The front suspension arms of the VAZ 2107 are subject to significant loads when driving, and given our roads, their premature failure is not surprising. Taking care of your own safety, you need to regularly check the condition of the suspension and promptly repair it. In this article I want to touch on how to replace the upper arm of the front suspension of a VAZ 2107 (this, in principle, also applies to models 2101 - 2106).

Replacing rear control arms Ford Focus 2 detailed instructions with photos

Replacing the rear arms of a Ford Focus 2 is required depending on the mileage and the wretchedness of the roads on which you travel.

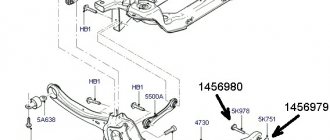

Of course, if the levers themselves are not deformed, then you can limit yourself to replacing the rear silent blocks of the Ford Focus. The rear suspension features a complex multi-link and fully independent suspension. This scheme allows you to achieve excellent controllability and driving comfort, but replacing the lever assembly (as prescribed by the manufacturer) can cost a pretty penny. The stamped trailing arms of the Ford Focus are connected to the subframe by three transverse arms through silent blocks. Below is a photograph of the entire structure, indicating specific elements for clarity.

Ford Focus 2 rear suspension elements

- 1 — silent block of the trailing arm

- 2 - trailing arm

- 3 - lower front arm

- 4 - upper lever

- 5 - shock absorber

- 6 - spring

- 7 — subframe

- 8 — adjusting bolt (bolt securing the rear lower arm to the subframe)

- 9 - anti-roll bar

- 10 - lower rear arm

- 11 — brake shield

All rear levers of the Ford Focus 2 are made of stamped steel with silent blocks pressed into them. There are 4 levers in total, these are the longitudinal, upper, lower front and lower rear levers. Next, we will tell you in detail how to remove each lever individually.

Lever structure

The front suspension arm (as, in principle, the rear one) is a monolithic part that connects the body to the wheel. The connection should be as rigid as possible. The supporting elements must not only hold the wheels in a vertical position, but also absorb shocks affecting the suspension.

Front suspension arm device

The part is installed exclusively on vehicles with independent wheel suspension, and axle beams are used for dependent suspension. The shape of the lever may differ depending on the design features of the suspension.

How does the front suspension of a car work?

Note! Cars are equipped with two types of levers - light alloy and made of steel. Steel products are considered more unpretentious.

Replacing the upper Focus arm

Replacing the upper arm of the Ford Focus rear suspension is carried out when there is mechanical deformation or wear of the silent blocks (cracked rubber, peeling, etc.) To remove the arm, we will need a platform or hole, ties for removing the rear spring and an adjustable stop for the lower arm.

We remove the spring using zip ties, remove the wheel, install an adjustable stop or hydraulic jack under the lower rear arm at the junction of it with the trailing arm, and use the stop to raise the arms so that the rear suspension is in the “car on wheels” position.

Using a 15mm socket, unscrew the bolt securing the upper arm to the trailing arm. This bolt also secures the brake hose bracket. Using a 15mm socket, unscrew the bolt securing the upper arm to the subframe.

Using a screwdriver, pry the ends of the lever out of the brackets and remove the lever from the car. We install the new lever in the reverse order with the deflection down.

Notes

It is better to replace the self-locking nuts of the upper ball joint and axle with new ones.

If you have play in the upper arm on your VAZ 2107 and it is hanging loose, then it’s time to change the silent blocks, or change the axle due to wear due to poor tightening.

If the bolt of the upper arm of the VAZ 2107 does not come out, treat it with a WD tool, then turn it with a wrench and lightly knock on it.

Video on replacing the upper arm:

One of the most common domestic cars is the VAZ 2107. The front suspension of any car is subjected to serious loads, and taking into account the state of our roads, the life of the suspension elements is significantly reduced. To ensure a comfortable and safe ride, you must regularly inspect the condition of all elements of the front suspension, paying special attention to ball joints, silent blocks and levers. If malfunctions are detected, you can repair the front suspension of the VAZ 2107 yourself.

