Home » Repair and maintenance

Repair and service

Author Mikhail Rassvetny Reading time 11 min. .3k. Published 01/01/2019

The efficient functioning of automotive equipment depends on the purity of the fuel poured at gas stations. The durability and performance of parts depend on the quality of the fuel and the presence of foreign impurities, dirt and water in it. For this reason, the fuel goes through 2–4 stages of purification. The fuel is cleaned through a system of fine and coarse filters that eliminate large and small contaminants.

- 2 Fuel filter structure diagram

- 3 Operating principle of TF

- 4 Choosing gas filters for diesel engines: what to look for

4.1 Video: how to choose a fuel filter for a car

- 5.1 Coarse filters

What is a diesel fuel filter

The quality of the fuel poured into the fuel tank affects the performance and service life of many vehicle systems and components. Diesel fuel sold at gas stations often contains foreign impurities, the ingress of which into a running engine can lead to deformation of its individual parts. Unwanted components of diesel fuel are retained and removed from it by means of fuel filters - special filter elements that clean the fuel from dust, rust, metal shavings and water.

Diesel engines of the latest models, more than other types of engines, require operation in conjunction with filter elements. This is due to the complexity and precision of their design, which requires the use of only high-quality fuel. In the case of engines running on diesel fuel, the degree of purification of diesel fuel should be maximum: gas filters installed in the fuel line should retain and prevent particles of dirt and other undesirable elements up to 5 microns in size from appearing in the fuel. At the same time, diesel fuel should not contain moisture: its accumulation in the engine can provoke corrosive processes and reduce the strength of the metal.

Diesel fuel poured into vehicles with diesel engines is cleaned using special filters. TFs are classified according to the level of diesel fuel purification into fine and coarse and are placed in the fuel lines of the car in pairs, due to which the efficiency of diesel fuel purification increases several times.

Diesel fuel filters vary depending on the degree of purification

Fuel filter structure diagram

In the vast majority of cases, diesel power units fail due to fuel system malfunctions. The efficiency of the filter and how thoroughly it cleans the fuel affect the functionality of the engine and its service life.

The separation of water and diesel fuel is carried out by filter cassettes inside the gas filter: the design of such an element is simple and does not include complex parts. The exception is expensive models - they have integrated moisture sensors and a system for discharging accumulated water.

Fuel filters mostly have a similar design:

- Diesel fuel prepared for purification.

- The fuel emulsion obtained at the outlet of the pump.

- Separation of foreign impurities and condensation.

- A mixture of purified fuel and moisture.

- Element made of hydrophobic material.

- A sump in which condensate accumulates.

The structure of a filter element for diesel fuel is quite simple.

The design of almost all diesel filters is similar. You can avoid the accumulation of water and condensation in the gas tank by regularly fully refueling your car - automakers advise doing this at least once a week. On average, the working life of a TF ranges from 30 to 40 thousand kilometers, but it can vary depending on the quality of fuel used. Deterioration in the performance of the fuel unit affects the power of the power unit when going uphill, and its complete failure or continued operation in a dirty state can trigger a major engine overhaul.

Where is the fuel filter located?

In older car models, it is usually located in the upper part of the engine, under the hood of the vehicle. On more modern cars it is often mounted in a container near the fuel pump. Finding the node we are interested in, as you can see, is easy, and the process of replacing it is also simple. This activity can be performed by any car enthusiast who is “armed” with the following tools and equipment:

- circle for sealing the lid and cartridge for the filter;

- a container into which the condensate flowing from the filter will be collected;

- vacuum hand pump equipped with a container for collecting fuel.

When working with the filter, it is important to take the following precautions:

- promptly wipe away fuel leaking from the mechanism, as it wears out the rubber;

- do not use heated objects, stay away from open fire sources and heating devices, do not smoke cigarettes;

- ventilate the premises where work related to the repair of the vehicle fuel system is carried out.

Operating principle of TF

TF works according to the following scheme:

- When passing fuel through a filter, it first passes through the inlet fitting and then through a coarse gas filter;

- the mechanical components of the diesel fuel are held in place by paper “curtains” of the filter;

- fuel, purified from impurities, is supplied to the fuel line.

Automotive oil filters are made using similar filter paper as fine gas filters.

In the fuel systems of cars of foreign brands, fuel filters of a more complex design, consisting of three fittings, are installed. Since the fuel system of such machines consists of a main and an additional line, the fittings are placed as follows: two go to the main line, one to the additional line. The latter is intended to relieve pressure in the system by dumping excess diesel fuel back into the fuel tank.

