Purpose of closed tanks

All of them, regardless of volume and performance, are designed to level out the expansion of the coolant (special liquids, water), which occurs when its temperature increases.

This is done in order to avoid destructive water hammer, damage to fittings, fittings, rupture of heating system pipes, and extrusion of gaskets.

Example: the coolant (water) expands by four percent as the temperature rises to 95 °C. Which is quite enough for the engineering system to fail.

Expanzomat design and components

Any such modern product consists of the following structural elements:

- housings;

- coolant chambers;

- a gas chamber into which ordinary air or inert gas is pumped;

- membranes.

The option of filling the gas chamber with inert gas is more preferable, because it provides the container with greater durability. But regular air is more accessible.

The membrane is made of elastic materials, therefore it is able to change its position as the temperature of the coolant increases or decreases. This structural element can be of the diaphragm or balloon type, and their operating principle is similar.

The tanks are connected to the heating system using a special pipe. A valve is provided for pumping gas. Closed-type containers are manufactured in a horizontal or vertical layout, which makes it easier to complete the heating system.

Tanks intended for installation in closed heating systems are equipped with pressure gauges to monitor internal pressure. Similar products intended for installation in systems of ordinary private houses operate at low loads not exceeding 3.5-4 bar, so they do not require measuring instruments.

You can also find two types of tanks on sale:

- with a non-replaceable or stationary diaphragm-type membrane, that is, a break, the wear of which will lead to the replacement of the entire device;

- with a replaceable balloon-type membrane.

In the first case, the products are distinguished by a more affordable price, in the second by greater functionality, maintainability and durability.

The design of flanged tanks allows you to replace a worn or damaged membrane, and in some cases you can even do this yourself. And replaceable membranes can withstand greater pressure.

Expansion tank operation diagram

When the coolant is cold, the tank membrane occupies as much space as possible. As the temperature rises, the pressure on it increases.

As a result, the specified structural element overcomes the resistance of the inert gas or air and changes its position, freeing up more space for the resulting excess liquid.

When the coolant cools down, the opposite process occurs to that described above. And then the cycles are repeated many times.

How to calculate the volume of the expansion tank

Do-it-yourself steering rack repair video

According to the rules for constructing water heating, the volume of the expansion tank should be equal to 10% of the total volume of the system. Therefore, in order to accurately calculate the volume of the tank, it is necessary to calculate the volume of all elements.

For example, one section of an aluminum radiator has a volume of 0.3 liters. The volume of the heating tank can be found in the product data sheet. You can calculate the volume of water inside the pipes if you know their length and diameter. For many, this is a rather complicated method of calculation, so you can determine the total volume when pouring water into the system. If buckets are used, then count them; if water is filled with a special pump, then take the meter reading.

Many experts recommend using the expansion tank volume indicator “with a margin”. For example, when calculating, it turned out that a total of 70 liters of water were filled, which means you need a seven-liter tank. Take a size up for your own peace of mind.

Currently, manufacturers offer two types of tanks, which are installed on floor-standing heating boilers and on wall-mounted ones. In the first case these are volumetric tanks, in the second they are flat. The difference in shape is significant, but the operating principle is the same.

Expansion tank cleaning products

To clean and wash the RB, car enthusiasts use various means - cleaners, solvents, citric acid, washing powder, etc. If the level of contamination is so high that nothing helps, you can try the following.

- Fill the tank 15% with fine gravel.

- Fill the tank with warm water up to half and add dishwashing detergent.

- Shake the tank with both hands.

- Empty the tank and rinse it with water.

The tank should be clean.

You can use ready-made products, for example, DIMER washing concentrate. In this case, cleaning is carried out as follows.

- Fill the tank 15% with DIMER concentrate.

- Shake the tank, tapping its body with your hands, and leave for 10 minutes.

- Fill the tank halfway with warm water.

- Use a long-handled brush to clean the inside walls of the tank.

- Pour out the solution and rinse the tank with warm water.

Fines for crossing the stop line and speeding will no longer bother you!

DIMER concentrate is quite effective in cleaning the expansion tank

There are many other ways to clean RB.

Video: flushing and cleaning the expansion tank

A serviceable and clean expansion tank is an important element of the engine cooling system. Any malfunctions can be easily diagnosed and fixed with your own hands. To do this, you just need to carefully follow the recommendations of specialists.

Recommendations for choosing a container

Communities Lada Priora Lada Priora Club Blog Micro FAQ 2. Checking the functionality of the expansion tank cap

The most important feature that you should pay attention to when choosing an expansion tank model is the volume of its tank. For closed systems with a small circuit, the volume of coolant in which does not exceed 150 liters, the capacity is easy to calculate

So, it should be:

- when using water as a coolant - 10% of the volume of the entire heating system (for example, if this figure is 100 liters, then the expansion tank must hold at least 10 liters);

- when using glycol liquid as a coolant - 15% of the volume of the heating system.

In the latter case, the capacity should be larger due to the greater expansion coefficient of the specified antifreeze.

