Replacement of silent blocks of the rear beam on a VAZ 2109. We do it every 100 thousand km.

Such work as replacing the silent blocks of the rear beam on a VAZ 2109 is not something out of the ordinary. Almost every car enthusiast has encountered such work. There are no particular difficulties with this repair; it is only important to do everything in a certain order. Before work, a number of steps should be taken to prepare the machine. This will greatly simplify your task. This procedure does not require much experience, and since you will need it relatively regularly, the easiest way is to learn how to do everything yourself. This way you can save a good amount of money on visiting the service.

How to choose a spare parts manufacturer?

Replacing rear control arms is not a cheap procedure, so car owners try to save on parts. There are options for branded parts, or OEM manufacturers. There is practically no difference in quality, but the cost is very different. Our service managers will help you choose a quality lever at a reasonable price. It does not matter what logo the other parts were installed with. If the rear trailing arms were replaced at a dealer service station, and you change the transverse arms at our service center, the quality will be just as high, and the cost of parts and labor will be significantly lower.

We are not burdened with obligations to manufacturers regarding the formation of a pricing policy. You pay only for real work, without a premium for the brand. The customer can also purchase spare parts from different manufacturers from us for subsequent installation. At the same time, you should not rush to the other extreme - repairing the suspension from a neighbor in a garage cooperative can result in too high a price after an accident.

When repairs are required

Replacement of silent blocks of the rear beam on a VAZ 2109, according to the manufacturer’s recommendations, occurs after 100,000 kilometers. But, in practice, silent blocks rarely last that long. The usual service life is a year or 30-40 thousand kilometers. Polyurethane ones last longer. The main reasons for such rapid wear:

- Low quality material;

- Upon visual inspection, damage is visible to the naked eye.

Any of these problems indicate the need to replace silent blocks.

What are silent blocks in a car: signs of malfunctions and replacement of silent blocks

As you know, a car suspension consists of a large number of parts that are connected to each other. At the same time, the silent block is an element of the car suspension, which is necessary for connecting the suspension parts.

Next, we will look at the general structure of silent blocks, their malfunctions and signs of problems with this part, as well as when and why they need to be changed, how silent blocks are replaced, etc.

Required Tools

The first thing you need to do is purchase suitable silent blocks (see the article “Which silent blocks are better, rubber or polyurethane”). The simplest option would be to purchase a wear-resistant rubber part. But, in this case, you need to prepare for their rapid wear. Spare parts made from polyurethane are more durable, but they cost 3 times more. It is advisable to use original silent blocks. If desired, you can use a part from a VAZ-2110; they are considered more durable. You will have to tinker with the installation of such an elastic band; it is slightly larger in diameter and will not fit into place easily.

Purpose and location of silent blocks

The word “silent blocks” comes from foreign cars; previously these elements were called rubber-metal hinges. The part is a connection of two metal tubes, between which there is a rubber insert. Silent blocks are installed in the rear and front suspension. The task of these elements is to change the angles of the wheels of the VAZ 2110. They are also the unifying parts of the suspension and dampen vibrations that appear during driving.

Important! The approximate service life of silent blocks is 100 thousand kilometers, but sometimes these parts wear out ahead of schedule. The service time depends on many factors: driving style, availability of a garage, regularity of VAZ 2110 diagnostics.

In this material, we will examine the replacement of silent blocks in the front suspension, since here they are subject to heavy loads, as a result, the rubber rubs and the tubes wear out. These VAZ 2110 parts are installed on the rear and front control arms. The joints are also used as mounts for the engine, gearbox and shock absorbers. The replacement can be done independently if you have an inspection hole and a jack.

Replacement

First you need to prepare the car. Wheel chocks are installed under the front wheels. Also, all threaded connections are processed with a liquid wrench; it is better to do this in advance. The work is carried out in the following order:

After driving 10-15 kilometers, be sure to tighten all threaded connections affected during the work.

Replacing the front suspension arm silent block

Regardless of the make and model of the car, the replacement process is almost the same. All you need to do is get to the part being replaced, dismantle it and install a new one. Below, the photo shows what the suspension of a Ford Focus 2 looks like. Work order:

- We place the car in a viewing hole or on a lift.

- Raise the front side on which the silent block will be replaced with a jack.

- Remove the wheel.

- Remove the protective casing and crankcase protection.

- Remove the ball joint. You may need a ball puller to remove the ball.