Replacing the lower front arm Focus

As in the case described above, we will need to remove the spring, remove the wheel and place an adjustable stop or a hydraulic jack under the lower arm at the junction of it with the trailing arm, and using the stop we raise the arms so that the rear suspension takes the “car on wheels” position. . Naturally, we do all this on a pit or overpass.

Then, using a 15mm wrench or socket, unscrew the bolt securing the lever to the trailing arm and remove the bolt. Similarly, unscrew the bolt securing the lever to the subframe and remove the bolt. Using a screwdriver, pry the ends of the lever out of the brackets and remove the lever. Photos for clarity are attached below.

Install the new lever in reverse order. In this case, it is worth considering one important point: the inscription “FRONT” on the lever should be directed towards the front of the car.

Diagnostics of levers

To check the condition of the trailing arm, you need to align it correctly: the end of the hinge must be in contact with the mandrel of the part for alignment. After that, the installation pins must be inserted into the corresponding holes. The entry of the fingers with force indicates deformation of the lever. If this does not require significant effort, then the part is fully operational.

Diagnostics of front suspension arms

On a note! To accurately determine the malfunction of the levers, diagnostics with their complete dismantling is necessary.

Replacing the lower rear arm Focus

The lower rear arms of the Ford Focus have spring support cups. The upper ends of the springs rest against the subframe cups. The cups have rubber gaskets. As in previous cases, we will need to remove the spring, plus unscrew the anti-roll bar. We place a stop under the rear lever (at the junction with the trailing lever).

The rear suspension has adjustable wheel toe angles, so we mark the position of the eccentric washer relative to the subframe so that when assembling and installing a new lever, the toe angles of the Ford Focus wheels are approximately maintained. In this case, the position of the adjusting bolt head does not need to be marked, only the washer relative to the subframe.

Using a 15mm socket, unscrew the bolt securing the lower rear arm to the trailing arm and remove the bolt. To be able to remove the adjusting bolt after unscrewing the nut, it is necessary to press the latch of the canister of the fuel vapor recovery system and move the canister away from the subframe.

Use a socket or a 18mm wrench to unscrew the nut, holding the adjusting bolt from turning with a 19mm wrench. Remove the eccentric washer and remove the adjusting bolt. The bolt has a groove for fixing the washer in a certain position.

Remove the lever from the car. Using a screwdriver, remove the rubber buffer from the lever and install it on the new lever. True, if the buffer is broken or has cracks and tears, it naturally needs to be replaced.

We install the lever in the reverse order, with the head of the bolt securing the lever to the subframe facing towards the front of the car. And the mark made on the eccentric washer should coincide with the mark on the subframe. The bolt securing the lever to the trailing arm and the nut of the eccentric bolt are finally tightened to the prescribed torques only under load, in the “car on wheels” position.

After replacing this lever, it is advisable to adjust the wheel alignment of the rear wheels.

Repair of the upper suspension arm

Purpose and design of the upper arms

The main function of the wishbones of the suspension becomes a limited movable connection between the wheels and the car body. In the front multi-link design, a metal piece connects the body to the steering knuckle, keeping the wheel from falling to one side.

In a rear multi-link suspension, due to its shorter length, the upper arms provide a negative camber angle when cornering (in compression), and a positive angle in extension. The position of the wheel perpendicular to the road when cornering gives the body additional stability.

The lever, as one of the load-bearing elements of the suspension, is designed individually for each new model, with an accurate calculation of the weight of the body, loads on the chassis and wheels. Therefore, there is no unification; using levers from another car is not practiced in car repair shops.

The shape of the upper suspension arms, depending on the type of chassis, can be straight or curved. Complex shapes include triangular (A-shaped), crescent-shaped, and H-shaped levers. To strengthen the fastenings of fingers and silent blocks on the body of the part, ring-shaped, cylindrical bosses are formed by casting, which can be located at the ends, in the center of the lever.