The volume of the tank for larger systems, the circuit of which circulates more than 150 liters, is most conveniently calculated using the parameter of the total volume of the system and a table for selecting a tank.

To calculate the total volume of the system, you can use the following methods:

- Measure the volume of coolant circulating in all individual elements of the system (boiler, radiators, pipelines) and then sum up the results obtained. This method is highly labor intensive, but at the same time it is the most accurate.

- Multiply each kilowatt of boiler power by 15, assuming that on average there are about 15 liters of coolant per 1 kW. This method is simple, but you should remember that you can trust the result only when you are confident in the correct selection of the heating element for the system.

- Drain all water from the system and refill it, calculating the required displacement.

You can also use formulas or an online calculator to calculate the required tank volume. Why is it necessary to know the volume of coolant, its temperature and pressure in the system.

The method with formulas is more complex and the volume obtained as a result of calculations will not differ significantly from the rough calculation given above. Moreover, the found value must be rounded up.

The most practical solution when choosing will be an expansion tank designed for closed-type heating systems, equipped with a safety valve.

The reason is that when the pressure rises to critical standards, the device will start working and bleed it. That is, this valve can significantly increase the safety of the entire heating system.

When purchasing a container, you should take into account that red paint is most often used to mark expansion tanks used for heating.

This feature will help to distinguish the desired product from other similar ones, for example, water supply tanks of similar size and shape - hydraulic accumulators, which are mainly covered with blue enamel.

But if necessary, you can find tanks of various colors, which will help you place the one you need in any room without compromising its aesthetic qualities.

When choosing, you should also pay attention to the quality of the materials used in the production of the container body and membrane. And the presence of a guarantee for the purchased equipment and instructions for installing and connecting it to the system

Expansion tank maintenance

Repair of expansion tank cap

The role of such a device as the expansion tank of the heating system cannot be underestimated; the instructions for this device provide a list of rules for its maintenance. These include:

- Once every six months it is necessary to check the tank for external damage - corrosion, dents, leaks. If suddenly such damage is found, then it is imperative to eliminate its cause.

- Once every six months, you need to check the initial pressure of the gas space for compliance with the calculated indicator.

- The integrity of the membrane is checked once every six months. If a violation is detected, it must be replaced (if such a possibility is provided).

- If the tank will not be used for a long time, then you need to keep it in a dry place and drain the water from it.

Next is how to check the heating expansion tank - its initial pressure of the gas space. To do this, disconnect the tank from the heating system, drain water from it, and connect a pressure gauge to the nipple of the gas cavity. If the pressure is lower than what was set at the same time when the expansion tank for heating was set up, the tank must be inflated with a compressor through the same nipple.

Pressure gauge readings for correct operation of the expansion tank

Checking the integrity of the membrane is also an important point. If suddenly, while checking the pressure of the gas space after you have drained the water, air flows through the drain valve, and the pressure in the gas space has decreased to atmospheric pressure, then the membrane is broken.

To replace the membrane, you need to go through several steps. First of all, the tank is disconnected from the heating system, then it needs to be drained. Next, the pressure of the gas cavity is released through the nipple. The membrane flange is dismantled. It is located in the area of the pipe connection to the pipes. The membrane included in the expansion tank device for heating is removed from the hole at the bottom of the housing.

Then you need to check the inside of the case to make sure there is no dirt or corrosion; if there is any, you need to remove them and rinse them with water, and then dry them. To remove corrosion, do not use products containing oils! The membrane holder is inserted into the hole at the top of the membrane. The bolt is screwed into the membrane holder, it is placed in the housing, and the holder is retracted into the hole in the bottom of the housing. The holder is then secured with a nut. After this, a membrane flange is placed on the body.

Installation

Heating system tank.

Some home craftsmen who try to carry out the installation processes themselves make mistakes. This leads to a violation of the integrity of the entire heating structure.

For example, you cannot bleed air from the tank that is pumped into it during the production process, that is, in a factory setting. If it happens that air spontaneously leaves the diaphragm, do not panic. By the way, you will determine this as soon as you light the boiler. The pressure gauge in the system will jump. To pump air into the tank, you can use a regular car pump

Please note that the expansion tank in the heating system must have an internal pressure not exceeding 1.5 atmospheres

But keep in mind that sometimes this indicator needs to be adjusted. The fact is that different systems have different lengths, which affects the pressure inside the pipeline. Therefore, experts believe that the pressure in the expansion tank should always be 0.2 atmospheres less than the pressure in the heating system. Why? If this does not happen, the coolant will not be able to penetrate the tank body, and such a tank will be a useless attribute.

Open tank option

Where is the best place to install expansion tanks? There is no specific place for them. Ease of service is a top priority. Whether they are above or below, on the wall or on the boiler, it makes no difference.

Experts recommend one place for this. This is a section of pipe between the boiler and the circulation pump if there is forced circulation of the coolant. And this place, as you understand, refers to the return circuit.

A prerequisite that must be taken into account when carrying out installation work is the installation of a shut-off valve, which is mounted on the pipe connecting the expansion tank and the return pipeline. It is necessary for those cases when the tank needs to be repaired or completely replaced.