- Remove the front arm. To do this, unscrew several bolts, 3-5 pieces. The lever can be easily removed.

- Remove the old silent blocks from the dismantled front arm. To do this, you need to use a puller or a chisel with a hammer.

- Clean the seat before installing a new part. Clean with sandpaper, wash and lubricate.

- Now you need to press in the new silent block using a puller. After installing it, assemble the unit in the reverse order of disassembly.

- After lowering the car, tighten the bolts.

Useful tips

The brake hose is located on the beam. If the eye is moved, it can be damaged. Pay attention to this point and be careful when working. Most often, damage occurs from contact with the mount. Always look at what it is leaning on.

In most cases, it will not be possible to simply unscrew the fastening nut. In this case, you need to tap it out. Just don’t hit the nut, hit the screw, the vibration will make it much easier to unscrew it. Using a pipe will also make the task easier. It is put on the knob, this way you can increase the lever and, accordingly, the force transmitted to the nut. As a rule, after such exposure, the most rusted connection gives in.

Conclusion

. The suspension of all cars on domestic roads is subjected to serious tests. Therefore, work such as replacing the silent blocks of the rear beam on a VAZ 2109 is not uncommon. In fact, there is nothing complicated here. The main thing is to do everything in a certain order, and there will be no problems during work.

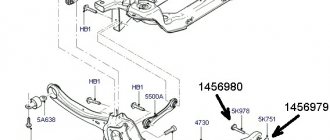

Article: 2110-2914054, additional articles: 2110-2914054R

Order code: 012796

- You may need

- show more

- Passenger cars / VAZ / VAZ-21101 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2110-10/podveska_zadnyaya-175/#part41718″>Lever joint Suspension / Rear suspension

- Passenger cars / VAZ / VAZ-21121 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2112-12/podveska_zadnyaya-175/#part50334″>Lever joint Suspension / Rear suspension

- Passenger cars / VAZ / VAZ-2110, 2111, 21121 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2110__2111__2112-415/podveska_zadnyaya-195/#part1304366″>Lever joint Suspension / Rear suspension

- Passenger cars / VAZ / VAZ-21141 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2114-647/rychagi_zadneiy_podveski-106/#part1670253″>Lever joint Suspension / Rear suspension arms

- Passenger cars / VAZ / VAZ-21091 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2109-701/rychagi_zadneiy_podveski-125/#part1931337″>Lever joint Suspension / Rear suspension arms

- Passenger cars / VAZ / Lada Kalina 1117, 1118, 11191 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_kalina_1117__1118__1119-1048/podveska_zadnyaya-153/#part2613411″>Lever joint Rear suspension / Rear suspension

- Passenger cars / VAZ / Lada Kalina 1119 Sport2 drawings

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_kalina_1119_sport-1556/podveska_zadnyaya-95/#part3439906″>Lever joint Rear suspension / Rear suspension

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_kalina_1119_sport-1556/podveska_zadnyaya-94/#part3439883″>Lever joint Rear suspension / Rear suspension

- Passenger cars / VAZ / Lada Kalina 21941 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_kalina_2194-1886/d301__podveska_zadnyaya-204/#part4211452″>Lever hinge Rear suspension / D301. Rear suspension

- Passenger cars / VAZ / VAZ-21081 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2108-18/podveska_zadnyaya-158/#part29579″>Lever joint Suspension / Rear suspension

- Passenger cars / VAZ / VAZ-21111 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2111-11/podveska_zadnyaya-175/#part46026″>Lever joint Suspension / Rear suspension

- Passenger cars / VAZ / VAZ-21151 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2115-65/podveska_zadnyaya-131/#part53930″>Lever joint Suspension / Rear suspension

- Passenger cars / VAZ / Lada Kalina 11181 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_kalina_1118-437/podveska_zadnyaya-128/#part1357945″>Lever joint Suspension / Rear suspension

- Passenger cars / VAZ / VAZ-21131 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2113-648/rychagi_zadneiy_podveski-106/#part1670253″>Lever joint Suspension / Rear suspension arms

- Passenger cars / VAZ / Lada Priora 21701 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_priora_2170-480/podveska_zadnyaya-125/#part1579580″>Lever joint Suspension / Rear suspension

- Passenger cars / VAZ / Lada Granta 21901 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_granta_2190-1236/podveska_zadnyaya-123/#part2981670″>Lever joint Rear suspension / Rear suspension

- Passenger cars / VAZ / Lada Priora 21728 Coupe1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_priora_21728_coupe-1878/podveska_zadnyaya-129/#part4190815″>Lever joint Rear suspension / Rear suspension

- Passenger cars / VAZ / Lada Priora 2170 FL1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_priora_2170__fl-1889/d300__podveska_zadnyaya-217/#part4225206″>Lever hinge Rear suspension / D300. Rear suspension

- There are no reviews for this product yet.

