Replacement procedure

Before proceeding directly to the replacement process, you need to understand that this procedure is quite complicated and will require considerable time. Thus, it is recommended to study the technological diagrams, as well as the design features of the motor. Next, we will collect the necessary tools to carry out the replacement.

Timing marks.

Let's consider the sequence in which operations should be carried out to change the timing belt on a Daewoo Matiz:

Despite the fact that the parts under the hood are located close to each other, there are no problems with access to components and assemblies.

- Remove the negative terminal from the battery.

- Unscrew the upper fastenings of the timing belt protective cover.

Using a 10mm socket, remove the upper protective cover that covers the timing belt. - Loosen the drive belt tensioner.

We remove the top cover, then loosen the tension on the drive belts of the generator, power steering, air conditioner and remove them. - We dismantle the front right wheel and fender liner.

To gain access to the lower part of the engine, we hang out and remove the right front wheel, as well as the protective casing behind it. - We place marks on the camshaft.

We remove the hanging belts and set the marks. Mark on the camshaft pulley. - The marks must match.

We see a mark on the generator drive pulley, which should coincide with mark 0 on the lower timing case cover. - Unscrew the crankshaft pulley mount.

Unscrew the crankshaft bolt and remove the attachment drive pulleys. - Remove the tube and oil dipstick.

To remove the lower belt, the tube and oil dipstick are removed. The cover is secured with 10mm head bolts, remove it.

- We remove the belt.

Timing belt and tension pulley used in the photo report. We install a new belt and roller.

- We carry out the assembly in the reverse order.

Since the tension roller is semi-automatic and the belt tension is set by the roller spring, it is only necessary to tighten the fixing bolt during installation with a force of 15 to 23 Nm.

In this car, if the timing belt breaks while driving, the valve bends, and the guide bushings also need to be replaced.

The process of replacing the timing belt of a Daewoo Matiz may seem difficult, and therefore it is worth calculating your strength. If the car owner is not sure, it is recommended to contact a car service center for operations. On average, the shift process can take from 1 hour to 3 hours.

Replacing the belt drive yourself

Let's first decide what we will definitely need when carrying out this procedure:

- set of horn keys;

- screwdrivers with different tips;

- jack;

- new belt;

- new o-rings;

- oil seals;

- Don't forget about rags.

A new belt should only be purchased from trusted stores. A low-quality consumable will fail early and will have to be replaced with a new one again.

1. So, let's start the repair and first of all dismantle the right front wheel. Then disconnect the left terminal from the battery. This way we de-energize the car, completely protecting ourselves. 2. In order to remove the protective housing, we will have to unscrew 2 bolts. We do this and remove the casing. 3. Now we have access to the belts, and we begin to dismantle the hanging belts. To remove the strap, we will have to move the generator to the side, having first unscrewed the mounting bolt. 4. Remove the power steering belt. To do this you will have to unscrew 3 bolts. 5. We should set the top dead center on the camshaft and crankshaft.

6. Now you need to remove the oil level dipstick. 7. Unscrew the crankshaft mounting bolt and remove it along with the pulley. In this case, the crankshaft should be in a fixed position. To fix it, you can use a large screwdriver. 8. Remove the housing and gain access to the timing belt. 9. Now you need to loosen the tension roller. Then the old belt can be removed, holding the roller from turning. 10. Then we proceed to removing the crankshaft pulley. 11. The tension roller is dismantled along with the tension spring. 12. If any defects are found in the oil pump o-ring, it will also need to be replaced. 13. Now we place marks on the oil pump and crankshaft pulley. 14. We also set marks on the oil pump and camshaft pulley.

15. Now the tension roller can be installed in its place. Once installed, it should be moved to the side for now so that it does not interfere with the installation process of the belt. 16. Put on the timing belt. 17. Check that the marks match by turning the crankshaft pulley to the right 2 turns. 18. Tighten the tension roller bolt until it stops. 19. Reassembly of the remaining units must be performed in the reverse order.

Part selection

Almost all Daewoo cars, including those made in Korea, are equipped with General Motors spare parts. At the same time, Matiz was no exception. The original timing belt for Daewoo Matiz has a catalog number - 96352965. The average cost in the automotive markets is about 2,500 rubles.

