Replacing the pump on a VAZ 2107 car

Failure of the VAZ 2107 pump, or water pump, can result in two breakdowns: the formation of a coolant leak and the appearance of a hum or knocking sound.

At the first malfunction, immediate replacement is required, since the gradual leakage of coolant can lead to overheating or even seizure of the engine. The appearance of a hum is the first sign of bearing failure, and can, over time, lead to the pump stopping. The consequence of this, as in the first case, may be overheating of the VAZ 2107 engine. So the replacement will only be a matter of time, and there is no point in delaying it. To complete the replacement work you will need a minimum of tools:

- Key to 8;

- Key for 10;

- Key to 13;

- Key to 17;

- Screwdriver;

- Container for collecting coolant.

From spare parts and materials, you should stock up on a new pump and coolant, since it will need to be topped up or replaced when performing work. When choosing a new pump, it is recommended to buy a factory-made VAZ pump. Others may be of inferior quality, which may result in money and time being completely wasted and requiring a new replacement soon.

Having collected everything you need, you can proceed directly to replacing the VAZ 2107 pump. The procedure is absolutely not complicated, and is accessible even to a novice car enthusiast. Taking this opportunity, you can also replace the coolant in the system. First, you need to drain the coolant from the engine block, or from the entire system if you decide to replace it. To do this, you need to unscrew the bolt in the block (and in the radiator, if a complete replacement is being performed), after first removing the plug on the radiator.

Next, using a 17mm wrench, loosen the generator tension nut and remove the drive belt from the pump pulley.

Using the same 17 key, unscrew the fastening bracket. After this, holding the pulley with a screwdriver, unscrew the three fastening bolts and remove it from the shaft.

Lastly, unscrew the four bolts securing the pump to the engine cylinder block.

Now there is nothing holding it anymore, we can safely remove the pump from the VAZ 2107 engine. Before installing a new one, we clean the seat of grease. Also, when installing a new pump, it is necessary to replace the gasket, otherwise you will have to repeat the entire procedure again. To ensure the tightness of the system, it is strongly recommended that the gasket be sealed with sealant.

Installation of the VAZ 2107 pump is carried out in the reverse order. There shouldn't be any difficulties during the assembly process. The only thing you should pay special attention to is the tension of the generator drive belt. A belt that is too tight can quickly fail, and insufficient tension can lead to belt slipping, and as a result, loss of charging or engine overheating.

At the end of the procedure, coolant should be added. You must remember to open the heater valve to prevent the formation of air pockets in the cooling system. After filling the fluid to the required level, start the engine and warm it up to operating temperature. After letting it run for a while, turn off the engine, and after allowing it to cool, add the missing volume. Also check that there are no leaks on the newly installed pump and that the belt is tensioned. After this, the VAZ 2107 is completely ready for use.

Pump replacement, preparation

Oddly enough, installing a new pump will not cost you much. Before starting work, prepare:

- a set of keys;

- new antifreeze;

- the pump itself;

- screwdriver;

- sealant;

- deep container to drain the antifreeze.

It is up to you to decide which pump to buy; it is recommended to buy a factory-made AvtoVAZ one. The original part is more wear-resistant than its plastic counterparts, which can fall apart at the most inopportune moment. Experienced car enthusiasts recommend taking a closer look at the companies Luzar, Nepu and ABRO.

Pump VAZ 2107

On cars with a liquid cooling system, including the VAZ 2107, one of the main elements responsible for maintaining the operating temperature of the engine is the pump. Thanks to this unit, the circulation of coolant is ensured. If problems arise or if the water pump fails, the normal operation of the power unit is disrupted, which can lead to serious consequences and expensive repairs.

Purpose

The operation of the pump is aimed at continuous circulation of coolant (coolant) through the engine cooling jacket. The antifreeze is heated under the influence of the rubbing elements of the power unit, and the necessary pressure in the system is created by a water pump. The liquid is directly cooled in the main radiator, after which the coolant again enters the cooling jacket. If circulation is interrupted for at least 5 minutes, the motor will overheat. That is why it is so important to monitor the proper operation of the node in question.

