VAZ injector sensors

Hello everyone, I apologize that I completely stole this from someone, but when I was looking for information on the speed sensor, this murzilka helped me a lot.

VAZ sensors

Sensors (VAZ injector)

Any injection system (VAZ 2108, 2109, 2110, 2111, 2112, 2113, 2114, 2115, NIVA...) includes a set of sensors for collecting information about the condition and operating mode of the engine.

MASS AIR FLOW SENSOR (MAF) VAZ

The VAZ mass air flow sensor (MAF) is installed on the air filter housing. The mass air flow sensor (MAF) measures the amount of air taken in by the engine in kg/hour. The device is quite reliable. The main enemy is moisture sucked in along with the air. The main malfunction of the mass air flow sensor (MAF) is an overestimation of readings at low speeds by 10 - 20%. This leads to unstable engine operation at idle, stopping after power modes, and possible problems with starting. Understating the readings of the mass air flow sensor (MAF) in power modes leads to “dullness” of the engine and increased fuel consumption. Typical idle air consumption is 8-10 kg/hour. At 3000 rpm - 28-32 kg/hour. Read more…

Price: 2000 rubles (Cost of the sensor including installation and performance testing)

THROTTLE POSITION SENSOR VAZ

The VAZ throttle position sensor is installed on the side of the throttle pipe on the same axis as the throttle valve drive. The throttle position sensor takes readings from the position of the gas pedal. The main enemies of the throttle position sensor are the sensor manufacturer and engine washers. The lifespan of the throttle position sensor is completely unpredictable. Malfunctions in the operation of the throttle position sensor are manifested in increased idle speed, jerks and dips at low loads. Read more…

COOLANT TEMPERATURE SENSOR VAZ

The VAZ coolant temperature sensor is installed between the block head and the thermostat. The coolant temperature sensor has two contacts (unlike the single-contact temperature sensor for the instrument panel, which is located next to it, do not confuse it). The main functional purpose of the coolant temperature sensor is akin to the “choke” on the carburetor - the colder the engine, the richer the fuel mixture. Structurally, the coolant temperature sensor is a thermistor (resistor), the resistance of which varies depending on the temperature. Typical values 100 g. — 177 Ohm, 25 gr. — 2796 Ohm, 0 gr. — 9420 Ohm, — 20 gr. — 28680 Ohm. Coolant temperature affects almost all engine management characteristics. The coolant temperature sensor is very reliable. The main malfunctions are a violation of the electrical contact inside the sensor, a violation of the insulation, or a break in the wires near the sensor due to a dangling throttle cable. Failure of the coolant temperature sensor - turning on the fan on a cold engine, difficulty starting a hot engine, increased fuel consumption. Read more…

Price: 150 rubles (Cost of the sensor including installation and performance testing)

KNOCK SENSOR VAZ

The VAZ knock sensor is installed on the engine block between the 2nd and 3rd cylinders. There are two types of knock sensors - resonant (barrel) and broadband (tablet). Different types of knock sensor are not interchangeable. The knock sensor is a reliable element, but requires regular cleaning of the connector. The operating principle of the knock sensor is similar to that of a piezo lighter. The stronger the blow, the greater the tension. Monitors engine detonation knocks. In accordance with the signal from the knock sensor, the controller sets the ignition timing. There is detonation - later ignition. Failure or breakage of the knock sensor results in engine dullness and increased fuel consumption. Read more…

Price: 250 rubles (Cost of the sensor including installation and performance testing)

OXYGEN SENSOR VAZ

The VAZ oxygen sensor is installed on the exhaust pipe of the muffler. A serious, but very reliable electrochemical device. The task of the oxygen sensor is to determine the presence of oxygen residues in the exhaust gases. There is oxygen - a lean fuel mixture, no oxygen - a rich one. The oxygen sensor readings are used to adjust the fuel supply. The use of leaded gasoline is strictly prohibited. Failure of the oxygen sensor leads to increased fuel consumption and harmful emissions. Read more…

Price: — (Cost of the sensor including installation and performance testing)

CRANKSHAFT POSITION SENSOR VAZ

The VAZ crankshaft position sensor is designed to generate an electrical signal when the angular position of a special toothed disk mounted on the engine crankshaft changes. The crankshaft position sensor is installed on the oil pump cover. This is the main sensor, based on the readings of which the cylinder, fuel supply time and spark are determined. Structurally, the crankshaft position sensor is a piece of magnet with a coil of thin wire. Very hardy. The crankshaft position sensor works in conjunction with the crankshaft timing belt. Sensor failure means engine stops. In the best case, the engine speed limit is around 3500 - 5000 rpm. Read more…

Price: 200 rubles (Cost of the sensor including installation and performance testing)

SPEED SENSOR VAZ

The VAZ speed sensor is designed to generate pulses, the number of which per unit time is proportional to the speed of the vehicle. The speed sensor is installed on top of the gearbox. On injection VAZs only 6-pulse speed sensors are used. The speed sensor informs the controller about the vehicle's speed. The reliability of the speed sensor is average. Oxidation of the connector and wires near the speed sensor often occurs. Failure of the speed sensor leads to a slight deterioration in driving characteristics (except for General Motors - the engine stalls when idling). Read more…

Price: without wires 250 rubles, with wires 350 rubles. (Cost of the sensor including installation and performance testing)

PHASE SENSOR VAZ

The VAZ phase sensor is designed to determine the angular position of the camshaft. On an 8-valve engine it is installed at the end of the cylinder head near the air filter. On a 16-valve engine - on the cylinder head near the 1st cylinder. On 8-valve engines manufactured before approximately 2005, there is no phase sensor. The absence of a phase sensor means that the injectors open in pairs-parallel mode. Availability of a phase sensor - phased injection, i.e. Only one injector opens for a particular cylinder. Failure of the phase sensor switches the fuel supply to pairwise-parallel mode, which leads to a slight (up to 10%) increase in fuel consumption. Read more…

Price: 8 valve engine - 250 rubles (Cost of the sensor including installation and performance testing)

Auto-Translated Original (RU)

Hello everyone, I apologize that someone completely and completely stubbed it, but when I was looking for information on the speed sensor, this murzilki helped me a lot.

