Troubleshooting

The driver's term "troit" means that interruptions are heard in one or more cylinders while the internal combustion engine is running. To fully verify this, you need to stand near the exhaust pipe. The changed sound of the engine is clearly visible here. The phenomenon is called “missing,” but the definition of “troit” arose from the functionality of four-cylinder engines. If one fails, only three remain in operation, creating a triple sound.

With this malfunction, the engine does not pull, especially when accelerating. Modern vehicles have three six-, eight-, and twelve-cylinder power units. In this case it is observed:

- body vibration;

- unstable low crankshaft speeds;

- increased fuel consumption;

- loss of power.

To accurately determine the cause of the problem, you need to pay attention to many signs: conditions when the engine does not pull, the moment when the sound becomes stronger - after warming up or when cold, at idle or under load, at low or high speeds, uniform movement, acceleration or coasting. Any little thing, sometimes meaningless, can suggest the right decision.

Diesel shakes and smokes fuel supply problems

If there are problems with the fuel supply, then the diesel engine starts to stall for the following reasons:

- the fuel pump does not create optimal pressure in the fuel supply system;

- the injection intensity is disrupted as a result of a malfunction of the diesel injector;

In both cases, fuel atomization deteriorates and the mixture does not burn completely. The fuel injection pump can create normal pressure, but the fuel injectors deliver different amounts of fuel to the cylinders. In such conditions, fuel is distributed unevenly among the cylinders, the engine shakes in different operating modes. If it is completely impossible to pump a portion of diesel fuel through the nozzle, the diesel engine begins to stall. Cleaning, repairing, or replacing injectors must be accompanied by adjustment of the injectors before installation on the engine.

At the same time, it is necessary to regulate the fuel injection pump. The pump may be worn out and/or incorrectly adjusted, resulting in insufficient pressure to deliver the required amount of diesel fuel through the rebuilt or replaced injectors. The diesel engine may start to run rough, with detonation. Replacing injectors is necessarily accompanied by checking the performance of the fuel injection pump.

If there are problems with both the fuel pump and the injectors, the parts must be adjusted, repaired or replaced immediately. Detonation on a diesel engine will quickly damage the engine.

Late fuel supply

The amount of time the fuel-air mixture remains in the cylinder before ignition will determine the degree of heating of the mixture. Heating affects the efficiency of fuel combustion, minimizing losses from poor-quality atomization. At the same time, the early injection moment (advance) causes wear of the diesel engine, while simultaneously increasing the power of the unit. For this reason, it is necessary to maintain a balance between the injection advance angle and the desired output from the engine.

Many fuel injection pumps are equipped with a solution that allows you to increase diesel speed during a cold start. It turns out that the injection of diesel fuel becomes early. After the internal combustion engine temperature rises, the idle speed is reduced to standard. The injection advance also reaches the optimal power/wear indicator in relation to a particular diesel engine design.

During engine operation under load, the injection advance should be late (increased). This is necessary for the most complete combustion of the mixture in the cylinders. Structurally, it may be possible to adjust the advance by changing the diesel fuel pressure when supplying diesel fuel to the injection pump. The regulator is installed on the pump, allowing you to change the fuel injection timing yourself.

If the fuel injection pump is worn out, then the fuel injection advance angle does not coincide with the crankshaft speed of the diesel engine. The result is engine tripping. Injection timing may also be disrupted due to wear of the fuel pump drive, failure of the pressure reducing valve, clogged return filter, etc.

Incorrectly adjusted injection timing can occur both at certain speeds and constantly, when operating a cold or warm diesel engine. In this case, the engine, which operates normally in idle mode, stalls when the gas pedal is pressed after increasing the crankshaft speed.

In some cases, increasing the injection timing without repairing injectors and fuel injection pumps allows you to achieve more stable engine operation when driving. The diesel engine still stalls when cold, but as the temperature rises it starts to run smoothly. You need to adjust the operation of the fuel injection pump so that it only adjusts when the engine is cold. After warming up, the diesel engine will operate stably both in idle mode and under load.

