List of recommended lubricants, working fluids and substitutes for UAZ

Lubricants

- motor oil

M-8-V, GOST 10541-78 or M-6z/10-V (DV-ASZp-10V) OST 38.01370-84. Northern automobile oil M4z/6V1 OST 38.01370-84. - transmission oil

TSp-15K GOST 23652-79. Substitute: automotive transmission oil TAP-15V or TAD-17I OST 23652-79. At temperatures below minus 20 °C, automotive transmission oil TSp-10 GOST 23652-79. - Lubricant

"Litol-24" GOST 21150-87, "Lita" TU 38.1011308-90 or "Litol-24RK" (grease SHRUS-4 - an analogue of "Litol" with the addition of molybdenum disulfide and other additives that reduce wear) - Graphite lubricant

USSA GOST 3333-80. - Grease

CIATIM 201 GOST 6267-74, CIATIM-221 GOST 9433-80.

Working fluids

- Coolant

TOSOL-A40M, TOSOL-A65M TU 6-02-751-86 (use in winter OZH-40, OZH-65 GOST 28084-89 is allowed) or “Lena-40”, “Lena-65” TU 113- 12-11.104-88. Water is clean and “soft” (rain, snow, boiled). - Shock absorption fluid

AZh-12T GOST 23008-78. Substitute: spindle oil AU OST 38.01.412-86. - Brake fluid

“Tom” TU 6-01-1276-82, “Rosa” TU 6-55-37-90, “Neva” TU 6-01-1163-78, GTZh-22 TU 6-01787-75 (see . also opinions about different brake fluids) - Electrolyte

with density, gf/cm3: 1.25 – for areas with temperatures up to -10 °C; 1.27 – for areas with temperatures up to -30 °C; 1.29 – for areas with temperatures up to -40 ° C (see also the article “Battery”) - Gasoline

A-76 GOST 2084-77, summer or winter grades.

up

Refueling data for wagon-type vehicles

Name

Car models

* It is possible to install only the main tank ** Including starting heater Engine 417 mod., 4-speed gearbox top

Standards for consumption of fuels and lubricants in road transport Р3112194-0366-97

approved by the Ministry of Transport of the Russian Federation on February 18, 1997. Valid until 01/01/2002) (Only basic figures, only in relation to UAZ vehicles. Full document: local copy from the Avto-Garant website)

Fuel consumption rates

The standards include the fuel consumption required to carry out the transport process. Installed for general purpose vehicles. basic rate in liters per 100 km of vehicle mileage.

Fuel consumption rates increase (including) under the following conditions:

- work in winter: in the southern regions of the country - up to 5%, in the northern regions of the country - up to 15%, in the Far North and areas equivalent to the Far North - up to 20%, in other regions of the country - up to 10% ( the maximum values of winter allowances for almost all regions of central Russia are 10%, valid for 5 months a year);

- work in cities with a population of over 2.5 million people – up to 20%; with a population of 0.5 to 2.5 million people – up to 15%; with a population of up to 0.5 million people – up to 10%;

- when driving the first thousand kilometers with cars that have undergone major repairs and new ones, as well as. when driving such vehicles under their own power – up to 10%;

- for cars that have been in operation for more than 8 years – up to 5%;

- work in difficult road conditions during seasonal thaw, snow or sand drifts, floods and other natural disasters - up to 35%;

UAZ 469

UAZ-469 is a domestic frame SUV, which was created primarily for the needs of the Soviet Army.

As the main army vehicle, it replaced another well-known model - the GAZ-69. It is interesting to read literature about the history of the creation of the UAZ-469: the need for a new, more advanced SUV than the GAZ-69 arose back in the 1950s. By 1960, the first prototypes were created: UAZ-460 and UAZ-469. The latter showed more convincing results in various tests and therefore it was decided to put it into mass production. And this serial production began just 12 years later - in 1972.

Since 1972, the UAZ-469 has been produced almost unchanged up to our times. And only in 2003, the second generation appeared - the UAZ Hunter, which you can also read about on our car portal Vodi.su. It should be noted that outwardly they are practically no different from each other, and the interior of the cabin suggests that this car was created not for a comfortable and safe ride, but for the difficult off-road conditions of Russia.

Specifications

First of all, it must be said that the UAZ-469 and UAZ-3151 are two identical models. It’s just that a new four-digit index began to be used after 1985 with the transition to the industry standard of 1966, which we talked about in the article about the carrying capacity of KAMAZ trucks.

It is clear that over the 40-year history of the UAZ, it has undergone updates and technical modifications several times, but the main characteristics have remained almost unchanged.

Engine

The engine performance of the UAZ-469 was not the best, even for those times. It was a 451M carburetor unit. Its volume was 2.4 liters. Maximum power was 75 horsepower. It ran on A-76 gasoline and could accelerate a 2-ton car to 120 kilometers per hour, and acceleration to hundreds took 39 seconds. And fuel consumption at a speed of 90 km/h reached 16 liters in the combined cycle.

In 1985, when the car was given a new index, it went through some updates.

In particular, the new UMZ-414 engine has become a little more agile and powerful:

- an injection system is installed - an injector;

- volume increased to 2.7 liters;

- power increased to 80 hp, and then to 112 hp;

- maximum speed - 130 km/h.

Transmission and suspension

The UAZ-469 was equipped with a simple mechanical 4-speed gearbox. There were synchronizers in 3rd and 4th gears. The car had full drive - with a rigidly connected front axle. Using a 2-range transfer case, it was possible to control power distribution when all-wheel drive was engaged. The transfer case is rigidly attached to the gearbox without an intermediate driveshaft.

In the civilian version of the car - UAZ-469B - the transfer case had one gear, without final drives in the axles, that is, cross-country ability was worse off-road.

The clutch was also quite simple - a mechanical drive, a lever clutch basket (later replaced with a petal one), a feredo disk, a clutch bearing - in a word, the simplest dry system. However, after modification in 1985, a hydraulic clutch drive appeared, which was quite the right solution for a fairly heavy domestic jeep. (However, the owners had a new problem - purchasing and replacing the master and slave cylinders).

Suspension - dependent. On later versions, as well as on the Hunter, anti-roll bars appeared. Since the MacPherson strut suspension is not suitable for off-road conditions, the UAZ was equipped with spring shock absorbers with trailing arms at the front, and springs and hydropneumatic shock absorbers at the rear.

