Purpose of thrust rods on the VAZ 2107

Tie rods provide protection against swaying and loss of control on the road, during sharp turns and obstacles. Even earlier versions of the car had similar problems. But inside the cars there were only ordinary springs; no one knew anything about the system with rods.

It is for this reason that the vehicle caused many problems when driving. Only over time the suspension was modified. A system was installed with several long rods. This part carried the main load.

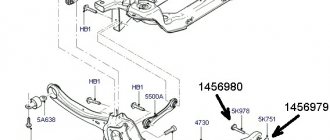

Classic VAZ 2107 cars and other models contain the following version of the torque rod kit:

- Long.

- Short.

- A large transverse one, which also serves as the basis for the entire system.

Installation location - near the car axle located at the rear. The system is visible only from the inspection hole, where repair work is usually carried out if the reaction rods are replaced.

Jet thrust malfunctions and possible consequences

If the load causes the axle to sway or shift, the impact will be taken by the jet thrust. The appearance of defects in parts leads to a deterioration in the overall behavior of transport. Damaged parts need to be replaced as quickly as possible.

The following factors often cause breakdowns:

- Exposure to chemicals from road compounds in winter;

- Impact of torsional loads. Occurs more often when colliding with obstacles. Only reducing the speed before these elements reduces the risks;

- Static loads. This factor is only reduced by the absence of overloads; it is impossible to completely get rid of it when operating rods on a VAZ 2107.

It is important to detect deformation, chips and cracks in a timely manner, for which periodic inspection of the entire system is organized. Welding seams and silent blocks are weak points that receive the most attention during inspections.

Silent blocks of any type are rubber, so they wear out faster than metal parts. Due to their wear, backlashes appear, becoming an obstacle to the stabilizing function. Welded joints, when they break, also lead to unpleasant consequences. It is recommended to remove them as quickly as possible.

With broken parts, driving is worse. Added to this is the unstable behavior of the body when defects appear in the jet rods.

Checking the condition of the jet rods on the VAZ 2107

100 thousand kilometers - new parts from the car are enough for this period, according to existing instructions. But the actual service life rarely exceeds 80 thousand kilometers, given real conditions.

The same instructions say that it is recommended to organize checks every 20 thousand kilometers. And here the experts recommend reducing the period by 5-10 thousand km to make it easier to avoid unpleasant surprises. You can’t do without an inspection hole and a mounting blade; this is the only way the jet thrust can be opened for viewing and other actions.

Test sequence

The steps are not that complicated:

- Installation of transport on a viewing hole or on an overpass;

- Mounting blades are inserted behind the traction eyes;

- The spatula rests against the jet thrust bracket. An attempt is made to shift the part, together with the silent block. If the action is successful, it means the part is worn out and needs to be replaced;

- Repeating a similar procedure with each silent block. If it moves sideways by a few mm, the need for replacement is obvious.

The rods themselves, along with the eyes, are also checked for wear. If any defects are detected, in this case the bushings and other parts are replaced.

Video checking jet rods on a VAZ 2107

Lower silent block

Replacing parts installed on the lower arm of a VAZ is a more labor-intensive process, because it cannot be removed, which means that all work will have to be done by weight.

The procedure is as follows:

- unscrew both nuts securing the lever;

- Install a puller on one side of it and pull out the silent block;

- do the same on the opposite side;

- install new parts and press them into the lever;

- screw the nuts, not forgetting to place thrust washers under them;

- return the wheel to its place;

- lower the car to the ground;

- tighten all previously tightened nuts until they stop.

Selection of thrust rods

The parts come from different manufacturers, the prices of which often differ several times. Production involves the use of spring steel as a base. Even when purchasing, it is easy to identify the presence of a defect in one case or another. It is necessary to inspect the part, especially in the welding areas. If there are chips and cracks, it is recommended to refuse the purchase. The fastening must not be damaged.

It is better to contact representatives of trusted stores. The main thing is not to forget to take a receipt, which simplifies the procedure for processing a return if necessary.