Premium models of foreign cars use sophisticated levers (spring-loaded, floating, adjustable, reinforced). For budget models, stamped or cast steel is used as the main material of the levers. In expensive foreign cars, they are cast from aluminum alloys, reducing the weight of the suspension. The shape and size of the levers for torsion bar, pneumatic, and active suspensions differ.

Causes of damage and diagnosis of suspension arms

Self-diagnosis of levers based on the behavior of the machine does not give accurate results. When driving in city traffic, deterioration in handling, deviations from a straight path, and slow exits from corners are hardly noticeable. Such symptoms are also typical for malfunctions of the shock absorber support and stabilizer strut. Drivers of foreign cars can drive for several weeks with broken rear suspension arms. Deformation of levers and worn silent blocks are dangerous due to accelerated wear of adjacent suspension elements: steering knuckle, ball joint, shock absorber, stabilizer.

The body of the lever is deformed and gets cracked from strong impacts on boulders, jumps from high curbs, and emergency collisions. The same reasons lead to breakage of fastenings. The most common reason for repairing upper hinges is the natural wear of silent blocks (rotary bearings) after long-term use, and damage to the threads of bolted connections.

The only way to make an accurate diagnosis is to inspect the suspension arms by an experienced auto mechanic (carried out with the car hanging) and check all hinge joints for play. Any play in the silent block indicates wear of the hinge; you need to replace the silent block of the lever or the assembly part.

Suspension arm repair

When repairing levers, they mainly replace the silent blocks and make ball joint crackers. As a rule, the hinges of the right and left levers wear out equally, so simultaneous repair of both levers is recommended. Only an experienced auto mechanic can determine options for welding cracks and straightening deformations of stamped steel. Aluminum parts of premium foreign cars, forged levers of complex configuration with non-removable silent blocks are not repaired (replaced as an assembly).

The operation of replacing the silent block itself takes a few minutes from an experienced technician at our car service center. Auto mechanics consider the main difficulties of repair to be dismantling the lever and correct installation of the repaired part in its original place.

Even for a simple repair of the upper front arm of the domestic VAZ “Seven” you need:

- hang the car on a lift;

- remove the wheel from the desired side;

- Unscrew the bolted connection to the front bumper;

- remove the ball joint;

- Unscrew the nuts on the lever axis;

- remove the lever;

- press out the silent block;

- press in a new hinge;

- assemble the pendant.

For foreign cars, such dismantling operations are supplemented by disassembling several sensors, brake pads, and brake system calipers.

When repairing domestic models, auto mechanics pay special attention to the correct installation of shims. At the customer's request, instead of rubber silent blocks, polyurethane rotary supports are installed. When repairing upper arms, it is necessary to use new camber bolts, self-locking nuts, spacer bushings, and ball joint boots.

Advantages of ordering repair of upper control arms in our car service center

Our technicians will check the entire suspension, chassis, brake system, and determine the play of ball joints and silent blocks of the upper arms. The assembly of the repaired lever is carried out using the correct technology, with the bolts tightened with torque ratchets at the required force.

When repairing the upper auto mechanic arms of the Auto Captain service:

- accepts cars of all models (including rare foreign cars);

- do not delay repair time;

- offer several options for purchasing silent blocks and ball joints;

- comprehensive repair of the chassis.

Customers' time and money will be saved by a simple ordering procedure, cumulative discounts, promotions, special offers, and evening reception of cars (until 10 p.m.). Judging by the reviews of regular customers, the main advantage of our car service will be the best prices for repair work in the Moscow region and the capital.

Replacing the Focus trailing arm

A silent block is installed in the front part of the Ford Focus trailing arm, through which the arm is secured with two bolts to the body. The rear wheel hub assembly is secured to the rear of the lever with four screws. Replacement of the lever is required when it is deformed or the silent blocks are worn.

As with other levers, we carry out replacement work in a pit or overpass (lift) with removal of the spring and wheel. Plus you need to place a stop under the lower arm. Without an adjustable stop, removing the bolts from the silent block eyes will be problematic.