VAZ sensors

Sensors (injector vases)

Any injection system (VAZ 2108, 2109, 2110, 2111, 2112, 2113, 2114, 2115, NIWA...) includes a set of sensors to collect information about the status and operating mode of the engine.

MASS FLOW SENSOR (DFB) VAZ

The air mass flow sensor (DFMS) VAZ is mounted on the air filter housing. The mass air flow (MWR) sensor measures the amount of air sucked by the engine in kg/h. The device is quite reliable. The main enemy is moisture, sucked together with air. The main malfunction of the mass air flow sensor (MWR) is an overestimate of the readings at low speeds by 10 to 20%. This leads to unstable operation of the engine at idle, stop after power modes, there may be problems with starting. Underestimation of the mass air flow (MWR) sensor at power modes leads to “stupidity” of the motor and increase in fuel consumption. Typical value of air flow at idle 8-10 kg/h. At 3000 rpm - 28-32 kg/hour. Read more…

Price: 2000 rubles (The cost of the sensor with installation and validation)

THROTTLE POSITION VALVE SENSOR

The throttle position sensor VAZ is mounted on the side on the throttle nozzle on one axis with the throttle actuator. The throttle position sensor reads the readings from the “gas” pedal position. The main enemies of the throttle position sensor are the sensor manufacturing plant and engine washers. The life of the throttle position sensor is completely unpredictable. Disturbances in the operation of the throttle position sensor appear in increased revolutions at idle, in jerks and failures at low loads. Read more…

COOLANT LIQUID TEMPERATURE SENSOR WHA

The temperature sensor of the coolant VAZ is installed between the head of the unit and the thermostat. The coolant temperature sensor has two contacts (unlike the one-contact temperature sensor for the instrument panel, which is nearby, do not confuse it). The main function of the coolant temperature sensor is akin to “pouring” on the carburettor - the cooler the engine, the richer the fuel mixture. Structurally, the coolant temperature sensor is a thermistor (resistor) whose resistance varies with temperature. Typical values are 100 gr. — 177 Ohm, 25 gr. — 2796 Ohm, 0 g. — 9420 Ohm, — 20 gr. - 28680 Ohm. The temperature of the coolant affects almost all the characteristics of the engine control. The coolant temperature sensor is very reliable. The main faults are a violation of the electrical contact inside the sensor, an insulation fault or an open in the vicinity of the sensor with a dangling “gas” cable. Refusal of the gauge of temperature of a cooling liquid - inclusion of the fan on the cold engine, difficulty of starting of the hot motor, the raised expense of fuel. Read more…

Price: 150 rubles (The cost of the sensor with installation and validation)

VAZ DETONATION SENSOR

The detonation sensor VAZ is mounted on the engine block between the 2nd and 3rd cylinders. There are two types of detonation sensor - resonance (barrel) and broadband (tablet). The sensor of detonation of different types is not interchangeable. The sensor knock is a reliable element, but requires regular cleaning of the connector. The principle of the detonation sensor as a piezo lighters. The stronger the impact, the greater the tension. Tracks knocking engine. In accordance with the signal of the knock sensor, the controller sets the ignition timing. There is a detonation - a later ignition. The failure or breakdown of the knock sensor is manifested in the “dullness” of the motor and the increased fuel consumption. Read more…

Price: 250 rubles (The cost of the sensor with installation and validation)

OXYGEN WHEEL SENSOR

The oxygen sensor VAZ is installed on the intake pipe of the muffler. Serious, but very reliable electrochemical device. The task of the oxygen sensor is to determine the presence of residual oxygen in the exhaust gases. There is oxygen - a poor fuel mixture, no oxygen - rich. The oxygen sensor readings are used to adjust the fuel supply. Strictly prohibited use of leaded gasoline. The failure of the oxygen sensor leads to an increase in fuel consumption and harmful emissions. Read more…

Price: — (Cost of the sensor with installation and validation)

WHEEL VALVE POSITION SENSOR

The crankshaft position sensor VAZ is designed to generate an electrical signal when the angular position of the special gear set on the engine crankshaft changes. The crankshaft position sensor is mounted on the cover of the oil pump. This is the main sensor, according to the indications of which the cylinder is determined, the time of fuel supply and sparks. Structurally, the crankshaft position sensor is a piece of a magnet with a coil of a thin wire. Very hard. The crankshaft position sensor is paired with the crankshaft toothed pulley. Sensor failure - engine stop. At best, the engine speed limitation in the region of 3500 - 5000 rpm. Read more…

Price: 200 rubles (The cost of the sensor with installation and validation)

VAZ SPEED SENSOR

The VAZ speed sensor is designed to generate pulses, the number of which per unit time is proportional to the vehicle speed. The speed sensor is mounted on the gearbox from the top. At the injection VAZ only 6 pulse speed sensors are used. The speed sensor informs the controller of the vehicle speed. Reliability of the speed sensor is average. Often, the connector and wires are oxidized near the speed sensor. The failure of the speed sensor leads to a slight deterioration in driving characteristics (except for General Motors — the engine stalls when driving idle). Read more…

Price: without wires 250 rubles, with wires 350 rubles. (Cost of the sensor with installation and validation)

VAZ PHASE TRANSMITTER

The VAZ phase sensor is designed to determine the angular position of the camshaft. On the 8-valve engine is installed in the end of the head of the block near the air filter. On the 16-valve — on the head of the block about 1 cylinder. On 8-valve engines, produced until about 2005, there is no phase sensor. The absence of a phase sensor means that the nozzles open in pairwise-parallel mode. The presence of the sensor is a phase sensor — phased injection, ie only one nozzle opens for a specific cylinder. Failure of the phase sensor converts the fuel supply into a pairwise-parallel mode, which leads to a certain (up to 10%) increase in fuel consumption. Read more…