Timing belt.

Also, it is worth considering that you will have to take a tension roller. You can purchase everything in one set, but it is better to select them separately. Timing belt tension roller - 94580139, cost - 1800 rubles. The total cost of replacement parts for the original is 4,300 rubles.

Analogs

You can choose analogues for those who want to save money without losing quality.

Timing belt

Timing belt guide roller

Timing roller.

Possible troubles if the belt breaks

Daewoo Matiz is equipped with a 0.8-liter engine with an injection. The design of this power unit includes a camshaft installed in a block with three cylinders.

The timing mechanism of Daewoo Matiz is presented in the form of a toothed belt. The latter transmits traction torque from the crankshaft to the camshaft and rotates the pump, which ensures the operation of the engine cooling system. This design causes consequences arising from a break or incorrect installation of the belt drive.

The engine of the Korean hatchback is compact in size. The engineers managed to reduce the dimensions of the power unit, among other things, by increasing the compression ratio in the working cylinders. Thanks to this solution, the volume of the chambers in which the fuel burns is reduced, and, as a result, the size of the engine. However, despite the effectiveness of the described measures, this feature poses a danger.

Often, when inspecting the engine compartment, owners of Daewoo Matiz discover that the valves are bent. This occurs due to a broken timing belt or in cases where the latter is not installed according to the marked marks. Such consequences also lead to damage to the valve sleeves, connecting rods and piston.

Replacement must be carried out in a timely manner. Automotive engineers recommend visually inspecting this part every 10-15 thousand kilometers and installing a new one if abrasions and other defects are found. If this procedure is not carried out, then due to a worn belt drive, the failure of the camshaft and crankshaft will accelerate.

Conclusion

Replacing the timing chain on a Daewoo Matiz is quite easy with your own hands. To do this, it is worth having minimal knowledge of the design of the vehicle engine, as well as following the instructions. And if problems arise, car services will always help.

Vehicle maintenance includes replacing the timing belt. To do this, you can visit a service station, but you can save money if you master this procedure yourself. How to replace the timing belt of a Daewoo Matiz is described in the article with detailed instructions and video.

[Hide]

Article number and cost of analogues of the original timing belt Daewoo Matiz

Since the original timing belt for Daewoo Matiz is expensive, car owners recommend purchasing analogues from third-party manufacturers. Since the performance and safety of the power unit depends on the reliability of the gas distribution mechanism drive, purchasing low-grade consumables is unacceptable. Therefore, products from trusted brands should be installed on the machine, the best of which are presented in the table below.

Table - Good analogues of the Daewoo Matiz timing belt

| Manufacturer | vendor code | Approximate cost, ruble |

| Kemp | 77643324 | 300-420 |

| Bosch | 1987948778 | 360-450 |

| Polcar | BS1987948778 | 560-670 |

| Koreastar | KBKD005 | 910-1100 |

| Contitech | CT910 | 520-600 |

During operation of the Daewoo Matiz, the main elements of the gas distribution mechanism drive wear out. Many parts have a similar service life to the timing belt. Therefore, during repair work, it is recommended to replace all elements approaching the end of their service life. For the convenience of car owners, many companies produce special kits for servicing the timing drive. The best kits that Daewoo Matiz owners recommend using are presented in the table below.

Table - Recommended kits for replacing the timing belt of Daewoo Matiz

| Manufacturer | Catalog number | Approximate cost, ruble |

| INA | 530045310 | 1300-1700 |

| SNR | KD45321 | 1100-1500 |

| Bosch | 1987946300 | 2000-2500 |

| Flennor | F904323V | 950-1200 |

| Ruville | 59003701 | 2600-3000 |

In what cases is replacement necessary?

The timing belt is a rubber rim with an inner surface in the form of teeth, which promotes better traction with gears and eliminates slipping when the engine is running. The purpose of this component is to synchronize the operation of the shafts: camshaft and crankshaft.

The long-term operation and safety of the engine depend on the quality of the material. A belt break while driving can have serious consequences, especially on 16-valve engines. If a break occurs, the valves can be bent, the pistons can deteriorate and the surface of the cylinders can be scratched, which will require a major overhaul of the engine or its replacement.