Pump design

On the VAZ 2107, as on many other passenger cars, the pump has almost the same design. The unit consists of a housing with a central shaft located inside, on which the impeller is fixed. The shaft is secured against axial displacement by means of a bearing, and the tightness of the structure is ensured by an oil seal that prevents coolant leakage. There is a hole in the pump cover through which the shaft comes out, where the pulley hub and then the pulley itself are attached to it. A belt is put on the latter, which on the “seven” rotates the generator and pump from the crankshaft. On modern cars, the pump rotates via a timing belt.

Where is

On classic Zhiguli models, the pump is located on the front of the power unit and is attached not to the block, but through a separate housing. By opening the hood, you can easily notice both the pump pulley and the assembly itself.

Which pump is better

For the VAZ 2107, water pumps with catalog numbers 21073–1307010, 2107–1307011–75 and 2123–1307011–75 are suitable. The last two options have an enlarged impeller and a slightly reinforced structure. Initially, these pumps were produced for Niva. The slightly higher cost of such pumps is fully justified by the better performance.

On “Sevens” equipped with both injection and carburetor engines, the same water pumps are installed, and their repairs are carried out in the same way.

The product in question is produced today by many companies, but the most popular are:

Air lock formation

Replacing the pump supply pipe and draining the antifreeze associated with the work can lead to the formation of an air lock in the cooling system.

There are 2 ways to fix the problem:

- With the engine warm, remove one of the 2 throttle body hoses for 5-10 seconds. A small amount of antifreeze may leak out, which must be added through the expansion tank.

- The car is installed on a rise (overpass) so that the radiator is higher than the engine. The expansion tank cap is removed and the engine is started. After removing the plug, coolant is added.

Maintaining the cooling system in good condition ensures high-quality operation of the car engine. When replacing the supply pipe of the coolant pump on a car with high mileage, it is recommended to simultaneously replace the used antifreeze and flush the entire system.

Signs of a pump malfunction

Sooner or later, problems arise with the pump and the unit fails. This may be due to both the high mileage of the car and the installation of a low-quality product. Therefore, it is worth considering what malfunctions may occur with the pump and what to do in this or that case.

Oil seal leak

It is quite easy to detect coolant leakage through the oil seal: a puddle usually appears under the car. If the sealing element is damaged, for example, as a result of wear, antifreeze will get to the pump bearing, as a result of which the lubricant will be washed out of the device, and the part itself will soon collapse. To prevent this from happening, it is necessary to periodically inspect the car and eliminate possible problems.

Appearance of noise

If extraneous noise is heard from the pump area while the engine is running, this indicates an imminent breakdown of the unit. The most likely cause of noise is failure of the bearings or weak fastening of the impeller. In any case, the part needs to be dismantled, subsequently damaged, repaired or replaced.

Video: how the pump on a VAZ makes noise

Decreased performance

Whatever antifreeze is used in the cooling system, it is a chemical substance. Over time, erosion occurs in the pump housing or impeller, which can lead to a decrease in the flow of pumped liquid. As a result, the motor may overheat with all the ensuing consequences. Therefore, if the coolant temperature sensor on the instrument panel begins to exceed +90˚С (operating temperature), it is worth thinking about a possible replacement of the pump or, at least, a revision of this unit.

Increased vibration

If increased vibration comes from the pump area, first of all you need to inspect the pump housing in the bearing area: sometimes cracks may appear on it. It would also be useful to check the correct installation of the generator belt, pump pulley and fan. If faulty parts are found, replace them.

Dirty coolant

If the coolant has not been changed for a long time, problems may arise with the pump. It is not difficult to determine if the system is dirty: the color of the liquid will be brownish instead of red, blue or green. If the antifreeze turns black, most likely oil has entered the cooling system.

How to check the pump's performance

You can check the functioning of the pump yourself. To do this you will need:

- Warm up the engine to operating temperature and clamp the upper pipe leading to the radiator. If you feel a surge in pressure when you release it, then the pump is working normally.

- There is a drain hole on the pump so you should pay attention to it. If the oil seal does not cope with its functions, then antifreeze may protrude from this hole.