All structural elements of the car are constantly exposed to vibration. Therefore, all measures have been taken in cars to reduce vibrations, and the main role in solving this problem is played by small and inconspicuous parts - silent blocks, or rubber-metal hinges. It is these details that are discussed in this article.

Today, in the next article in the series “Crystal VAZs or typical breakdowns of domestic cars,” we will talk about the latest developments of the Volzhsky Automobile Plant: Lada Grante and Lada Largus. Let's talk about the history of the creation of these models, as well as their characteristic malfunctions.

The series of articles “Crystal VAZs, or typical breakdowns of domestic cars” talks about typical problems and malfunctions of cars produced by the Volzhsky Automobile Plant. Today we will talk about the front-wheel drive Samara family, as well as its modern analogues.

Usually, replacing the rear silent blocks of a VAZ 2110 is quite cheap. Therefore, many decide to perform this procedure directly at home. What are the advantages of replacing it yourself? The fact is that replacing silent blocks in the rear beam of a VAZ 2110 will cost several times less.

Replacing rear beam silent blocks on a VAZ 2109

Silent blocks produced by AvtoVAZ can safely be called one of the highest quality parts. It is not surprising that other foreign manufacturers also use them for their cars.

Element appearance

The durability of almost any part, including the silent block, directly depends on the driving style of the motorist. The service life of the element is more than 30 thousand kilometers.

The purpose of silent blocks in a car and when to change them

Silent blocks in a car can be found in almost every component suspension or engine mount. Let's consider the purpose of silent blocks, when they should be changed and what they consist of.

The car suspension is not a simple mechanism. For the most part, these are moving parts to control the car or for a comfortable ride. One such example is rubber-metal hinges, or better known as silent blocks.

More often they find out about their replacement when they fail, and then they wonder what they are and what they are intended for. To understand everything, let's take a closer look at the silent block, its components and purpose.

Features of elements

The main function of silents is to eliminate vibrations and deformations that occur during vehicle operation.

When choosing new silent blocks for the rear beam of a VAZ 2109, pay attention to the markings. It should be 2109-2914054. For VAZ 2114-15 models, the markings are different, but the elements themselves are very similar.

In principle, it is possible to install a silent block from a dozen on a VAZ 2109, but you will have to work hard with pressing in the rubber bushing due to the difference in size. The reverse procedure is not possible.

Rear beam

When to replace hinges

As a rule, a high-quality rear silent block of the front lever can last quite a long time, up to 100 thousand km. But if you take into account the state of domestic roads and take into account other difficult operating conditions of the car, experts recommend carrying out a technical inspection of the suspension every 50 thousand km.

Before inspection, the hinges should be cleaned for a better visual assessment. The presence of large play, as well as cracks in the rubber, its swelling, and ruptures indicate a malfunction of the part. Silent blocks cannot be repaired, but can only be replaced.

Any driver should know that the presence of a malfunction of one or another system, component, or unit of a vehicle poses a potential threat to all road users. In this regard, if you discover faulty silent blocks of the front lower arms or other components, you should immediately replace them. This can be done at any car service center. Although the process itself is not so complicated, and the work can be done independently. True, outside help won’t hurt, especially for the first time.

Symptoms of a problem

There are several main signs of failure of the rear beam silent blocks, including:

- Unstable behavior of the car on the roads;

- Tires wear unevenly, which is not difficult to notice from the tread pattern;

- When driving on a bad road (that is, 95% of all our roads), unpleasant squeaks and impacts on the car body are observed.

These signs are indirect, since they may be associated with other failures of the vehicle’s chassis. For example, dull knocks are also a sign of a faulty rear pillar. Therefore, in order to make sure that there is a particular problem, you will need to fully diagnose the chassis.

All about silent blocks: description and varieties

The function of the silent block is to connect the rear suspension beam and the car body.