For each vehicle, the manufacturer sets its own maintenance schedules, which are indicated in the operating instructions. For Daewoo Matiz, it is recommended to replace the timing belt after 18 months or after 60 - 80 thousand kilometers. But do not neglect regular scheduled inspection of the condition of the strap, which is performed either once a year or after 20 thousand kilometers. It is necessary to change the product if:

- cracks, tears, and creases appeared;

- the edges are frayed;

- the fabric has delaminated;

- there are traces of oil;

- service life has expired.

Replacement timing

Manufacturers indicate when to change the timing belt. It is recommended to replace it after a mileage of no more than 40 thousand km. The frequency of replacement may be slightly different, it depends on the operating conditions of the vehicle, the quality of the consumables used, and the technical condition of the engine. It is the last factor that most often leads to a situation where, while the engine is running, the belt suddenly breaks. The material used to make the timing belt is resistant to technical fluids used on the machine, especially motor oil, coming into contact with its body. The rubber of the belt swells, so it can be easily cut off by the teeth of the timing pulleys. If you notice even the slightest leak of engine oil or antifreeze, the problem should be repaired. And wear on the teeth of the crankshaft and camshaft pulleys also accelerates the failure of the drive belt.

Step-by-step replacement instructions

The replacement procedure is performed on a cold engine. To carry out work, it is better to drive the car onto an overpass or inspection ditch.

Tools

To work you need to prepare:

For a 0.8 liter engine, you can purchase a timing belt 96352965 with 107 teeth and a width of 25.4 mm. For a one-liter power unit - 96610029 with 109 teeth and a width of 25 mm. You should definitely change the tension roller, the original number of which is 94580139. If you need to change the cooling system pump, then the original consumable number is 96518977 (Hepu 799).

Stages

- For ease of operation, you need to remove the right wheel and fender liner.

- After unscrewing the 4 bolts, remove the protective casing.

- Thus, we gained access to the timing belt.

- To continue work, you need to remove the hanging belts. Having loosened the fastening bolt with a key “12”, remove the generator and remove the strap.

- Then, loosening the 3 bolts on the power steering pump, remove the belt.

- We set the top dead center of the first cylinder on the crankshaft and camshaft, respectively.

- We take out the dipstick to measure the oil level.

- Next, unscrew the mounting bolt and remove the crankshaft pulley along with the mounting bolt. At the same time, we fix the crankshaft from turning by inserting a screwdriver into the appropriate place.

- To remove the protective plastic casing, it is necessary to remove the dipstick tube.

- By removing the lower protective cover, we get full access to the timing belt.

- Next, to dismantle the strap, you need to loosen the tensioner mounting bolt.

- While holding the roller, remove the old belt.

- Then we dismantle the crankshaft pulley.

- Then remove the tension roller along with the spring.

- You need to check the rubber O-ring in the oil pump housing. If it has any defects, it should be replaced.

- Next, we check the coincidence of the marks on the back of the casing and the camshaft.

- At the same time, you need to install marks on the oil pump casing and the crankshaft toothed pulley.

- Then we install the tension roller with the spring in place and move it as far as possible to the side.

- Now we put the timing belt on all the branches.

- After turning the crankshaft pulley two turns, you need to check all the marks again.

- Now tighten the bolt on the tension roller.

- Reassembly is then carried out.

- During assembly, the belt tension is checked, which is adjusted using a tension roller.

This concludes the process of replacing the timing belt on a Daewoo Matiz with your own hands.

We have been waiting for this for a long time and finally it came to us, we meet the three-cylinder beast Daewoo Matiz, replacing the timing belt and roller. The engine capacity is 0.8 liters, the speedometer shows almost 40,000. Since the car was just purchased, the owner decided to play it safe and rightly so, because no one can guarantee that the speedometer is the same as in real life.

There is very little space under the hood and that is the only problem. To replace the timing belt we will need three heads for 10, 12, 17 and the same keys. Straight arms, a keen eye and about two hours of free time will also come in handy.

First, let's examine the beast. It seems to me that the designers based it on some Japanese cartoon character.