Parameters and ground clearance

In terms of its size, the UAZ-469 fits into the category of mid-size SUVs:

- length - 4025 mm;

- wheelbase - 2380;

- width - 1805;

- height - 2020 millimeters.

The curb weight of the car was 1670-1770 kilograms, and the fully loaded weight was 2520 kg. The UAZ carried up to 675 kilograms of payload, which is not so much, because it could accommodate 5-7 people (note that the SUV was mainly intended for transporting command personnel, and command personnel were never distinguished by their low body weight).

The ground clearance height of the UAZ-469 reached 30 centimeters, and that of the civilian UAZ-469B - 22 centimeters.

Interior and exterior

The car was not designed for a comfortable stay during the trip, and therefore the interior does not impress with its appearance. Suffice it to say that until 1985 there were no head restraints on either the front or rear seats. The front panel is metal. The instruments are located along the panel, so you had to turn your head to read the readings. The speedometer is located almost under the steering wheel.

There are no glove compartments on the passenger side, except that a first aid kit could be installed under the front panel. The metal handle on the dashboard helped to stay in the seat on steep uneven roads.

The back row of seats was a solid bench with a backrest; 3 passengers could fit on it. It was also possible to install an additional row of seats in the luggage compartment. The rear seats were sometimes removed completely to increase interior space and carry cargo.

Installation of the GAZ V8 4.7 engine on a UAZ

January 9, 2020 Article

How to install a Gazovskaya "eight" on a UAZ.

I initially posted this report on the UAZbook website, and then, having slightly modified it and supplemented it with some photographs, I decided to post it on my website.

So…

Having read in one of the issues of the magazine “ 4x4 ” an article about the UAZ “Gennadich” (I don’t remember, however, which issue, January or February for 2004, I can’t say for sure), which has a 4.7-liter injection Gazovskaya eight, I was eager to install V8 for your UAZ (31519, military bridges, iron roof, engine was a 100 UMZ-421).

Before this, I re-read on the UAZBUK forum everything that was available at that time about the installation of these engines on UAZs (many thanks to Oleg “Gennadich” Poisyev, Mikhail “Mikbo” Borisov for consultations and detailed descriptions on the UAZBUK of the V8 ).

It took a long time to realize my plan, I looked at a bunch of used GAZ-53 engines - I didn’t like any of them, the condition of each of them was extremely disgusting, but there was only one thing attractive about these engines - the relatively low price. The devil knows who used these used engines before and how they used them and what kind of “rakes” and all kinds of “troubles” might come out in the near and distant future. As a result, the decision was made to purchase a new one. But this process dragged on for a long time due to lack of financial resources.

Finally, having acquired enough money, I bought from scratch a ZMZ-523 engine , 4.7 liter, carburetor, installed on GAZ trucks and PAZ buses.

hero of the report.

Before installing the new engine, I stretched it all out, checked the gaps in the valves (half of the valves were “pinched”), the gaps between the electrodes of the spark plugs (the same picture), the ignition timing setting (the norm), and the level in the carburetor float chamber (it turned out to be more than necessary) .

I drilled holes in the ZMZ-523 clutch housing for the UAZ gearbox. At the same time, he did it very simply - he removed the bells from the old and new engines and took them to the Almaty Experimental Car Repair Plant. At this plant, a cool guy named Alexander used a coordinate machine to drill new holes in the V8 , taking dimensions from the old one - it turned out very accurately, with a tolerance of a few hundredths of a millimeter. Then I cut the threads for the studs myself using M12 taps, Nos. 1 and 2, with a thread pitch of 1.75. I didn’t make any amplifiers or the like in the places where the studs were attached to the new bell - this may of course seem strange, but my intuition suggested that everything would be fine.

New holes for the UAZ box.

Studs for UAZ gearbox.

Then, I dismantled the entire “face” of my UAZ. Since after installing the V8 it was decided to put FBel-160M tires , I immediately (as they say “so as not to get up twice”) raised the body above the frame using rubber bands from the suspension of Zhiguli-08, -09 models (the lift turned out to be 6 and a penny centimeters ) - but later, I stopped liking this design and I replaced these rubber bands with barrels made of duralumin 7 centimeters high and 6 centimeters in diameter, and also stuck additional UAZ root sheets and earrings from Gazelle into the springs, and trimmed the edge of the arches a little more. It turned out to be a kind of “combined elevator”.

Then he removed the radiator and pulled out the old “heart” of the UAZ, complete with gearbox and transfer case. First, I removed all the levers from the box and transfer case so that they would not interfere during dismantling.

While the factory was working on the clutch cover, I installed disc brakes on the front axle from Pavel Grekov from Moskovskaya, which had been lying with me for a long time and were waiting for their installation on the bridge (if anyone is interested, the company’s contact phone number is 8-926-228-28-70, In addition to disc brakes for military axles, this company does a lot of other interesting things for UAZs).

The caliper is from Sobol, the brake disc is from UAZ-3160, the caliper bracket, extended studs and a spacer for the brake disc are original ExtremeAuto parts.

Then I cut the front engine mounts out of their places. To do this, using a grinder cutting disc, carefully, so as not to saw through the frame, I cut the welding seams of the supports, carefully loosened them with a sledgehammer left and right, and they safely left their factory places.

Then I mated the new engine to the gearbox. It has already been written many times before that the input shafts of the UAZ and GAZ gearboxes are the same in all sizes, so there were no problems when joining the units.

Fitting the transfer case to the engine.

Assembly of a single power unit.

After joining, I removed the original front cast-iron supports from the V8 and made new ones from a 50x50 mm corner (I picked up the general concept from Mikhail “Mikbo” Borisov).

New engine mounts - front view...

...and from the side. Next, having aligned the engine assembly with the gearbox and transfer case on the car along the rear supports (which are between the box and the transfer case), “tying” them to the corresponding “original” supports on the frame, I noted the places on the engine partition of the body where the cylinder heads rested and, in the future, the exhaust pipes of the exhaust system will rest. Afterwards, I carefully (well, not quite carefully) cut out these places with gas and made recesses for the abutting parts of the engine, and the latter, after welding the supports, took its place.

First fitting of the “new heart”.

The engine took its place.

