge-chain drive. A link chain with good flexibility is used as a belt. With this system, cone pulleys are made of special types of steel due to high loads. This scheme and operating principle of the variator have high efficiency. And all because energy losses are significantly reduced.

How does driving a car with a CVT gearbox differ from others?

If the robot (robotic transmission) is equipped with a joystick, which is responsible for turning on the necessary modes, then the variator is no different from the regular automatic transmission that we are all accustomed to. However, one feature still exists. In some cars, the variator can additionally be set to a mode in which the gear ratio will not change (in this case, the device will turn into a regular automatic transmission). For some drivers who, due to stereotypes, cannot correctly assess the parameters when accelerating a car, this option is preferable. The fact is that when a car with an automatic transmission is installed, the engine increases speed gradually. When the variator is operating, the power unit immediately picks up the required rotation speed, and then only the gear ratio changes. As a result, the engine sounds a little louder than usual, and due to the same number of engine revolutions, it is difficult for the driver to follow the dynamics.

CVT device

A variator, or continuously variable transmission (CVT) in English, looks like the same automatic transmission. At first glance, it is impossible to determine that it is installed in the car, because its lever is no different from the lever of a regular classic automatic transmission, even the transmission modes are the same: P, R, N, D. However, the principle of operation of the variator is completely different, it does not have the usual, a fixed number of gears, such as 1st, 2nd and so on. There are a huge number of gears in a variator, they constantly vary, hence the name of the device itself. That is why there are no shocks either when starting the car or when changing from one speed to another. The variator smoothly and accurately changes the gear ratio while the car is driving, as it accelerates and decelerates.

Pros and cons of a variator

We will compare CVT with an automatic transmission, since the robot, as mentioned above, is mechanical, and other types of transmission are not so popular.

Main advantages of CVT:

- No shocks or jerks during movement.

- The engine operates with a smooth change in power depending on the situation.

- Virtually an infinite number of gears, which allows for optimal fuel consumption.

- Low noise level during operation.

- High controllability and response.

- Competent optimization of all vehicle running systems.

Now about the disadvantages. The most important of them is the high cost of repairs, since the design of the device consists of many expensive elements. It must also be said that in our country there are very few service centers that undertake such work.

In addition, about ten liters of special oil, necessary for proper operation of the transmission, should be periodically poured into the variator. This liquid is quite expensive and is sold either at company representative offices or in specialized salons. You understand that such salons are not available in every city. In some cases, to reduce repair and maintenance costs, the best choice would be to purchase a contract CVT.

Should I buy a car with a CVT?

When purchasing a car with this type of gearbox, you need to remember that an aggressive driving style will lead to the fastest possible wear of gearbox parts.

In this connection, their replacement or replacement of the entire gearbox as a whole will be required. This is a rather expensive procedure. Therefore, for those who prefer a measured driving style and want to save on consumption, this type of gearbox will be more comfortable.

Pros and cons of a variator

Like any device, a variator has its pros and cons. For some, the advantages are more important than the negative, but for others, the negative points will not be acceptable.

Pros:

- low fuel consumption;

- low level of emissions into the atmosphere;

- improved acceleration dynamics;

- high smoothness;

- are more reliable than automatic transmissions;

- have relatively low weight;

- simple unit design;

- low noise level.

Minuses:

- not suitable for high power engines;

- it is not advisable to drive in an aggressive mode;

- the presence of a large number of sensors;

- expensive lubricant;

- rarely repaired.