- While the engine is running, you need to listen to extraneous sounds. If a hum is heard from the pump, then most likely the bearing has become unusable. You can check it with the engine turned off by shaking the pump pulley. If play is felt, it means the bearing needs to be replaced.

Work on checking the pump with the engine running should be carried out carefully, not forgetting about the rotating fan and high coolant temperature.

Troubleshooting

This unit has a fairly simple design, so the faults are not too varied: a coolant leak or a bearing failure.

They are often connected, but the consequences of these two breakdowns should be separated. In the first case, a critical decrease in the antifreeze level and engine overheating is possible. It will be possible to drive some distance, you will have to add antifreeze (if there is none, water). In the second case, the bearing may jam, which will lead to a break in the pump belt and a complete lack of engine cooling. In this case, you will not be able to continue moving.

In both cases, an immediate replacement of the VAZ 2107 pump is necessary, since this unit cannot be repaired.

The following problems are typical for water pumps of classic VAZ models:

- bearing wear and resulting shaft play;

- antifreeze leakage through the oil seal;

- shaft distortion and jamming.

The pump impeller is inserted into a separate housing mounted on the cylinder block

Almost all pump problems are the result of bearing wear. With little wear and play of the shaft, the pump operates normally. As the gaps in the bearing separators increase, the oil seal begins to leak antifreeze, and unnatural noises are heard from the pump installation site when the engine is running - a hum or crackling sound. As a result, the shaft becomes distorted. The further scenario can develop in three ways.

- The bearing jams and the belt jumps off the pulleys. The engine continues to run, but the red battery discharge lamp lights up on the dashboard, and the coolant temperature rises sharply to the maximum.

- As a result of bearing jamming, the shaft breaks into two parts. As in the first case, when the engine is running, the battery discharge lamp lights up and the maximum coolant temperature is observed.

- Due to the skewed shaft, the rotating impeller breaks a hole in the wall of the pump housing, through which all the antifreeze comes out within a few seconds, and the engine instantly overheats. In this case, you will have to change not only the pump, but also the housing in which the impeller broke the wall.

As a result of bearing wear and misalignment, the pump shaft may break.

Unlike front-wheel drive VAZ models, where the pump is hidden under the timing cover, in the “classic” it is in plain sight. Therefore, it is much easier to avoid unpleasant consequences. You only need to periodically check the pump as follows.

- Start the engine, open the hood and listen. If there are suspicious noises from the front of the engine, manually press the accelerator and increase the speed until the hum becomes clearly audible.

- Carefully inspect the front of the engine for coolant leaks.

- If you find traces of leaking antifreeze, grab the pump pulley with your hand and shake it along the shaft axis in order to detect any play.

- If you feel a slight play when the belt is tensioned or you doubt the diagnostic result, unscrew the nut securing the generator to the adjusting bracket and loosen the belt. After this, pump the pump pulley again.

The nut keeps the belt taut

If you notice a slight play, you should not immediately start replacing the water pump. It will still “live” for 3-5 thousand kilometers. However, its condition will have to be constantly monitored and a new pump will have to be purchased in advance.

If there is any leakage of antifreeze, noticeable play in the shaft, and a cracking sound is heard during operation, the pump should be immediately replaced with a new one.

Pump repair

If it has been determined that the pump needs repair or replacement, you first need to prepare the necessary tools for work:

- a set of keys;

- container for draining coolant;

- flat or Phillips screwdriver.

Removal

After preparing everything you need, you can start disassembling:

- Open the hood and drain the coolant by unscrewing the corresponding bolt on the cylinder block and the plug on the radiator.

- Remove the generator belt by loosening the top fastening nut and reducing the tension.

If the pump is replaced without a housing, then there is no need to remove the nozzles and tube (points 5 and 6).

Disassembly

Repair work will require disassembling the water pump. The procedure is carried out in the following order:

- Dismantle the impeller, having first clamped the pump in a vice.

- The shaft is knocked out.

- Remove the oil seal.