Price: 8th valve engine — 250 rubles (Cost of the sensor with installation and operation check)

Powered by Google Translate

Like 384 Share: Follow this User

Modern cars have a microcontroller to control the operation of all vehicle systems. In order for the microcontroller to receive information from various vehicle components, a large number of different sensors are installed on them. One sensor indicates the temperature in the cabin, another is responsible for exhaust toxicity, the third monitors the position of the headlights, the fourth determines whether the driver is sitting in the seat or not, and so on. It gets to the point of insanity: the low beam light on the car burns out, but it won’t start. The controller throws an error, which is also not so easy to decipher. This is understandable - this is the bread and butter of automaker service centers. In this regard, the old VAZ 2109 looks very attractive: they have very little electronics. Yes, and that one is very primitive. The coolant temperature sensor has failed - no problem, the generator does not work - also a problem, drive until the battery runs out. For modern foreign cars this is impossible: the controller will see a malfunction, prohibit the engine from operating and will require the driver to eliminate the malfunction. Compared to the injection model, the carburetor VAZ 2109 has fewer sensors. Of these, the only one that really affects engine operation is the Hall sensor. The remaining sensors are needed to inform the driver about the state of the vehicle systems, or to turn on/off actuators. Let's list the sensors of the VAZ 2109 carburetor: 1. Hall sensor 2. Coolant temperature sensor. 3. Oil pressure sensor. 4. Fan switch sensor. 5. Reverse sensor. 6. Parking brake sensor. 7. Throttle valve limit switch. 8. Speed sensor. * Many people mistakenly claim that the VAZ 2109 carburetor has an idle speed sensor. It is not true. The VAZ 2109 carburetor has an idle speed solenoid valve. A valve is not a sensor, it is an actuator. It does not transmit its signal, but rather receives control voltage from the idle speed economizer. 1. I would call the VAZ 2109 the most important sensor.

Without it, the car engine will not start. Remove every single other sensor and the machine will work. It will not work without a Hall sensor. The purpose of the Hall sensor is to transmit pulses about the rotation of the engine camshaft to the commutator. The sensor is designed to determine the moment a spark is formed by the switch. Without it, there will be no spark and, accordingly, the engine will not start. The sensor is installed in the housing of the ignition distributor of the VAZ 2109 and connected directly to the switch. In case of malfunction, we can easily replace it. 2. Designed to display the engine temperature on the panel.

The coolant temperature sensor (hereinafter referred to as DTOZH) is a thermal resistance, that is, a resistance that varies with temperature. The engine is cold - the resistance of the coolant temperature indicator is high and the coolant temperature gauge needle does not move. As the engine warms up, the DTOZ resistance drops and the indicator needle rises vertically. If the temperature gauge stops showing the engine temperature, a DTO check is necessary. 3. is intended to inform the driver about the presence of oil pressure in the lubrication system of the VAZ 2109 engine.

Classic VAZ 2109 models show oil pressure in the range from 0 to 5 atmospheres. VAZ 2109 shows only the PRESENCE of oil pressure, without indicating its value. 4. installed in the radiator of the engine cooling system and is designed to turn on the fan when the coolant temperature is above 90 degrees.

The fan switch is a regular thermal switch that is closed at temperatures above 90 degrees and open at lower temperatures. 5. Designed to turn on the reversing lights when reverse gear is engaged. This is also a regular limit switch, which is connected to ground when the driver engages the reverse gear of the VAZ 2109. 6. The parking brake sensor simply turns on the parking display lamp on the instrument panel of the VAZ 2109. Also a regular limit switch, activated by the parking brake lever. 7. The throttle limit switch is designed to determine whether the gas pedal is pressed or not. Connected to forced idle economizer.

In any car, the cooling system plays one of the main roles. Every motorist should know how to check. Temperature sensors are installed on all injection and carburetor machines, but their functions are slightly different.

For example, on carburetor engines, the temperature sensor only allows you to display information about the current parameter value on the dashboard. But in injection systems, one sensor allows not only to display the current system temperature on the instrument panel, but also sends a signal to the computer, which turns on the cooling fan.

Why is the sensor needed?

This device is needed to show the driver the temperature value in the cooling system. As mentioned above, the ECU turns on the cooling fan mounted on the radiator using this sensor.

In addition, by analyzing the data coming from the device, the microcontroller system allows you to adjust the crankshaft speed at idle (idle) during warm-up.

At the same time, the ratio of air and gasoline in the fuel mixture changes and the ignition angle is adjusted. The design of temperature sensors used in cars uses the properties of semiconductors. Such materials have different resistance to electric current when the ambient temperature changes.

But the sensors that are installed on carburetor engines and turn on the cooling fan are made from. They simply deform when they reach a certain temperature and switch the power contacts.

Forced activation of the VAZ 2109 fan

Scheme for turning on the VAZ 2109 fan using a relay

It is not difficult to force the VAZ 2109 fan on, you just need to think a little and understand the principle of operation of the entire system. The need to cool the radiator arises when you are driving through traffic jams (and it doesn’t matter at all whether this happens in winter or summer). In hot weather, of course, overheating occurs more strongly.

But when driving for a long time in the starting mode and instantly stopping, the antifreeze in the cooling system simply boils. Today we will look at the reasons why the VAZ 2109 fan does not turn on in automatic mode, replace the temperature sensor, and also draw up a small diagram for forcing the fan to start. The latter turns out to be useful, since the quality of thermal switches leaves much to be desired.

Why doesn't the electric fan work?

There are not many reasons:

- The motor winding burned out.

- The thermal switch has failed.

- Destruction of electrical wiring.

So, what to do if the fan suddenly stops turning on? First of all, open the heater tap, this will increase the circulation of coolant. Don't forget to turn on the heater radiator fan to help it cool faster.

When the temperature begins to drop slightly, turn off the engine. You open the hood and you see a not very pleasant picture - the antifreeze is gone, half of the compartment is wet. It is necessary to add fluid to the expansion tank. If this happens in the summer, then you can add water (the main thing is to change it to antifreeze before winter).