After installing the engine, it became obvious that the steering gearbox needed to be moved forward about 12 centimeters, since the new left engine mount had “removed” it from its rightful place.

I had to work hard with the placement of the steering gear. (Loaves rule again) When trying to push it into a new place, it (the gearbox) slightly rested its front part against the first cross member of the frame. In addition, when trying to “fit” the gearbox at the factory angle relative to the frame, its splined shaft was placed exactly opposite the left exhaust manifold and, naturally, did not want to connect with the steering column shaft in any way. Following the advice and example of “Gennadich”, the lower part of the gearbox was turned at a greater angle to the right side, as a result of which the shaft turned to the left, coming out from under the exhaust manifold, which made it possible to easily “connect” the steering mechanism shaft with the steering column shaft using a short splined shaft made to order at the same Almaty Experimental Car Repair Plant. To attach the steering gearbox to the frame, a special platform was made and welded. I grabbed the steering column with an additional bracket...to hold it more securely.

In the near future I plan to “match” the power steering from the GAZ-66 to the native UAZ steering system. New location of the steering gearbox (red dots indicate the old mounting locations of the gearbox).

washout

When installing the clutch slave cylinder, it was necessary to plug its standard side hole for the hose, because, as Mikbo predicted, the slave cylinder, taking its place, ended up so close to the frame side member that it was impossible to screw the hose into it. As a result, the hose was screwed into a specially widened hole in the end cover of the working cylinder.

Then he re-intertwined the original wiring harnesses under the hood, moving some of the wires from side to side. Namely, the starter wires from the left (in the direction of travel) side to the right, and the wires of the oil pressure sensor and the oil pressure warning lamp sensor from the right to the left. I connected the throttle and air damper control cables, mounted the generator and did other related little things like installing drive belts, pulleys and connecting the fuel line - here everything went without problems or hiccups.

I struggled for a long time with the choice of radiator - the old one seemed insufficient, and the standard one from the truck was very large and did not want to fit into the space between the engine and the “TV” in absolutely all dimensions. I even thought about picking up some kind of radiator from a foreign car, but then I decided not to bother and, at my own peril and risk, left the old, three-row one from UAZ, paired with a powerful electric fan from Volga, reassuring myself with the thought that practice would show the correctness of the choice solutions and, if anything, the cooling system can be redone at any time.

To install a radiator with a fan, it was necessary to shred the inside of the “TV” and invent a new mounting system for both the radiator and the electric fan. A tube with a socket for the fan switch sensor was cut into the upper radiator pipe, and a tube with a fitting for draining coolant from the interior heating stove was cut into the lower pipe.

After all this, I decided to radically change the fan circuit - I plugged in two VAZ fans - subjectively they blow stronger than one from Volgov and cover the entire radiator.

Toward the end of the engine installation, I tinkered with making a new exhaust system tract. At the same time, at first I wanted to divide the exhaust from start to finish into two branches, but then I decided to combine it into one. In principle, there was nothing complicated and the entire process of constructing the exhaust tract can be described in three words - fitting pipes in place, cutting pipes at the required angles, welding them. After assembling the exhaust tract, I insulated all hydraulic lines and electrical wiring harnesses that run in close proximity to the exhaust manifolds and exhaust pipes. I insulated it in the following way: I cut the fuel rubber hoses purchased for this occasion, put them on the lines and bundles, and wound aluminum foil tape over the hoses.

Having replaced the “face” with wings, I discovered that the oil filter housing did not allow the hood to close. Just a couple of centimeters!.. I didn’t dare bother with altering the oil filter - I just cut a neat hole in the hood and attached a square-shaped cap - it turned out beautiful, stylish and in keeping with the theme.

Having finished the above mentioned task, he walked around the car on all sides, filled it with coolant and Liqui Moly engine oil and, standing still, praying to all the known and unknown gods, turned the ignition key...

The engine, after a couple of unclear flashes in the cylinders, came to life and spoke with a low guttural sound, similar to the one with which the GAZ-66 announces itself. Test runs did not reveal any noticeable problems in the design. After painting and registration of alterations in the traffic police, a long, hopefully, operation will begin, during which I will check the correctness or error of the work carried out.

In conclusion, I would like to note that in no case do I claim exclusivity, originality or ideality of the solutions that I applied during the installation of the GAZ engine on my UAZ. Therefore, I will be happy to listen to sensible comments and suggestions from competent colleagues on this topic. Write to “soap” - vlood77dogmail.ru. True, this report did not include a number of photographs - I undertake to upload them to the site later. I hope that my report will be useful to all those who are thinking of sticking a V8 under the hood of a UAZ. Good luck!!!

Dzhipstroy, based on materials:

Almaty, Kazakhstan, August 2006 – February 2007. www.vlood77

Dzhipstroy

Specifications

The UAZ 469 vehicles were equipped with a 451MI engine, which was in many ways similar to the Volgovsky ZMZ 402. The UAZ 469 engine replaced the outdated GAZ-69 as a modernized vehicle. During development, many design features were taken from the GAZ-21 and GAZ-24.

In parallel with this, a civilian version of the car was produced with the marking 469B, which was renamed in 1985 and received the marking UAZ 31512.

Let's consider the main technical characteristics of the UAZ 469 engine, as well as the device:

UAZ-451MI

UAZ-4178

ZMZ-4021.10

Modifications

UAZ-315196

- UAZ-469 - military version with a two-stage final drive, final drives and ground clearance of 300 mm, after modernization in 1985 it received the index UAZ-3151

- UAZ-469B

- the main, “civilian” version with a single-stage main gear (there are no final drives in the bridges) (clearance = 220 mm), after modernization in 1985 it received the index - UAZ-31512 (with a metal top - UAZ-31514 and with 2, 89-liter engine UMZ-4218 - UAZ-31519) - UAZ-469BI - version 469B with shielded electrical equipment (for example, for R-403M - radio relay transceiver VHF radio station)

- UAZ-469BG - medical, equipped with seats for medical staff and stretchers, after modernization in 1985 it received the index UAZ-3152

- UAZ-469РХ - radiation-chemical reconnaissance vehicle

Non-serial

- UAZ-3907 “Jaguar” is an amphibious vehicle based on the UAZ-469. The amphibian has two propellers installed in front of the rear axle.