Remove the three wheel speed sensor wire holders from the trailing arm holes and disconnect the wire block from the wheel speed sensor.

Using a 10mm head, unscrew the self-tapping screw securing the stop of the parking brake cable sheath and remove the stop from the hole in the lever.

Disconnect the lower end of the shock absorber from the trailing arm, then disconnect the transverse suspension arms from the trailing arm.

We remove the hub assembly, then use a 15mm head to unscrew the two bolts securing the lever to the body and remove the trailing arm.

Install the new trailing arm in reverse order. An important point - we finally tighten the threaded connections in the “vehicle on wheels” position (under load), this will extend the life of Ford Focus silent blocks.

Ford Focus 2 replacement of rear levers: we will tell you in detail

The second generation Ford Focus car is modern and very reliable, both in terms of suspension, engine, transmission, etc. The suspension, by the way, can even cope with our roads and serve for quite a long time. It should be noted that one of its disadvantages is the complexity of repairs, which is quite difficult to carry out on your own. However, if you have the necessary skills, knowledge and tools, then the process is quite feasible. Replacing the front and rear suspension arms requires several hours of time, and we will tell you later how to do this correctly on a second-generation Ford Focus.

The rear suspension on the Ford Focus 2 has a simple design, which allows it to achieve the highest reliability. But, despite this, constant load, driving on bad roads and the influence of other factors lead to the failure of its various elements.

Lower arm of the front suspension VAZ 2107

The VAZ 2107, popularly known simply as the “Seven,” is the latest rear-wheel drive representative from the model range of the popular domestic manufacturer. Unlike front-wheel drive cars, the front suspension here has fewer parts, so diagnosing and repairing it is much easier and you can handle everything yourself, without involving expensive specialists.

The “Seven” has an independent front suspension, the main parts of which are two levers: upper and lower. The lower arm connects the hub or steering knuckle to the car body. Due to the front suspension arms, the wheels are held in a vertical position, and the lateral forces that arise while the vehicle is moving are dampened.

Lower arm housing

The lower arm is fixed to the suspension cross member, which is mounted on the front side members. A ball joint is attached to it, and a spring also rests on the lower edge. All this makes it difficult to replace this suspension element, but even a novice car enthusiast can cope with such a task with his own hands. It is enough to determine the cause of the breakdown, and then act in accordance with the developed rules and recommendations of specialists.

Spherical bearing

A ball joint is securely fixed directly to the lower arm. This is a hinge element that connects the lever and the hub. The ball joint absorbs all the impacts that occur when the wheel hits uneven roads, so special attention is paid to its strength.

Serviceable ball joints limit the swing of the wheel in the vertical direction, but at the same time allow it to move freely in the horizontal plane. When a ball joint breaks, the wheel turns spontaneously, and if this happens while driving, it can lead to an accident.

This element is a hinge, the main part of which is a ball rod, on one side there is a ball, on the other there is a thread. The rod is securely pressed into the eye with a plastic liner, after which the entire structure is covered with a boot to prevent moisture and dust from entering the friction points. Modern manufacturers usually use transparent boots, which allows you to assess the condition of the hinge without removing this element.

Since the ball joint is a very important and responsible part of the suspension, if it needs to be replaced, you need to purchase only high-quality products. Some of the most reliable and popular manufacturers of ball joints are the following brands: “TRACK”, “KEDR”, “BELMAG”, LEMFORDER (German company). In addition, any major manufacturer offers reinforced versions of such parts; they are also called sports: “Track-sport”, “Cedar-trial-sport”, etc.

Silent block

The silent block is a part that allows the lever to rotate on an axis. It consists of two metal bushings, between which there is a rubber insert.

Modern industry offers silent blocks made of rubber and polyurethane. Nowadays, basically everyone is switching to polyurethane silent blocks, since they have a longer service life, but their cost is several times higher than their rubber counterparts.