Check the operation of the electric motor - disconnect the connection block and directly supply power from the battery to it. Is the propeller spinning? This means that everything is fine with the winding, put the block in place. On later modifications, only the sensor switch is responsible for turning on the VAZ 2109 fan.

To check it, you need to remove two wires from it and connect them. If the rotor begins to rotate, then the fault lies in the sensor. The way out of this situation is to continue moving by connecting these two wires. There is no need to isolate them, since the activation of the VAZ 2109 fan is controlled by ground (if a bare wire gets caught on a part of the body, then it’s okay).

And the third reason is broken wires. There are two wires to the VAZ 2109 fan sensor: directly from the fan and ground (body). If no problems have arisen before, then try to make a reliable ground, since by default in nines the negative wire from the fan sensor goes towards the fuse box and is lost there.

Find a place near the radiator where you can connect the negative power cable. These are all the malfunctions that may await you. Now it’s worth talking about the useful button for forced airflow.

How to correctly install the VAZ 2109 fan switch button

There are two options - through a relay or using just a switch. The relay connection diagram is simple - you need to connect two wires parallel to the sensor. They both must go to the normally open terminals of the electromagnetic relay. This scheme avoids the presence of high current in the switch.

Two thin wires must be brought out under the dashboard and connected to the contacts of the button (or switch). Thus, a control element for the low-current winding of an electromagnetic relay is installed inside the car, and all high-current circuits are located under the hood.

And now, if the VAZ 2109 fan sensor fails, you just need to press a button to cool the engine. For this purpose, a standard relay with normally open contacts is used. Similar ones are installed on light and electric motor drives. Its price in the store is about 50-70 rubles.

The cost of the fan switch sensor is about 100 rubles. As a result, after spending a couple of hundred and half an hour of time, you will create a reliable system that will not let you down in difficult times.

I will say for myself: after it boiled in traffic a couple of times, due to the fan not turning on, I had to install a regular switch and relay. Unfortunately, nothing was found except the heater fan switch from the six, so I installed it. And now, as soon as I approach a jam, I simply turn on the fan. And I turn it off after stopping. This does not affect maneuverability and speed. Even taking into account that the carburetor nine (holds idle 900-930), no jerks or attempts to stall occur.

But you can, of course, use a different scheme - for example, turn on the VAZ 2109 fan directly with a switch, without using a relay. But this risks the fact that the contacts of the switch will constantly burn out, and its service life becomes much shorter.

Or you can use buttons without locks; to do this, you need to include one semiconductor diode in the control circuit for turning on the VAZ 2109 fan. But turning off such a system is possible if you break the power circuit with the second button.

But these are trifles for a person who more or less understands electrics. These are useful little things worth adding to your car so that the failure of the VAZ 2109 fan sensor does not take you by surprise.

Video about the fan on the VAZ 2109:

https://youtu.be/https://youtu.be/wdpTUvxVWFU

_

vaz-remzona.ru

Operating principle of the device

It is imperative to know how the device works before checking the coolant temperature sensor. DTOZH VAZ-2110 is installed directly in the thermostat housing. It has two outputs, one of which is connected to the housing and is connected to ground, and the second goes to the microcontroller control unit.

A voltage of 5 V is supplied from the microcontroller to the DTOZH. It then goes to the working element through a spring made of conductive material. The thermistor has a negative temperature coefficient, therefore, as the temperature in the cooling system increases, its resistance decreases.

Based on the voltage difference, the electronic control unit calculates the temperature value. If the device fails, it must be checked, and if a breakdown is detected, it must be replaced with a new one. There is no point in repairing or trying to restore the device; its cost is not very high.

Symptoms of failure

But before you check the VAZ-2109 coolant temperature sensor, you need to pay attention to the symptoms that may occur if this device breaks down:

- An error message appears on the dashboard.

- It is difficult to start the engine when cold.

- When the motor overheats, the cooling fan does not turn on.

- Increased gasoline consumption.

- When the engine is idling, the speed is high.

The fan in the cooling system may also not work due to a breakdown in the power system. Often relays, wires, and electric motors fail. Therefore, you need to make sure that the fan is in working condition; to do this, replace the electromagnetic relay and connect the motor directly.

Engine temperature display: note to Nines owners

Each car engine is equipped with a device for measuring the temperature of the power unit. This component allows the driver to detect overheating in time and eliminate this problem. What is the fan switch on sensor on a VAZ 2109 with a carburetor engine, what is its structure and how to replace it - read on.

Location of the coolant sensor in the VAZ 2109

First, it is advisable to know where the engine temperature sensor is located. On models 2108, 21099 and VAZ 2109, the coolant temperature sensor is installed between the cylinder head and the thermostat, in the exhaust pipe.

Device and principle of operation

The engine temperature controller itself is a thermistor-resistor device characterized by a negative temperature coefficient. The resistance parameter itself can be measured only when the temperature decreases or increases.

When the power unit heats up as a result of operation, the resistance indicator decreases; if the engine cools down, this parameter increases. For example, at the operating temperature of the engine on a VAZ 2109, the resistance is equal to 180 Ohms, and if it is 40 degrees cold outside, then the resistance will be equal to 100,700 Ohms. On one side of the DTOZH VAZ 2109 injector there are two contacts, and on the other there is a sensitive component, which is located directly in the flow of consumables.

As for the principle of operation, when the driver turns on the ignition, the control unit transmits voltage to the regulator via a resistor. Since the DTOZH itself is a thermistor, the voltage supplied from the control unit changes immediately taking into account the temperature of the consumable. When the parameter decreases, the unit analyzes the temperature and, in accordance with these data, determines the required volume of gasoline for injection. As the power unit warms up, the volume of gasoline that is transferred to the cylinders will decrease.

Two antifreeze temperature sensors for VAZ

In addition to starting, according to the readings of the regulator, the ECU adjusts the operation of the power unit at idle speed. As a result, he independently makes decisions on enriching the combustible mixture at high and medium loads on the internal combustion engine. This indicator can be changed depending on the ignition timing.