- UAZ-Martorelli is a variant of the UAZ-469B, exported to Italy, where the car was significantly modified. There were several modifications: with the “native” gasoline engine UMZ-451M (2500 cm3, 75 hp) it was called UAZ-Explorer

, - with Peugeot XD2 diesel (2500 cm3, 76 hp) - UAZ-Marathon

, - with a turbodiesel from Vittorio Martorelli VM (2400 cm3, 100 hp) - UAZ-Dakar

, - with a FIAT gasoline engine (2000 cm3, 112 hp) - UAZ-Racing

.

Service

Maintenance of the power unit on the UAZ 469 is carried out according to the standard scheme. Thus, the service interval is 15,000 km before the first major overhaul. After restoring the engine, it is recommended to carry out maintenance every 10-12 thousand km in order to preserve the life of the engine.

During maintenance, the engine oil and oil filter are changed. So, mostly car enthusiasts like to pour mineral or cheap semi-synthetic oil into the engine. Moreover, if you take mineral water, then it is not of the best quality that ends up in the power unit.

Every second for a UAZ engine is a comprehensive replacement of consumables. In it, the vehicle owner must perform the following technical work:

- Change oil and filter element.

- Replacing the fuel filter.

- Cleaning the carburetor.

- Replacing the air filter element.

- Checking the spark plugs.

- Adjusting the valve mechanism.

- Checking gaskets for breakdown.

Review of faults and methods for repairing them

Thanks to the grooves in the pistons, the UMZ 421 engine does not bend the valve with its pistons. Its individual faults are considered:

| Oil consumption | maximum 0.3 l/1000 km |

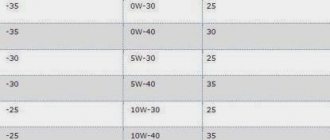

| What kind of oil to pour into the engine by viscosity | 15W40, 5W40, 10W30, 10W40, 20W40 |

| Which engine oil is best by manufacturer | Liqui Moly, LukOil, Rosneft |

| Oil for UMZ 421 by composition | synthetic in winter, semi-synthetic in summer |

| Engine oil volume | 6 l |

| Operating temperature | 90° |

| ICE resource | stated 250,000 km |

| Adjustment of valves | nuts |

| Cooling system | forced, antifreeze |

| Coolant volume | 10.7 l |

| water pump | with plastic impeller |

| Spark plugs for UMZ 421 | Czech Brisk DR17YC/A |

| Spark plug gap | 0.8 mm |

| Timing drive | gear |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | removable with non-return valve full-turn |

| Flywheel | with clutch landing diameter 200 mm or 215 mm |

| Flywheel mounting bolts | M12x1.25 mm, length 26 mm |

| Compression | from 10 bar, difference in adjacent cylinders maximum 1 bar |

| XX speed | 800 min-1 |

| Tightening force of threaded connections | spark plug – 60 Nm |

| Coolant getting into the cylinders and lubricant | irreparable defect, present only in the first batches of motors |

| Jumps in idle speed and power | Regular adjustment of valve clearances is required |

| Knocking sound in crankshaft bearings | replacement of worn-out liners |

The problems with the thermostat have disappeared, since the three-way version from Volga is used here. The viscous coupling, designed to regulate the speed of rotation of the impeller, often fails.

Repair of UMZ 421

Tuning

Tuning the UAZ 469 engine with a volume of 2.5 liters is carried out by analogy with the engine produced by ZMZ 402. Since the designs are similar, tuning the power unit is quite simple.

To increase power characteristics, it is necessary to bore the cylinder block to dimensions of 95 mm. In this case, lightweight pistons and a crankshaft are installed in the engine. To ensure maximum effect, it is recommended to change the cylinder head to an injection one and, accordingly, install an electronic fuel injection system.

Do not forget that lightweight valves and guide bushings should be installed in the new cylinder head. All this will make the engine lighter by several tens of kilograms.

To prevent the power unit from overheating during operation, a cooling system kit is installed, which includes a sports pump and silicone pipes for the engine cooling system.

Instead of the original copper radiator, you need to mount a lightweight three-row aluminum one. Also, you will have to change the high-voltage wires and the ignition system. A separate item is the installation of a new clutch kit, as well as changing the ignition box.

Example of engine tuning

Tuning engines installed on UAZ vehicles is not so easy to do. Any interference with the motor may result in a decrease in traction force. And the models of many engines are outdated, so too many innovations and changes can play a cruel joke on them.

It is possible, of course, to modernize some mechanisms and systems. Changes to the piston group must be carried out with caution, following the instructions. The piston rings are replaced with forged ones, which are of higher quality and stronger. A well-known company produces just such rings. If desired, you can install other parts, but the work will require a professional approach and the appropriate tools.

The crankshaft is being balanced

You can balance the crankshaft of a UAZ 31514 car at home only with a flywheel. By installing the crankshaft on one of the ribs of the T-shaped plates, the heaviest point is determined. The crankshaft will roll along the plates until it stops with the heaviest point down. From this point you will need to remove a small layer of metal, periodically checking the result.

The timing belt has a number of features, so it is better for non-specialists not to change its design. Moreover, the camshaft is tuned only for sporting purposes. If something goes wrong, engine performance will only worsen.

The intake and exhaust manifolds on the UAZ 31514 are tuned by many car owners. The primary task is to eliminate the step between the windows and the collectors. The holes often don't line up.

Serrations inside the commutator bore can be removed by rough machining or more thorough polishing. This modification will improve engine performance in terms of uniform filling of the cylinders and improve its performance.

Technical characteristics of the UAZ 469 car

Popular to this day, the domestic jeep

The UAZ 469 all-terrain vehicle, which appeared in our country in the early 70s of the twentieth century, remained for a long time the best domestic SUV. Thanks to its high reliability, maintainability in field conditions and low price, this unpretentious hard worker still remains the standard all-wheel drive vehicle for many.

Indeed, what other car can you fill with a cloudy brownish liquid called A-72 gasoline, used motor oil and castor oil instead of brake fluid, and then drive our entire great country from end to end without ruining the engine and brake system. The technical characteristics of the UAZ 469 are unique; they allow this SUV to be used in conditions that would kill any other vehicle.