What can you add to the expansion tank? The right choice with scientific basis

The difficult task of transferring the exterior of a flashy crossover to a new chassis was solved brilliantly. Kaptur is truly beautiful

Imagine opening the hood and discovering a critically low coolant level. Or the car itself informed you about this by suddenly lighting up a warning on the dashboard. And while many people carry oil “to top up” after a recent change in the trunk just in case, this happens extremely rarely with antifreeze. So you go to the nearest specialty store with the difficult question of what to add and in what proportion? The answer, as a rule, is obvious and is tied to the color of the liquid that is already splashing in your expansion tank. So, most likely, you will be advised to add red to red, green to green, blue to blue. How true is this, especially when it is not possible to unambiguously determine the color of the old liquid? Unlike automobile oils, which have a clear classification system that facilitates the selection of analogues, antifreezes do not have generally accepted international standards. They are limited only by the internal standards of the car manufacturers. Moreover, the same brand may have several of them, depending on the year of manufacture and model. A classic example is Volkswagen, which has five types of antifreeze, but not all of them can be mixed with each other without losing their properties. So it turns out that both the seller’s advice and your own choice - most often the lottery is “suitable or not suitable”. For the correct answer and general development, you will have to dive a little into the intricacies of antifreeze compounds. The basis of all automotive antifreeze is an aqueous solution of monoethylene glycol (MEG), to which a little glycerin is added to reduce the cost and reduce environmental risks. It is MEG that provides the necessary low-temperature properties. But with a single base, there are many combinations and colors of antifreeze, which can easily confuse an inexperienced driver. At the same time, their systematization is quite possible, but you need to look not at the color, but first of all at the base of the liquid, at what material the cooling system is made of, and a little at the additive package.

All antifreezes are divided into several groups. The first of them is inorganic hybrid, often called silicate, since they contain silicates (colors: green, blue-green, blue, yellow). Greens and blue-greens were among the first to be born and went through the entire process of evolution. Silicate antifreezes can be divided into two subgroups: North American and European types. North American antifreezes contain phosphates, while their use in European ones is strictly prohibited. Among North American mixtures, there is a small subgroup of antifreezes with a reduced silicate content - Low Silicate Formula. It is worth noting that most modern antifreezes produced in Europe have reduced the silicate content, and they can serve as an analogue of the American Low Silicate Formula. On the label of silicate type antifreeze you can see the marking G11 or G48. For example, this designation is available for Liqui Moly Ku..hlerfrostschutz KFS 2000 G11, which is widely represented on our market. Actually, the G11 designation is a Volkswagen standard, but now almost all antifreeze manufacturers use it as a marking of the type of liquid and even a common noun. Inorganic antifreezes are oriented for use in engines with cast iron blocks, are well compatible with brazed copper radiators and perfectly protect aluminum parts from corrosion, since if it occurs, they quickly seal the damaged areas, creating a near-surface film. Their main disadvantages are low stability and rapid aging. Precipitated spent additives turn into an abrasive, which inevitably shortens the life of the water pump seals. If your cooling system is predominantly made of light metals, the second group of antifreezes, which use carboxylate organic acids as the main corrosion inhibitor, is suitable for you. Organic antifreezes also vary in composition and color. Types G12, G12+ and G30 (VW), G33 (PSA) and G34 (GM) are painted in orange, red or pink shades. As an example, the same Liqui Moly Ku..hlerfrostschutz KFS 2001 G12+. All such antifreezes contain two or more types of carboxylate acids, but do not contain silicates, phosphates, borates, nitrates, amines and nitrites. They resist corrosion well throughout the entire volume of liquid and are designed to protect aluminum parts. If you risk pouring organic antifreeze into an engine with a cast iron block, be especially careful to monitor the level, as corrosion of the ferrous metal surface may develop at the antifreeze-air interface. Another type of antifreeze in the same group is Honda Genuine Coolant Type 2 (blue) and Toyota Long Life Coolant (red). They contain the same subspecies of carboxylate acid and phosphates. This type of carboxylate acid has a negative effect on some engine gaskets. It should be mentioned that until 2000-2001, Honda and Toyota offered a different type of antifreeze, which did not contain silicates, but had an excess amount of phosphates. In Europe, phosphates are not used mainly due to the increased hardness of the water (there it is allowed to use ordinary tap water for diluting antifreeze concentrates). Hard water can cause phosphates to precipitate, and if you are preparing a solution from such a concentrate, use only distilled water. The third group is lobrid antifreeze. They use the same type of carboxylate acids as the Honda Type 2 or Toyota LFC, plus a small amount of silicates. Despite the fact that the lobrid type of antifreeze officially does not contain phosphates, in fact they are present in it, only in very small quantities. They use different colors: yellow, sometimes green and orange. There are some nuances here, because the color depends on the car manufacturer, the car model, and even on whether it is poured on an assembly line or at a service station. As you can see, antifreezes of different class and composition can be the same color, so when choosing a top-up you can’t rely only on color. After all, all antifreezes are initially colorless. Manufacturers add dye to them only to give them “individuality” and to simplify the determination of the fluid level in the expansion tank. Sometimes the dye is fluorescent, which helps to quickly find leaks. The amount of dye is minimal - a few grams per ton. The dye does not have any effect on the properties of the liquid. So, we have come to the obvious conclusion: the most correct choice is according to the car’s operating instructions. The type of coolant or at least the manufacturer's brand name must be indicated there. However, often the instructions are lost, and there is nothing definitive on the Internet. What to do in this case? If you need to add a small volume - up to half a liter, and the reason for the loss has not yet been identified, it makes sense to use distilled water. The fact is that a slight loss of antifreeze may be a consequence of boiling water, because monoethylene glycol itself does not evaporate so easily. At the same time, the antifreeze becomes more concentrated, and adding water will only restore its density. A small amount of water will not affect the low-temperature properties. If you need to add more, then you should ask yourself the question: when was the last antifreeze change and is it not better to replace it completely? It is useful to remember that the resource of modern antifreeze is not unlimited, although it can reach a couple of hundred thousand kilometers. The additives lose their properties over time, causing corrosion and wear of the water pump seals. In such a situation, it is better to completely change the fluid without waiting for problems. And more about the resource. If the anti-corrosion properties of antifreeze are approximately equal for all classes, then in terms of other indicators, organic and lobride have the longest service life, because they were designed. But inorganic antifreeze is recommended to be changed at least once every three years, and their warranty period is limited to three years, since clots may form during storage. During operation, such clots do not form. Is there a universal antifreeze available at retail that meets most automakers' requirements? We would recommend the already mentioned carboxylate Liqui Moly Ku..hlerfrostschutz KFS 2001 G12+. It is sold almost everywhere and is additive compatible with all commercially available analogues, excluding only lobrid-type antifreezes. At the same time, you can buy Kuhler Reiniger flushing fluid. Don't neglect flushing the cooling system. Even in a two-year-old car, it surprises with the amount of dirt that the radiator and engine block have accumulated. Flushing will remove sludge from decomposed additives, scale from mineral salts in the water and traces of oil that often gets into the cooling system.