Video: how to disassemble a pump on a “classic”

Bearing replacement

To replace the bearing, you will need to disassemble the pump and knock the shaft out of the housing. On the “classic”, the bearing and shaft are one part. Therefore, if one of the parts fails, the entire product is replaced. In order not to make a mistake when buying a pump shaft for a VAZ 2107, you need to take the old part with you, since the axles can differ in both diameter and length, which the seller does not always know about.

The shaft is changed in the following order:

- Using a puller, press out the impeller.

Replacing the oil seal

Due to constant contact with antifreeze, the oil seal sometimes fails, which leads to a leak. To replace the part, it is necessary to dismantle the impeller and knock out the shaft and bearing. To do this, you can use an old axle, which is inserted with the opposite end into the pump hole.

Then the shaft is driven in by striking with a hammer until the oil seal comes out of the housing. The new sealing element is inserted and pressed into place using a suitable adapter.

Replacing the impeller

If the impeller is damaged, for example, the blades are broken, then the part can be replaced. Damage usually occurs upon contact with the housing due to severe wear of the shaft or bearing. Regardless of the material of the impeller, the part is attached to the axle by pressing. To replace the plastic impeller you will need:

- Having secured the shaft on the reverse side in a yew, use an M18 tap with a pitch of 1.5 mm to cut the threads inside the impeller, having previously lubricated the tool with engine oil.

- Screw a special puller into the hole and tighten the outer bolt.

- By rotating the head of the inner bolt clockwise, press out the impeller and remove it from the shaft.

- The metal impeller has threads cut from the factory, so the part is simply pressed out with a puller.

When reinstalling, the part is pressed onto the shaft using a hammer and a suitable attachment, avoiding damage to the blades. You need to make sure that the lower part of the impeller rests against the ring on the oil seal, after which it needs to be seated 2-3 mm inward. This will ensure a tight fit of the rotating part to the ring.

Video: how to remove the impeller from the pump shaft

In most cases, owners of VAZ 2107 and other cars do not repair the pump themselves, but simply replace the part.

Installation

Assembly and installation of the unit is carried out in the reverse order. The only thing you should pay attention to is the gaskets - it is recommended to use new ones. In addition, the connections between the pump and the pipes are coated with sealant. When the part is installed, add antifreeze. In order to prevent the formation of air pockets, disconnect the thin hose of the cooling system from the carburetor (on a carburetor engine) and ensure that the antifreeze flows out of the hose and fitting, after which the connection is made. Start and warm up the engine, inspect the pipes for leaks. If everything is in order, the repair can be considered successfully completed.

Replacing or repairing the pump on a VAZ 2107 yourself is within the capabilities of every owner. The only thing is that in some cases special devices will be required. Otherwise, a standard set of tools will suffice. To ensure that the pump operates for a long time, it is recommended to select the part from trusted manufacturers.

Replacing the pump on a VAZ 2107

During operation of the internal combustion engine, it heats up. To avoid excessive engine overheating, cars use a water cooling system. VAZ 2107 cars also use a water cooling system, the key mechanism of which is the water pump. It is thanks to him that the coolant circulates in the system. The VAZ-2107 pump is replaced when the mechanism fails. We will learn more about this from the material.

The final stage of pump replacement

Pour coolant into the radiator. To avoid air locks, you need to open the stove valve to maximum. Don't forget to disconnect the antifreeze supply hose from the intake manifold. Put it in place only when antifreeze starts flowing from this hose.

After filling the antifreeze to the required level, start the engine and let it warm up to operating temperature. After letting it run for a while, turn it off, after the engine has cooled, add the missing amount of antifreeze, if necessary. Also check the belt tension. After all these steps, the car is ready for use.

Purpose of the VAZ 2107 pump

A water pump is a device whose main mechanisms are a shaft and an impeller. The pump shaft is driven by transmitting torque from the engine crankshaft. Torque is transmitted through a pulley and a belt drive, which connects components such as the crankshaft and the generator.

On VAZ 2107 cars of the carburetor type in the first years of production, the pump pulley is also used to attach the forced cooling fan. Modern VAZ 2107 models of injection and carburetor types are equipped with electric cooling fans, so there is no need to drive the fan.