The “goat” also has disadvantages, in particular, a tarpaulin awning instead of a normal roof and a weak stove, which make your teeth chatter when traveling in the winter season. But they are more than compensated by the awareness of the fact that along the way you won’t get stuck in a snowdrift and freeze your limbs.

General characteristics of engines

The main suppliers of engines for UAZs were the Ulyanovsk Motor Plant and the Zavolzhsky Motor Plant. UMZ has become famous for being practically the only Russian manufacturer of engines for off-road vehicles. All modern engines produced from the plant’s assembly line meet Euro-4 standards.

ZMZ produces more than 80 different modifications of engines ranging from 2.2 to 4.6 liters. The units of this plant are installed on both small SUVs and buses of domestic and foreign companies.

There are other types of engines that are installed on UAZ 31514 vehicles:

- UMZ 4218.10 volume 2.8 l (petrol);

- ZMZ 410.10 volume 2.9 l (petrol);

- UMZ 420 with a volume of 2.4 liters (petrol);

- ZMZ 514 with a volume of 2.2 l (diesel);

- Andoria 4CT90 2.4 l (diesel).

The Andoria engine, installed on UAZ 31514, Iveco and UAZ Patriot vehicles, is produced not in Russia, but in Poland. These engines are in demand not only at the Ulyanovsk Automobile Plant. They are also installed on other Russian-made vehicles.

Basic engine UMZ 421.10 for UAZ

The base UMZ 421.10 engine with a carburetor system, having a volume of 2.9 liters, runs on gasoline. Has a gas release system. Can operate at temperatures from -50 to +50 degrees Celsius. A modification of this motor was unit 4218.10.

The main difference between the UMZ 4218.10 is the gas exhaust system, which is not configured. This simplifies the installation of the engine on UAZ vehicles, even with a carriage-type body. Currently, motors of this series have several modifications.

Basic characteristics of the body and engine

Brief description of the UAZ 469 (469B):

- body - steel, open;

- type - frame convertible station wagon;

- number of places - 7;

- number of doors - 5;

- length - 4025 mm;

- width - 1805 (1785) mm;

- height - 2050 (2015) mm;

- base - 2380 mm;

- ground clearance - 300 (220) mm;

- weight without load - 1600 (1540) kg;

- weight with full load - 2400 (2280) kg;

- fuel tank volume - 78 liters;

- maximum speed - 90 (120) km/h;

- ford depth - 0.7 m;

- maximum climbable height with driver and 1 passenger - 57°;

- the maximum climbable height at full load is 31°.

Since the start of production, the UMZ 414 engine has been installed on the civilian modification of the SUV.

Military models were equipped with the same power unit, but with a pre-heater, so the motor has a different index - UMZ 41416.

- type - gasoline, atmospheric, 4-stroke;

- number of cylinders - 4;

- arrangement - in-line, vertical;

- operating order - 1-2-4-3;

- cylinder diameter - 92 mm;

- piston stroke - 92 mm;

- engine displacement - 2.5 l;

- compression ratio - 6.7;

- power - 75 l. With.;

- maximum torque - 167 Nm;

- average gasoline consumption on the highway is 10.75 liters per 100 km;

- maximum gasoline consumption off-road is 17.25 liters per 100 km;

- weight of the UMZ 414 engine with attachments and clutch, but without fluids - 163 kg;

- weight of UMZ 41416 with canopies and clutch, but without fluids - 165 kg;

- coolant volume (coolant) - 13 l;

- operating coolant temperature - 80-90°C;

- engine oil volume in the cylinder block - 5.8 l;

- normal oil pressure at idle is 0.5-0.8 kg/cm³;

- normal oil pressure at speed is 2-5 kg/cm³.

Under the hood of the 469 model

Changing the oil in the UAZ gearbox

Changing the oil SEQUENCE OF OPERATIONS Drain the oil from the gearbox immediately after the trip, before it cools down. We recommend combining this operation with changing the oil in the transfer case.

We install the car on an inspection ditch or a lift.

Using a 12mm hex wrench, unscrew the drain plug, placing a container with a volume of at least 2 liters.

Drain the oil.

If the used oil is dark in color* or there are visible metal particles in it, wash the gearbox by tightening the plug, clearing its magnet of steel shavings. Then…

... use a 12mm hex key to unscrew the filler plug (for clarity, the front driveshaft has been removed).

Using an oil syringe, pour approximately one liter of a mixture of transmission or engine oil (70–80%) with kerosene or diesel fuel (20–30%) into the box and tighten the filler plug.

Having engaged first gear, start the engine for 2-3 minutes. Completely drain the flushing oil (draining time is at least 5 minutes). Clean the drain plug again and tighten it.

Using an oil syringe, fill the gearbox with fresh transmission oil in a volume of 1 liter (1.3 liters for a five-speed gearbox). We wrap the filler plug.

Where and how much is literally a rhetorical question for Patriot owners when it comes to refueling gasoline or DDT, oil and brake fluid. The first thing that attracts attention in the design of the UAZ Patriot from refueling tanks is the presence of 2 gasoline tanks, which not every car can boast of, even in the same class as the Patriot itself.

In addition to the gas tank, there is a whole list of containers and hydraulic systems (for example, the cooling system) that need to be refilled. Let's try to figure out why, how much and where, and also whether there are differences between the manufacturer's recommendations and reality.

- Gas tanks (refueling containers) of the UAZ Patriot are theoretically equivalent in volume

. But in fact, they manage to pour up to 39 liters into the right tank, instead of 36 liters for which the tank is designed. The myths about the volume of 87 liters for both tanks have not been confirmed on the forums, although sometimes the testimony of owners of Patriots of different years of production fluctuates up to 40-44 liters. In any case, you should listen to the manufacturer’s recommendations and not try to shove a gun that falls out of the tank at a gas station.

- The cooling system also has loading standards - 12 liters

. For radiators with horizontal pipes, this parameter will be 2 liters more.

- The optimal oil volume in the transmission of a 5-speed UAZ Patriot gearbox is 2.5 liters

. Dear patriotic owners, you should not focus on the very edges of the filler plug. There is no need for excess transmission oil either, so pour oil slightly below this level, because the main drive gears for the UAZ Patriot “redBTR” (main pair) should not “sink”, but only “dip”.

- Many have already discovered through experience that the front and rear axles of the UAZ need to be filled equally

, without bothering with the difference in volume. Theoretically, 1.4 liters are poured into the rear axle, and 1.5 liters into the front axle.