Replacing rubber silent blocks on a VAZ 2107 with polyurethane ones allows you to:

- reduce deformations occurring in the suspension;

- improve car handling;

- remove the squeezing that is typical of rubber products;

- reduce noise and vibrations that occur while driving.

Axle bolt

The axis of the lower arm is rigidly connected with two bolts to a beam fixed to the front side members. On the axis, the mobility of the lower arm is ensured by the presence of silent blocks.

Replacing the upper Focus arm

Replacing the upper arm of the Ford Focus rear suspension is carried out when there is mechanical deformation or wear of the silent blocks (cracked rubber, peeling, etc.) To remove the arm, we will need a platform or hole, ties for removing the rear spring and an adjustable stop for the lower arm.

We remove the spring using zip ties, remove the wheel, install an adjustable stop or hydraulic jack under the lower rear arm at the junction of it with the trailing arm, and use the stop to raise the arms so that the rear suspension is in the “car on wheels” position.

Using a 15mm socket, unscrew the bolt securing the upper arm to the trailing arm. This bolt also secures the brake hose bracket. Using a 15mm socket, unscrew the bolt securing the upper arm to the subframe.

Using a screwdriver, pry the ends of the lever out of the brackets and remove the lever from the car. We install the new lever in the reverse order with the deflection down.

Rear dependent suspension, classic suspension

This type is a characteristic feature of the “classic” Lada. A special feature of this design is cylindrical coil springs, which act as elastic components. The rear axle beam “hangs” on these two springs, which is fixed to the body by four longitudinal arms.

This set is complemented by a reactive crossbar, the purpose of which is to improve handling performance and dampen body roll.

Ride and comfort leave much to be desired, as a result of the large weight of the unsprung masses and the rear axle itself. This is especially true when the rear axle is driving, since the main gear housing, gearbox and other elements are attached to the beam.

When to change rear control arm silent blocks on Ford Focus 2

The wear is immediately visible.

There is no need to explain to anyone that a silent block is a rubber-metal bushing to dampen vibrations and reduce the load on suspension elements.

The fact that they have their own tensile strength is also understandable. Replacing rear suspension silent blocks may be necessary after 80–100 thousand mileage, and the following are considered signs of malfunction:

- knocking and creaking in the rear axle area;

- car instability during sudden lane changes and cornering;

- the car pulls to the side when braking;

- uneven wear of the rubber on the rear wheels;

- broken wheel alignment angles of the rear wheels.

If you do not notice the severe wear of the silent blocks in time, then in addition to repairs, you can spend heavily on replacing suspension parts and new tires. And safety along the way will also be at risk.

What silent blocks will we install?

Repairing the rear suspension sometimes involves not replacing silent blocks, but completely replacing the arms. Firstly, it’s easier, and secondly, there will be a guarantee that the suspension geometry will be preserved.

New silent blocks have been installed.

But there is a danger of running into counterfeits; more and more fake levers made of disgusting quality steel are appearing on the market. However, if the levers are in good condition, and only the silent blocks are out of order, we will change them. Replacement work costs on average about 4–4.5 thousand rubles, depending on the service, so we’ll save money and replace the silent blocks ourselves.

There are many types of silent blocks on the market, but Lemforder elements have long remained one of the most popular. Here are their catalog numbers:

- Lemforder 31938 01 , this is a silent block of rear wishbones, to replace them you need four, the inner diameter of the bushing is 12.2 mm, the outer diameter of the race is 32.2 mm;

- Lemforder 31940 01 — silent block of a curved rear lever with an internal bushing of 12.2 mm, cage diameter 36.2;

- Febi 34249 , sold as a kit on both sides with mounting bolts, installed in front of the rear trailing arm;

- Febi 29451 bolts with M12x1.75 thread, head with a diameter of 24 mm, wrench 15;

- two adjusting bolts for installing Mazda BP4K-28-66ZB ;

- two adjusting washers Mazda BP4K-28-473A ;

- Hanse HR 402 183 - lower rear wishbone, outer silent block, inner bushing with a diameter of 12.3 mm, outer race 36.3 mm;

- inner silent block of the lower wishbone, Hanse HR 402 182 , diameters are the same;

- two anti-roll bar bushings Lemforder 34054 01 .