The pump ensures the circulation of coolant in constant mode after starting the car engine. If the pump does not function, the cooling cycle will be disrupted, which will lead to excessive overheating of the motor and failure. It is very important to replace the pump in a timely manner, otherwise the consequences will be fatal.

Water pump problems

The pump has a fairly simple design, so identifying faults is not difficult. Malfunctions may be associated with failure of the bearings, and there may also be a leak of coolant due to wear of the sealing seals. Such problems have various types of consequences:

- If there is a coolant leak, the antifreeze level will decrease and the engine will overheat. If coolant is leaking, you can compensate for its deficiency by adding antifreeze or water. If a fluid leak occurs, it is important to promptly identify this type of failure.

- When the bearings jam, the consequences of this phenomenon cause the belt to break. In this case, continuing to move is strictly contraindicated.

Replacing the pump on a VAZ 2107 car, injector or carburetor, if the above reasons occur, is mandatory. At home, you can repair the VAZ 2107 pump yourself. How to do this is shown in the video below.

However, experts do not recommend resorting to repairing the product, since it is much easier and more efficient to replace the pump than to buy a repair kit and carry out repair work. It is especially important to pay attention to the integrity of the main pump components.

What is needed for replacement

To replace the pump, you will need to use the necessary tools. These tools include:

- Keys for 8,10,13 and 17.

- A container to drain antifreeze from the system.

- Screwdriver.

The first step is to drain the coolant from the system, and only after that can you begin to replace the device. The process of replacing a water pump does not present any difficulties, but when performing work it is important to follow a clear sequence. We will look further at how the fluid is drained and the pump is replaced on a VAZ-2107.

How to remove a pump from a car: step-by-step instructions

To replace the water pump on a VAZ 2107, you need to drain the coolant. This is done by removing the cap from the radiator, as well as sequentially unscrewing the plug on the radiator and cylinder block. After draining the antifreeze, you can begin work on replacing the water pump. Step-by-step instructions for replacing the pump on a VAZ 2107 car:

- When loosening the nut securing the generator housing, remove the belt.

- Using a key set to “13”, you need to unscrew the bolted connections that secure the pump pulley. After unscrewing the bolts, it should be dismantled.

- Unscrew the fastenings of the coolant supply pipes and then remove them.

- Carry out the process of unscrewing the bolted connections by which the pump is fixed, and then dismantle it.

- After the pump is dismantled, it is necessary to replace the sealing gasket. The old gasket must be changed.

- Unscrew the 4 fastening nuts of the pump, and then disassemble it.

- Install the new pump along with the O-rings. O-rings and gaskets cannot be reused.

- Now you can assemble all the parts in the reverse order of removal.

From the instructions described above, it is clear that the process of replacing the pump is not particularly difficult. Before resorting to such actions, you should find out how to check the water pump. Checking the serviceability of the water pump involves performing the following procedures:

- Antifreeze leak detection. If the water pump fails, a coolant leak will inevitably occur. The location of the water pump housing should be inspected.

- The occurrence of extraneous noise. If the device makes strange noises, then this is the reason that it will soon need to be replaced.

- Formation of excessive vibration. Excessive vibration indicates bearing failure.

- System contamination. If you do not replace the antifreeze for a long time, this will certainly cause the pump to fail.

The pump is an important mechanism in every car. The serviceability and efficiency of this unit affects the quality of engine cooling, as well as its integrity.

Replacing the Hyundai Solaris engine water pump

Auto News

Used cars have fallen in price in Russia

Sales of used cars in April fell by almost half compared to a year earlier.

At the same time, used cars have not increased in price, and in some Russian regions they have even become cheaper. 26 Jun 2020 06:56:39 +0000

We compiled a rating of the most expensive cars to maintain in the Russian Federation

Experts selected the most popular cars on the Internet for their rating. It became known that carrying out three maintenance in Moscow is more expensive than in St. Petersburg. The Skoda Karoq has the most expensive service in the capital - for 3 maintenance you will need to pay 46.8 thousand rubles.