- The normal volume of oil in shock absorbers is 0.32 liters

and it must be maintained at the proper level by regularly topping it up. We remind you that the volume may vary depending on the modification of the shock absorbers themselves. - There are also differences in volumes when filling the power steering

. UAZ Patriot refueling tanks vary from 1.1 l (for model 31631 - 1.3 l).

- For the steering mechanism, 0.25 liters of brake fluid

or a special composition for hydraulic systems is sufficient, for brakes - 0.6 liters.

- 0.18 liters of brake fluid must be poured into the drive of any clutch

, pumping to remove air, and the filling tank of the UAZ Patriot must be filled at all times.

- The cover of the expansion tank of the UAZ Patriot SWAG of the UAZ Patriot windows “hides” 5 liters of special equipment

. . The impressive volume cannot be ignored in harsh operating conditions, in which the Patra must feel like a fish in water, and the driver needs a good view without mud interference.

In principle, these are the main refueling tanks for the UAZ Patriot. There is no need for special measuring containers; it is only important to follow the min/max markings of the containers and not bring the level of liquids to the limit values. There is also a list of recommendations for brands of oils and other liquids. If you have your own observations and comments on this issue, we will be glad to see notes from the logbooks in the comments to the article.

According to the requirements of the factory operating instructions, the cooling system of UAZ vehicles must use all-season coolant of the brands OZH-40 and OZH-65 “Lena”, TOSOL A-40M, TOSOL A-65M, or OZH-40 and OZH-65 TOSOL-TS .

It is, of course, necessary to follow the requirements of the manufacturer, but in modern realities, when the choice of various antifreezes and antifreezes on store shelves is quite large, if you wish, you can always choose a more technologically advanced and advanced coolant for your car’s cooling system.

Specialized stores sell ready-to-use coolants with the names Antifreeze and Antifreeze. All of them, with very rare exceptions, are suitable for use in UAZ vehicles. Despite the different names, Antifreeze is usually the same Antifreeze, only with slightly better performance characteristics. They will be discussed in more detail below.

Filling volume of the cooling system of UAZ vehicles.

- UAZ Patriot, UAZ Pickup and UAZ Cargo with the ZMZ-409 engine - 12.0 liters. - UAZ Patriot, UAZ Pickup and UAZ Cargo with a ZMZ-409, ZMZ-51432 CRS engine and a radiator with horizontal pipes, as well as with an Iveco F1A engine - 14.0 liters. — UAZ Hunter models UAZ-315195 and UAZ-315148 — 12.5 liters. — UAZ Hunter model UAZ-315143 — 16 liters. — UAZ-3153, UAZ-31519, UAZ-315194 — 11.5 liters. — Van UAZ-374195 and truck with a double cabin and a wooden cargo platform UAZ-330395 — 12.7 liters. — Sanitary vehicles and UAZ-396255, UAZ-390995 Farmer and bus UAZ-220695 — 13.7 liters. — A truck with an extended wheelbase UAZ-330365 and a utility vehicle with an extended wheelbase UAZ-390945 — 13.6 liters.

Coolant replacement interval in the cooling system of UAZ vehicles, reuse of antifreeze or antifreeze drained from the system.

According to the service book data for 2020, the manufacturer recommends completely replacing the coolant every 60,000 kilometers or after 4 years, whichever comes first. In fact, the replacement interval should be calculated taking into account the performance properties of the filled antifreeze or antifreeze. If the vehicle is operated under difficult conditions, it is recommended to shorten the coolant replacement interval in the cooling system of UAZ vehicles. The plant considers the following to be difficult conditions:

- towing, - mostly short trips of 4-5 kilometers or long distance trips at low speed, - constant use in large cities, - constant use in areas where the air temperature often falls outside the range of minus 15 to plus 30 degrees Celsius - frequent use on dirty and dusty roads, as well as roads on which chemical reagents are used to treat the road surface.

In addition, the need to replace the coolant occurs if:

— Its service life has reached or exceeded the time specified by the manufacturer. — There were leaks or coolant, after which water or liquid from another manufacturer was added to the cooling system. — When the color or shade of the coolant changes, which is the first sign of loss of performance of the additives. — When other liquids enter the coolant, for example from the engine lubrication system.

When repairing an engine or cooling system, when the coolant is drained, its reuse is permitted if a clean funnel and container are used for draining and storage. Before reuse, it is advisable to filter the coolant.

Antifreeze - types and composition.

The term "Antifreeze" originated abroad. It was used to refer to a concentrate that was added to water in a car's engine cooling system. However, this term then took into account only the cold-protective role of this product, assuming that its use was a seasonal need.

Now the name Antifreeze implies not only the cold-protective properties of the product, but also reflects its function as a heat exchange medium designed to protect the engine cooling system from corrosion and damage in all operating conditions all year round.

Automotive antifreezes usually consist of ethylene glycol, less often - propylene glycol, which, unlike ethylene glycol, is not toxic, but is much more expensive, water and additives. Ethylene glycol is poisonous and can enter the human body through the skin. It is most dangerous if you drink it.

The ethylene glycol solution is quite aggressive to the materials of the parts - steel, cast iron, aluminum, copper, brass, solder. Therefore, a complex of additives is added to antifreeze, giving it anti-corrosion, anti-cavitation and anti-foam properties. Ethylene glycol, in addition to lowering the freezing point, leads to an increase in the boiling point of the coolant, which is an additional advantage when operating cars in the warm season.

Dyes are also added to antifreezes, giving them one color or another, which has nothing to do with its performance properties. Color is mainly necessary to distinguish one fluid from another, determine the level of coolant in the expansion tank, and also to distinguish smudges of coolant from smudges of other operating fluids.

Currently, antifreezes, based on the composition of functional additives, are conventionally divided into four types: carboxylate (OAT), hybrid (Hybrid), lobrid (Lobrid) and traditional (Traditional). Carboxylate antifreezes G-12, G-12+ contain corrosion inhibitors based on organic (carboxylic) acids and have the longest service life - more than 5 years.

G-11 hybrid antifreezes contain, in addition to organic (carboxylate) inhibitors, also inorganic inhibitors - silicates, nitrites or phosphates. Service life 3-5 years. Lobride antifreeze G-12++, G-13 is a relatively new type of coolant in which an organic base is combined with a small amount of mineral inhibitors.