There are two temperature sensors on a carburetor car. One turns on the fan, the other is responsible for indicating the temperature on the dashboard.

Possible faults

There are several reasons why the regulator on the VAZ 21099 refuses to work.

So, why DTOZH does not work:

- An electrical contact is located inside the device structure. Over time, this contact may simply break or cracks may form on it. If a break occurs inside the structure, this may cause complete failure. That is, the DTOZH will simply burn out. If there are cracks on the contact, the DTOZH, in principle, can work, but as a result of the lack of normal contact, the regulator will transmit incorrect data about antifreeze.

- Poor device insulation. If the insulation is broken, short circuits may occur in the operation of the device. Accordingly, ultimately, these short circuits can lead to the DTOZH, again, burning out and having to be replaced.

- There was a broken wire near the regulator. As a result of the break, the regulator will not be able to activate the fan designed to cool the power unit. Accordingly, this will lead to the engine overheating and may even boil (the author of the video is a Mechanical Technician).

How can a car owner understand that the DTOZh is out of order and it’s time to replace it?

To do this, it is enough to know about the main signs of problems, which we will discuss below:

- The fan designed to cool the engine can turn on randomly at any time. In particular, the driver should be wary that the fan turns on when the engine is not completely warmed up. Remember that the fan should always function when the internal combustion engine is overheated.

- The driver has difficulty starting a warmed-up internal combustion engine. The cooling system should automatically adjust the temperature, but because the unit is faulty, it cannot receive the correct signal.

- If you carefully monitor the operation of the car, you will notice that gasoline consumption has increased. The increase in consumption is due to the fact that the car is simply overloaded when running on a hot internal combustion engine.

- If the device fails completely, the gauge on the dashboard will show an incorrect temperature signal. A ten-minute drive is enough to warm up the engine. If after 10 minutes the temperature has not risen to the optimal temperature or when starting the internal combustion engine, the dashboard shows overheating, this indicates a malfunction.

Checking and replacing DTOZH

There are several options for diagnosing the device - the first one:

- The negative probe from the voltmeter must be connected to the engine and turn on the ignition.

- Using a tester, it is necessary to determine what voltage parameter is generated during movement.

- If the DTOZH is working, then the voltage should be at least 12 volts when the battery is fully charged. If the obtained indicators are lower, it is necessary to replace or repair the device.

Temperature and resistance table

The second diagnostic method:

- You will need to set the multimeter to voltmeter mode - measurements are carried out in the range from 100 Ohms to 10 kOhms. Also prepare a thermometer that can measure temperatures greater than one hundred degrees. The regulator should be removed and placed in a container with antifreeze.

- You need to warm up the coolant. As a result of an increase in temperature indicators, you need to monitor the readings given by the thermometer.

- Using a multimeter, you should measure the resistance of the DTOZH at different temperature conditions. The obtained parameters should be compared with those indicated in the table above.

How to make the replacement yourself:

1. Disconnect the wires that are connected to the DTOZH. 2. Unscrew the regulator with a wrench. 3. Remove the device and replace it with a new one.

- First of all, all the coolant must be drained from the radiator. Then disconnect the negative terminal from the battery, simply unscrew the nut with a wrench and disconnect it.

- Next, you need to disconnect the block with wires that connects to the DTOZH.

- Use a wrench to completely unscrew the device. Next, the regulator is removed from its seat; as mentioned above, this is the cylinder head exhaust hose. There is a rubber seal on the device itself; it cannot be lost when dismantling the DTOZH, especially if you have a new sensor without a seal.

- Then install the new regulator in its seat, in the outlet hose. Using a wrench, tighten the adjuster all the way. After installation and tightening, the previously disconnected wiring harness should be connected to the DTOZH. The final step in this process is to pour the antifreeze back into the radiator and reinstall the disconnected negative battery terminal.

Video “Visual instructions for replacing the device”

You can learn how to replace the sensor yourself at home from the video below (the author of the video is Thoughts and advice from Mustafa Murtazaev).

Was this article helpful?This article was helpfulPlease share the information with your friends

avtozam.com

Major sensor failures

You need to know how to check the coolant temperature sensor with a minimal set of tools on hand. All you need is a multimeter. Among the main sensor failures are the following:

- The calibration of the thermistor is violated, because of this the resistance of the element does not correspond to the temperature values that are set for the sensor.

- The positive terminal of the device is shorted to ground.

- The seal of the element is broken.

- There is no electrical contact in the connector, the wiring is broken.

Causes of breakdowns

If the calibration is violated, the sensor begins to show “weather”. As a result, the ECU uses incorrect information and adjusts the ignition and fuel injection in a way that is not required. As a result, a cold engine is quite difficult to start, gasoline consumption increases, and the cooling system fan turns on spontaneously.

If a short circuit occurs in the sensor, the cause is usually destruction or deformation of the housing. Such a breakdown is detected by the electronic control unit; it issues an error signal to the dashboard. The tightness of the sensor housing is also lost due to mechanical damage, much less often as a result of long-term operation, especially with running water in the cooling system.

If there is no contact, the microcontroller switches the motor to emergency mode. At the same time, the cooling system fan operates constantly to prevent engine overheating. If you can restore contact in the electrical wiring without problems, then in the first three cases only replacing the sensor will help.

Cooling fan connection diagram

To turn on the engine cooling fan on the VAZ 2109, a temperature sensor installed in the radiator is used. When using an old-style mounting block (17.3722) on a car, the fan is turned on via a relay; in the new-style mounting block, this relay is absent and the fan is turned on directly. If you look closely at both schemes, you will notice that they differ quite slightly.