It is worth remembering that tripping and detonation cannot be fully compensated by constant manipulations with injection advance by adjusting and adjusting the fuel injection pump. This method can be considered a temporary measure. Long-term operation with obvious malfunctions has a noticeable effect on the service life of a diesel engine. For this reason, it is necessary to constantly monitor the condition of the diesel engine power system and promptly carry out maintenance and repair of high-precision diesel fuel equipment.

Possible reasons

Uneven engine operation can be observed as a result of the following general malfunctions:

- the most common reason is failure of spark plugs;

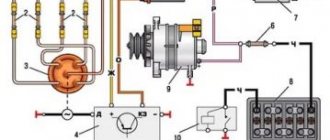

- incorrect ignition timing adjustment;

- breakdown of high-voltage wires;

- air filter clogged;

- use of spark plugs for purposes other than their intended purpose;

- carburetor not adjusted;

- capacitor failure;

- burnout of pistons and valves;

- wear, breakage, deformation of piston rings;

- violation of operating valve timing;

- high wear on valve rockers;

- air leakage through the vacuum brake booster or intake manifold;

- leaky membrane of the vacuum ignition timing regulator;

- wear of the distributor shaft or rotary plate bearing;

- destruction, breakdown, hardening, wear of valve stem seals;

- breakdown or burnout of the cylinder head gasket.

It is necessary to begin repairs when a non-functioning cylinder is identified. Finding it is not particularly difficult. With the engine running, the tips of the high-voltage wires are removed from the spark plugs one by one. On the working cylinder, after removal, the sound becomes different. If, after removing the tip, the sound remains the same, this cylinder does not work.

Why does the VAZ 2114 engine start to stall?

As soon as a breakdown has been detected, it is important to understand why the engine begins to stall and take appropriate measures. So, in order to find out the reason, it is necessary to carry out a set of certain actions that will help determine the malfunction

1. Start the engine, set the parking brake and open the hood.

2. This point is the most important. You'll need your hearing here, so listen to the sound of the engine and remember it well.

3. Place one hand behind your back, and with the other hand (be sure to wear a glove), take turns pulling out the high-voltage armored wires. The bottom line is that disconnecting a wire in a “healthy” cylinder leads to a change in engine performance. It starts to work even more unstable and may stall. Therefore, if you pull out the wire from the spark plug of a cylinder in which the mixture is not ignited, the sound of the engine will not change and it will work the same.

It is worth explaining that ignition of the mixture occurs due to a spark that appears at the tips of the spark plug. If there is no spark, we can assume that the fault lies either in the spark plugs or in the high-voltage wire, so the test begins with what is close to the cylinder - the spark plugs. Since the armored wire is checked by replacing it, the process of checking the armored wire will not be described.

Analyzing and fixing the problem

If the ignition is set incorrectly, the engine jerks and slams. It must be listened to in low operating mode. With a strong mode, the work is leveled out, and skipping beats is not heard. Early ignition manifests itself in jerks when cranked by the starter.

A damaged hose, valve, or diaphragm of the vacuum brake booster allows air to leak from the atmosphere. Excess air leans the fuel mixture. The spark plug gets wet and cannot create a normal spark to ignite the mixture. The fault can only be identified experimentally.

When a cold engine revs heavily, this indicates a problem spark plug. Its appearance speaks volumes to an experienced mechanic. The normal color of the insulator is light or slightly brownish. Oil traces and carbon deposits on the insulator indicate that the spark plug is being filled with an over-enriched mixture; there is no normal sparking. The spark plug body must be free of cracks and chips. It must be checked for spark quality. If sparking is weak, the spark plug must be replaced.

A breakdown of high-voltage wires and a capacitor occurs when the engine is not warmed up. This malfunction can be observed in the dark. Surface sparkling is noticeable on the wires and capacitor above. The resistance during measurements should not exceed 20 kOhm.

Burnout of pistons and valves is determined by measuring engine compression. The engine shakes constantly: cold, hot, loaded, at idle.

Problems with spark plugs and wires

Can the engine stall due to spark plugs? It's over, yes! This is the thought that first comes to mind for motorists. Late or early ignition, as well as a too weak spark, can lead to the problem described above. Drivers need to dismantle the spark plugs and check the integrity of the entire structure. Damage to the insulating material is immediately visible to the eye.

Soot on the spark plugs also indicates a problem. A mixture containing too high a concentration of gasoline is supplied to the cylinder. A layer of soot leads to interruptions in the operation of the candle. It can form for several reasons:

- The motor is constantly subjected to prolonged warm-up.

- Cylinder compression ratio too low.

- The timing belt has moved one or more teeth.

- Problems with the injector or carburetor.

It is recommended to carry out a more thorough diagnosis, determine the real reason for the formation of carbon deposits on the spark plug and replace it with a new one. This should solve the tripping problem.

If the engine stalls when cold, but the spark plugs are fine, inspect the wires. A sign may be the appearance of tripling during high humidity or after rain. It is the violation of the integrity of the armored wire that causes the engine to stall after washing, but all the symptoms completely disappear after some time. If the engine is running hot, it is necessary to inspect the cylinders and piston rings.

Finally

In conclusion, we will give advice from experienced drivers. Even if the car suddenly starts idling, you should not panic or get upset. There is always a decent way out. The machine can move at low speed in idle mode to the nearest service station. You can get expert advice by phone or iPhone. Replace a faulty spark plug by purchasing one at the nearest gas station. If you are afraid of more severe damage, a tow truck will help deliver the vehicle to the repair site.

One of the most common engine malfunctions is interruptions in the operation of one or more of its cylinders, which among motorists is referred to as “troubling the engine.” Anyone who has encountered this phenomenon is probably familiar with its symptoms. But not all car enthusiasts know what the causes and consequences of such a breakdown are. Today we will tell you in detail why the engine misfires, how to diagnose and properly repair the engine.

Key causes of failure

One of the most popular questions is, why does the engine stall? There can be a huge number of reasons, and diagnosing each individual part will require time and effort. However, four main directions can be identified that lead to tripling:

- ignition system problems;

- malfunction of the fuel supply system;

- power system problems;

- reduction in compression due to wear of the cylinder-piston group.

It is recommended that you check each group for problems. This will save you time on diagnostics and subsequent repairs.

Manifestation of malfunction

First, you need to make sure whether your problem really fits the definition of “engine trouble.” To better understand the cause of the occurrence, you need to understand the very essence of the malfunction, and at the same time decide whether your dilemma is similar to the one described below.

So, what happens to the car and what changes in engine performance can occur? To begin with, as we said earlier, the engine life will noticeably decrease. This is especially noticeable in cars with manual transmission (we'll talk more about this below). In addition, the most likely thing is that the car will begin to shake and vibrate while driving. Vehicle acceleration deteriorates sharply, operating speeds decrease, and the level of fuel consumed increases by almost several liters.

Air System Inspection

Excessive or insufficient amount of air in the intake is one of the most common causes of engine tripping. The system may lose seal, causing the engine to draw in more air. It is quite possible to check the air system in a garage. To do this you need to do the following:

- Close the intake pipe near the air filter.

- Start pumping air to create a pressure within half an atmosphere.

- If the pressure drops, then the system is not completely sealed. This is where you need to look for a leak.

A lack of air can be caused by a clogged air filter. It must be changed in a timely manner.

How to understand what is wrong with the engine

It is very important to identify the problem in time, find the cause and begin to properly eliminate it. Otherwise, ignoring or unqualified assistance may result in costly major repairs.

One of the possible manifestations of the problem is a situation where the engine idles at idle speed. To be more precise, there is instability at idle speed, and the electronics often demonstrate increased fuel consumption. To make sure of this, you should check which of the cylinders needs repair or complete replacement. You can read more about this procedure, as well as other probable causes, below.

How to determine a bad cylinder

When carrying out repairs, it is very important to identify the problematic cylinder. There is a proven method for this, which is used by many automotive specialists. It involves removing the armor wires from the spark plugs one by one. The procedure for determining an inoperative cylinder consists of the following steps:

- Find a dielectric base to stand on during the procedure. This can be a thick rubber mat or a wooden board.

- Start the engine, and then keep the speed around 1500.

- Take the wire itself (not the cap) and disconnect it from the spark plug. If the sound of the engine has changed, then the cylinder is working.

- Reinstall the wire and then follow the previous step for the rest. If the engine sound does not change when disconnected, then you have found a faulty cylinder.

Possible causes and action plan

This paragraph identifies the most likely causes of the malfunction we are considering. Here are the most likely answers to the question “why does the engine stall at idle.”

Engine malfunctions (electronics and ignition)

Very often, drivers can observe how the engine shakes at idle. First of all, you need to make sure whether the breakdown is related to problems in the car’s electronics. This is very important, because replacing and repairing it is one of the most expensive in current foreign cars, and therefore by starting with diagnosing this problem you can save money and time.

It will also not be superfluous to determine whether the ignition settings are set correctly. Sometimes their failure can cause the power unit to trip. In fact, this will manifest itself as the car jerking and when revving up. To verify the fact of this problem, watch the engine strokes (sometimes you can observe regular skipping), making sounds (characteristic “patting”). Timely adjustment of the ignition will help correct the situation.

Non-working spark plugs

The basis of such a problem as engine tripping. We wrote about it a little higher. Now let's look at everything in more detail. First, you should start the engine, and without turning it off, check the existing spark plugs one by one by disconnecting them from the power supply (do not forget to correctly disconnect the high-voltage wire and generally adhere to the rules for working with high-voltage equipment).

To make sure that each spark plug is working, we must focus on the sound of the engine. When the working spark plug is disconnected from the power supply, the sound of the motor should change synchronously. But with a non-working cylinder, such changes will not happen, which means that such a spark plug requires replacement.

Breakdown of high-voltage wires

You can verify this by seeing the breakdown of high-voltage wires. In a dark room, isolated from light, you can observe the appearance of a spark. This leads to replacing the broken wiring, or repairing the capacitor. The same procedure can be carried out using a wiring tester.

Incorrectly adjusted valves

The main problem for this reason is the presence of a gap between the valves, which determine the operation of the entire assembly. The cylinders are not sufficiently saturated with the fuel-air mixture and, as a result, you can observe how the engine shakes at idle, when cold, and while driving. It is necessary to configure and adjust the valves by first checking the instructions or consulting with professionals.

Deformation of piston rings

A rather rare phenomenon that is not taken for granted by many, but in vain. To ensure its presence, it is necessary to check the compression level in the engine cylinders. It is necessary to focus on the measurement results. If the level is low, it will be enough to add a small amount of oil to the cylinder. But if the level is too high, it is necessary to inspect the piston system in detail and work on its repair.

Air filter

It would seem how an air filter can influence such engine inoperability. However, this is precisely the reason why most people make a huge mistake. Their mistake is when they forget to change the air filter when changing the oil. Over time, when the filter becomes clogged, the car begins to “suffocate.” Spark plugs filled with gasoline do not work properly due to low saturation of the fuel-air mixture. Improving engine performance can be achieved simply by replacing the filter.

Distributor malfunction

One of the reasons when moving is when you press the gas. It is important to determine the situation, since the design of the distributor includes a large number of different bushings, shafts and bearings. It is one of these parts that affects the operation of the entire distributor. You can deal with this situation by carrying out a detailed repair or replacement of the distributor.

Serious engine malfunctions (burnt valve or piston)

One of the most serious breakdowns that ends with a major engine overhaul. Due to operation in very aggressive conditions, valves and pistons may not withstand the load, and the metal in their construction is prone to destruction. This can lead to failure of many engine compartment systems. In addition to the engine tripping, the tightness of the combustion chamber is compromised. As a result, the gas formed as a result of fuel combustion has a detrimental effect on all systems in the car and leads to malfunctions.

These were the most important and determining reasons by which you can determine whether the engine of your car is troit or not. It is very important to carry out prevention regardless of the appearance of the first signs of engine tripping. In addition, under no circumstances should you put off the necessary repairs, since causes of breakdowns that may seem insignificant at first glance can develop into something larger and more significant in the future.

Causes of engine tripping

On the one hand, engine tripping is a seemingly understandable reason for everyone, but in fact, tripping is (most often) just a consequence of some kind of malfunction. Here we will look at the main causes of engine tripping, and accordingly, we will find ways to eliminate this headache.

In this case, you need to start checking by identifying the non-working cylinder:

- To do this, start the engine and open the hood.

- We listen to the sound of the engine and remember it.

- We begin to pull out the high-voltage wires one by one.

- When we pull out the high-voltage wires, the corresponding cylinder stops working and the sound of the engine changes and starts to double. Our task is to find the wire that, when pulled out, will not change the sound of the engine, which means we will find a non-working cylinder.

Next, what we need to do is determine whether a spark is formed on the spark plug in a given cylinder or not, in order to determine in which direction we should move next.

Spark plug

We take a spark plug wrench and unscrew the spark plug, look at the condition of the electrode:

- brick color - indicates normal operation of the cylinder;

- smoked, with a little soot, etc. – indicates that the engine is not operating properly, either due to excess oil or too much fuel remaining.

Such deposits on the spark plug prevent it from working properly, creating a weak and irregular spark. Cleaning the spark plugs or replacing them will not help in this case, because... you need to look for the cause of the soot that appears: it could be

- malfunction of the non-return (exhaust) valve (needs to be adjusted - if it is clamped, replaced - if it is burnt out);

- low compression in the cylinders (at least 10-10-10-10) - measure the compression correctly, make the appropriate repairs - most likely either your rings are stuck or the valves are burnt out;

- displacement of the valve timing - here either the timing belt is not installed correctly, or it has jumped off - the belt must be removed and reinstalled with phase adjustment;

- the injectors are overfilled - they need to be changed (how to replace the injectors?);

- low pressure in the fuel system (how to check the pressure?);

- The oxygen sensor readings are incorrect - you need to replace it;

- Carbon deposits can also appear when the engine is idling for a long time, if the spark plug has a non-standard heat rating - such spark plugs need to be replaced.

Pay attention to the white spark plug body: if there are black dots or stripes on it, it means the spark plug is broken and needs to be replaced

How to check the spark on a spark plug?

Next, we need to check whether the spark plug gives a spark or not: to do this, we put a high-voltage wire on the unscrewed spark plug and place the metal body of the spark plug on the engine (make sure that the electrode does not touch the engine body). Then we ask the assistant to start the engine (turn the starter for 2-3 seconds), and at this moment we look to see whether a spark appears on the spark plug or not.

No spark or weak sparking

If a spark appears, then move the spark plug away from the mass by 1 cm and repeat the previous action again.

If the spark has noticeably weakened and is barely visible, then we have poor sparking.

Poor spark formation or no spark at all may be caused by the following faults:

- high resistance of high-voltage wires, or wire breakage;

- To do this, you need to check the high-voltage wires and replace them (the high-voltage wires may not be installed correctly);

- ignition module malfunction - check and replace;

- ECU malfunction - have it repaired or replace it with a new one;

- DPKV malfunction - its malfunction will be indicated by an error that can be read using the BC or carried out diagnostics. A non-working sensor needs to be replaced;

- again, the timing belt could have slipped a couple of teeth - disassemble it and reinstall it according to the timing marks.

If there is a spark, and a good one, then all that remains is to look at the rings, compression, valves, injectors, which have already been described above. We wish you good luck in finding your problem!

Engine misfires when cold or hot

In this problem, valves are most often the cause: every 20 thousand km. valve clearances need to be adjusted. The bottom line is that if your engine stalls when cold, then the gap is apparently too large, then the engine heats up - the gap decreases, and engine operation returns to normal. The situation is the same with the engine stalling when hot, but vice versa: when it’s cold, the gap is normal, but when it’s hot, the valve is clamped and the engine starts to stall.

On the Internet it is often recommended to change spark plugs and high-voltage wires for this problem, but I would not advise you to simply waste money and buy something at random without understanding it.