26 Jun 2020 15:39:48 +0000

Ford introduced the new F-150 pickup truck

Ford has officially unveiled the new generation of the Ford F-150 pickup truck, its hybrid version. The vehicle will feature new exterior panels that give the truck a more modern appearance. Inside the cabin there will be an updated multimedia system and a display with a larger screen.

26 Jun 2020 11:33:09 +0000

New rules will apply for Russian drivers from July 1

Some drivers will now have to take more tests. We are talking about those citizens in whom the narcologist finds signs of alcohol or drug abuse. In addition, from July 1, new rules for legalizing changes in the design of a car will come into force.

25 Jun 2020 19:05:28 +0000

Russia is proposed to abandon sales of cars with internal combustion engines by 2030

Russia has been proposed to abandon automobile fuels made from petroleum products by 2030. This proposal was made by the Greenpeace organization at an online conference with the participation of Russian and foreign experts. This was announced on June 25 on the organization’s official portal.

26 Jun 2020 14:36:28 +0000

Tesla took last place in the ranking of car quality

The Initial Quality Study (IQS) portal conducted an annual study of car quality. Their report is based on the results of surveys conducted among car enthusiasts regarding the technical problems of a particular brand that they encountered during the first 90 days after purchasing a car.

25 Jun 2020 16:23:00 +0000

The restyled Lada Niva SUV will appear in 2023

According to the publication Gazeta.Ru, AvtoVAZ will present the updated Lada Niva SUV in 2023. The Croatian supplier of the Togliatti plant AD Plastik Group has signed a contract for the supply of plastic exterior elements and external components for the new car.

26 Jun 2020 16:44:04 +0000

Germany asked to resume sales of Lada cars in the EU

According to the document, Lada provides a wide selection of niche models. Such cars have been bought in Europe for about 40 years. During this time period, the brand managed to acquire a lot of fans.

26 Jun 2020 11:29:34 +0000

In Russia, the introduction of new tuning rules has been postponed until July 1, 2021

The new car tuning rules planned for introduction from July 1, 2020 have been postponed by the decision of the board of the Eurasian Economic Commission until July 1, 2021. This is reported on the website of the Russian government.

26 Jun 2020 15:28:09 +0000

Do-it-yourself replacement of a VAZ 2107 pump

Internal combustion engine - converts some energy into mechanical work. One of the most important conditions for long-term operation is good cooling. Without heat dissipation, the engine will quickly overheat and seize.

Every modern internal combustion engine has a built-in cooling system. The engine cooling system is a complex mechanism that includes many elements. One of the main elements is the pump. A pump is a mechanically driven pump that pumps coolant and thereby cools the engine.

In this article we will figure out how to replace the pump on a VAZ 2107, list the tools for the job, and also tell you how to identify the fault and select a new pump.

Description and design of the pump

The engine cooling pump, or water pump, is the part of the system that cools a hot engine. Without the system working properly or components failing, motors overheat and bring a lot of trouble to their owners.

The water pump or engine cooling system pump circulates fluid through the power unit to the cooling elements, thereby ensuring a constant operating temperature inside the structure.

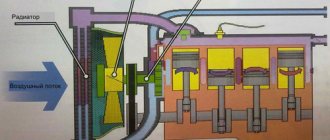

Before proceeding directly to the analysis of the main elements of the water pump, it is worth understanding the overall engine cooling system. To do this, it is worth considering what elements are included in it, and how the coolant circulation process takes place:

- Radiator.

- Expansion tank.

- Water pump.

- Thermostat.

- Water jacket inside the engine.

- Set of pipes.

- Drain taps and plugs.

An expanded range of engine cooling system parts also includes: heater radiator and heater pipes.

Currently reading

Installation and repair of the muffler resonator

How often to change the timing belt on a car: what you need...

The engine cooling pump circulates coolant throughout the system. Thus, it is worth understanding that, like any pump, it consists of parts, namely:

- Frame.

- Impeller.

- Drive shaft.

- Bearing.

- Sealing ring.

- Clamping spring (on older models of domestic cars).

- Pulley (on most models, a removable part of the pump).