Scheme for switching on the engine cooling fan on a VAZ 2109 with mounting block 17.3722

1 — Fan motor 2 — Motor activation sensor 3 — Mounting block 4 — Ignition switch

K9 - Relay for turning on the fan motor A - To terminal “30” of the generator

Scheme for switching on the engine cooling fan on a VAZ 2109 with mounting block 2114-3722010-60

1 — Fan electric motor 2 — Sensor 66.3710 for turning on the electric motor 3 — Mounting block

A - To terminal “30” of the generator

vaz-2109.ru

Where is DTOZH located?

Before checking the VAZ-21099 coolant temperature sensor, you need to find it on the engine. On domestic cars with front-wheel drive, this device is located on the thermostat housing. In carburetor cars, the temperature sensor is installed in the engine block, also on the thermostat side, under the ignition distributor.

In other cars, this device can be located either on the outlet pipes near the cylinder head or on the thermostat. Some vehicles use two sensors, one of which is required for the temperature gauge located on the dashboard to function. And the second sensor sends a signal to the microcontroller ECU.

Description of DTOZH and DVV

Where is the coolant temperature and fan activation sensor located in 2109 with an injector or carburetor engine, what should I do if the device does not work? First, let's look at the basic questions regarding the purpose, device and principle of operation.

Purpose and functions

The main purpose of the DVV is to activate and deactivate the ventilation device on the engine radiator in order to cool the power unit. The device turns the fan on and off based on the temperature of the liquid in the cooling system. On injection machines, this is DTOZH; turning the fan on and off is controlled by the brain according to the readings of this sensor.

As for the TOZh controller in the VAZ 21093, this device is intended to display readings about the antifreeze temperature on the car’s dashboard in the cabin. With its help, the driver can find out about possible overheating of the power unit.

Location

As for the location, in models 2108, 2109 and 21099 the DTOZH is located between the engine cylinder head and the thermostat, in particular, on the intake hose. The DVV is installed in the threaded hole of the expansion tank with coolant. If you look in the direction of travel of the car, the refrigerant container is installed on the right.

Principle of operation

First, let's look at the operating principle of the antifreeze temperature controller. This device is a thermistor-resistor that operates with a negative coefficient. The amount of resistance in this case can be measured as a result of a decrease or increase in the temperature range. When the car engine heats up, the resistance on the device decreases, and when the power unit cools down, this value increases. For example, when the engine is fully warmed up, the resistance value on the device is 180 Ohms, and at low negative temperatures (-40 degrees) this figure will increase to 100,700 Ohms.

When the driver activates the ignition by turning the key in the lock, the control module (ECU) begins to supply voltage to the controller using a resistor. The DTOZH itself, as mentioned above, is a thermistor; accordingly, the incoming voltage will change in accordance with the temperature of the liquid. When this value decreases, the control module analyzes this, according to which the required volume of fuel for injection into the cylinders is determined. As the car engine warms up, the volume of fuel used for injection will drop.

As for the DVV, it is installed in the negative cable gap, which is connected to the ventilator activation relay in the fuse box. When the temperature value increases to 99 degrees, a short circuit occurs at the controller contacts due to the bimetallic plate. As a result, the current through the device flows to a relay located in the block, from where it is supplied to the electric motor of the device on the fan, ultimately activating the latter (the author of the video is the AndRamons channel).

In “Nines” produced after 1998 and equipped with safety blocks from the VAZ 2114, there is no relay in this section of the circuit. Therefore, the regulator itself is also mounted in the gap of the negative cable, but only the one that is connected directly to the fan. In this case, the closure occurs at a similar temperature. If the antifreeze cools, the plate opens the contacts, causing the electric motor to turn off.

How to remove and check the sensor?

It is imperative to dismantle the device before checking the coolant temperature sensor on the VAZ-2107. To do this you need:

- Disconnect the wire from the negative terminal.

- Then disconnect the plug with wires from the sensor body.

- Unscrew the device using a spanner or open-end wrench.

During repairs, it is advisable to cover the hole with a clean rag. The check is as follows:

- Pour cold water into an electric kettle.

- To check the calibration, you must use an electric thermometer (the more accurate, the better).

- The multimeter is connected to the sensor contacts; be sure to observe the polarity. Switch the tester to ohmmeter mode.

| Water temperature, ºС | Sensor resistance, Ohm |

Installing a new device

If all readings differ slightly, then this can be attributed to measurement error. But if the difference is significant, it is necessary to install a new sensor. And you can buy them at any car store; the cost of these devices is relatively low. Installation is carried out in the reverse order to dismantling.

Do not use FUM tape or silicone sealants when installing the sensor. It is enough to install a new copper washer, which will ensure the proper level of tightness in the system. If you use sealants, they can get inside the system and the channels will become clogged. It will be difficult to clear the system of this kind of blockage; you may even have to completely disassemble the engine piece by piece to get rid of them.

If you notice that the coolant temperature gauge of the VAZ 2109 shows an incorrect value, then there is a need to check it. The coolant temperature sensor is designed to monitor engine temperature. Of course, this sensor does not affect the operation of the cooling system of the VAZ 2109. The operation of the cooling system is influenced by the thermostat and the sensor on the radiator, which turns on the radiator cooling fan when the coolant temperature is more than 90 degrees. The coolant temperature sensor is intended only for INDICATORING the engine temperature on the instrument panel of the VAZ 2109. However, this is also important; you, as a driver, must know the temperature of your engine.

The VAZ 2109 coolant temperature sensor is a thermal resistance, that is, an electrical element that changes its resistance depending on the temperature. The VAZ 2109 operating manual says that to check the coolant temperature sensor, it must be removed, then placed in a glass of water of a known temperature and its resistance measured. As always, the developers took the most difficult route: to get the sensor out of the engine, you need to drain the antifreeze to the level of the sensor (and this is not very easy to do, considering that you will have to remove some hose to drain it), go somewhere to heat the water and check it later go back to the car, screw the sensor into place and fill it with antifreeze again.

You can do it much simpler: take three resistors - one 600 Ohm, the second 160 Ohm, the third 100 Ohm. These resistors will simulate a temperature sensor. Open the hood, remove the chip from the temperature sensor and bring it to the battery. We insert a 600 Ohm resistor at one end into the battery ground, and attach a sensor chip to the other end.