The secondary function is to dampen oscillations and vibrations during movement. The design of this unit element is quite simple. It consists of only two components: a bushing and a rubber gasket. Bushings are divided into external and internal. The external ones are made of plastic, the internal ones are made of metal. The rubber gasket located in the empty space between the bushings does not completely fill it. Rubberized areas alternate with “voids,” which allows this element of the assembly to twist more easily if necessary. The design of the silent block simultaneously performs two options: it resists loads on the beam in motion, and also does not allow the rubber gasket to tear.

Traditionally, car parts are installed in their proper place in compliance with all requirements. As for the silent block, it also has a spatial orientation, so installing it correctly is very important.

While the vehicle is moving, the part is exposed to a number of external influences:

- environmental influences: rain, wind, hail and snow;

- the influence of shaking, impact loads from driving on uneven road surfaces;

- the influence of the torsional load that occurs when the rear beam moves.

These processes are considered to be natural, so the wear factor from them is included in the design of the silent block by design engineers. Under normal conditions, with measured driving on a high-quality road, the connecting element of the suspension will easily cover up to 100 thousand km. In reality, the situation described above happens extremely rarely. More often, the silent block is influenced by a number of external factors:

- incorrect installation of the silent block: non-compliance with technology, etc.;

- driving on a sand-salt road in winter;

- regular driving on bad roads with potholes, potholes, etc.

The less often you expose your vehicle to movement in the situations described above, the longer the silent block and the suspension as a whole will function properly. The silent block of the Renault Logan rear beam is a completely wear-resistant part if you provide it with at least the least gentle conditions.

Choice

Before you start replacing the silent blocks of the rear beam, you need to decide what exactly you will replace the old, worn bushings with.

We figured out the markings and realized that for the VAZ 2109 you need to take only those that are suitable in size and diameter for the rear beam of the nine.

Today, for the VAZ 2109 they offer two types of silents, differing in the material of manufacture.

Silent block type

Peculiarities

They are not as durable, but provide greater softness when operating the car's suspension.

A more rigid modification, in which the increased rigidity is the main disadvantage. At the same time, these products are more resistant to temperature changes, do not deform so quickly, and remain operational longer.

Size difference

What is a silent block?

The silent block also has another name - rubber-metal hinge. It consists of 2 combined metal bushings, separated by a durable elastic polyurethane insert.

Its primary task is to dampen vibrations in the connections of parts that occur when the machine moves. Uneven road surfaces, potholes and other obstacles transfer a large amount of shock loads to the car’s suspension. Up to 90% of them are taken over by the silent block.

The car's suspension uses two types of rubber-metal joints for the front and rear wheels. This allows the shock load to be evenly distributed along the entire length of the suspension. Additionally installed in the mounting elements of the gearbox and engine.

Replacement

To replace you will need:

- New rear silent blocks;

- A small wooden beam;

- A device for pressing in a silent block (you can do the job without it);

- Open-end wrenches;

- Socket wrenches;

- Spanners;

- Hammer.

Dismantling work

When everything is ready, you can start working.

- Place the car on a level surface in the garage above a pit or overpass. Be sure to place wheel chocks and shoes under the wheels. All for your safety.

- It is better to remove the rear wheel to make it easier to work.

- But it is not at all necessary to remove the rear beam. Just complicate your work with unnecessary dismantling processes.

- On the left side of the driver is the pressure regulator rod for the rear brakes. It will disturb you while you work, so we advise you to remove it. This is done by removing the locking bracket of the rod and the handbrake cable. You will remove the latter from the right side from the mount.

- Unscrew the nut from the bolt with a 12mm wrench that holds the rear beam to the bracket. This may cause problems. Place a socket wrench on the driver to increase leverage on the fastener. Remove the bolt, lift the car with a jack and move the beam down. It will come out of the eyelet this way. Do not overdo it to avoid damaging the nearby brake hose. If you press too hard on the pry bar while moving the eye, you risk breaking the hose.

- Take a pre-prepared wooden block and insert it between the body and the beam. This must be done so that the beam is below the eye.

- Using a hammer and a drift (regular metal tubing will do), knock out the old worn bushings. By the way, if you come across such a concept as “fungi”, don’t worry. This is what car enthusiasts often call these bushings because of their external similarity.

- Clean the seat from accumulated dirt and rust. Be sure to lubricate the areas with soapy water. Without it, it will be difficult to press in new silent blocks. Or use a simple dish detergent. Under no circumstances should you lubricate the seats with grease or oil, as these substances will soon begin to corrode the element.