All parts look something like this

Life time

With careful operation of the car, the levers can last at least 100 thousand km. (several major renovations). Of course, it is possible to achieve such a service life of a steel part in the absence of serious loads on the chassis. Given the state of our roads, sometimes even the most durable elements fail ahead of schedule.

Suspension arm life

The main factors influencing the service life of the machine’s suspension and levers, in particular, include:

- quality and timeliness of maintenance;

- quality of consumables used;

- driving style (aggressive style significantly reduces the resources of chassis elements);

- driver accuracy (regular diagnostics of the suspension, lubrication and washing of its elements are required);

- exposure to external factors that cause corrosion of levers (chemical reagents and salts on the roads);

- load on the suspension (largely depends on the cargo being transported and the condition of the road surface).

How long do suspension arms last

? It must be taken into account that light-alloy suspension arms, installed on some cars in order to reduce the overall weight, are considered more vulnerable when compared to steel products. Therefore, their resource is approximately 55-60 thousand km. The advantage of such levers is to improve vehicle controllability.

What determines the life of a car's suspension?

Replacing the lower front arm Focus

As in the case described above, we will need to remove the spring, remove the wheel and place an adjustable stop or a hydraulic jack under the lower arm at the junction of it with the trailing arm, and using the stop we raise the arms so that the rear suspension takes the “car on wheels” position. . Naturally, we do all this on a pit or overpass.

Then, using a 15mm wrench or socket, unscrew the bolt securing the lever to the trailing arm and remove the bolt. Similarly, unscrew the bolt securing the lever to the subframe and remove the bolt. Using a screwdriver, pry the ends of the lever out of the brackets and remove the lever. Photos for clarity are attached below.

Install the new lever in reverse order. In this case, it is worth considering one important point: the inscription “FRONT” on the lever should be directed towards the front of the car.

Symptoms of a problem

The levers are highly durable and reliable, so in most cases replacement is required only when repairing the entire front suspension of a car as part of scheduled maintenance. But there may be exceptions and the part must be replaced earlier than the scheduled maintenance.

Signs of a bad front suspension arm

Let's look at the main signs of a faulty front suspension arm. These include:

- the appearance of characteristic sounds in the front part of the suspension when driving on a flat road;

- increasing the free play of the steering wheel;

- clicking or crunching noise in the front wheels when cornering;

- increase in braking distance;

- hum in the suspension during uniform movement;

- decreased vehicle stability at high speed;

- large roll during sharp turns.

Symptoms of faulty suspension arms

The presence of all of the above symptoms indicates a malfunction in the front suspension of the car, as well as the need for a separate check of the arms. To confirm the failure of these levers, diagnostics are needed. This is the only way to identify wear or damage to a suspension element.

Worn front suspension arm

Preparing tools and accessories for replacement

Before changing the silent blocks of the rear levers on the Focus, you need to make sure that all the necessary tools and accessories are at hand. First of all, you will need either pullers with grips for pressing out silent blocks, or a press. It is not always possible to knock out the bushings with a sledgehammer, even if you have spacers of the required diameter. But spacers are still necessary. Here are their drawings and dimensions. This is a spacer for pressing out the silent blocks of the spring-loaded rear lever:

And with this spacer the bushings of the curved wishbone are pressed out:

And these are the dimensions of the spacer for removing the silent blocks of the straight wishbone:

In addition, we will need a standard tool, a set of sockets, aerosol penetrating lubricant and a tie for removing the spring, as well as a standard jack and an adjustable stand (hydraulic jack).

Replacement of silent blocks of rear arms of Ford Focus 2

We place the car on a viewing hole or overpass, install wheel chocks under the front wheels and remove the rear wheel nuts. Jack up the rear of the car and remove the wheel.