Filter elements of a more complex design are installed in cars of foreign brands

Choosing gas filters for diesel engines: what to look for

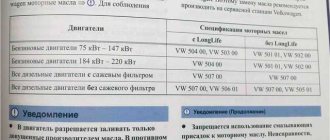

When choosing a TF for a diesel power unit, several aspects are taken into account:

- It is advisable to purchase only original filters designed specifically for diesel engines. Today there is a huge assortment of gas filters on the market, so the likelihood of stumbling upon counterfeit products is very high. Ideally, it is advisable to purchase fuel filters that are designed for a specific make and model of car. For this reason, when selecting a gas filter, you must rely on the catalog number - it must match the one specified by the manufacturer.

- The filtration fineness is calculated before purchasing a gas filter. It is measured in microns and is indicated by the manufacturer on the product packaging in the column “nominal and absolute filtration levels.” By nominal we mean 95% efficiency of particle retention by the filter components. The absolute indicator determines the quality of fuel purification and the class of the gas filter and is in most cases 98%. When choosing a TF, you should also take into account its specific type - coarse or fine cleaning. The first type retains large impurities when filtering diesel fuel, the second - the smallest ones remaining in the fuel that has gone through the stage of coarse purification. The double cleaning method is considered the most effective and widespread today, since it allows for better fuel filtration and provides engine protection. In addition, it allows you to extend the working life of both filters.

- The lowest prices are always offered for low-quality fuel filters. High quality filter components have a high price, which determines the final cost of the TF. Modern filter models are made using cellulose, synthetic and combined materials. Fully synthetic fuel filters are the most expensive, but they also have the longest service life. The cheapest are cellulose filters: in their design, the role of a cleaning element is played by special porous paper. Combined models combine cellulose and synthetic layers, which improves the quality and efficiency of fuel filtration.

- The use of diesel fuel requires the installation of a water-fuel separator. It is designed to eliminate flammable condensate and prevent moisture from entering the diesel fuel. The accumulation of water in fuel can not only reduce engine power and efficiency, but also damage it. In most cases, separators are installed simultaneously with fuel filters.

- The last requirement is that the fuel filter must be installed together with the heating device. As the ambient temperature drops, paraffin in diesel fuel begins to thicken, which complicates the supply of diesel fuel to the engine. To prevent this, a special heating device is installed in the motor.

Video: how to choose a fuel filter for a car

Why do you need to change the filter?

As a rule, replacing the fuel filter is carried out due to the negative consequences caused by the effects of resins on the engine fuel system and on its functioning as a whole. In addition, condensates cause the development of corrosion processes. Because of this, the engine deteriorates and breaks down over time. For the same reason, in the winter season the engine may not start. Condensate is also insidious in that it can form water plugs or freeze in the fuel line. This prevents gasoline or diesel fuel from entering the cylinders.

Types of TF

The fuel cleaning system includes a sediment filter, fine and coarse filters, and a fuel intake. Purification of diesel fuel from impurities is carried out in several stages as it passes through the filter elements.

Two types of filters are produced for diesel power units:

- prefabricated (their design provides for the replacement of individual parts);

- non-separable.

The filter elements of collapsible TFs are made of ceramics and brass. Such models can be used repeatedly - they can be washed and cleaned of accumulated dirt. The only disadvantage of such filters is their high cost.

Disposable filters are non-separable filters, inside of which there is a filter element. Once clogged, they require replacement with new and clean ones.

Coarse filters

A filter element that effectively cleans diesel fuel from foreign impurities whose particle size exceeds 0.05 mm. It consists of molded brass plates, between which there are calibrated gaps that do not allow large particles of dirt to pass through, but at the same time easily conduct fuel.

The design of wire slot fuel filters resembles a glass with brass wire wound on top of it.

The gap between the turns of the wire is 0.07 mm. Fuel under pressure from the fuel pump is passed through all the gaps between the wires, while the glass traps all impurities that are larger than the gap between the turns. Dirt that accumulates on the glass is easily washed off during vehicle maintenance.

Coarse TF allows not only to clean the fuel from foreign impurities, but also to prevent moisture from entering the vehicle’s fuel system. It retains water contained in diesel fuel in large quantities, which subsequently settles to the bottom because it is heavier than diesel fuel. The design of the device includes a special filter that measures the total proportion of water in the fuel and notifies the driver.

The coarse filter protects the vehicle's fuel system from paraffin contained in diesel fuel entering it. At low temperatures, paraffin crystallizes and can clog the engine, causing it to fail. Diesel fuel is cleaned of paraffins by heating it with a special heating element and passing it through a paper curtain that conducts current.