Replacing jet rods on a VAZ 2107

It is necessary to prepare a kit with tools and consumables in advance. Their main list is as follows:

- Hammer;

- Set with open-end wrenches. The reinforced double type parts are sometimes difficult to remove without additional tools;

- Blades for installation;

- WD-40 – this composition removes rust;

- A set with new reaction rods, including a transverse one.

When everything is ready, they begin the work itself.

Removing jet rods

Removing old parts is the first step where work begins.

The process involves the following sequence:

- A wire brush is used to remove rust and dirt from threaded connections. Then WD-40 is used for processing. You will need to wait some time before the work can continue. The instructions are also relevant for the classic model.

- Completely unscrew the nut, due to which the washer is held on the free side. This process is difficult, it is better to take a long wrench and, if necessary, re-treat the surface with WD-40.

- Dismantling the bolt and nut, moving to the other side. The rear parts are dismantled in almost the same way.

- Unscrewing the nut from the lower shock absorber mounting. The bolt with the spacer sleeve is also removed.

- Shift towards the shock absorber itself. Otherwise you won't be able to access the second bolt.

- Clean the bolt threads with a wire brush, then apply WD-40 again.

- Unscrew the nut and pull out the bolt. The elastic band also changes if necessary.

The bolt is simply cut off if the nut cannot be unscrewed. Removing the reaction rods involves using a spatula for installation. Remains of the fastening must be removed if the bolt had to be cut off.

Reverse welding of cracks will not help when they appear on the surface. The seam then still cannot withstand the load. Such parts can only be replaced in full.

Replacing bushings and silent blocks on VAZ 2107 rods

Silent blocks with bushings are disposable parts that need to be replaced immediately. In a garage, restoring parts becomes impossible. To replace you will need to acquire the following things:

- The beard is 10 mm in diameter.

- Hammer.

- Press-fitting device. It may also be needed when the rear axle is being repaired.

Sequencing

Follow the above instructions when removing the traction. Parts must be pre-treated with WD-40. A wire brush helps remove dirt and dust. Further actions are performed according to the specified algorithm:

- After removing the rod, the bushing should be removed without problems;

But this behavior is typical for parts without serious rust, with severe wear. Otherwise, you will have to use a hammer to knock the structure out of its place. The beard is inserted inside first.

- They get rid of the silent block if the rubber part is damaged too much. Use a screwdriver or a mounting shovel to pry up parts that prevent everything from being freed;

- Using a sharp knife or sandpaper, carefully clean the surface of the eyelet inside. Remains of rubber and rust should then disappear completely;

- A new bushing is placed in the eye and pressing is carried out using new equipment;

- The beard helps to cope with this part of the work. The main thing is to act carefully to avoid damage.

How to change front suspension silent blocks

Replacing silent blocks on a VAZ 2107 is a rather labor-intensive task that can take more than one day. Replacing silent blocks can be done with a purchased puller or with a puller made from improvised means.

What are they

The silent block is a hinge. Translated as “quiet block”. Structurally, it consists of two metal bushings connected to each other by a rubber insert. The part is designed to connect suspension elements, and the presence of rubber allows you to dampen vibrations that are transmitted from one unit to another. The silent block must perceive and endure all deformations to which the car suspension is subjected.

On the VAZ 2107, silent blocks are installed in the front and rear suspension. At the front, levers are attached using this part, and at the rear, reaction rods (longitudinal and transverse) connect the axle to the body. To ensure that the car's suspension is always in good condition and handling does not deteriorate, you need to monitor the condition of the silent blocks and replace them in a timely manner.

Varieties of “quiet blocks”

Silent blocks can be made of rubber or polyurethane. It is generally accepted that replacing rubber suspension components with polyurethane ones, where possible, will only improve the characteristics and performance of the suspension.

What are the reasons for failure

It is imperative to monitor the condition of silent blocks, since all parts have a lifetime. And rubber wears out both during operation of the machine and when it is idle.

The service life of the hinges is approximately 90-100 thousand kilometers (if the rubber or polyurethane is of high quality).

When do hinges need to be replaced:

- lack of “responsiveness” of the car when turning the steering wheel sharply;

- During the inspection, deformations of the devices are revealed;

- knocking from the suspension while driving over uneven surfaces;

- play in the locations of parts.

If you are not sure that the devices should be replaced, you can visit a service station, where the technicians will carry out diagnostics and inform you about the need to replace the joints on the machine.

Additional reasons for replacement:

- High mileage of the car, which causes the rubber to dry out, lose its elasticity and cause cracks and tears to appear;

- Contact of chemicals with the rubber of the silent block. Since the suspension element in question is located near the engine, it is likely that it will be exposed to oil, which leads to the destruction of rubber;

- Incorrect installation. Fastening the bolts of the levers should only be done after the car is installed on the wheels and not hung on a lift. If tightened incorrectly, the rubber of the silent block becomes strongly twisted, which leads to rapid failure of the product.

How to replace upper control arm joints

The described method does not require complete removal of the element from the car.

- To gain access to the lever, jack up the front wheel on the side where the work is being done and remove it. You will also have to unscrew and remove the plastic wheel arch protection (if equipped);

- We unscrew the nut of the upper arm mounting bolt, having previously treated it, as well as the hinges themselves with WD-40;

- We unscrew the bumper mounting bolt, since it will interfere with the removal of the lever fastening element;

- Remove the mounting bolt. After this, the hub will go down, which will make it possible to rotate the lever on the ball joint, so that the side with the hinges is on the outside. This will provide full access to the silent blocks, without the need to completely remove the lever;

- Using a puller, we press out the worn element: we put a washer on the long bolt, and then a piece of pipe with a diameter larger than the silent block. We pass the bolt through the hinge, so that the pipe begins to rest against the lever, and the hinge itself is inside it, put on the second washer and screw on the nut. We take two keys - with one we tighten the nut, and with the second we hold the bolt. When twisted, the nut and washer will push the hinge into the pipe until it comes out completely;

- Before installing a new element, clean the seat and lubricate it with soapy water. For planting, we use a puller with a tube of smaller diameter so that it rests against the side;

- Pressing is done like this: we put a washer and a tube on the bolt, into which we insert a new element. We pass the bolt through the hole in the lever, add the second washer and nut. Before tightening, center the silent block relative to the hole. We tighten the nut until the hinge rests on the washer. Unscrew the puller and install a piece of larger diameter on it. We position the device so that the pipe is on the side where the hinge moves. By tightening the nut, we seat the silent block until the bulges on its outer ring rest against the lever;

- We change the second hinge in the same way. After this, we turn the lever back, lift the hub to align the holes of the lever and the car body, install the mounting bolt, lubricating its body and threads with nigrol (or other lubricant), tighten the nut, put the wheel in place and remove the car from the jack.

Purpose of silent blocks

Silent blocks are called hinges consisting of two or one metal bushings connected through a rubber insert. The part in question in the form of metal bushings serves to combine suspension units, and rubber materials serve as dampers of vibrations that occur when the machine moves, transmitted from one unit to another. Due to these small parts, the service life of the car suspension is extended, since all vibrations, deformations and vibrations are smoothed out using a silent block.

The design of the VAZ-2107 vehicle uses a corresponding number of silent blocks located in the front and rear suspension. In the design of the front suspension of the seven, the devices in question are used to fix the levers, and in the rear suspension they are used to connect the reaction rods connecting the axle to the body.

This is interesting! The design of the car in question uses silent blocks of different sizes, which depends on their location. These hinges are made not only from rubber, but also from polyurethane. Both materials have their advantages and disadvantages, but in any case, it is necessary to monitor the condition of the hinges and change them in a timely manner so that you do not have to repair the entire suspension.

Signs of malfunction of levers and silent blocks

Any part has its own service life. The more stress a part experiences, the faster it wears out. It is imperative to monitor the condition of the silent blocks, since over time the following consequences are observed: the rubber begins to tear, beating and vibrations occur at the joints. Moreover, rubber wear occurs not only when the machine is in operation, but also when it is idle, since rubber material tends to deteriorate under the influence of many factors.

The approximate service life of the devices in question is 90-100 thousand kilometers. Moreover, this only applies to hinges made of high-quality rubber or polyurethane. It is also worth noting that polyurethane products have a longer service life, unlike rubber ones, but at the same time they have such disadvantages as installation difficulties (it is almost impossible to install them without a special puller), and also the suspension with them becomes stiffer.

This is interesting! The need to replace devices sometimes arises much earlier, which is facilitated by the quality of the road surface on which the car is driven. Often, even high-quality hinges on “bad” roads can last no more than 50 thousand kilometers.

The need to replace hinges can be diagnosed by a number of the following signs:

- Lack of “responsiveness” of the car when the steering wheel is turned sharply.

- During the inspection, deformations of the devices are revealed.

- Knock from the suspension when driving over uneven surfaces.

- Backlash in the locations of parts.

If you are not sure that the devices should be replaced, you can visit a service station, where the technicians will carry out diagnostics and inform you about the need to replace the joints on the machine.

Replacing the upper arm joints

If there is a need to replace the devices in question, then it is worth mentioning that the parts cannot be repaired. After they wear out, you will need to buy a new set of silent blocks for the car and install them in place of the old ones. To replace silent blocks on a VAZ 2107, you will need to stock up on the following tools:

- Puller - this makes installing new parts much easier. Instead of a puller, you are allowed to use a homemade device, but how to make one is described in detail at the end of the article.

- Wrenches.

- Metalworking tools: hammer and chisel.

- Mount.

Silent blocks VAZ 2107

On the Internet, the specifics of replacing the silent blocks of the suspension of the VAZ 2107 and other cars of the domestic and foreign automobile industry are often discussed. The problem is actually urgent and is due to the poor quality of our roads. Since the silent block is one of the important elements of the vehicle suspension design, special attention must be paid to its selection and replacement.

What are silent blocks

The silent block (hinge) structurally consists of two metal bushings connected to each other by a rubber insert. The part is designed to connect suspension elements, and the presence of rubber allows you to dampen vibrations that are transmitted from one unit to another. The silent block must perceive and endure all deformations to which the car suspension is subjected.

Where are they installed?

On the VAZ "Seven" silent blocks are installed in the front and rear suspension. At the front, levers are attached using this part, and at the rear, reaction rods (longitudinal and transverse) connect the axle to the body. To ensure that the car's suspension is always in good condition and handling does not deteriorate, you need to monitor the condition of the silent blocks and replace them in a timely manner.

What types of silent blocks are there?

In addition to the purpose of silent blocks, you need to know that these products can be made of rubber or polyurethane. It is generally accepted that replacing rubber suspension components with polyurethane ones, where possible, will only improve the characteristics and performance of the suspension.

Silent blocks made of polyurethane are characterized by a longer service life, unlike rubber ones.

The disadvantage of polyurethane elements is their high cost - they are about 5 times more expensive than rubber ones. When installing polyurethane products on a VAZ 2107, you can improve the car's behavior on the road, reduce deformations in the suspension, and also eliminate the so-called squeezing, which is characteristic of rubber elements. This means that the suspension will operate in the condition intended by the designers at the factory. With the correct selection and installation of polyurethane parts, noise and vibration are reduced and shocks are absorbed, which indicates the better performance of such hinges compared to rubber ones.

Replacing silent blocks of the lower arm

When silent blocks fail, as a rule, they cannot be restored; this is due to their design. To carry out work on replacing the rubber-metal joints of the lower arm on a VAZ 2107, you will need the following tools:

- silent block remover;

- ball joint remover;

- keys for 13, 22, 24;

- hammer;

- chisel;

- mount;

- lubricant (for example, WD-40).

The procedure for dismantling the lower arm is as follows:

- Raise the car using a lift or jack.

- Remove the wheel.

- Loosen the lower arm axle nuts.

During assembly, new nuts should be used to tighten the lever shaft and ball pin.

Video: how to replace the silent blocks of the lower arms of a VAZ 2101–07

The same puller is used to remove and install silent blocks. You only need to change the position of the parts depending on what operation is intended (pressing in or pressing out).

Replacing silent blocks on the upper arm

To replace the hinges on the upper suspension arm of the seven, you need to remove it. This is not difficult to do; you just need to lift the wheel and unscrew its mounting bolts. After this, your gaze will have a wonderful view of all the suspension elements, including the upper control arm. On it, replacement of VAZ-2107 silent blocks is carried out only after complete dismantling. Please note that the lever is attached to the body using an axle bolt, and also to the hub using a ball joint.

The ball does not need to be pressed out of the hole in the hub; you just need to unscrew the three bolts that secure it to the suspension arm. It only needs to be removed completely if it is being replaced. After unscrewing the three ball bolts, you need to remove the lever from the body. To do this, unscrew the nut from the axle and knock out the last one. That's all, the lever has been removed, now clamp it tightly in a vice and use a puller to remove the old hinges. Using the same puller, put the new ones in place. And now you can mount the lever in place.

Replacing the upper arm joints

To replace the silent blocks of the upper arm, you will need the same tools as when repairing the lower elements. The car is lifted in the same way and the wheel is removed. Then carry out the following actions:

- Unscrew the front bumper bracket fasteners.

How to replace the upper silent block

First of all, unscrew the vertical bolt that serves to secure the front bumper - without this you will not be able to get to the axle. Then remove the nut holding the ball joint, and then press the finger out of its bipod with a puller.

- disconnect the upper arm from the body (you will need two 22 mm wrenches);

- fix the latter in a vice;

- Using a puller, remove the silent block and put a new part in its place.

Now all that remains is to assemble the entire assembly, proceeding in the reverse sequence described. And at the very end you need to do the following:

- turn the steering wheel;

- Tighten the bolt and nut holding the upper arm until snug.

Replacement of silent blocks of reaction rods

Tie rods are an integral part of the rear suspension of classic Zhiguli cars. They are secured by a bolted connection, and rubber bushings are used to reduce loads and compensate for impacts from uneven road surfaces. Over time, these products also become unusable and require replacement. It is best to change them comprehensively, rather than individually.

Tools and materials you will need:

- keys to 19;

- new silent blocks;

- penetrating lubricant;

- metal brush;

- mounting blade.

Let's consider replacing torque rod bushings using the example of a long longitudinal rod. The procedure with other suspension elements is carried out in a similar way. The only difference is that to remove the long rod, you need to remove the lower shock absorber mount. The work consists of the following steps:

- Clean the fastener from dirt with a brush, treat it with a penetrating liquid and wait for a while.

If the inner race protrudes slightly on one side, it needs to be leveled with a hammer.

After replacing the silent block, the rod is installed in the reverse order, not forgetting to lubricate the bolts, for example, with Litol-24, which will make it easier to dismantle the fasteners in the future.

Video: replacing torque rod bushings on a VAZ 2101–07

Tips for replacing silent blocks

- To remove silent blocks, ball joints and steering ends, you must use pullers. If you knock out parts with a hammer, you can damage the threads on them. Also, due to impacts, cracks may appear on the welded joints of the levers.

- Before installing the hinges, it is necessary to clean the old bolts and pins from rust and dirt, and then lubricate them with machine oil.

- Polyurethane silent blocks have a much longer service life than rubber ones. Considering that the cost of silent blocks is low, and the work of replacing them is quite labor-intensive, it is preferable to use polyurethane-metal silent blocks.

- If the old silent block cannot be pressed out, it should be cut with a hacksaw.

- Replacing silent blocks is a responsible and quite complicated job. A loose nut may cause an accident. Therefore, if you do not have sufficient experience in plumbing, it is better to entrust the replacement of silent blocks to professionals at a service station.

- Replacing the silent blocks of the VAZ 2107 violates the alignment angles of the front wheels. To adjust the wheel alignment angles, special equipment is required, without which the work cannot be done efficiently. Therefore, after replacing the silent blocks, you must definitely go to a service station, where specialists will adjust the wheel alignment.