Bottom line. If a small top-up is required, add distilled water. If you need to add more than half a liter, look for the leak, evaluate the remaining life of the antifreeze and think about a complete replacement with flushing the entire cooling system. It’s definitely not worth adding a large amount of antifreeze to an unknown product!

Malfunctions of the VAZ expansion tank and its repair

Malfunctions of the tank can occur both as a result of its improper operation, and in the event of accidental mechanical impact. For example, in the event of an accident, the tank may be damaged and burst, or due to increased fluid pressure in the system. In any case, diagnostics and urgent repair of the tank are necessary, since without it the functioning of the cooling system is not possible.

In total, the expansion tank suffers from three “diseases”:

Valve cover jammed. The VAZ expansion tank cap is designed to release excess pressure from the system. When it jams, the pressure increases, and many parts of the system simply burst. The same can be said about the expansion tank itself, which always suffers first. At the first symptoms (hissing when opening the lid), it must be replaced. If replacing the cover is not possible, you can try to repair it. To do this, it is unscrewed and disassembled. The valve spring is sawed off into a certain number of turns and the spring is reassembled. After that, it should work.

How to fix a faulty tank cap on a VAZ 2109?

Many owners of VAZ 2109 cars are faced with a problem such as incorrect operation of the expansion tank cap. Its valve either cannot hold the pressure or simply does not release. In this case, the spring is to blame, the stiffness of which was not taken into account correctly by the manufacturer.

First, the cover must be disassembled. To do this, it is better to use a flat-head screwdriver and any pliers. When all the parts are on the table, it is necessary to reduce the elasticity of the safety spring. To do this, the number of its turns is reduced using pliers. As a rule, the safety valve is shortened by 1 turn, and all others by 2. After this, the elasticity of the spring decreases and the expansion tank cap is ready for use again.

This is how it is finalized, as you noticed, this procedure can be performed without the help of auto mechanics and will significantly save money on repairs

The expansion tank is an important element of the engine cooling system. Its failure is most often associated with wear and mechanical damage. All faults can be fixed quite easily on your own.

Heating expansion tank device

The expansion tank device consists of the following elements:

• water chambers;

Depending on the type, the design configuration may vary.

In total, there are two types of tanks used to equip heating equipment.

• The open design is a metal container with an open top. At the bottom of the tank there is a threaded connection for connection to the boiler. The open view model must be installed at the highest point of the system to function properly. The design of this modification does not require shut-off valves and membranes. Even the lid does not play any functional role except as a barrier against dust and debris.

• The closed structure is a metal sealed capsule with built-in elements. The existing two chambers are separated by a membrane made of rubber. This helps prevent corrosion of the metal from contact with water. The connection pipe to the boiler comes out of the top. Such a tank can be installed anywhere, with the exception of a tie-in near the circulation pump.