- Now it presses in new elements. Ideally, you should have a special pressing tool. If you don't have one, use a regular hammer.

- Take out a wooden block.

- Armed with a second jack, lift the beam and insert the mounting bolt into place and tighten it with a nut.

- Reinstall the rear wheel and lower the car to the ground.

Only upon completion of all these stages can the bolts of the new silent blocks be tightened until they stop.

Such an operation should not cause any special problems, so it is not at all necessary to go to a service station and spend extra money.

Pressing tools and methods

At the factory, the silent block is pressed into the beam seat and is held there solely by friction. Therefore, you won’t be able to simply knock it out and get it out. It would be best to press out and press the part with a special puller. In the absence of one, you can resort to drilling out the rubber damper, which will loosen the tension a little, and cutting the outer ring with a hand hacksaw. On the Internet you can find methods in which the outer ring is bent with a chisel or a screwdriver is driven under it, and then the silent tape is knocked out of its seat. We do not recommend using such barbaric methods, as there is a risk of damaging the seat in the beam.

The design of the puller is a prefabricated mechanism consisting of mandrels, a pin and two nuts. The outer diameter of one mandrel, for which a thick washer is best suited, should match (preferably even a little smaller) with the diameter of the outer metal holder of the silent block on the press-out side. The second attachment will serve as a stop and a cavity into which the silent will go when pressed out. Its diameter must be greater than the internal diameter of the seat in the beam. As mandrels you can use large washers, bearing races, pieces of pipes of suitable diameter. There are universal wheel bearing puller kits on the market that may be suitable for repairing the rear beam.

What other tools are needed besides a puller? You need spanners and sockets for unscrewing the beam mounting brackets and the silent block itself. When completely removing the rear beam, you will need to unscrew the lower shock absorber mount and the brake hose, and you will also need keys to bleed the brake system. It is most convenient to carry out work from the inspection hole.

Do-it-yourself replacement of rear beam silent blocks on a VAZ 2110

The procedure for replacing the silent blocks of the rear beam on a VAZ 2110 car is usually carried out independently by the owner of the car. Repairs of this kind do not require special skills and experience, plus they are quite cheap.

Rear beam

Today we will talk about where exactly it is better to make a replacement, how to choose the right silent blocks, and also how to carry out the process itself in two ways.

Tips for replacing and operating VAZ 2110 silent blocks

- Rear silent blocks must be replaced every 50,000 km, because they are the least durable products compared to other rubber beam bushings.

- Even if one silent block fails, the other one should be changed, because if you replace only the non-working one, the remaining one will “knock” after it, because its resource was already running out.

It is worth noting that the success of repairs to replace silent blocks depends on the qualifications of the car owner, the availability of the necessary special tools for removal, and experience in the operations performed.

To replace the front arm silent blocks on VAZ 2110 cars you will need:

- lubricant or liquid soap (can be replaced with detergent or soapy water);

- wrenches (both socket and socket) for 24, 17 and 19;

- ratchet with a head for 24, 17 and 19;

- chisel and hammer;

- penetrating fluid WD-40;

- a universal cup puller or a piece of pipe whose diameter allows free entry of the silent block;

- metal brush;

- knife and screwdriver (with a blunt end);

- inspection hole;

- jack;

- new silent blocks for VAZ 2110.

By the way, the price for rear silent blocks from VAZ with article number 21100291405400 will be 140 rubles per piece, and its polyurethane analogue from the manufacturer VTR with article number LADA0401RP is 460 rubles.

The price is indicated for spring 2020 in Moscow and the region.

We hang out the back of the car. Disconnect the parking brake cable from the beam and bracket.

Garage or service station

All car owners can be divided into two categories:

- Those who carry out most of the repairs themselves in their garage, and only in emergency cases turn to a car service;

- Those who prefer not to touch anything with their own hands, but completely entrust repairs and maintenance to the masters of service stations.

Each of them is right in their own way. Therefore, we have no right to reproach those who do not want to carry out repairs themselves. After all, garage and professional repair of silent blocks, like other components, has its advantages.

STO has the following advantages:

- A high-quality, responsible car service provides a guarantee for repairs performed;

- In the event of a repeated breakdown covered by the warranty, repairs will be carried out free of charge;

- Professionals are professionals; they have extensive experience and knowledge, which allows them to competently perform their work.

But first you need to find such a car service, which, alas, is not an easy matter. Many provide a guarantee, but when you re-apply, they do everything possible to prove that the breakdown does not comply with the terms of the guarantee. A banal trick.

Repairing your garage will provide the following advantages:

- Significant financial savings, since you only have to spend money on consumables;

- The quality of the work performed by a master is always in doubt if you do not know this person personally. So self-repair may be much better than at a service station;

- You purchase the silent block, and the master only installs it. Why pay money for work that you can do yourself?!;

- Guarantee that a new one will be installed instead of the old silent block. Questionable service stations can easily install an old, more or less usable silent block instead of the one you gave them. You know what the result is.

Replacing the upper Focus arm

Replacing the upper arm of the Ford Focus rear suspension is carried out when there is mechanical deformation or wear of the silent blocks (cracked rubber, peeling, etc.) To remove the arm, we will need a platform or hole, ties for removing the rear spring and an adjustable stop for the lower arm.

We remove the spring using zip ties, remove the wheel, install an adjustable stop or hydraulic jack under the lower rear arm at the junction of it with the trailing arm, and use the stop to raise the arms so that the rear suspension is in the “car on wheels” position.

Using a 15mm socket, unscrew the bolt securing the upper arm to the trailing arm. This bolt also secures the brake hose bracket. Using a 15mm socket, unscrew the bolt securing the upper arm to the subframe.

Using a screwdriver, pry the ends of the lever out of the brackets and remove the lever from the car. We install the new lever in the reverse order with the deflection down.

Replacing the lower front arm Focus

As in the case described above, we will need to remove the spring, remove the wheel and place an adjustable stop or a hydraulic jack under the lower arm at the junction of it with the trailing arm, and using the stop we raise the arms so that the rear suspension takes the “car on wheels” position. . Naturally, we do all this on a pit or overpass.

Then, using a 15mm wrench or socket, unscrew the bolt securing the lever to the trailing arm and remove the bolt. Similarly, unscrew the bolt securing the lever to the subframe and remove the bolt. Using a screwdriver, pry the ends of the lever out of the brackets and remove the lever. Photos for clarity are attached below.

Install the new lever in reverse order. In this case, it is worth considering one important point: the inscription “FRONT” on the lever should be directed towards the front of the car.

Replacing the lower rear arm Focus

The lower rear arms of the Ford Focus have spring support cups. The upper ends of the springs rest against the subframe cups. The cups have rubber gaskets. As in previous cases, we will need to remove the spring, plus unscrew the anti-roll bar. We place a stop under the rear lever (at the junction with the trailing lever).

The rear suspension has adjustable wheel toe angles, so we mark the position of the eccentric washer relative to the subframe so that when assembling and installing a new lever, the toe angles of the Ford Focus wheels are approximately maintained. In this case, the position of the adjusting bolt head does not need to be marked, only the washer relative to the subframe.

Using a 15mm socket, unscrew the bolt securing the lower rear arm to the trailing arm and remove the bolt. To be able to remove the adjusting bolt after unscrewing the nut, it is necessary to press the latch of the canister of the fuel vapor recovery system and move the canister away from the subframe.

Use a socket or a 18mm wrench to unscrew the nut, holding the adjusting bolt from turning with a 19mm wrench. Remove the eccentric washer and remove the adjusting bolt. The bolt has a groove for fixing the washer in a certain position.

Remove the lever from the car. Using a screwdriver, remove the rubber buffer from the lever and install it on the new lever. True, if the buffer is broken or has cracks and tears, it naturally needs to be replaced.

We install the lever in the reverse order, with the head of the bolt securing the lever to the subframe facing towards the front of the car.

And the mark made on the eccentric washer should coincide with the mark on the subframe.

The bolt securing the lever to the trailing arm and the nut of the eccentric bolt are finally tightened to the prescribed torques only under load, in the “car on wheels” position.

After replacing this lever, it is advisable to adjust the wheel alignment of the rear wheels.

Replacing the Focus trailing arm

A silent block is installed in the front part of the Ford Focus trailing arm, through which the arm is secured with two bolts to the body. The rear wheel hub assembly is secured to the rear of the lever with four screws. Replacement of the lever is required when it is deformed or the silent blocks are worn.

As with other levers, we carry out replacement work in a pit or overpass (lift) with removal of the spring and wheel. Plus you need to place a stop under the lower arm. Without an adjustable stop, removing the bolts from the silent block eyes will be problematic.

- Remove the three wheel speed sensor wire holders from the trailing arm holes and disconnect the wire block from the wheel speed sensor.

- Using a 10mm head, unscrew the self-tapping screw securing the stop of the parking brake cable sheath and remove the stop from the hole in the lever.

- Disconnect the lower end of the shock absorber from the trailing arm, then disconnect the transverse suspension arms from the trailing arm.

- We remove the hub assembly, then use a 15mm head to unscrew the two bolts securing the lever to the body and remove the trailing arm.

Why change silent blocks

Before you begin replacing the rear beam silent blocks on a VAZ 2110, you need to figure out why such a procedure is being carried out at all.

In fact, it is not always silent blocks that cause car problems. But there are situations in which repairs should be performed immediately.

- When traveling, the tires begin to squeak. If the silent blocks are out of order, they cannot move at the same time as the wheels, they are inferior in rotation speed, which is why noise occurs.

- Knocks are heard from the rear of the car.

- The car is difficult to control, the rear end constantly skids, and it is difficult to take turns.

- There is uneven wear on the rear tires; they lose their quality faster than the front tires.

- In some cases, tires go flat even though there is no damage.

Checking silent blocks

Sometimes it is impossible to immediately determine whether a VAZ 2110 part is working or not. You can check the silent blocks without dismantling them. To do this, you need to drive into the inspection hole and inspect the hinge - it must be clean, otherwise the damage may not be noticed. The rubber part of the hinge must not have any tears or cracks. Another sign of a damaged part is improper camber/toe. When the hinges break, the lower and swing arms lose stability and become crooked.

It is also necessary to check the play; if it is too large, replacement will be required. It is not recommended to postpone repairs, since faulty rubber-metal joints negatively affect the handling of the VAZ 2110: the car pulls and throws.

The silent block of the rear beam is a rubber-metal hinge. The part serves as an elastic insert between the car components. It consists of two bushings, between which there is a seal made of rubber or other elastic material. Recently, polyurethane has become widespread. A gasket made of elastic material allows you to dampen vibrations between components and not transfer vibrations to the car body.

The silent block of the rear beam is used not only for connecting suspension units to each other. The element is also attached to the anti-roll bar, at the mounting points of the gearbox and engine of the car. But the suspension has the most severe operating conditions due to dust, dirt, moisture and active movement of parts, so replacement is done regularly.

Rubber bushings are not items that will last forever. Usually they last for 100 thousand kilometers, but due to harsh operating conditions, the replacement period may come earlier. After half this period, it is necessary to check the suspension. This is the only way to understand the degree of wear of the unit and determine whether it needs to be replaced.

Visual inspection procedure:

- drive the car into a pit or lift it with a jack;

- clean the suspension mounting points from dirt;

- carry out an inspection.

The rubber insert must not have cracks or tears. Signs of this kind indicate that it is time to replace the silent blocks of the rear beam. A worn part will subsequently affect handling, and this, in turn, will affect the safety of the car owner and others.

Sometimes the part wears out earlier, especially when driving off-road. The degree of wear can be assessed by the behavior of the car.

Signs of wear on silent blocks:

- when driving in a straight line or when braking, the car pulls to the side;

- increased wear of rubber on the sides;

- increased vibration when driving;

- creaking or knocking in the suspension area;

- the suspension began to work harder.

The presence of one or more signs means that it is time to service the suspension. Delay can be costly. Untimely replacement will lead to loss of control in a critical situation, as well as accelerated tire wear. The hinge seats will also be damaged and then the lever will have to be replaced - this will increase the cost of repairs.

Metal parts of the part break extremely rarely. The rubber gasket usually wears out.

Reasons for premature replacement:

- Long-term use, which leads to drying out of the rubber seal and loss of properties.

- Interaction with chemicals. Oil and gasoline destroy rubber.

- Incorrect installation.

Premature wear indicates that the cause needs to be found and eliminated. Otherwise, the replacement procedure will soon have to be repeated. Oil leaks will be clearly visible, and installation should be carried out strictly according to the instructions and connections should be checked.