We go into the salon and turn on the ignition - the temperature gauge needle should show about 50 degrees.

Then, instead of the 600 Ohm resistor, we insert a 160 Ohm resistor - the temperature indicator arrow should show 90 degrees.

On the third 100 Ohm resistor, the temperature gauge needle should show more than 100 degrees. If, when connecting resistors and changing them, the temperature indicator shows the above values (they may differ slightly), then the wire from the sensor to the indicator and the indicator itself are working. Please note that if you drive a car for more than 10 minutes, that is, on a probably warmed-up engine, but the gauge does not show the temperature, then your temperature sensor is really faulty and needs to be replaced, it is inexpensive, about 2-3 $ and is sold in any auto shop. If you connect resistors between ground and the sensor connector, and when the ignition is turned on, the arrow stands dead in place, then the problem is not with the sensor. It is necessary to check the wire from the sensor to the indicator and the temperature indicator itself.

When troubleshooting, repairing and servicing, many people forget about a number of important sensors that are installed on the car. However, their malfunctions can lead to serious damage to the VAZ 2109 carb.

Sensors VAZ 2109 injector

Although VAZ 2109 cars stopped being produced at the end of 2014, there are a huge number of them traveling on the roads of the country. The latest nine models were produced with an injection-powered engine power system. Compared to the original carburetor models, the injector contains a large number of additional sensors. A carburetor car had only one single sensor that affected engine operation - a Hall sensor. The remaining sensors of the carburetor model - oil pressure sensor, coolant temperature sensor, fan switch sensor, reverse sensor - do not affect engine operation in any way. The temperature sensor and oil pressure sensor are installed on the instrument panel and serve to inform the driver about the temperature and presence of oil pressure in the engine lubrication system. A machine with an injector contains an electronic control unit - ECU, which can also be called a controller. This controller is the brains that control the operation of the engine. The controller is an electronic device that controls the operation of the engine by sending signals to the injectors based on the state of various sensors installed on the car.

Sensors VAZ 2109 with injector

The following sensors are installed on a VAZ 2109 with an injector: 1) Mass air flow sensor (MAF) 2) Throttle position sensor (TPS) 3) Coolant temperature sensor (DTOZH) 4) Knock sensor 5) Oxygen sensor 6) Crankshaft position sensor (DPKV) 7) Speed sensor Phase sensor To understand why each of the sensors listed above is needed, let's look at the block diagram of engine operation control: 1) In order to regulate the air/gasoline ratio, the injection engine control system has a mass air flow sensor (MAF). ).

Phase sensor To understand why each of the sensors listed above is needed, let's look at the block diagram of engine operation control: 1) In order to regulate the air/gasoline ratio, the injection engine control system has a mass air flow sensor (MAF). ). Based on the signal from this sensor, the controller regulates the duration of the pulse supplied to the injector, that is, the amount of fuel. The mass fuel flow sensor is installed in the air filter housing. Depending on the modification of the controller, the mass air flow sensor has two different types of output signal: a) Depending on the amount of air flow, the voltage from the sensor changes; b) Depending on the amount of air flow, the frequency of the sensor output voltage changes. In general, the task of the mass air flow sensor is to send a signal to the controller about the amount of intake air. 2) Throttle position sensor. The throttle valve is mechanically connected to the TPS. The throttle valve opens when you press the gas pedal; when the pedal is released, the throttle valve is closed. TPS is a regular rheostat, the slider of which is driven by the throttle valve. When the gas pedal is released and the throttle valve is closed, the signal from the TPS to the controller lies within 0.4..0.7V. As soon as the driver presses the gas pedal and the throttle valve opens slightly, the voltage at the TPS output begins to rise. When the throttle valve is fully open, the voltage at the sensor output is more than 4V. Receiving a signal to open the throttle valve, the controller increases the duration of pulses to the injectors, thereby increasing engine speed. 3) The VAZ 2109 coolant temperature sensor is designed to transmit information about the engine temperature to the electronic control unit, also known as the ECU, also known as the controller. If this sensor is faulty, it will be difficult or impossible to start the VAZ 2109 engine in cold weather. Receiving a signal from the DTOZH indicating that the engine is cold, the controller forms an enriched combustible mixture to start the engine. As it warms up and the temperature increases, the controller reduces the amount of gasoline in the mixture to its normal value. The principle of operation of the sensor is that the resistance of the sensor changes depending on the temperature. When the engine is cold, the resistance of the sensor is high; as it heats up, it decreases and on a warm engine it is 170 Ohms. 4) The knock sensor is designed to eliminate detonation in the engine. If the ignition timing calculated by the controller is correct, then the car engine runs smoothly, without shaking. However, if the engine begins to knock, then the ignition timing must be changed. This is what the knock sensor is used for. The sensor is installed on the engine cylinder head. Inside the knock sensor there is a piezoelectric element that generates voltage when the engine detonates. The stronger the detonation, the higher the signal level from the sensor. The controller processes the signal from the knock sensor and adjusts the ignition timing to prevent further detonation. 5) Oxygen sensor - feedback on the quality of combustion of the mixture in the engine. If the sensor shows a low oxygen content in the engine exhaust gas, it means that the mixture is being prepared over-enriched, it is necessary to reduce the pulse duration to the injectors. If, on the contrary, the amount of oxygen is large, the fuel mixture is lean, and it is necessary to increase the fuel supply for normal engine operation. The use of an oxygen sensor allows you to control the chemical composition of exhaust gases and reduce emissions into the atmosphere. 6) The crankshaft position sensor is a kind of analogue of the ignition distributor with a Hall sensor on a carburetor VAZ. The crankshaft position sensor counts the teeth of a special disk mounted on the engine crankshaft. The toothed disk has a special place where there are no teeth - this place corresponds to the top dead center of the first cylinder of the engine. Thanks to the engine crankshaft position sensor, the controller knows which cylinder and at what point in time fuel and spark supply is required. 7) The speed sensor is installed in the gearbox and is designed to determine the speed of the vehicle. The principle of operation of the speed sensor is as follows: while driving, the speed sensor generates impulses to the controller, the frequency of which depends on the speed of the vehicle. Pulses come rarely, which means the car is moving slowly. Impulses come often - moves quickly. Each pulse means moving a certain distance, which is recorded in the controller’s memory. The phase sensor is installed only on cars with a 16-valve engine. The phase sensor is designed to determine the angular position of the engine camshaft. That is, the phase sensor allows the control system to determine which engine cylinder now needs to be supplied with fuel and a spark.