In modern systems, open tanks are practically not used. Design features and functionality are already outdated. But it can be used in combination with a low-power boiler for heating small houses.

The operating principle of a closed tank is to distribute heated liquid from the system into a membrane device. Due to this, high blood pressure begins to normalize.

Membrane replacement process

When the membrane wears out, the following types of work should be performed:

- disconnect the tank and drain;

- release pressure using the nipple;

- There is a membrane in the place where the pipeline is connected. The membrane flange is dismantled. Afterwards the holder is released;

- the membrane is removed;

- The inner surface of the expansion tank is checked for dirt and rust. If necessary, flushing is carried out;

- you need to know that the membrane is sensitive to oils. So it is unacceptable to use them as anti-corrosion agents on the inside of the case.

Installation of a new element

As already mentioned, original spare parts are not the best option. A more optimal solution would be to install a reinforced model of the expansion tank on the UAZ Patriot instead of the original one. As a rule, car owners in this case take an expander from the Volga GAZ 31105. This option is characterized by increased reliability, so it will serve you for a long period. But there is one drawback: the model from the Volga cannot be installed on its original bracket.

It will also be interesting to read: Lada Niva Urban 4x4: review and technical specifications

To produce suitable fasteners, we adhere to the following algorithm:

- we make a U-shaped structure that corresponds in size to the new tank;

- we make holes on the ribs where the expander can later be attached;

- bolts are mounted into the holes, then we weld them;

- we make a bracket with which you can fix the frame on the body;

- We paint the frame to increase its durability.

If everything is done correctly, the finished design will be much more reliable than the original version, which will save you a lot of money and effort on repairing the unit.

Purpose of the expansion tank

The purpose of the expansion tank is to compensate for the volume of coolant that changes depending on its temperature. Briefly, the device of the expansion tank can be described as follows. The material of the expansion tank is transparent plastic. There are special marks on its walls that help control the coolant level - minimum and maximum. So, the expansion tank cap on the Lada Priora is located in the neck located on top. A plastic stopper seals the neck. The plug itself also contains two valves assembled into a single block - inlet and outlet. The release valve is activated when the pressure in the expansion tank reaches 110 kPa. Opening the exhaust valve increases the boiling point of the coolant, thereby preventing intense vaporization. When the coolant cools, its volume decreases, thereby creating a vacuum in the system. The inlet valve is activated when a certain vacuum level is reached and allows air into the expansion tank.

Often, the expansion tank is repaired only if it is found to be leaking

However, it is important to monitor the proper operation of both the thermostat and valves. For example, if the coolant boils, it is imperative to check the functionality of the valves

In particular, leakage of the exhaust valve will lead to a decrease in the boiling point of the coolant, and jamming of the same valve in the closed state will lead to a problem such as an emergency increase in pressure in the system. This, in turn, can cause damage to the hoses and radiator.

Replacing the expansion tank

In particular, replacing the expansion tank on a Priora is done as follows:

- A Phillips screwdriver should be used as the main tool. First of all, remove the expansion tank plug. To do this, you need to unscrew the drain plug at the bottom of the radiator tank on the right side and drain the liquid from it. By the way, replacing the coolant must be carried out according to all the rules - for example, you cannot mix different coolants. After draining is completed, the drain plug should be tightened. It should be noted that if you drain the liquid not from the tank, but from the radiator (during its repair), then all the liquid from the tank will also flow out,

- it is necessary to loosen the clamp securing the steam exhaust hose of the heater radiator and remove the hose from the expansion tank fitting,

- in the same way, it is necessary to remove the steam exhaust hose of the radiator of the cooling system (also from the expansion tank fitting),

- After loosening the clamp of the charging hose, this part can be easily disconnected,

- expansion tank, to remove it you need to move it up and at the same time remove its rear edge from the recess of the engine shield trim. This way it can be easily removed from the car.

- It is necessary to drain the remaining coolant from the reservoir.

The expansion tank is installed back in the opposite order of removal. The cooling system should be filled with liquid, taking into account all the standard requirements for this procedure. Then you need to tighten the cap of the expansion tank, start the engine, after which you should check that there are no coolant leaks at the junction of the tank hoses. The engine needs to be warmed up to operating temperature at idle speed - this will allow air pockets to be removed from the system.

DIY expansion tank repair

During operation, the expansion tank is constantly affected by deformation: the container contracts and expands due to temperature changes - this is its operating mode. At peak values, cracks appear on the walls of the tank. The problem can be solved in two ways: buy a new tank or repair the old one.

Expansion tank crack

The material used in the manufacturing process of expansion tanks does not react with any adhesives, regardless of brand. This suggests that it will not be possible to properly repair the tank by gluing it. Those car owners who decide to restore the capacity, as a rule, resort to the following methods:

- seal the cracks of the case using a metal mesh;

- epoxy resin, special sealant or cold welding are used.

Due to the constant exposure of the expansion tank to high pressure and temperature, cracks appear on the vessel over time

. It is worth noting that cold welding and epoxy eliminate the problem only temporarily and you will still have to return to repairing or replacing the tank.