Selecting New Items

Polyurethane

To replace and ensure reliable operation of the car, you need to purchase good silent blocks. Choosing them is not difficult if you know some nuances:

- For the VAZ 2110 model, elements with catalog number 2110 2914054 are suitable. They have the required outer diameter corresponding to this specific VAZ model;

- Do not try to purchase a silent block from a “nine” and install it on your “ten”. Nothing will come of such events, no matter what anyone says;

- Make sure of the quality of the products. Low-grade silent blocks have flooded the market, but their service life leaves much to be desired. Good parts are made from high quality materials that can withstand extreme loads and temperatures.

Rear beam silent block

Silent blocks are included in the standard equipment of cars. They are often very reliable and do not require emergency replacement when purchasing a car. If these details are erased, it will not be very soon. And yet, after a few years, you will be faced with the need to change the silent block of the rear beam. If you used the car incorrectly and did not spare it, then this need will come to you even faster. How to understand that the silent block needs to be replaced? For example, your car will no longer be stable when cornering, and your tires will begin to wear very unevenly. You will also notice how the body shakes at the slightest unevenness in the road, and the rear beam of the car will begin to creak. Of course, squeaks can be signs of other machine malfunctions, so pay special attention to the combination of these factors.

Replacement methods

We will tell you about two main ways to replace silent blocks on the rear beam of the “tens” , which can easily be used in a garage.

Which method to choose is up to you to decide. But before that, familiarize yourself with them in more detail.

First way

The method is not particularly difficult if you strictly follow the instructions. To begin with, we note that the silent block is located at the bottom of the car. Therefore, you will need a jack or inspection hole.

Defects

- Raise the car with a jack or drive it into a viewing hole. The second option is more convenient, since this way the view of the bottom will be better. And it’s much more convenient to work standing up than lying under a car.

- It is not necessary to completely remove the rear beam. When dismantling it, you will need to remove additional brake hoses, which takes a lot of time.

- It is better to disconnect the sorcerer so as not to damage it during the repair process. But shoot carefully.

- Now remove the nut with a 19mm wrench. You will have to make a serious effort, which is why some car owners call their comrades for help. If there are no assistants, pre-treat the thread with the almighty WD40 or plain water. This will allow the fastener to oxidize. Then clean it with a wire brush, which will make it easier to remove the element.

- Using a crowbar, lower the beam down a little, but do not remove it completely.

- There is an elastic band on the beam that should be cut off, otherwise it will interfere with the work process. Just keep in mind that if the rubber band is old, feel free to remove it. It is better to dismantle a good product by drilling a small hole.

- Now the silent block is removed.

- The new part is generously lubricated and pressed into its rightful place. Just do not use grease for lubrication, as this substance corrodes the part. The best lubrication option is regular soap or any available detergent.

- Return the sorcerer to its place and tighten the beam.

Second way

The second option for replacing the silent block is even simpler. But he also has his tricks.

Easy way

- Raise the car on a jack or drive it into a viewing hole.

- Using the same 19 mm wrench, remove the fastening nuts on the rear beam. This will allow you to detach the beam from the bracket.

- Remove the unscrewed bolt and move the rear beam eye down slightly.

- To make work easier, insert a wooden beam between the beam and the body, approximately the same size as a regular building brick.

- Remove the silent block by hitting it with a hammer.

- Lubricate the new block with something slippery, which will allow the element to do its job better.

- Press the silent block into its place.

- Remove the inserted beam and return the beam to its original position, securing it with fasteners.

At this point, the procedure for replacing the silent block of the rear beam of your domestic “ten” produced by AvtoVAZ can be considered complete.

Both methods allow you to independently, without unnecessary problems, resolve the issue of a failed silent block. Just in case, don’t forget to call a friend in the garage who will help you at the most difficult stages.

What is a silent block?

Essentially, it is a rubber-metal hinge, which consists of two metal bushings and a rubber insert. It is rubber that acts as a shock absorber and absorbs all vibrations that pass through the body. Traditionally, front control arm silent blocks are made in a cylindrical shape.

There are companies that use polyurethane during the production of hinges. In this case, operational and technical characteristics are improved. And their service life increases by 5 times, which also applies to cost.

Silent blocks are installed in different places. It could be:

- the suspension system itself;

- place of attachment of levers;

- anti-roll bar mounting location;

- engine mount.

And since the silent blocks of the front control arms take on enormous loads (axial, radial, torsion, etc.) when the car moves, they are the first of all suspension parts to fail. However, due to their low cost, replacing them is not expensive.