Replacement timing and sequence of actions

The timing belt on Daewoo Matiz is replaced every 60,000 km. mileage, according to the recommendations of the instructions, which do not take into account the peculiarities of climatic conditions and the driver’s driving style. If we take into account the quality and the brand itself, then the period is very long; experienced drivers recommend 40,000-45,000 km. mileage or 3 years without mileage limitation.

The prerequisites for imminent death are:

- periodic sounds coming from under the hood;

- sudden engine stop.

In this way, you gained experience in carrying out replacements and saved some money.

As you can see, replacing the timing belt on a Daewoo Matiz is not that difficult, you just need to strictly follow the recommendations and have a little patience. We hope our article recommendation will be useful to readers. We look forward to your practical advice for exchange of views and discussion. There are two types of timing drive: belt and chain. The advantages of a belt drive are low noise, simplified engine design and reduced weight. However, the service life of the belt is short and on average does not exceed 60 thousand km, in contrast to the chain, the service life of which is more than 100,000 km. The vast majority of chain drive engines have automatic chain tensioning.

Breakage and shearing of belt teeth are the most common belt drive failures. The consequences of a broken belt are related to the design of the engine. If the timing belt breaks, the valves will certainly meet the pistons, which, at best, will lead to deformation of the valve stems. To replace bent valve stems together with oil seals, it is necessary to dismantle the cylinder head. If the belt breaks at idle, 2-3 valves will need to be replaced; if in operating modes - up to replacing all valves. If the guide bushings are cracked, the cylinder head will need to be repaired.

Often, when replacing a belt, it is overtightened, which can negatively affect its condition: the tighter the belt is, the faster the cord threads will break. A weakened belt will also not run for a long time: its vibrations lead to undesigned loads on the teeth in the places where they come out and approach the pulley (the belt teeth do not fall into the cavities of the pulley teeth). Undercutting and subsequent separation of the teeth from the base is inevitable.

In order for the belt to run for a long time, you need to ensure that the belt is properly tensioned. It is important that the belt tension mechanism works properly. Another condition for the normal operation of a belt drive is the ease of rotation of all shafts. If one of them rotates tightly or with uneven force (sticks), then before installing a new belt, the cause of the jamming must be eliminated. It is important to make sure that there are no oil leaks that could result in oil getting onto the belt. If this happens, you need to fix the leak, wash the belt and pulleys of oil, and best of all, replace the belt. The belt drive should always be kept clean.

The timing belt, abbreviated as the timing belt, is replaced if cracks, tears or other damage is detected. In addition, according to the manufacturer's recommendation, for a Daewoo Matiz car it is recommended to replace the timing belt every 90,000 kilometers, regardless of its condition. It is quite possible to replace the timing belt on a Daewoo Matiz with your own hands. And to make this procedure more convenient, it is best to drive the car onto an overpass or put it in a pit in the garage and remove the mudguard in the front wheel arch.

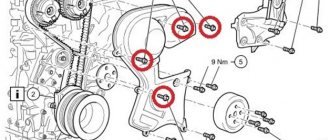

The figure shows a diagram of the timing drive (gas distribution mechanism): 1 - crankshaft toothed pulley; 2 — tension roller; 3 — toothed pulley of the coolant pump; 4 - camshaft toothed pulley; 5 — timing belt.

1 - Using a “10” wrench, unscrew the 4 bolts securing the upper timing belt cover (one of the bolts is not visible in the photo, as it is located on the other side of the cover).

2 - Remove the top cover. And then, using the head at “17”, turn the crankshaft clockwise and visually check the condition of the belt. When replacing the belt, install the piston of the 1st cylinder in the BMT at the end of the compression stroke (shown in the same article about adjusting thermal clearances). Remove the engine oil level indicator from the guide tube. Remove the power steering pump drive belt and the alternator drive belt.

3 - Holding the crankshaft from turning with a screwdriver, inserting it between the flywheel teeth through the hole in the lower part of the clutch housing,...

4 — ...unscrew the crankshaft pulley mounting bolt using a socket “17”.

5 - Remove the pulley.