Some car enthusiasts are wondering what and how to repair cracks in the plastic housing of the expansion tank? To carry out the procedure at home you should:

- clean the housing at the crack site with a clean rag or napkin;

- degrease the area with solvent and then dry;

- cut a piece of brass mesh with small cells along the length of the damage;

- apply a strip to the repair site;

- Using a heated soldering iron, solder the mesh to the edges of the crack so that a reinforced layer is formed over the entire area of the mesh;

- grind the seam;

- Apply putty, a layer of primer and paint.

The most common and affordable way to restore an expansion tank is soldering using a fine metal mesh.

For the procedure discussed, you will need a soldering iron with a minimum power of 40 W with a flat tip. You can restore the seal of the tank using a special red Done Deal sealant, which is intended for plastic. Before applying the substance, the body is thoroughly cleaned and degreased.

Video: repairing the expansion tank by soldering

How to install

There are no significant restrictions affecting the installation location of the expansion tank in the system. Nevertheless, it is advisable to carry out the installation at any convenient point in the return line of the existing heating system.

The reason is that the coolant there is cooler. And this allows you to significantly extend the life of the expansion tank and its membrane.

In addition, if you install the tank near a solid fuel boiler, then in certain situations steam may enter the coolant chamber. As a result, the container will lose the ability to compensate for the expansion of the coolant.

Installation of the tank can be done in two ways. These include installation:

But it should be understood that the first option is intended only for cases where the expansion tank has a moderate volume.

You should not skimp on connecting the tank to the heating system.

So this procedure should be performed using:

- a shut-off valve with a so-called “American” - this design element will allow you to quickly remove the tank from service and, if necessary, replace it, without waiting for the coolant to cool down;

- a tee with a drain tap, which will allow you to quickly empty it before replacing the tank;

- pressure gauge for measuring pressure;

- safety valve or nipple to regulate the pressure inside the equipment.

After installing the tank, it must be configured correctly, taking into account the manufacturer’s recommendations given in the instructions for the purchased equipment. So that the pressure in the tank is appropriate, i.e. less than in the system, which will allow the membrane to deform when the coolant heats up.

If the calculations were carried out incorrectly and the heating system contains a tank of a smaller volume than required, then it will not cope with its duties, but the error can be corrected.

Why do you need to purchase and install a second container in the system? The capacity of which is the difference between the required volume and that available in the tank operating in the system. This method will reduce financial losses.

Errors and tips for eliminating and preventing them

The correct options for installing the tank were discussed above. But ordinary users are capable of performing incorrect actions without understanding the essence of possible problems. To prevent such situations from occurring, the following information will be useful:

- A hydraulic accumulator placed directly behind the boiler will work with coolant heated to the maximum temperature in the circuit, which is not recommended. In this area, the liquid expands more strongly, which can cause too large pressure drops;

- Frequent changes in pressure occur immediately downstream of the pump. That is why it is also not recommended to install a tank there;

- When fully filled, the expansion tank becomes significantly heavier compared to its original state. That is why the mounting of the buffer tank must be designed for appropriate loads;

- The hydraulic accumulator is selected with a volume of at least 10% of the amount of coolant in the entire heating circuit.

Signs of a faulty expansion tank cap

Often the high pressure valve fails; it simply begins to release antifreeze at normal levels, or does not release it at all.

When the normal pressure is released (with a warm engine), antifreeze or antifreeze splashes out and, accordingly, it decreases. Steam can often come out from under the hood because the liquid gets onto the hot exhaust manifold. Moreover, the engine temperature is not in the red zone, that is, it is working - which means 90% of the lid.

If the vacuum valve fails, completely different symptoms will appear. This is how air pockets often arise in the system - this leads to the following: the engine overheats, and cold air comes out of the stove.

To be honest, there can be a lot of reasons, for example, another sign is when pipes burst or clamps break. YES, the tank itself can burst - this means that the high pressure valve does not release the “excess” and it begins to exceed 1.5 atmospheres, which, by the way, can damage the radiators themselves, let me remind you of their two main ones and the stoves (in the cabin).

So if your connecting clamps or other connections start to “snot”, and hoses often get knocked out, change the cover.

How does the coolant reservoir cap work?

The engine cooling system is completely sealed. However, due to the fact that the coolant is made on the basis of methyl alcohol, it can increase in volume during the heating process.

Therefore, excess liquid, as well as compressed air, enters the reserve tank when heated - the expansion tank. If the air in the system is strongly compressed due to an increase in the volume of liquid, then the release valve in the lid is activated: it opens slightly and excess air comes out.

Further, when the car sits for a long time, the opposite reaction occurs: the engine and the liquid cool down, due to which the volume of antifreeze is sharply reduced. Accordingly, air pockets appear in the system. Thanks to the inlet valve, these plugs are quickly removed from the system.

Valves in the lid maintain the required pressure in the system

Malfunctions of tank caps and their consequences

A leaky expansion tank cap can cause additional and “unnecessary” air leaks into the system. The fact is that if the pressure inside the system corresponds to atmospheric pressure, then the liquid will begin to boil at the temperatures at which this should occur. Thus, there will be a leak of coolant and subsequent overheating of the engine. The latter can easily fail.

