Many car enthusiasts neglect special knowledge in the diagnostics section of car problems: they say, if problems arise, I’ll contact a car service center. In fact, basic knowledge is necessary precisely in order not to miss the moment of mandatory contacting a car service and thereby avoid serious problems.

The chassis of your car is its most important component and at the same time one of the most problematic; the chassis is the first component that suffers from the quality of the roads. The behavior of the car on the road directly depends on the condition of the chassis.

Chassis diagnostics are necessary for the proper and safe operation of your machine. The chassis includes wheels, front and rear suspension, and the vehicle frame. As a result of constant loads both during movement and at rest, chassis components are subject to a higher degree of wear and may require replacement.

Car suspension diagnostics

Faced with all the listed symptoms, your task will be to determine the suspension element that has failed.

- Front suspension.

In order to diagnose the front suspension of a car, you will first need to open the hood. While the vehicle is on the ground, i.e., the suspension components are under load, inspect the upper strut mounts. Pay close attention to the gap between the cup and the body (mudguard). The photo below shows that a screwdriver can fit into the existing gap.

The fact that the upper cushions need to be replaced will be indicated by a gap, the size of which is close to one and a half centimeters. Try rocking the car. If the body moves more than twice after you stop pumping it, the shock absorbers need to be replaced. After this, the vehicle should be raised (using a jack or hydraulic lift) and the shock absorbers should be examined from the side, paying attention to the presence of any leaks. If you notice them, get ready to change your shock absorbers.

Now grab the car wheel and swing it in different directions, both left and right and up and down. Swinging from right to left can lead to knocking noises from the steering rod, or (which is more common) from its tip. When faced with such sounds, call a helper, while one of you pumps the wheel, the other can understand what is causing the sounds. To do this, you will need to properly grasp the rod and see where the play occurs - in the tip or in the rack itself.

If extraneous sounds occur when the wheels rock up and down, then the ball joint is worn out. However, even the absence of extraneous sounds and play cannot one hundred percent guarantee its excellent condition. The ball joint needs additional checking using a mount (we'll talk about this a little later).

Now you need to spin the wheel to understand the condition of the wheel bearing. If you hear a hum or grinding sound, you can throw it away immediately. Spin the wheel again, while grasping the spring with one hand. If the bearing condition is unsatisfactory, you will feel vibration on the spring. In this case, very soon a hum and a grinding noise will appear, which means an immediate need for a new bearing.

Take the pry bar in your hands and crawl under the car. Since a jack will not help you in this case, and there is no hole in your garage, it is better to immediately take the car to a service center.

Check the condition of the silent blocks of the levers. Using the stretcher as a support, move them in different directions (longitudinal and transverse). If you notice a slight play, do not be alarmed, since this is a normal phenomenon (rubber is deformed in any case), but it should occur after you apply significant effort. There are two silent blocks for each lever (there are four in total), a stronger play of one of them will be noticeable immediately.

Now you can return to the ball joint. By moving the lever next to it up and down, you will notice how much wear it has. If you have doubts about your own strength, use a pry bar. Insert it into the gap between the fist and the lever and swing it - there should be no play at all.

Diagnosing a car's suspension will also not be complete without checking the condition of the anti-roll bar. It is unlikely that you will be able to break the stabilizer itself (theoretically it can be bent, but this will require considerable directed effort), so first pay attention to the bushings. Insert the prybar between the subframe and the stabilizer near the bushing and start rocking - the harder the better. Over time, the bushing becomes oval, which causes play in the stabilizer. After this, check how it is secured in the levers. To do this, try using a pry bar to swing the bolts; if you notice any play, it means the rubber bands need to be replaced.

Now pay attention to the stabilizer links. In the worst case, the strut itself may be broken, which, unfortunately, is not uncommon on our roads.

- Rear suspension.

Diagnosis of the rear suspension of a car should also begin with the wheels. Since the ball joints are missing at the rear, check the alignment of the wheel bearings. As with the front suspension, spin the wheel, listen for sounds, check the springs. Without noticing any extraneous sounds, play or vibration, you can judge the serviceability of the bearing. Now get under the car. Inspect the shock absorbers, make sure there are no traces of leaks, then use a pry bar to check the condition of the silent blocks at the bottom of the shock absorbers. Ideally, you should notice the delamination of the silent block, but this requires sufficient experience.

But you will certainly notice the detachment of rubber from the bushings on the silent block of the beam (a larger element makes it easy to pick it up with a mount). However, in some cars you can notice the wear of the rear silent block with the naked eye (it simply breaks and the beam hangs on the bolt in the bracket). In such a situation, you will hear an extraneous knock while the car is moving. However, if we are talking about age-related wear, then the beam will not make any sounds. However, visually the problem - incorrect camber - can be noticed. Lastly, inspect the springs. It is not always possible to notice their subsidence, unlike the breakage of springs.

In general, the simplicity of the design affects the absence of extraneous noise in the event of malfunctions of the rear semi-independent suspension. The need to diagnose and repair the suspension of a used car can be judged by a decrease in its handling. However, such repairs are unlikely to cost a fortune, unless, of course, we are talking about replacing a beam on an old premium class car (previously, they were not equipped with a multi-link rear suspension).

But if you come across a badly worn suspension, then it’s worth thinking about how the owner generally looked after his car and whether there is such a great need to buy this particular car.

Diagnostics and replacement of springs

Breakage of springs in the chassis of a car is a fairly common occurrence; parts fail for several reasons:

- the car is often driven on bad roads;

- the machine is regularly overloaded;

- Poor quality parts installed.

Typical malfunctions of these suspension elements are sagging of the spring itself or breakage of the spring coil. The rear springs usually suffer from overload, and the rear axle becomes lower in height than the front axle. To lift the trunk, different methods are used:

- put additional spacers under the springs;

- replace standard springs with reinforced ones.

If one of the springs breaks, a knock appears in the suspension, and the car sags in the place where the spring coil burst.

Related articles:

- Types of interior tuning on a VAZ 2107 car Rear-wheel drive VAZ classic cars are no longer produced in Russia, and have recently become less common on the roads, however, the cars are still quite popular and in demand. […]

- How to reduce fuel consumption on a UAZ Patriot SUV Potential buyers always ask a question that worries them - what is the fuel consumption of a UAZ Patriot car per 100 km? Consumption data is given in the technical specifications of the car, only [...]

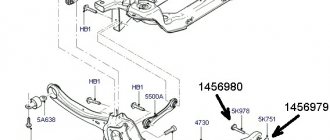

- Replacing the arms and silent blocks of the front suspension of a Ford Focus 2 The car is deservedly popular - it is very reliable, the front suspension is also durable, the chassis parts almost always produce their […]

Diagnostics of hydropneumatic suspension Hydractive

Before diagnosing your car's suspension on a vibration stand, familiarize yourself with the symptoms that are typical for Hydractive suspension problems:

- the car does not rise/lower;

- its normal position is violated (the front or rear part may be lifted up, there is a strong subsidence, the car may seem to “lie down”);

- an error message appears on the instrument panel;

- extraneous noises and sounds occur in the chassis;

- hydraulic fluid turns brown instead of natural green;

- fluid leakage is noticeable;

- the frequency of clicks of the pressure regulator in the hydraulic accumulator increases (normally they can occur once every half hour).

The main malfunctions inherent in the Citroen hydropneumatic suspension include:

- failed solenoid valves;

- problems arising in the steering wheel rotation sensors, body height sensors, etc.;

- breakdown of the hydraulic pump (on average, designed for a mileage of about 100 thousand km);

- leakage in hydrospheres (service life is approximately 150 thousand km);

- failed hydraulic accumulators;

- breakdown of hydraulic system pipes;

- breakdown of the computer responsible for controlling the suspension;

- wear of the bearings of the rear levers (calculated for approximately 40 thousand km), in some cases, the levers themselves;

- problems with stabilizer struts (their service life is approximately 50 thousand km);

- breakdown of silent blocks of front levers, ball joints, steering rods, ends, stabilizer bushings (designed for a mileage of about 80 thousand km).

The safety of the Citroen hydropneumatic suspension depends on the timely diagnosis of the vehicle suspension and troubleshooting.

Mineral hydraulic fluid requires replacement every 50-60 thousand km, synthetic - every 100-120 thousand km. The manufacturer recommends using Total and Elf brands. At the same time as replacing it (depending on the car model, from 3 to 7 liters may be needed), it is also necessary to clean the filters.

Every 120 thousand kilometers, the hydraulic system needs to be cleaned of chemical deposits, for which a special Total Hydraurincage fluid is used.

When carrying out maintenance, it is necessary to pay attention to the pressure in the wheel spheres and hydraulic accumulators. A pressure of about 15 atmospheres indicates the need to pump them up; pressure close to atmospheric pressure indicates that the part needs to be replaced (the diaphragm was probably damaged). The spheres are designed for operation for approximately 100–150 thousand km, if we are talking about new car models - approximately 200 thousand km.

Recommended articles to read:

- Repair Citroen C4 sedan: diagnostic tips

- Automatic transmission Citroen C4 sedan: operating instructions

- Selling a Citroen: how to do it most profitably?

Car chassis repair

A car with any mileage, even less than 10 thousand kilometers, may need chassis repairs. If there are extraneous noises, play in the steering wheel and other unpleasant moments when driving, it’s time to send the car for diagnostics.

If problems are identified in the chassis, you should contact a service center, where specialists, using professional tools and equipment, will carry out repair work, which may include repair or replacement of:

- rear and front shock absorbers;

- steering rods and steering tips;

- brake discs, pads, drums;

- bearings of support cups and hubs;

- shock absorber springs;

- brake hoses;

- steering systems, etc.

It must be remembered that the safe movement of a vehicle consists of the reliable operation of all elements of the vehicle’s chassis. It should be regularly diagnosed and, if necessary, repaired. Work should be trusted only to experienced specialists who guarantee the quality of services and spare parts used for repairs.

Why is it best to take your car for suspension diagnostics to an official service center?

Any malfunction of a vehicle almost always means the need for large financial and time costs. Many people think about where it is better to go, including in order to diagnose the car’s suspension. Some people service their car in a nearby garage, while others prefer to go to a specialized car service center.

At first glance, garage workshops have advantages - proximity to you, as well as affordable prices for car suspension diagnostics, especially compared to official dealers. But at the same time, you cannot count on any guarantees, as well as on receiving penalties if the repairs are performed poorly. The work of professional services is structured completely differently - the craftsmen give a guarantee for the work performed.

However, when contacting specialized service centers, the likelihood of car owners receiving low-quality services is minimized, which means the risk of repeated contact with time costs is also reduced. The staff of professional car services is staffed with experienced and highly qualified specialists who are knowledgeable in various types of repairs, as well as in computer diagnostics of car suspension. In addition, in this case we are talking about saving time, since it is not difficult for professionals to identify and eliminate the problem in a short time.

In addition to qualified personnel, the difference also lies in the equipment used. Sometimes the impossibility of detecting the causes of a car malfunction in the garage is due precisely to its absence. This means that high-quality diagnostics of a car’s suspension can be performed in a professional car service center that has the necessary specialized equipment and is equipped with the latest technology.

But even after diagnosing the car’s suspension in a garage service and identifying the cause of the malfunction, it may happen that there is simply not enough equipment to perform high-quality repairs.

Another undeniable advantage of specialized car services is their operating time and willingness to help customers almost around the clock. A number of workshops have already switched to 24-hour operation.

Diagnostic stages

Typically, diagnostics of a vehicle's chassis are divided into two parts: checking in motion and checking in place. In the first case, you need attentiveness and good hearing. An experienced mechanic, sitting behind the wheel of a car, will quickly determine the cause of a knocking, grinding or squeaking noise with an accuracy of 99%. Here are the characteristic signs by which faulty parts of a car chassis are recognized while in motion:

- steering mechanism, rods - at high speed the car is taken away from straight-line motion, backlash and vibration appear;

- wheel bearings - vibrate and hum when driving on smooth asphalt;

- stabilizers - the car rolls heavily when cornering;

- CV joint - at low speed, when turning the steering wheel, clicks are heard;

- support bearing - when driving over bumps or speed bumps, a knock is heard;

- pads, discs, caliper - the car pulls to the right or left when braking, the braking distance increases;

- silent blocks - a dull knock is heard during acceleration;

- shock absorber - when driving on a dirt road, it knocks in the wheel area;

- Stabilizer bushings - creaking when cornering.

If the car moves unstably at average speed on a flat road, this already indicates different tire pressures or loss of wheel alignment.

A more thorough diagnosis is carried out statically. Usually the car is placed on a jack, but it is better to use a lift. The bottom of the car is cleared of dirt in advance so that during inspection everything is clearly visible and nothing falls off.

Where in St. Petersburg can you get high-quality diagnostics of your car suspension?

Our auto centers will not only perform high-quality diagnostics of your car’s suspension, but will also quickly repair it. The company has been operating on the market for more than 20 years, providing high-quality services for servicing and repairing cars of all brands and any year of manufacture at affordable prices. Our service stations have the latest equipment and are equipped with special tools, and our employees are highly qualified.

In addition, at our official Citroen dealer, you can purchase cars of this brand with maximum discounts.

More detailed information can be obtained on our website or contact our managers directly. We will be glad to see you in our showroom and auto center!

Liked? Tell your friends:

Why do you need chassis diagnostics and is it possible to do without it?

Good condition of the chassis reduces driving risks and helps in extreme situations. For example, when you need to avoid a collision by sharply braking or turning to the side. If the suspension is faulty, it is life threatening! Therefore, the unit must be checked constantly. On Russian roads, all elements are subject to excessive loads. They “swallow” shocks and vibrations caused by unevenness. The safety margin of parts is more likely to be used up when driving at high speed.

You can't do without suspension diagnostics. Determining the “obsolescence” of parts in a timely manner means protecting yourself from more serious breakdowns and financial costs. Therefore, it is recommended to carry it out every 10-15 thousand kilometers or at least twice a year. More often than not, it makes no sense to control the suspension. It is better to carry out this event together with the seasonal tire replacement, leaving a gap of 6 months between the next check.

It is mandatory to check the chassis of a car purchased from the secondary market. In order not to get a “pig in a poke”, you need to check the nodes correctly. Finding defects will significantly reduce the price of the car.

It is extremely important to carry out timely diagnostics to prevent failure of various suspension elements. Often low quality parts are installed instead of original spare parts. They increase the load on the suspension. Another destructive effect on the chassis is caused by bad roads, with potholes and pits.