How does the product work? Using a drive belt that is hooked onto a pulley, the system is put into operation. The movement from the pulley is transmitted to the shaft, and then to the impeller, which then circulates the coolant.

It is worth noting that the higher the crankshaft speed, the more the engine heats up, so the crankshaft pulley is paired with a belt with a water pump pulley.

Thus, the faster the main shaft of the power unit rotates, the higher the pump speed, and therefore the coolant circulates faster. Simply put, the faster the crankshaft rotates, the faster cooling needs to be carried out, which is why the crankshaft and pump speeds are paired.

How to identify a pump malfunction?

There are several main symptoms of a malfunction:

- The most common is gasket damage and coolant getting into the pump bearing. The coolant very quickly washes the lubricant out of the bearing and the pump jams. To avoid this, you need to look at the seal every now and then and replace it if necessary. The more mileage on the pump, the more often you need to do this. The service life of the pump on a VAZ 2107 is on average 80-100 thousand kilometers.

- Coolant leakage through the oil seal. You can determine this by looking at the pump flange (at the place where the oil seal is), everything should be dry.

- Extraneous noise when the pump is running. Typically, noise when the pump operates indicates a worn bearing or a malfunction of the impeller.

- Increased vibration of the pump during operation. Vibration indicates that you need to check the pump housing in the bearing area for cracks. You also need to check whether the alternator belt, pump pulley and fan are installed correctly.

- Dirty cooling system. If the fluid has not been changed for a long time and it is brown, then there is a high probability of pump failure.

If one or more of the symptoms listed above are detected, the pump should be replaced. We do not recommend repairing the pump on a VAZ 2107 due to the low cost of a new spare part.

For those who still want to try their hand at repairs, watch the procedure in this video:

Diagnostics and identification of supply pipe faults

A malfunction of the cooling system associated with an antifreeze leak is manifested by a decrease in its level in the expansion tank and a critical reading of the temperature sensor.

Antifreeze leak

Mechanical damage to the supply pipe or its depressurization in the area of attachment to the pump or engine block may be accompanied by:

- The release of steam in the engine compartment due to coolant entering the “pants” of the manifold.

- The appearance of a stain from leaked antifreeze where the car is parked, VAZ 2110, VAZ 2112, VAZ 2114 and Priora - in the area of the front part, VAZ 2109 - between the engine and the passenger compartment.

Additive Additive

Regularly topping up antifreeze and adding additives to eliminate coolant leaks is not a solution to the situation. Replacing the pump supply pipe with a new one will not take a lot of time and money to purchase parts and gaskets.

Pump selection

The VAZ 2107 is equipped with pumps with the following catalog numbers:

- 21073–1307010 - standard;

- 2123–1307011–75 - pump with reinforced design.

Pumps for “sevens” are produced by many companies. We recommend paying attention to:

The impellers on new pumps are made of plastic, cast iron, and steel. We recommend purchasing with a plastic or cast iron impeller.

Pumps are also sold with or without housings. If you have no mechanical damage to the body, you should not overpay; buy a separate pumping element.

Replacement process

Now we need to remove the drive belt. Loosen the nut marked below and use a pry bar to move the generator towards the engine. After this, the belt will loosen and can be removed.

Next you need to remove the pump pulley. We unscrew the three mounting bolts with a thirteen key. To prevent the pulley from spinning while unscrewing, insert a slotted screwdriver near the bolt and hold it. If you have a copper radiator installed, then to remove the pump pulley you will have to unscrew the fan.

Unscrew the bolt securing the generator from the pump. Seventeen key bolt.

We unscrew the four bolts securing the pump with a thirteen key.

When you remove the pump, coolant will flow directly onto the generator. You can wrap the generator with film or drain the coolant from the block. The block drain bolt is marked below.

We take the pump flange with our hand and remove it from the studs with rocking movements. Even if you have previously drained the liquid from the block, we recommend placing a large basin in front of the pump.

We clear the pump mounting area of the old gasket, put on a new one and reassemble it.

See the procedure for replacing the VAZ 2107 pump in this video: