Engine speed jumps at idle

If the revs jump while driving, your engine needs technical attention.

Let's figure out the reason why the tachometer needle on the engine jumps. Let's consider options for failures in the operation of power units with an injector and carburetor. And also diesel engines. As we know, the engine must be warmed up before driving. At the same time, with the gradual warming up of the engine, the tachometer needle is at approximately 2.5 thousand rpm.

As it warms up, the engine speed decreases. They should be at around 750-800 rpm. If the engine speed starts to jump, it can be said that the “iron heart” of your car needs urgent technical assistance. Interruptions are accompanied by a hum with a gradual increase and subsequent decrease in the noise level.

Problems with the injection engine

It is the cars where the injector is installed that are most often susceptible to this disease: jumps in idle speed. The reasons for such strange behavior can be different, but the most common are:

- Air masses entering the cylinders in large quantities.

- Failure of the idle speed controller.

- Problems with the oil pan ventilation valve.

- The cause may be a malfunction related to the crankcase mass air flow sensor.

- The throttle valve often gets stuck. Its progress becomes unregulated.

Why does the VAZ tachometer jump?

It often happens that the needle starts to twitch. If the car is fuel-injected, then troubleshooting involves connecting a diagnostic scanner and checking the engine systems. Jumps in the TX-193 needle in most cases are also a symptom of malfunctions associated with its electrical circuit. The reasons for this behavior of the device may be:

- lack of good contact at the negative terminal of the battery;

- oxidation or burning of the brown wire on the ignition coil;

- burning or wear of the contacts of the ignition distributor cap or slider;

- wear of the distributor shaft bearing;

- shorting the red wire powering the device to vehicle ground;

- malfunction of the crankshaft position sensor (for injection engines).

About the problems of diesel engines

Diesel engines are also susceptible to this disease. Most often, the idle speed is capricious if rust has formed on the impeller of the fuel pump (fuel pump). This process is caused by moisture, which is present in the fuel (diesel). This is what causes corrosion.

How to normalize the operation of units at idle, what is necessary for this

To restore the status quo, you need to do the following:

- normalize air leaks in the cylinders of the power unit;

- check the IAC. Replace if necessary;

- clean the ventilation valve;

- if there is a suspicion that the hot-wire anemometer is “capricious”, carry out diagnostics. Based on the results of the inspection, it may need to be replaced;

- clean and restore normal operation of the throttle valve;

- configure the idle modes of the power unit;

- if necessary, replace the carburetor solenoid valve;

- For stable operation you need to clean the jets.

On diesel engines, remove rust from the fuel pump impeller.

Electronic control unit.

Air entering the cylinders in excess is detected by the ECU, which signals problems: the balance of air and fuel is disturbed. Problems arose in creating a combustible mixture. If more fuel is supplied, the speed increases proportionally. To eliminate the increased speed (reduce the flow of fuel), you need to reduce the speed, otherwise the shocks will continue.

Failure of the IAC is associated with loss of integrity of the electrical wire. Low-quality fuel is rightfully considered to be the culprit of these troubles.

- Mass fuel flow sensor.

The failure of this element is caused by a film formed by waste oils in excess quantities. Another reason why the fuel sensor fails is problems with the control element of the air masses in the cylinders (hot-wire anemometer). The ECU receives distorted data.

It may jam. Reason: Used oil interferes with normal operation. Or the drive mechanism has broken down. Most often, this defect is inherent in carburetors.

Useful tips

Failure or malfunctions in its operation often lead to the ECU receiving a premature signal to warm up the power unit, while the engine is still cold.

A similar situation can occur when air leaks appear or problems arise with the air flow sensor (MAF). In this case, the control unit incorrectly calculates the actual amount of air that enters the cylinders, as a result of which the correct ratio of fuel and air will be disrupted (disturbance of mixture formation).

Quite often, engine jerking at idle can occur precisely when the internal combustion engine is cold. In this case, you should pay special attention to the motor temperature sensor.

Failure or malfunctions in its operation often lead to the ECU receiving a premature signal to warm up the power unit, while the engine is still cold.

Read more: Why it is better to buy winter tires in advance

Taking into account the incorrect readings of the temperature sensor, the control unit automatically reduces the amount of fuel supplied to exit the so-called increased “warm-up” speed mode, however, in this case, the cold engine begins to operate unstably, the engine twitches, and vibrations increase.

The revs are jumping, what is the process of normalization?

If the speed jumps, you should check the line through which air flows and its integrity. To do this, you need to remove the tubes and thoroughly blow out each one. This procedure is easy to perform using a pump or compressor. As an additional means of checking, you can take a WD 40 solution and see in which area the liquid evaporates faster. If a problem is found, the defective hose should be replaced with a new sample.

If there are problems with the regulator, diagnostics are performed. To check, use a device: a multimeter (we find out the resistance readings). If the sensor shows 40-80 Ohms, this is a signal to replace the failed regulator.

Safety first

When carrying out work to restore stable readings of the power unit at idle speed, it is necessary to observe safety precautions. Carry out work in a ventilated area. Lighting a fire and smoking is not allowed when checking the operation of the engine.

Personal protective equipment must be used. Work in special clothing. Wear gloves and safety glasses to avoid getting fuel in your eyes.

And

Most of the restoration process and checking the operation of the power unit can be done on your own. You do not need complex tools or specially equipped premises. Some of the work can be done outdoors or in your garage. The main thing is to observe the safety regulations of the work and use personal protective equipment.

If you do not have the opportunity to cope with the vagaries of the power unit on your own or the problem arose while the car was moving, contact the nearest service center or technical assistance station.

The technicians will find out why the speed is jumping and will carry out a set of restoration measures.

Naturally, the choice is yours. In the first case, you save your money. In the second case, you receive high-quality service at a professional level. You decide.

Finally

Timely elimination of power unit surges at idle speed will save you from more serious problems associated with engine repair. On the other hand, you want a comfortable ride, not jumps on the road!

Types of devices

Tachometers are also divided into standard and remote ones, depending on the installation method. If everything is clear with the regular ones, then the remote ones can have several types of purposes.

First of all, the remote tachometer is intended for mounting on the instrument panel and giving the vehicle a more individual appearance. Depending on the preferences of car enthusiasts, such a device is more convenient.

Decorative stands and grips for mounting on a dashboard have been added to the design of the tachometer; it has a mainly digital signal processing principle. If it is available, there is no problem with how to check the tachometer, which is installed on the instrument panel; to do this, you need to compare the readings in different engine operating modes. Such devices are often used by professional sports racers and lovers of individuality in the design of their cars.

avtoexperts.ru

The engine is the “heart” of a car, and like the human heart, interruptions sometimes occur in the functioning of this “organ”. We become aware of problems with the engine by reading the rpm. If the speed of the power unit begins to float, the engine gives us a signal that something is wrong with it. In our material today we will tell you what breakdowns are hinted at by jumping engine speeds, how to correctly diagnose and repair them.

The reason for the appearance of floating speed

The driver can find out that there is something wrong with the engine speed by looking at the tachometer. During normal operation of the power unit at idle, the needle of this device remains at the same level (usually within 750-800 rpm), and if the engine has problems, the needle either falls or rises (range from 500 to 1,500 rpm and higher). If the car does not have a tachometer, then the floating speed can be heard by ear: the rumble of the engine either increases or decreases. And also - by the increasing and decreasing vibrations penetrating into the car interior from the engine compartment.

As a rule, unstable engine speed occurs at idle. But even at intermediate engine speeds, dips or rises in the tachometer needle can be detected - this is typical for diesel engines. Let's consider these two cases separately to understand why these phenomena occur.

Speed jumps at idle

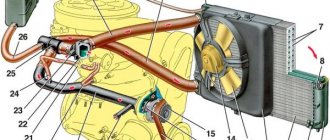

Floating idle speed most often occurs on injection engines. This is due to the peculiarity of regulating the operation of the idle system by the electronic engine control unit (ECU). The electronic “brains” of the car constantly read information about the idle speed, and if it is violated, they give a command to the sensors responsible for the correct functioning of the system to correct the situation. Idling may be disrupted due to excess air getting into the fuel system, and specifically into the engine cylinders. In this case, the mass air flow sensor signals the ECU that excess air has entered the combustion chamber. To equalize the amount of air and fuel that together form the air-fuel mixture, the “brains” command the injector valves to open and let more fuel into the cylinders. At this moment, the engine speed increases sharply. Then the ECU “realizes” that it has supplied too much fuel to the cylinder and limits its supply - at this moment the speed drops sharply.

Video “Troubleshooting tachometer problems”

This video tells you what needs to be done to prevent the meter needle from twitching (the author of the video is T-Strannik).

A tachometer is a measuring device installed on cars to determine the speed of rotation of the crankshaft of the power unit. It provides the ability to monitor changes in engine speed, in order to avoid operation at too low or too high frequencies (when the tachometer needle jumps) of the crankshaft rotation.

Using the tachometer, the required engine operating mode is selected.

The main purpose of the tachometer is to switch gears in a timely manner, which allows you to select the most economical and optimal engine operating mode. Since even an inexperienced driver can determine the desired switching point when the needle approaches the red zone, or drops to the minimum level. The tachometer is also used to configure and adjust the operation of the power unit at idle and to periodically monitor the speed of the structure while driving at different speeds and under different loads on the vehicle.

The basic principle of operation of the tachometer is based on determining the quantitative value of the pulses that the sensors send. Depending on the order of signals, the intervals between signals and their intensity, the device determines the shaft rotation speed with a given accuracy. Pulse signals can be counted in both directions in equal proportions.

Certain indicators are converted using a calibrated device into certain rotational speed values. Therefore, the tachometer needle moves in the appropriate direction; if the speed indicator does not respond when the engine is running, then the tachometer is not working.

In order to determine the reason for the lack of speed readings, it is necessary to understand the design features of the tachometer and determine a list of possible malfunctions.

The tachometer needle jumps

People help! The tachometer needle lives a separate life. It looks something like this. The car starts up, runs, at some point the tachometer needle begins to jump up and down, returns to its place, and then as a result goes to zero, and the engine begins to stall. At the same time, during the needle jump, the engine runs at the same speed. I changed the distributor, since the speed sensor is located in it; checked the generator - OK; moved the computer from my car to another car - it works; gas tank - washed; fuel filter - changed; the fuel pump is working. After all the procedures, the diagnosis did not change. I don’t know what to do next. Self-diagnosis shows no malfunctions.

Check the ground wire that goes from the battery to the starter. I got unscrewed from there, the symptoms were the same.

Or maybe the pot just doesn’t work, so it’s tripping wildly, maybe there’s a problem with the air meter, maybe a high-voltage wire, maybe a spark plug, a vacuum.

which means “during the needle jump, the engine runs at the same speed.” I had the same symptoms (only the engine worked according to the arrow), they cleaned the throttle valve + replaced the spark plugs = everything is OK

Does the pump still work or is it just humming? How old is the car? You can't see it from the signature.

It looks like the engine was running smoothly, but the needle was not running smoothly on its own. It was similar, I checked all the contacts, pros and cons, unscrewed, cleaned, lubricated, but not with VDhoy!, special fluid for electrical contacts, tightened it, it went away.

It’s just not clear why the oil filter was changed, the tank was cleaned, etc. If, as far as I understand, the problem has nothing to do with the operation of the engine. The issue is purely electrical. but the following question arises: why do the cars stall as a result of the arrows being laid down? So the arrow lives its own life or everyone is like that together with the engine.

Last edited by Ladan; 11/30/2010 at 5:47 pm.

2 Ladan The man checked everything, excluding various options.

I'll tell you how it was for me. At one not-so-wonderful moment, during a long drive, jerks in engine operation began to appear (which were still accompanied by jumps in the tachometer needle). After this, the BDZ and KXX were cleaned. To no avail. Then replacing the fuel filter, fuel pump, and flushing the tank at the same time. Also to no avail. Later, during test drives and just while driving, I noticed that if you drive during the day (and around the city), there are no symptoms. They appeared either while driving on the highway or at night. Both facts were united by the fact that the low beam headlights were turned on. And not immediately, but after some time. However, while there were no jerks, the same jumps in the tachometer needle were observed, and only later a connection between jerks in engine operation and the tachometer appeared. I also noticed that if you let the car coast, it tried to stall, and sometimes it succeeded. By the way, the battery was discharged to ***** after long trips. The first battery even died. That. I came to the conclusion that it was an electrical issue. I replaced the generator (there was a spare one in the garage). The problem has disappeared. I was happy. But not for long. Later all the parsley happened again. Desperate. I removed the second generator and took it to a competent electrician. He unsoldered it, checked each node separately, assembled it, checked the gene under load - everything was ok. After that, my friend and I stupidly sat down at the table, took the electrical diagram of the car and began to reason, simultaneously cutting off options. We localized the problem in the area of the main ground wire (the one that goes from the battery to the engine). I went to the car, opened the hood, pulled the wire, after which it ended up in my hand