- We thoroughly clean all suspension elements from dirt, treat the threaded connections with penetrating lubricant, wait a few minutes for the lubricant to soak in.

We lubricate everything we see.

Remove the spring by compressing it with zip ties.

Unscrew the nut securing the stabilizer strut.

- We rest the hydraulic jack or stand against the lower rear arm in the place where it is articulated with the spring-loaded arm, thereby loading the suspension elements.

- We mark the position of the washer, which corrects the camber angles of the wheels. You can use a center punch for this, but setting the correct wheel alignment will still be necessary; we will set approximate angles.

- Using a 15mm spanner, unscrew the bolt of the joint between the trailing and lower rear arm, then remove the bolt from the hole.

- To get to the adjusting bolt on the subframe, you need to move the adsorber. We press the latch and move the adsorber as far as possible to the side, after which you can remove the bolt.

- We unscrew the marked wheel alignment adjustment nut with a 18mm spanner, while holding the bolt head with a 19mm spanner.

- We take out the adjusting bolt, the lower rear arm should remain in our hands.

Getting ready for re-pressing.

- Using spacers and a press or a special puller with grips, we press out the silent blocks, clean the seating surfaces from dirt, apply a small layer of grease and press in new silent blocks.

The remaining silent blocks are changed using the same method with the arms completely removed. Assembly is carried out in reverse order. Soft and silent suspension for everyone and vivid travel impressions!

Replacing rear silent blocks for Ford Focus 2

Replacing rear silent blocks for Ford Focus 2

is an alternative to replacing suspension arm assemblies. Although the manufacturer himself requires a complete replacement of the part, our citizens prefer to save money. After all, the cost of assembled levers and silent blocks for Ford Focus 2 are incomparable.

We replace the rear silent blocks of Ford Focus 2 after removing the levers. You can see how to remove each lever in detail and with photographs here https://myautoblog.net/2016/06/zamena-zadnix-rychagov-ford-focus-2/. A special feature of the Focus design is a completely independent rear suspension, which has 4 levers on each side. Each lever has its own silent blocks of completely different sizes and degrees of resistance to loads. Official dealers do not change the silent blocks, they change the lever assemblies.

The rear suspension arms of the Ford Focus 2 are made of stamped steel. If you take a regular sledgehammer and start pressing out old silent blocks, you will easily bend the levers, so this option will not work. You can remove the levers and go to the nearest car service center, where, using a special press, they will squeeze out the old silent blocks and press in new ones. This will cost you quite little and will only take a few minutes.

If you decide to press out yourself, then you can’t do it without special tools. The main thing is not to deform the lever; if this happens, then it can be thrown away. If for most levers you can select suitable pipe trimmings, heads, and using a vice or special devices that are sold in any auto parts store, remove and install silent blocks.

There are no problems with such silent blocks (as in the photo above), especially if you already have experience in removing similar suspension elements on a Focus or other cars.

The main difficulty comes from this silent block, which is located in the trailing arm of the rear suspension of the Ford Focus 2. Pictured below.

Firstly, it is installed in one single position, so when removing it, you must clearly record (mark) the position of the eyes. If the eyelet holes do not fall into place, then all your work was in vain. Photo for clarity below.

To remove and install this silent block, you will need a special “glass” (so as not to damage the lugs during installation) having the following dimensions: diameter 58 mm, height 70 mm, internal diameter 35 mm and depth 50 mm. Only with the help of this device will you be able to replace the silent block of the trailing arm.

Buying a silent block together with an assembled lever is very expensive, so it’s easier to grind a glass of this size from some mechanic or look for other options.

Using this “glass” you squeeze out the silent block, just keep in mind that you can squeeze it out only in one direction. Also, when pressing, the silent block is inserted in only one position.

For reference, the trailing arm of the rear suspension of the Focus 2 has a rather complex shape and is the element on which the rear wheel hub is attached, so the part experiences quite serious loads. In the photo above, the arrow indicates the position of this difficult silent block.