Do-it-yourself silent block remover

The VAZ 2107 hinge puller can be purchased ready-made or made by yourself. If you have the right equipment and materials, every car enthusiast can make the tool. It is also worth considering that the quality of purchased devices today leaves much to be desired. You can replace the rubber-metal hinge without special tools, but this will require much more time and effort.

Sequencing

To make a homemade puller you will need the following:

- a piece of water pipe 3 cm long with an internal diameter of 40 mm and an external diameter of 50 mm;

- washer with an outer diameter of at least 50 mm;

- M12 bolt 7 cm long with washers;

- two pieces of pipe 10 cm long and 40 mm in diameter;

- vice;

- hammer;

- lubricant

The puller manufacturing process consists of several stages.

- By striking with a hammer, they ensure that a 40 mm pipe section has an internal diameter of 45 mm, i.e., they try to rivet it. This will allow the lower arm joint to pass freely through the pipe.

In order to drive your car confidently and without accidents, you need to periodically inspect and repair the chassis. Wear of silent blocks affects driving safety, as well as tire wear. To replace damaged hinges, you will need to prepare the necessary tools and perform repairs in accordance with step-by-step instructions.

Replacing silent blocks in the upper control arm of a classic with your own hands.

So, let's begin! In rear-wheel drive VAZs, the silent blocks in the upper arm can be changed without even driving into a hole and without removing the arm from the ball (provided that you have a remover for silent blocks). But first you need to determine whether the bushings of the silent blocks are stuck to the bolt securing the lever to the body. To do this, jack up the car and remove the wheel.

Arrows point to bolt and nut

We loosen the nut securing the upper arm with a 22mm wrench and try to turn the bolt. If it spins and the bushings stay in place, then you're in luck! But if this bolt rotates with great force and the bushings rotate with them, then as they say: “Houston, we have problems!” Next we will consider both cases.

If the silent blocks are not stuck.

Further actions depend on whether you have a puller for silent blocks. If there is one, then you don’t have to remove the lever completely, but just unscrew the nut 22 to the end, take out the bolt and turn the lever towards yourself (for the convenience of further repairs).

We turn the lever for convenience.

Next, take a puller and press out the silent blocks.

Removing the silent block using a puller

And with his help we press in new silent blocks. Before pressing, the mounting hole must be cleaned and preferably lubricated with lithol. In the upper arms, silent blocks are pressed into place up to the ribs, as shown in the photo below.

The new silent should be pressed in exactly like this.

But what to do if you don’t have a silent block remover ? Then you will have to completely remove the lever. We take out not only the bolt securing the upper arm to the body, but also take out the ball from the hub (this is faster than unscrewing 3 bolts securing the ball to the arm). Detailed removal of the ball joint is written here.

We removed the lever, put the lever ear on a pipe or on a yew tree (as in the photo), the main thing is that the silent block does not rest against anything, and knock it out with a hammer.

To press in new ones, we need a mandrel (old bearing, piece of pipe, nut head). The inner diameter of the mandrel must be equal to the diameter of the skirt of the new silent block. And we begin pressing in new parts using this mandrel, having previously lubricated the seat with lithol. Reassemble in reverse order.

Important: we pull the bolt securing the lever to the body only under the load on this wheel! Those. The car should not be on a jack, but on all wheels!

If the silent blocks are stuck to the bolt.

This is a very difficult case, since you will have to spend a long time trying to get the bolt that secures the front upper arm to the body.

For those who want to save themselves a lot of time and are ready to fork out a little, I advise you to buy a new bolt, this lever from disassembly and just cut off the old bolt with a grinder.

Well, if you have time and nerves, then we take a gas burner in our hands and burn out the silent block. Follow fire safety precautions! After all the rubber has burned out, you can begin to knock out the bolt. Get ready to do this for a very long time. After you remove the bolt, knock out the remaining clip of the burnt silent tape from the lever and follow the instructions written above.