6 — Unscrew the bolt securing the bracket for the guide tube of the engine oil level indicator using a socket set to “10”.

7 - Remove the oil level indicator guide tube.

8 — Unscrew the 3 bolts securing the lower cover of the timing belt with a head set to “10”.

9 — Remove the lower timing belt cover.

10 - To loosen the tension of the timing belt, loosen the bolt securing the tension roller using a socket at “12”.

11 — Applying force to the tension roller (the direction is indicated by the arrow in the photo), rotate the roller relative to the mounting bolt, overcoming the force of the roller spring. Hold the roller in this position and tighten its bolt.

12 — You can also loosen the timing belt tension by using pliers to disconnect the tension roller spring from the screw head and loosen the tension of the roller mounting bolt.

13 — Remove the timing belt from the crankshaft sprocket and tension roller.

14 — Remove the timing belt. When the timing belt is removed, the camshaft and crankshafts must not be turned at large angles; this is necessary to avoid damage to the gas distribution mechanism.

15 - The marking of the timing belt indicates: 109 teeth and a belt width of 25 millimeters.

16 - If necessary (if severe wear or damage to the teeth is detected), remove the toothed pulley from the toe of the crankshaft. To remove the tension roller, disconnect its spring from the coolant pump screw head and completely unscrew the pulley bolt.

17 - Remove the tension roller along with the spring.

18 - In the photo you can see the already dismantled tension roller with a spring. The roller should rotate evenly, silently and without jamming. If this is not the case, or if traces of grease appear from under the bearing seals, it is necessary to replace the tension roller with a new one. Install the new timing belt in reverse order.

19 - In the hole in the oil pump housing for the oil level indicator guide tube, remove the old ring from the hole and install a new ring in its place.

20 — When installing the tensioner pulley, insert its axis into the hole in the oil pump housing. Screw in the tension roller mounting bolt, but do not tighten it.

21 — Before installing the belt, check the alignment of the marks on the camshaft pulley and the rear cover of the timing belt, as well as on the crankshaft timing pulley and the oil pump housing.

If the marks do not match, you need to turn the crankshaft and camshaft until the marks match. Install the timing belt first on the camshaft pulley and then on the crankshaft. Place the timing belt behind the tension roller and put it on the coolant pump pulley, while the front branch of the belt must be tensioned. Use pliers or a screwdriver to tighten the tension roller spring and place its bent end behind the head of the screw screwed into the hole in the coolant pump housing. Turn the crankshaft by the pulley mounting bolt two turns clockwise and check the alignment of the marks on the crankshaft timing pulley and the oil pump housing, as well as the alignment of the marks on the camshaft timing pulley and the rear timing belt cover. Tighten the tension roller mounting bolt to the required torque. Install all previously disassembled parts in reverse order.

Required tools: 10mm wrench; heads for 10, 12, 17; screwdriver, pliers.

(Visited 94 times, 1 visits today)

Many owners of Daewoo Matiz were faced with the need to replace the timing belt. In a car service, this operation is quite expensive. We will try to figure out how to carry out the procedure with our own hands, and also consider which chains are suitable in addition to the original part.

Video material

The video will tell and clearly show the process of replacing the timing mechanism on a Daewoo Matiz.

We remove everything unnecessary

To get to the timing belt we will need to remove two belts, the generator and the power steering with air conditioning. First, loosen the two twelve bolts securing the power steering pump. One at the back.

One in front.

Move the pump to the cylinder block and remove the belt. Next, loosen the two lower bolts of the generator.

And one on top.

We also move the generator towards the block and remove the belt. Next, remove the upper timing belt cover by unscrewing the four bolts. It will not be easy to unscrew the lower left one, since the hoses are in the way and there is very little space, I remembered the mother of all Uzbeks three times while unscrewing it.

Set the top dead center. Turn the crankshaft clockwise until the marks on the camshaft sprocket and the protective casing match.

The marks on the lower timing belt casing and the crankshaft pulley should also match. For ease of perception, it is shown on the removed parts.

Unscrew the crankshaft pulley. To block the engine, we engage fifth gear, tighten the handbrake all the way, put stops under two wheels and, with a slight movement of a one and a half meter lever, tear off the bolt. Turn off the speed. Afterwards, the mark on the camshaft pulley may run away a little; it must be set again.

Remove the crankshaft pulley. To remove the lower timing belt cover, it is necessary to remove the oil dipstick, as it interferes with unscrewing one of the bolts. We unscrew one bolt of the dipstick, take it out, then unscrew the four protective covers and remove it.

We remove the timing belt by unscrewing and removing the tension roller along with the spring.

There is also a mark on the crankshaft sprockets; it should coincide with the low pressure of the oil pump.

Is it necessary to change the pump?

After replacing the belt drive, the question arises about the need to carry out this procedure in relation to the pump. The engineer recommends doing this after a run of 120 thousand kilometers. The replacement of the pump on a Daewoo Matiz will have to be carried out earlier than the specified period if:

- when examining the engine compartment, traces of antifreeze are revealed;

- extraneous noise occurs from the engine;

- I'm worried about a grinding noise coming from where the pump is located.

It is also necessary to replace the pump if the cooling system pump bearing jams. In addition, this procedure is recommended to be carried out in cases where defects are detected on the surface of a given part. But identifying cracks on the pump is quite difficult due to the design features of the Daewoo Matiz. The fact is that on a Korean hatchback this component can only be inspected after removing the timing belt.

We begin installing a new timing belt

Let's check all the marks again. We put the tension roller in place together with the spring, put the guide pin into the hole, and do not install the bolt yet, this will give us the opportunity to pull the roller further when installing a new belt. We first put the new timing belt on the camshaft sprocket and secure it with a plastic clamp so that it does not slip off in the future. Don't forget about the direction of rotation on the belt.

Next, we put it on the crankshaft sprocket and make sure that the right branch of the belt is tensioned, then on the tension roller and pump. We install the tension roller bolt, do not tighten it. A few degrees, without much effort, we turn the camshaft counterclockwise, thereby slightly tensioning the right branch of the belt. We check with our hands whether the spring has tensioned the tension roller, try to move it towards the belt, and then tighten the roller. Remove the clamp and turn the crankshaft two turns.

We check the marks and tension of the belt, try to turn it ninety degrees with two fingers, if it turns more, then it is necessary to tighten the timing belt. If everything matches and the tension is normal, install all the parts in the reverse order of removal. Well, if not, we repeat everything from the beginning.

Attention!

When replacing the timing belt on a Daewoo Matiz, more than one auto technician was not injured, all the tricks were performed by professionals, you can repeat them!

Belt Access

Before you replace a worn part, you need to gain access to it. So, after placing the car on the overpass, remove the fender liner related to the arch of the right front wheel. Next we can work with the upper timing cover, which can be accessed from under the hood. It is held on by four screws, which will need to be unscrewed using a size ten wrench. Three screws are located within sight, and the fourth can be reached from the opposite part of the body.

Now you can remove the top cover of the gas distribution mechanism. Turn the crankshaft slightly clockwise. This way we can inspect the belt and see if there are any defects on it. Having found any abrasions (these may be small cracks that are easy to detect when turning the belt), we begin to replace it. If everything is in order and there is no oil on the belt, you can install the timing cover back.

Video: Daewoo Matiz 0.8 l Replacing the timing belt and roller

Good luck on the roads. No nail, no rod.

Daewoo recommends checking the timing belt on the Matiz every 30 thousand km. and change it every 90 thousand km. If cracks, creases, tears or traces of oil appear on the belt, the replacement interval should be shortened. The work does not require any special tools; ordinary sets of wrenches and socket heads are sufficient. The only difficulty can be unscrewing and tightening the crankshaft bolt with the right torque, just like on any other machine. The layout of the engine compartment is quite dense, but there are no particular difficulties with access to components and assemblies.

First you need to remove the top cover covering the timing belt. It is secured with 10mm head bolts.

Remove the top cover. Next, you need to loosen the tension on the drive belts of the generator, power steering and air conditioning and remove them.

To access the bottom of the engine, you need to hang out and remove the right front wheel. There is a protective cover behind it, which also needs to be removed. The generator fasteners often become sour, so I recommend loosening the lower generator mounting bolt to loosen the belt.

Remove the hanging straps. We set the tags. It looks like this on the camshaft pulley.

There is a mark on the generator drive pulley; it should coincide with mark 0 on the bottom cover of the timing case.

Unscrew the crankshaft bolt and remove the attachment drive pulleys.

In order to remove the lower belt cover, you need to remove the tube and the oil dipstick itself. The cover itself is secured with bolts with a 10mm head. Remove.

Unscrew the tension roller and remove the timing belt.

We install a new belt and roller. Gates also makes good belts.

The tension roller is semi-automatic, that is, the belt tension is set by the roller spring; you only need to tighten the fixing bolt during installation with a force of 15-23 Nm. After installing the belt, you need to make 2 revolutions of the crankshaft and check that the marks match. It is located here on the lower timing pulley.

We assemble everything in reverse order. The lower crankshaft bolt is tightened with a force of 65-75 Nm.

Video:

The process of operating a Daewoo Matiz car is impossible without replacing the timing belt after a certain mileage. If this condition is not met, the car owner may incur additional costs for major repairs of the car’s power unit. Replacing the belt is carried out by specialists at repair centers or independently. A guarantee of correct replacement of worn parts will be the installation of a timing mark.

This “baby” is equipped with a gasoline engine with three cylinders; it has a working volume of only 800 cm3. Later, a liter power unit began to be installed on this car. The cylinder block is cast from cast iron, the cylinder head is made of aluminum alloy. The operation of each cylinder is ensured by two valves. One each on the inlet and outlet channels. The engine power is 52 horsepower, which is more than enough for a small car. The camshaft is located in the upper part of the cylinder head and is driven by a toothed belt drive.

Engine Daewoo Matiz

To achieve high engine efficiency, a high degree of compression of the working mixture in the cylinders was selected. This was achieved by reducing the size of the combustion chamber, so if the belt drive breaks, the valves can meet the piston heads, which entails damage to the valves, pistons, connecting rods, and other parts of the crank mechanism. The car's operating instructions instruct owners to change worn timing drive parts with a mileage of no more than 60 thousand km.

Most owners complete this operation before the specified time. This depends on the operating conditions of the machine and its technical condition. In general, the engine has a long service life; it can last more than 200 thousand kilometers. The disadvantages of the engine include frequent distributor failures in the ignition system. After switching to an injection power system, such problems are no longer observed.

How to change the timing belt on Daewoo Matiz

You will need

- - a set of keys;

- - screwdrivers;

- - chisel;

- — timing belt and pulley.

Instructions

Prepare the car for repairs. It is advisable to change the timing belt on an inspection pit, lift, or overpass. First, remove the wing from the front arch. The dimensions of the car are so small that the engine and all attachments are packed very tightly under the hood. Therefore, it is more convenient to carry out repairs with the wing removed. Now, using a 10mm wrench, unscrew the four bolts that secure the top cover to the block. After this, remove the cover.

Examine the belt by turning the crankshaft clockwise. Check to see if the edge of the belt is eaten away. If it has even wear, it is slipping and catching on the roller. The cause of the belt slipping is usually the pump. The bearing in it fails, play appears, causing the pump pulley to tilt slightly to the side. It is advisable that when replacing the timing belt, the pump is also replaced. This will save you from too frequent repairs to the timing belt assembly.

Remove the dipstick that controls the oil level. Then set the piston of the first cylinder to top dead center. There is a mark on the camshaft pulley that must be aligned with the mark on the cylinder head. In this case, the mark on the crankshaft should coincide with the mark on the clutch block. If you look from below, you will see an inspection window in the clutch housing, through which you can see the marks on the crankshaft.

Disconnect the accessory drive belts. First remove the belt that drives the power steering pump, then remove the alternator belt. Next, unscrew the crankshaft pulley mounting bolt and remove it. To prevent the Matiz engine crankshaft from turning, hold it with a screwdriver inserted into the inspection window of the clutch housing. You can also use a chisel if you don't have a strong screwdriver. The main thing is to fix the crankshaft in place, holding it by the ring teeth. Remove the bolt that secures the dipstick tube bracket to the engine block. After this, move the handset to the side. Then unscrew the bolts securing the bottom cover and remove it. Unscrew the roller mounting bolt and turn the last one to loosen the belt tension. Remove the timing belt. Try not to rotate the shafts, otherwise the operation of the valves will be disrupted.

Install a new belt, first check that all marks on the shafts match. When changing the timing belt, be sure to install a new roller, because its service life is quite short. By turning the roller, achieve the required timing belt tension. Be careful not to overtighten as this will cause rapid wear. A weak tension can cause the belt to move one or two teeth. Then put everything back together in reverse order.

www.kakprosto.ru

Why is it important to align the timing marks?

It is impossible to obtain full performance from the specified motor parameters without meeting certain conditions. One of them is the correct installation of valve timing. For this purpose, there are installation marks in the timing mechanism drive. Without them, it is impossible to correctly set the position of the camshaft relative to the crankshaft. If the position of the gear is shifted even by one tooth, the engine operating parameters will be greatly impaired. The ignition will be set early or late. This will affect not only the parameters of the motor, but also its technical condition. Carrying out the operation of installing the marks of the timing drive mechanism is not a difficult operation, but it requires care when performing it. You can read more about the belt replacement procedure in

This part in the cylinder head is responsible for opening and closing valves in the intake and exhaust channels. Only complete filling of the cylinders with the air-fuel mixture and subsequent removal of exhaust gases will ensure that the specified engine parameters are obtained. The camshaft is driven by a pulley, which is driven by the rotation of a toothed belt. The correct installation of the pulley on the camshaft is ensured by a pin that will not allow it to rotate arbitrarily relative to the shaft.

In order for the cams to open or close the valves at the right time, installation marks are applied to the timing mechanism drive. The upper inner part of the protective roof has an arrow on the body, obtained by stamping during its manufacture. The camshaft pulley also has a mark, which is a mark on one of the teeth. The pulley should be rotated until the mark and the arrow are directed exactly opposite each other. After this, you can continue working further. The mark is installed with the belt removed, otherwise the motor can be damaged. In this case, you should carefully inspect the shaft seal; if engine oil leaks through the seal, it should be replaced with a new product.

When the intake valve is open, the piston must be at top dead center so that when it moves down, the cylinder is filled with the working mixture. The piston is driven by the crankshaft through a connecting rod. If the operation of the crankshaft is not synchronized with the camshaft, you can not only fail to start the car’s power unit, but also disable it for a long period. To prevent this from happening, installation marks are applied. The shaft pulley is installed through a key; it will not be able to rotate arbitrarily. It has a tooth with a notch, which was obtained during the manufacturing process of the pulley.

The crankshaft oil seal protective cover also has an arrow-shaped mark obtained during casting. The shaft together with the pulley is rotated until the mark on the tooth is located exactly opposite the mark on the oil seal cover. This operation should be performed with the timing belt removed to prevent the pistons from meeting the valves. If there are traces of engine oil leaks on the oil seal cover, it should be replaced, otherwise the lubricant will accelerate the failure of the drive belt.

About the engine

This “baby” is equipped with a gasoline engine with three cylinders; it has a working volume of only 800 cm3. Later, a liter power unit began to be installed on this car. The cylinder block is cast from cast iron, the cylinder head is made of aluminum alloy. The operation of each cylinder is ensured by two valves. One each on the inlet and outlet channels. The engine power is 52 horsepower, which is more than enough for a small car. The camshaft is located in the upper part of the cylinder head and is driven by a toothed belt drive.

To achieve high engine efficiency, a high degree of compression of the working mixture in the cylinders was selected. This was achieved by reducing the size of the combustion chamber, so if the belt drive breaks, the valves can meet the piston heads, which entails damage to the valves, pistons, connecting rods, and other parts of the crank mechanism. The car's operating instructions instruct owners to change worn timing drive parts with a mileage of no more than 60 thousand km.

Most owners complete this operation before the specified time. This depends on the operating conditions of the machine and its technical condition. In general, the engine has a long service life; it can last more than 200 thousand kilometers. The disadvantages of the engine include frequent distributor failures in the ignition system. After switching to an injection power system, such problems are no longer observed.