Replacing rear suspension arms in a Ford Focus 2

I didn’t believe the servicemen’s conclusion and checked the suspension myself - it turned out that the verdict was more severe. All levers, except those that sentenced! (But during the replacement process the situation changed, more on that later). I bought everything that I considered to be out of order. I would also buy spring-loaded levers, which were rejected at the service center, but I didn’t have enough money, so next time. In general, I bought: Silent blocks of trailing arms — febi (2*462); Lower transverse arms with bolts - febi (2*992); Transverse upper (sickles) - lemferder (2*1424). Replacing the levers is not difficult, as long as the bolts do not rust to the point of being cut off. I was afraid for the silent ones. I bought several tins at the Krepezh store to build a press-out device; I also wanted to adapt the existing press-out device for a different type of silent. The procedure began:

I lifted the car onto stands.

Jacked up the lever to remove the arms. In this position of the jack, the lever does not move to the side when lowered. And it’s better not to lower it all the way unless you plan to change the spring arms. I lowered and removed the spring; when installing, the spring did not fit evenly into the upper rubber pad.

The rubber bands are fine.

I started unscrewing the bolts, but did not pull them out completely until the trailing arm was completely ready for removal.

I removed the trailing arm completely to make it easier to press the silent block; to do this, you need to remove the brake caliper.

To remove the caliper you need to unscrew two 13mm bolts, one can be unscrewed with a head, the other with a z-shaped spanner. And under the plugs there was a hexagon for 7 (there was no 7, but two for 8, so I sharpened it with a grinder and made it). I removed the bracket with the pads and hung the caliper on a wire.

I took it off, heavy, and tired after half a day of torment.

This lever is in good condition; the bushings were changed last year, as it turns out.

This (sickle) is cracked.

Using this design, I pressed out the rubber part of the silent.

Dancing with a tambourine began, the real thing. To begin with, I cut off the ring, I don’t know why, then there was meaning and logic.

The piece of iron did not react to the blows. There was a metal blade, and I used it to saw this ring for a long time.

Then he knocked it out with a chisel - he pressed it out! Now we need to press it in.

I pressed it using this glass...

...and these pieces of pipes and parts of an unsuccessful design, clamped in a large vice. I made a multi-layer cake and pressed it with a vice. This method requires a vice that can open approximately 20 cm. I didn’t get to this point right away, I tried in different ways. If my homemade design had been made from 4-5 mm sheets, and not from tins, it probably would have worked out. From morning until nine in the evening, I could only press in one silent seal, and didn’t even remove the second one. Time was wasted trying to get the trailing arm without removing the caliper, i.e. on the hoses. All the operations to free the lever from the remnants of the silent, given that the lever itself weighs about 15 kg, were even more difficult. To cut pipes of 5.5 and 8.5 cm of 89th thick-walled pipe, I had to cut three cuts with a 125 mm grinder. To make a cake in a vice, there was not enough centimeter to fully fit between the jaws, so the vice often came out of gear. The next day everything went smoothly, I already knew what to do. When removing the trailing arm, I removed the caliper in advance. Silent, i.e. I pulled out the rubber part by hand and even recorded a video. Then I immediately put the lever in a vice and, not with a blade, but with a piece of metal, I cut off the remaining silent tape. Then the process was established, the equipment was already ready from yesterday, it was pressed in just over one hour (after all, no one changed the vice). I also took sunflower oil with me for pressing. Well, I put everything back together. During assembly, I realized why it is necessary to jack up the suspension to the “car on wheels” position. In this position, the levers take a normal position and everything is assembled well, both the levers fit in and the bolts fit in. During operation, when the wheel lowers (the body rises), the silent blocks of all levers begin to tighten, trying to return the wheel to its normal position. That's the elasticity of the suspension from each lever. The lower straight arms turned out to be in good condition, I think they can be sold inexpensively. And the spring-loaded, outer silent block is in terrible condition.