The other side of the problem is the formation of an air lock. The air lock moves along with the coolant and prevents it from performing its functions. The liquid heats up and boils, which leads to its leakage, and in winter, due to an air lock, poor operation of the interior heater radiator is possible.

The worst thing is when the lid is hermetically closed, but has stopped releasing pressure into the atmosphere. As pressure increases, coolant begins to push out through pipe connections and other “holes in the system.” In the best case, everything will work out and you will only have to change the cover. At worst, the expansion tank can easily rupture and then repairs will cost much more.

Operational Maintenance

It must be remembered that during breaks in use, the tanks, like other components of the heating system, should be emptied and then dried. This point should not be ignored, as failure to comply will lead to corrosion and reduced service life.

When using any closed tank, owners should regularly perform a number of simple operations.

Which include:

- periodic inspections to detect corrosion and mechanical damage - this procedure should be carried out twice a year;

- checking the pressure in the system, which is performed every six months;

- periodic inspections of the integrity of the membrane - such operations are carried out according to the manufacturer’s recommendations.

And in addition, throughout the entire operation, users will have to comply with the requirements regarding permissible temperature and pressure standards.

To repair tanks, you should use only original components, as this will ensure not only the required performance, but also safety of use.

The following article will introduce you to the rules and features of selecting an expansion tank for open-type heating systems, which owners of houses with open heating circuits should read.

So, what is an expansion tank?

The name speaks for itself. The tank is designed to expand. Any coolant filling the heating system expands when heated. And this, in turn, entails an increase in pressure in the system.

Read more about the types and designs of such tanks here - https://kvarremontnik.ru/rasshiritelnyjj-bak-dlya-otopleniya/

How can this be prevented? Using a reservoir of air that has the ability to be easily compressed. It is thanks to this ability of air that there will be no significant pressure surge.

The entire volume of the increased coolant will go into the expansion tank. And in the absence of it, hot water will either pour out of the system, or one of its elements will rupture, depending on the type of heating system.

Read: the consequences of a strong increase in pressure - water hammer.

How to clean the inside of the expansion tank

The expansion tank of the cooling system may become contaminated during operation, not only outside, but also inside. While cleaning the container from the outside is not that difficult, cleaning it from the inside is quite problematic. Contamination can be of various types: sediment, scale, oil, etc., as a result of which even the level of liquid in the vessel may not be visible. To eliminate contamination, first of all, the container must be removed from the car. Depending on the design, the housing may be separated by partitions, which complicates the cleaning process. You can try to remove dirt through the hole in the plug using available tools, for example, wrapping a rag around a wooden stick, sticking it inside and wiping off the dirt.

Sometimes it becomes necessary to clean the expansion tank as a result of its contamination. For these purposes, you can use both available means and materials, and special liquids.

Depending on the type of contamination, citric acid, washing powder, kerosene or white spirit can help. There is another option - a mixture of powder, gasoline and warm water, which is poured into the tank, the holes are closed and left for a day. The container needs to be shaken periodically. Some car enthusiasts pour a little sand into the vessel and clean it by shaking, but it is not always possible to achieve perfect cleanliness. If none of the above helps, they resort to the use of modern chemicals, the variety of which today will satisfy the needs of any car owner.

The expansion tank of the cooling system is a reliable part. However, there are times when problems arise with the container. To avoid having to resort to premature replacement of the tank, it is recommended to periodically check the cap for the functionality of the valves. If the part is in good working order, it will be possible to avoid rupture of the housing from high pressure.

A car's expansion tank is an integral component of the cooling system. Its task is to compensate for the increasing volume of antifreeze or antifreeze at high temperatures and increased pressure in the cooling system. The design features of the cooling system dictate what shape the expansion tank has and what additional functions, in addition to collecting liquid, it has.

Expansion tank device

Tank structure

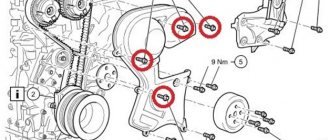

It is made from stamped metal half-forms, which are connected to each other by rolling. There is a neck on the bottom side of the body; it is on its side that the tank is connected to the heating system. On the upper side there is a nipple through which air is pumped into the diaphragm located inside the housing.

A special cover is installed in the upper part of the housing on a bolted connection. It is only necessary in one case, if you need to inspect the tank or replace the diaphragm.

How does the tank work? Expanding water enters the tank through the neck and occupies the space between the walls of the housing and the walls of the inflated diaphragm. The air in the diaphragm is compressed and its size decreases. As soon as the coolant begins to cool, the diaphragm returns to its original volume, squeezing the coolant out of the expansion tank. As you can see, everything is quite simple.

What is this node for?

An element such as the UAZ Patriot expansion tank is a plastic container designed to compensate for the volume of coolant (the indicator may vary based on the temperature of the liquid, so the container is needed for excess antifreeze when it is heated). Thus, the tank is an important component of the cooling system of the power unit.