Fuel filter that cleans fuel from impurities whose particle size exceeds 0.05 mm

Fine filters

Small mechanical impurities no larger than 60 microns in size can cause no less harm to a diesel engine than large ones. Only fine filters can clean fuel from such inclusions. The design of such TFs is created in such a way that they can withstand high pressure in the fuel system. To create them, mainly steel and high-strength plastic are used.

The TF housing contains four sections closed with caps. In the center of each of them there is a rod on which is placed an element shaped like a glass. Filter paper is located inside such an element. The contact area between the filter and fuel increases several times due to the corrugated surface of the paper. The cardboard frame protects the paper from damage. The frame has small holes through which the fuel passes through the paper. Such devices trap particles up to 4 microns in size. The corrugated paper in the filter needs to be replaced regularly.

Fine filters are best placed in front of the fuel pump, since in this place the system pressure is minimal, which will protect the element from breakdowns and leaks. This arrangement also increases the service life of the pump, since it will work with purified, high-quality fuel.

Fine diesel fuel filter traps particles up to 4 microns in size

Device replacement policy

The frequency of replacement of filter elements is indicated by the manufacturer in the vehicle operating manual. The fuel filter selected for replacement must not only match the size, but also have the required degree of filtration and throughput. In most cases, the manufacturer's manual indicates the type of filter material and the filter itself. Installing an inappropriate fuel filter can significantly reduce the life of a car engine.

Scheduled replacement of fine and coarse fuel filters for most cars with diesel power units is carried out every 40 thousand kilometers. Official dealers recommend reducing the time interval by 30–50% if the vehicle is used in extreme conditions. The following conditions are accepted as extreme:

- high engine load;

- hot and humid climate;

- high dust content in the air;

- regular transportation of cargo or trailer;

- extreme driving style;

- use of low quality diesel fuel.

The listed factors negatively affect the service life of the fuel filter, causing its premature wear.

The frequency of replacing the filter element is indicated in the vehicle's operating manual

Unscheduled replacement of the filter element is carried out when the following signs of vehicle malfunction appear:

- the engine “troubles”;

- acceleration occurs slowly;

- sudden losses and surges in power while driving;

- increased fuel consumption.

If the symptoms described appear, there is a high probability that the cause is the fuel filter.

Why install an additional filter?

Indeed, if it is difficult to deal with the chemical composition of the fuel - you have to constantly change consumables, monitor the cleanliness of the mesh, etc. - then by installing an additional TF you can achieve a lot. And the automakers themselves know this, because some initially took care of this: for example, Toyota, on whose cars you don’t have to invent anything or mess with the design. And many diesel cars are standardly equipped with an additional pre-filter. It is placed in the engine compartment, in front of the main device.

Installing an additional filter

Some enthusiasts argue that installing an additional filter is not worth it, as this increases the load on the gas pump, the car loses dynamics, fuel consumption increases, etc. In fact, this is certainly not the case. If the installation is carried out correctly, there will be no side effects; on the contrary, the dynamic and traction characteristics will improve, because the purest fuel will flow into the engine.

Fuel filter heater

In any climatic conditions, the most effective method of combating the crystallization of diesel fuel is heating systems - electric and combined. The operating principle of such systems is based on heating diesel fuel and melting the paraffin crystals formed in it. Coarse and fine fuel filters, being critical components of the fuel system, most often require the installation of heaters. An electric heater is used to heat a certain amount of fuel before starting the engine, sufficient to start the power unit and warm it up. Install it on the coarse fuel filter. The heated return maintains a high temperature of the fuel and prevents it from thickening while driving.

To eliminate the phenomenon of crystallization of diesel fuel, fuel filter heaters are used

The performance and service life of a diesel engine largely depend on the quality and purity of the fuel used. Fine and coarse fuel filters are responsible for both parameters, thanks to which diesel fuel is cleaned of foreign impurities and dirt. The use of such filter elements allows you to extend the working life of the fuel system and car engine.

- Author: Mikhail Rassvetny

Good afternoon. My name is Michael. Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

Fuel filters for diesel cars

About diesel cars, it must be said that their fuel system is much more complex than a gasoline one, and in addition to a coarse filter and a fine filter, they are also equipped with a special separator for separating water from fuel. Filters can also be equipped with all kinds of insulation and heating (to avoid crystallization of paraffin from diesel fuel in cold weather).

Fuel filters on a diesel car can be located either in the fuel tank itself or under the bottom or under the hood (the mesh is most often in the tank, and the fine filter and separator are most often under the bottom or under the hood of the car). The cost of diesel filters themselves, as well as the cost of replacing them, is usually noticeably higher than gasoline ones.