Description

A car suspension diagnostic stand is a mechanical chassis detector, with the help of which one person can easily simulate wheel movement in different directions.

During such a test, the wheel rushes behind the movable part of the device and applies force to the rods, hinges and shock absorbers. As a result, all hidden damage to the suspension becomes visible even in the earliest stages of wear. Without such a diagnostic stand, it is impossible to transmit lateral vibrations to the car for a long period of time. Even if the auto repair shop uses all of its auto mechanics to rock the vehicle manually, the diagnosis will be far from accurate, and the car may end up with only new scratches and dents. Another outdated and ineffective alternative to a “play detector” is the use of a mount. In this case, it is very easy to damage parts, paint and protective coating of the car. And the test result will again be at a very low level.

Car suspension. Operating principle and main malfunctions

Today we will find out what is called a car suspension, why a vehicle needs it, and also consider its features and operating principle

CAR SUSPENSION. PRINCIPLE OF OPERATION AND MAIN FAULTS

Good afternoon, today we will learn what is called a car suspension

, why the vehicle needs it, and also consider its

features

and

operating principle

.

In addition, we will tell you how to identify the main malfunctions

in

suspension

,

the causes

of their

occurrence

and

methods of elimination

.

Thanks to the suspension

the vehicle is ensured

to be safe

while driving.

of comfort

and

dynamics

depends on the suspension elements , including achieving optimal

technical characteristics

to reduce

fuel consumption

.

In order to determine the main malfunctions of suspension parts

in its operation, you need to understand how it is

designed

, as well as how

it functions

.

1. Concept, purpose and principle of operation

car suspension

the main task

of any

suspension

is the conversion of impact energy when driving over uneven surfaces into the movement of elastic-type elements in order to level out the formation of “

breakdowns

” and ensure comfortable movement.

Elastic elements

or

levers

reduce the impact force that is transmitted to the vehicle body, resulting in smoother movement and improved technical performance.

Elastic elements

in the

suspension

, in addition to

levers

, can also include

springs

or

leaf springs

.

Suspension

The car not only

softens shocks

, but also dampens vibrations that are formed from

levers

with

springs

.

shock absorbers

soften vibrations .

If they were absent, then when the vehicle drives over uneven surfaces, the car would sway vertically for a long time, thereby worsening the adhesion of the tires to the road surface

, which in turn creates the risk of

being pulled

onto the side of the road or into a ditch.

the functions described above

,

the suspension

must transmit

the impact force from the wheels to

the vehicle body, as well as resist lateral loads when they occur during turning.

These functions

are directly provided by

suspension parts

such as

rods

, which, together with

spring

or

spring

elements of the elastic type, if present, provide

support

and

alignment

of the car at the time

of body roll

.

The main purpose of the suspension elements

and the mechanism as a whole is

to optimize the smoothness of the ride

, create maximum

comfort

,

stability

in motion, that is, the ability to control, counteract

skidding of the vehicle's chassis

and

increase

the vehicle's maneuverability.

However, the parameters described above, as a rule, conflict with one another, and therefore engineers and designers find various compromise solutions. An example would be a hard suspension

, which reduces comfort with the durability of the main components, or vice versa,

a soft suspension

, which increases comfort, but reduces the stability of the car on the road.

2. Causes of suspension malfunctions, detection methods and elimination methods

In order to determine suspension faults

independently, you must initially master the ability to listen to the operation

of the suspension

.

Hearing the operation of the suspension

will help us in that we will be able to distinguish

extraneous sounds

that indicate various

malfunctions

from the usual, so to speak factory ones.

For example, if we hear weak, soft empty sounds

, then this is not a malfunction, but refers to the normal operation

of the suspension

.

sharp sounds

occur , which come from

ball joints

,

hinges

or

absorbers

with

springs

, this is

an indirect sign of problems

in

the suspension units

.

If you notice the symptoms described above, you must immediately contact a service station for a thorough diagnosis

, where they will clearly identify

faulty

and

worn parts

, and also make a professional

replacement

.

Heavily worn

and

faulty suspension elements

, for example

shock absorbers

, can cause

body to sway

when driving over uneven surfaces.

In order to independently

determine

a worn

or

faulty

vehicle shock absorber, you need to press on any front or rear corner

of the car

body and then immediately release it.

If the part is in good working order

,

body

should immediately return to its original position and without play, immediately stop.

However, again, we note that service and repair specialists at technical stations can certainly determine excessive wear

,

malfunction

of a particular

shock absorber

, as well as other

suspension parts,

using a special

diagnostic stand

.

The most important thing when detecting malfunctions

suspension

elements is that there is no need to delay their repair, because firstly, this is a threat to the safety of the driver and his passengers, and secondly, the

worn part

parts with assemblies

unusable , which will result in more

expensive repairs

than would have been the case initially.

The table below provides information that characterizes the main reasons

and possible

methods for eliminating

certain

malfunctions suspension parts

, as well as

indirect signs

that indicate

increased wear

or

breakdown

.

independently check the rubber covers at least once a month

, which provide protection for

hinges

,

levers

,

shock absorbers

, as well as

suspension rods with steering

.