Based on the signal from this sensor, the controller regulates the duration of the pulse supplied to the injector, that is, the amount of fuel. The mass fuel flow sensor is installed in the air filter housing. Depending on the modification of the controller, the mass air flow sensor has two different types of output signal: a) Depending on the amount of air flow, the voltage from the sensor changes; b) Depending on the amount of air flow, the frequency of the sensor output voltage changes. In general, the task of the mass air flow sensor is to send a signal to the controller about the amount of intake air. 2) Throttle position sensor. The throttle valve is mechanically connected to the TPS. The throttle valve opens when you press the gas pedal; when the pedal is released, the throttle valve is closed. TPS is a regular rheostat, the slider of which is driven by the throttle valve. When the gas pedal is released and the throttle valve is closed, the signal from the TPS to the controller lies within 0.4..0.7V. As soon as the driver presses the gas pedal and the throttle valve opens slightly, the voltage at the TPS output begins to rise. When the throttle valve is fully open, the voltage at the sensor output is more than 4V. Receiving a signal to open the throttle valve, the controller increases the duration of pulses to the injectors, thereby increasing engine speed. 3) The VAZ 2109 coolant temperature sensor is designed to transmit information about the engine temperature to the electronic control unit, also known as the ECU, also known as the controller. If this sensor is faulty, it will be difficult or impossible to start the VAZ 2109 engine in cold weather. Receiving a signal from the DTOZH indicating that the engine is cold, the controller forms an enriched combustible mixture to start the engine. As it warms up and the temperature increases, the controller reduces the amount of gasoline in the mixture to its normal value. The principle of operation of the sensor is that the resistance of the sensor changes depending on the temperature. When the engine is cold, the resistance of the sensor is high; as it heats up, it decreases and on a warm engine it is 170 Ohms. 4) The knock sensor is designed to eliminate detonation in the engine. If the ignition timing calculated by the controller is correct, then the car engine runs smoothly, without shaking. However, if the engine begins to knock, then the ignition timing must be changed. This is what the knock sensor is used for. The sensor is installed on the engine cylinder head. Inside the knock sensor there is a piezoelectric element that generates voltage when the engine detonates. The stronger the detonation, the higher the signal level from the sensor. The controller processes the signal from the knock sensor and adjusts the ignition timing to prevent further detonation. 5) Oxygen sensor - feedback on the quality of combustion of the mixture in the engine. If the sensor shows a low oxygen content in the engine exhaust gas, it means that the mixture is being prepared over-enriched, it is necessary to reduce the pulse duration to the injectors. If, on the contrary, the amount of oxygen is large, the fuel mixture is lean, and it is necessary to increase the fuel supply for normal engine operation. The use of an oxygen sensor allows you to control the chemical composition of exhaust gases and reduce emissions into the atmosphere. 6) The crankshaft position sensor is a kind of analogue of the ignition distributor with a Hall sensor on a carburetor VAZ. The crankshaft position sensor counts the teeth of a special disk mounted on the engine crankshaft. The toothed disk has a special place where there are no teeth - this place corresponds to the top dead center of the first cylinder of the engine. Thanks to the engine crankshaft position sensor, the controller knows which cylinder and at what point in time fuel and spark supply is required. 7) The speed sensor is installed in the gearbox and is designed to determine the speed of the vehicle. The principle of operation of the speed sensor is as follows: while driving, the speed sensor generates impulses to the controller, the frequency of which depends on the speed of the vehicle. Pulses come rarely, which means the car is moving slowly. Impulses come often - moves quickly. Each pulse means moving a certain distance, which is recorded in the controller’s memory. The phase sensor is installed only on cars with a 16-valve engine. The phase sensor is designed to determine the angular position of the engine camshaft. That is, the phase sensor allows the control system to determine which engine cylinder now needs to be supplied with fuel and a spark.

Coolant temperature sensor VAZ 2109 (carburetor)

The VAZ 2109 coolant temperature sensor (carburetor) is an extremely important element of the car’s cooling system. Therefore, you should monitor its performance.

2108, 2109 and 21099 have the same coolant temperature indicator sensors.

The design of this device is very simple. It has a built-in thermistor that responds to temperature changes and changes the resistance, depending on the indicators.

Below we provide a table that is used to check the sensor performance (DTOZH).

Cooling system VAZ 2109

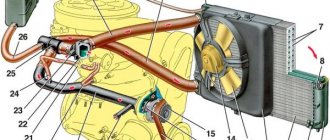

The liquid cooling system of the engine of the VAZ 2109 injector is a closed-type system with forced circulation of antifreeze (coolant). The system consists of the following units:

See:

- water pump with impeller, driven by a timing belt;

- a thermostat that directs the coolant in a small or, in other words, large circle based on the degree of engine warm-up;

- a radiator consisting of two plastic containers for coolant flow and aluminum tubes for heat dissipation, located in the front part of the engine compartment to facilitate air access;

- an expansion tank equipped with inlet and outlet valves to maintain standard pressure in the system;

- fan

located in front of the radiator for effective heat dissipation.

Radiator fan VAZ 2109 carburetor does not work.

The operation of the fan is critical in the hot season when traffic is slow. Under these conditions, overheating of the motor is especially likely and, accordingly, high-quality operation of the fan is necessary. The cooling air flow must be properly supplied to the radiator

. If the VAZ 2109 injector cooling fan does not work, then the cooling system may “boil.”