There are a number of marks on it, thanks to which you can control the amount of liquid in the container and, accordingly, in the system itself. There is a plug on top of the tank through which antifreeze is poured. The plug ensures the tightness of the unit. This eliminates the possibility of coolant leakage.

The design of the expansion tank on the UAZ Patriot requires the presence of three holes . The largest hole is located at the bottom. With its help, antifreeze is distributed throughout the system. Two slightly smaller holes are located at the top of the container. They provide compensation for the fluid while it is heating.

Video review about the expansion tank UAZ Patriot:

Video - How to remove the expansion tank on a VAZ 2110 - 2112

Violation of the tightness of the connection between the tank and the pipes. This kind of malfunction is less common, but it can also happen. This is mainly due to poor selection of the diameter of the rubber pipe. In this case, it is necessary to treat the joints with automotive sealant. To do this, the coolant is drained from the tank and the pipe is disconnected.

Apply a layer of sealant to the inside of the pipe. After this, apply the same layer of sealant to the tube located on the expansion tank. After waiting 5 minutes, the pipe is put on and tightened with a clamp.

Now the sealant needs to dry. This happens within 24 hours and only after that you can add antifreeze or water and operate the car again.

This substance appeared relatively recently. The need to use a sealant arose in connection with the use of antifreeze as a coolant, due to its high fluidity. Automotive sealants are able to withstand fairly wide temperature differences that reach 300 degrees Celsius. Therefore, even if the engine boils, the system will still remain sealed and will be suitable for further use.

Mechanical damage to the expansion tank. Perhaps the most terrible malfunction and most often ends with the replacement of the latter. Rarely does anyone repair an expansion tank, but it can still be done. To do this, you need to have some skill in using a soldering device. It is worth noting that the crack can only be sealed in the upper part of the tank, where there is no access for coolant, but air can enter the system.

To do this, the coolant is drained from the expansion tank, it is removed and freed from the cap. The essence of soldering is to melt two parts to a thick state and stick them together as they dry. To do this, you need to press the two elements against each other and place the tip of a blowtorch between them. As soon as fine melting of the elements occurs, it is necessary to immediately pull the tip back.

In case of severe damage to the tank, such as, for example, its splitting or pieces breaking off, repairing the tank is considered impractical and it must only be replaced.

Reasons for oil getting into the expansion tank

Both fluids - coolant and lubricant - circulate in the car in different systems independently of each other. They perform different functions, so they must be isolated inside the engine. If a problem arises mixing engine oil with antifreeze, the driver must understand that this is only possible if the systems are depressurized.

It happens for the following reasons:

Crack on the expansion tank

- malfunctions of the oil radiator;

- mechanical damage to the cylinder head, heat exchanger gasket;

- destruction of the pipes through which the coolant passes;

- the occurrence of cracks and other defects in the expansion tank;

- the cooling system pump becomes unusable.

In addition to the reasons listed, the use of incorrect refrigerants, namely mixing them, can also cause breakdowns. Each coolant has its own classification. Each of them has different properties and consists of certain ingredients. When additives that are incompatible with each other interact, an uncontrolled chemical reaction may begin, which will cause depressurization of the system. Therefore, before pouring new antifreeze into the car, it is necessary to drain the old fluid.

Please note that the color of the coolant does not in any way characterize the class to which it belongs. This is just a dye added by the manufacturer. So don't try to lump two, say, red coolers together based on their visual similarities.

how to disassemble, how to clean and repair

There is not a single unnecessary detail in the design of the car. Each element performs its function, even such a small part as the expansion tank cap. Most car owners do not even suspect that the cap is used not only to close the tank, but also to stabilize the pressure in it. Therefore, repairing the coolant tank cap seems to be one of those procedures that, if necessary, will have to be done with your own hands.

Repair of expansion tank cap

Without paying due attention to such a seemingly insignificant element as a cover, the driver may face serious engine damage. Few people know, but the expansion tank cap controls the pressure in the cooling system. Special valves inserted into the cavity of the cover relieve excess pressure or release air to increase the volume of antifreeze required for circulation in the system.

Repairing the tank cap includes three stages:

- Disassembly.

- Cleaning.

- Replacement of elements.

Moreover, even a novice driver can complete all stages.

How to disassemble the cover

Repairing the expansion tank cap yourself is the simplest procedure, since the cap has a simple design and does not require special tools for its restoration. All you need is your hands and a screwdriver with a thin flat blade. You need to follow the following algorithm:

- Unscrew the cap from the tank.

- Remove the product and clean it with a dry cloth to remove any drops of coolant.

- A rubber seal is inserted into the cavity of the lid; you need to pry it off with a screwdriver blade and pull it out.

- Then remove the spring that is hidden under the rubber.

- Immediately under the spring you can see a small valve device - pry it up with a screwdriver and pull it out. The second valve is located next to the first one - it also needs to be removed.

This completes the disassembly of the expansion tank cap. All components have been dismantled - you can start cleaning them.