This is especially true in cases where there were powerful impacts on the suspension

or driving through deep bumps.

The fact is that if

various types of

protective covers

rupture , the rapid failure of the parts that they cover will be inevitable.

In order to be sure of all the covers

that are in

suspension

, it is best to drive the car into a pit or overpass and visually, using a flashlight and lamp, thoroughly check everything

by pressing on the rubber elements

.

Video review: “Car suspension. Operating principle and main malfunctions”

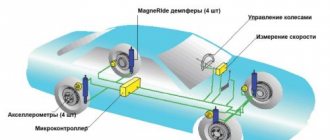

The car suspension diagnostic stand allows

- determine the visual condition and degree of wear of hinge joints, rubber and rubber-metal silent blocks, CV joints, suspension struts and their fastenings, suspension arms, springs, leaf springs, steering rods and stabilizer rods, torsion bars, steering elements, as well as difficult-to-diagnose play in suspension elements;

- simulate the impact of road surface forces that occur while the vehicle is moving on the front and rear axles in a loaded state with the engine turned off and without extraneous noise;

- check the integrity of the body and/or frame on which the suspension elements are located;

- Explain and demonstrate to customers the need for repairs.

Advantages and disadvantages

When evaluating a suspension, its consumer properties are taken into account: vehicle stability on the road, ease of control and comfort. Most often, car enthusiasts are little interested in the technical details of the car. These issues are dealt with by the engineers who create it. They choose the type of suspension, select the optimal dimensions and technical characteristics of individual components. During development, the machine undergoes many tests, so it meets all consumer requirements.

It is known that comfort and controllability are properties that are often opposite, since they depend on the stiffness of the suspension. They can only be combined in complex multi-link suspensions. The smooth running of the car is ensured by silent blocks and ball joints, as well as clearly adjusted kinematics. When hitting obstacles, shocks are well absorbed. All suspension elements are attached to the subframe thanks to powerful silent blocks, so the interior is isolated from wheel noise. The main advantage is controllability.

This suspension is used on expensive cars, providing good adhesion of the wheels to the road surface and the ability to clearly control the car on the road.

The main advantages of a multi-link suspension:

- the wheels are independent of each other;

- low weight of the suspension, thanks to aluminum parts;

- good grip on the road surface;

- good handling when cornering;

- Possibility of use in a 4x4 scheme.

Multi-link suspension requires high-quality roads, so it wears out quickly on domestic roads. The complexity of the design makes the cost of the suspension very expensive. Many manufacturers use non-separable levers on their models. Because of this, their cost is quite high.

Suspension manufacturers

The suspension is an element of the car platform that gives it unique qualities. It must be said that in the European automobile market there are a number of companies, manufacturers of spare parts, making a significant contribution to the development of components and components of automobiles. These know-how are being implemented by automakers, onto whose assembly lines the companies that develop spare parts supply their products. Among them:

- Delphi Corporation is a company that ranks second after Robert Bosch GmbH in terms of production of spare parts for cars of different classes. It is the main contract supplier of products for GM. Delphi suspensions have original status and are installed if warranty repairs are necessary;

- Wulf Gaertner Autoparts AG mainly produces air suspensions; spare parts from the MEYLE-HD series deserve special attention. These suspensions can withstand increased loads;

- ZF Friedrichshafen AG is one of the world's largest suppliers of suspensions and has a significant number of patents in its production area;

- Robert Bosch GmbH – the active suspensions of this brand deserve special attention.

Skoda Kodiak suspension

History of appearance

Attempts to make the movement of a vehicle softer and more comfortable were made in carriages. Initially, the wheel axles were rigidly attached to the body, and every unevenness in the road was transmitted to the passengers sitting inside. Only soft cushions on the seats could increase the level of comfort.

Dependent suspension with transverse spring arrangement

The first way to create an elastic “layer” between the wheels and the carriage body was the use of elliptical springs. Later, this solution was borrowed for the car. However, the spring had already become semi-elliptical and could be installed transversely. A car with such a suspension handled poorly even at low speed. Therefore, springs soon began to be installed longitudinally on each wheel.

The development of the automotive industry has also led to the evolution of the suspension. Currently, there are dozens of their varieties.

Torsion elements

Under external loads, the torsion elements are deformed and return to their original position when returning to rest. Thanks to them, the car body maintains stability and a given position.

In the suspension, spring elements compensate only for vertical loads and smooth out movement on uneven roads and when passing obstacles.

As already mentioned, these functions are performed by torsion springs, which restore their position under torsional loads in a semi-independent suspension. Independent suspension uses only springs on the shock absorbers. Leaf springs are used less frequently, but are cheaper and quite functional. Shock absorbers can be powered by air springs, but this solution is not applicable in mass production of cars due to its high cost. However, it is used in the construction of industrial vehicles and trucks.

Untimely technical service

If you don’t do maintenance on your chassis, serious problems can also arise. There are many consumables in the suspension that need to be changed on time. For example, the tire pressure must be normal, otherwise fuel consumption will increase slightly, the alignment must be done, and the struts and silent blocks must also be changed. If you don’t do this, then one problem will lead to another, this applies to all cars, especially the BMW brand.