Traditional antifreezes contain inorganic substances as corrosion inhibitors - silicates, phosphates, borates, nitrites, amines, nitrates and their combinations. Antifreezes of this type are already considered obsolete due to their short service life of about 2 years and their inability to withstand high temperatures of more than 105 degrees for a long time. Antifreeze and its numerous modifications precisely belong to the traditional type of antifreeze

.

Antifreeze standards.

There are no uniform standards for antifreeze, but there are the most recognized ones. For example, American - ASTM D 3306, D 4340, D 4985 and SAE J1034, English - BS 6580, B55117, Japanese - JIS K 2234, French - AFNOR NF R 15-601, and German - FVV HEFT R 443.

As with motor oils, some automakers may specify their own tolerances for antifreeze. For example, for Audi, Seat, Skoda and VW this is TL 774D (G12), F (G12+), for Mercedes-Benz - 325.3, for Renault and Ford - WSS-M97B44-D.

Antifreeze - types and composition.

TOSOL is the name of an automobile coolant developed in 1971 for VAZ cars to replace the Italian “PARAFLU” by specialists from GosNIIOKhTa - State Research Institute of Organic Chemistry and Technology. The first three letters of the abbreviation TOSOL indicate the department of organic synthesis technology, and the letters OL are added to form a word similar to the name of alcohols - ethanol, butanol, methanol. According to another version, “OL” is an abbreviation for the Separate Laboratory that developed antifreeze.

The TOSOL trademark has not been registered, so it is widely used by all coolant manufacturers. The performance properties of these liquids may vary and depend on their composition. Antifreeze, like antifreeze, is a solution of ethylene glycol, water and various additives.

TOSOL A-40M consists of 44% water and 56% ethylene glycol, and provides a boiling point at normal atmospheric pressure of at least 108 degrees. It is recommended to use it in areas with an ambient temperature of at least minus 40 degrees. TOSOL A-65M consists of 35% water and 65% ethylene glycol, and boils at normal atmospheric pressure at a temperature of at least 110 degrees. It is recommended for use in the Far North and similar areas.

Externally, standard TOSOL A-40M is most often a blue liquid, and TOSOL A-65M is red. A change in the color of antifreeze during operation indicates a loss of its performance properties. In particular, the development of corrosion inhibitors, and the need for replacement. For example, blue TOSOL A-40M, as it ages, first becomes blue-green, then green, then yellow and may completely discolor.

The rate of aging and color change of antifreeze depends on the operating temperature of the coolant. In particular, when the engine operates with constant overheating, about 100-105 degrees and above, the antifreeze may turn yellow and lose its qualities after several hundred hours of engine operation.

Aged antifreeze, due to the development of additives, can cause the formation of a thick layer of scale in the system. This can lead to deformation of parts, local and excessive thermal expansion, and corrosion of aluminum blocks and cylinder heads.

Features of transmission, chassis and control systems

The unique characteristics of the UAZ 469 are largely due to the successful design of the transmission. This vehicle system consists of a dry single-plate clutch, a gearbox, a transfer case, a rear drive axle, a front axle, and wheel drives for an army modification of an SUV.

Technical characteristics of the gearbox:

- type - 4-speed, manual;

- synchronizers - in 3rd and 4th gears.

- 1st gear - 4.12;

- 2nd gear - 2.64;

- 3rd gear - 1.58;

- 4th gear - 1.00;

- reverse gear - 5.22;

- gearbox weight without lubrication - 33.5 kg;

- The volume of oil in the gearbox is 1 liter.

Transfer case specifications: 2-speed, manual.

- direct transmission - 1.00;

- low gear - 1.94;

- power take-off - up to 40%;

- weight with hand brake, without lubrication - 37.4 kg;

- the volume of oil poured is 0.7 l.

Cardan transmission - 2-shaft, open.

- front - 2-hinge, combined;

- front shaft weight - 6.9 kg;

- rear - 2-hinged, tubular;

- rear shaft weight - 8.25 kg.

- type - detachable, with gearboxes on all wheels;

- gear ratio - 5.38;

- final drive ratio - 2.77;

- gear ratio of wheel gearboxes - 1.94;

- front axle weight - 140 kg;

- rear axle weight - 121.5 kg;

- the volume of oil poured into each bridge is 1 l;

- the volume of oil poured into each wheel gearbox is 0.3 liters.

- type - detachable;

- final drive ratio - 5.13;

- front axle weight - 120 kg;

- rear axle weight - 100 kg;

- the volume of oil poured into each bridge is 0.85 l.

UAZ-3151

In 1985, the car was modernized, the geared version, according to the new classification, received the index 3151. The cars appeared:

- Hydraulic clutch release;

- Cardan shafts with radial-face seal bearings;

- New lighting devices (two-section sidelights, three-section rear lights FP-132, side repeaters);

- Electric windshield washer;

- Suspended clutch and brake pedals;

- High-reliability drive axles with a changed gear ratio of the main pair and wheel gearboxes;

- Brake system with dual-circuit drive and signaling device;

- Split safety steering column;

- More efficient and reliable heater;

- Some cars have a fully synchronized 4-speed gearbox, a vacuum brake booster;

- The power of the UMZ-417 engine has been increased to 80 hp. With.;

- The maximum speed of the car increased to 120 km/h.

Specifications

The UAZ, originally designed for the needs of the army, showed excellent results and capabilities in tests. The UAZ-469, whose technical characteristics were superior to its analogues, amazed customers. The engine produced 75 hp. With. with a volume of 2.5 liters. The relatively low power paid off with low revs, which gave the desired advantage off-road. Later, the engine became 5 “horses” more powerful, which allowed it to accelerate to 115 km/h.

The carrying capacity of the UAZ is 675 kg with a total weight of 2450 kg. Easily pulls a trailer with a load of up to 850 kg. External variety is provided by a soft canvas version, hard inserts or a completely metal body in later modifications of the UAZ-469. Technical characteristics were strengthened year after year.

In 1993, the SUV underwent some changes and received new designations. The military version became known as UAZ-3151, and the civilian version - UAZ-31512. In 2010, the car received its name: the proud name Hunter and a new gloss.

As for technical equipment, the UAZ-469 is a masterpiece of Ulyanovsk engineers. A special feature of the braking system was a two-chamber master cylinder, dividing it into two working components for each axle separately. The clutch to the 4-speed gearbox was made via a hydraulic drive. The steering featured a split column. During the modernization process, carburetors were changed. The last option in 1985 was the K-131, which replaced the K-129V.

Story

The UAZ-469 was designed for transporting people, cargo and light car trailers on all types of roads. Development of the car began in the 1950s; in 1958, the first prototype, called the UAZ-460, was built. The car looks like an American Jeep - a tough, utilitarian SUV, but not very comfortable. It is interesting that already in 1965, images of the UAZ-469 could be found in the Soviet press, but the car was still far from being put into production.

The first UAZ-469 rolled off the assembly line of the Ulyanovsk Automobile Plant on December 15, 1972. They replaced the GAZ-69. The Volga GAZ-21, well known to the mechanics of those years and known for its reliability and structural safety margin, was largely used as an aggregate base.

Under the designation UAZ-469, the car was produced until 1985, after which, in accordance with the 1966 industry system, it received the four-digit number 3151 (the UAZ-469B car received the number 31512).

In August 1974, three completely standard (without winches and traction chains) UAZ-469 vehicles reached a glacier on Mount Elbrus at an altitude of 4200 meters during a test run.

In February 2010, the Ulyanovsk Automobile Plant announced the resumption of production in a limited batch of a model called UAZ-469 (index UAZ-315196

). Changes have been made to the design to increase comfort (spring front suspension, front disc brakes, power steering (complete with metal roof), ZMZ-4091 112 hp engine), however, the solutions used in the original design are also used and have undergone changes: split Timken bridges, which received steering knuckles from Spicer bridges; metal bumpers complemented by plastic “fangs”; tailgate, previously used on the UAZ Hunter Classic).

In January 2011, the UAZ-469 disappeared from the Ulyanovsk Automobile Plant catalog, having reached the limit of 5,000 vehicles. The UAZ Hunter Classic has returned to its place, the price of which is significantly higher than the price of the 469.

Tuning UAZ-469

The big advantage of the UAZ is the ability to modify and add various equipment. The main points include:

- Increased ground clearance.

- Installation of a winch.

- Various external decorations.

First of all, the owner of an SUV wants to increase its cross-country ability. The easiest way is to increase the wheel size. The vehicle's arches and the strength of the axles leave plenty of room for choice. Sometimes it is enough to install high tires of 31 inches, and the UAZ will be pulled up beautifully above the ground. To raise it even more, it may be necessary to trim the arches and install special spacers between the frame and the body. In this case, the size of the disk is most often not increased, but reduced, setting the radius to 15 instead of 16.

The second point, of course, is a winch, or better yet two: one is placed on the front bumper, the other on the rear. True, this “decoration” also has a minus: an increase in the weight of the car as a whole. Which is the exact opposite quality of increasing the cross-country ability of the UAZ-469. The technical characteristics of the “bobby” will show their best side. An expedition trunk and a ladder on the rear door will be a beautiful and practical addition.

Tuning the UAZ-469 will become brighter and more noticeable when installing the kengurin. This may add extra pounds, but it will give you the opportunity to quickly move through light undergrowth. Those wishing to operate an SUV through certain water obstacles should acquire a snorkel and carry out additional sealing of the engine compartment.

The UAZ-469 car, the price of which ranges from 50 to 200 thousand rubles, naturally becomes more expensive due to the installed add-ons. Changes in appearance will not add cross-country ability to the car, but will express your individuality. Such moments include painting, applying airbrushing, replacing stamped wheels with cast ones, installing hood and window bumpers, and installing additional optics.

Power unit UAZ-469

The UMZ-417 engine, as well as some of its modifications, is installed on the people's favorite car. Its capacity is 2.5 liters and corresponds to 75 liters. With. The military and civilian versions differ in designation: the number 8 at the end for the first and 9 for the second. The UAZ-469 military engine has shielding for high-voltage wires and a distributor sensor. The power unit itself is made of a special aluminum alloy, and the cylinders are made of cast iron liners.

The engine of the UAZ-469, the technical characteristics of which correspond to its profile, is as easy to operate as it is to repair. This is facilitated by the availability of components and their price.

UAZ 39626 and Patriot engines

The UAZ 39629, otherwise known as a “sanitary” vehicle, is most often used for transporting patients and is available in most medical centers. Widely used in both cities and rural areas. These machines are equipped with three different engines.

- ZMZ-402.

- UMZ-4178, similar in characteristics to the first, only the manufacturing plants differ. These engines have a displacement of 2.4 liters and a power of 92 horsepower.

- UMZ 4218 with a volume of 2.8 liters and 98 liters. With. under the hood.

UAZ Patriot cars are equipped with a four-cylinder, four-stroke engine of the ZMZ 409.10 series. The valves are located at the top, and the cooling is liquid. The ignition system of this engine is microprocessor-based, fuel injection is distributed. The ZMZ-51432 diesel engine for the UAZ Patriot is simply a necessity.

Diesel fuel is more economical and practical

In Russia, diesel fuel is gradually becoming fashionable, but until recently the production of diesel engines was just a plan. Foreign diesel engines, as a rule, were not suitable for the UAZ Patriot, and attempts to aggregate them were abandoned.

Reviews of the UAZ Patriot diesel engine from the foreign company IVECO F1A end with negative reviews about its quality. Maybe because Ulyanovsk or Trans-Volga engines are more common for Russian cars. The volume of the foreign engine is 2.3 liters and the power is 116 horses. The Italian engine is noisier and less powerful. However, owners of a Patriot with a foreign engine will be pleased with good traction and fairly economical fuel consumption - just under 10 liters per 100 km.

Not long ago, the Zavolzhsky Motor Plant began producing a diesel engine for the UAZ Patriot and UAZ Pickup SUVs. The ZMZ-51432 engine is a small-displacement engine, its volume is 2.2 liters, and complies with the Euro-4 standard. The engine has a maximum power of 114 horsepower, 3500 rpm and low fuel consumption.

The engine has many original parts, which has improved its energy and economic performance. At the same time, emissions of harmful substances were reduced: by half compared to engines that comply with Euro-3. The noise level has decreased in accordance with standard requirements.