Sale and replacement of diesel spare parts in Northwestern Administrative District

You can restore or service a diesel engine in the north-west of Moscow at DVS-Car. This is a modern site where you can diagnose this type of engine and eliminate faults identified during a condition check. Wear of the piston rings, scuffing of the pistons, breakdown of the cylinder head gasket, water getting into the fuel - this is a small part of the possible troubles.

Skilled craftsmen restore damaged diesel engine parts using professional equipment and according to auto repair standards.

Having all the necessary requirements for high-quality diagnostics, replacement or repair of a diesel unit, such as

- professional equipment

- software

- qualified mechanics

This workshop provides a warranty period for all work performed.

More detailed information

Complete repair of a faulty diesel engine is a technical undertaking of increased complexity and involves carrying out a fairly large list of works, among which we can highlight

- preliminary computer or mechanical diagnostics

- replacement of faulty components

- checking and restoration of diesel-related components (fuel injection pump, cylinder head, timing belt)

- post-repair tuning of a diesel engine and fuel injection pump

- maintenance activities (replacement of diesel consumables)

The listed works cannot fully reflect all the services that the owner of a foreign car with a diesel engine can receive at the Dvigavto-HD service station.

It is worth noting that major and current repairs of a diesel engine in this car service are carried out quite quickly and inexpensively.

During repairs and restoration of normal operation of both the diesel engine and the fuel pump, reliable spare parts from different manufacturers are used. Replacing faulty spare parts with high-quality mechanisms is one of the conditions for professional engine repair.

By the way, you can buy any spare parts for a diesel foreign car at this technical center, since the sale of components is also part of the activities of this auto repair company.

Of course, when purchasing spare parts, the client can be provided with an installation service.

The following work is carried out here:

- diagnostics of diesel engines

- appropriate repair of the internal combustion engine, due to faults identified during scanning and aimed at eliminating their causes

- checking the condition and necessary restoration of important engine components and fuel supply (cylinder head, fuel pump)

- major restoration of a diesel foreign car engine

In this technical center, located in the South-Eastern Administrative District, the car owner is given a guarantee after the work is completed. Considering that the price list of this structure can be correlated with average prices, the choice of this car service in the Ryazan region is optimal.

The specialized auto service center Auto-Storm on Aviamotornaya (South-Eastern Administrative District) positions itself as a specialized technical center where you can quickly and inexpensively repair a diesel engine of any foreign car, as well as restore the associated units.

The use of modern technical literature and diagnostic and adjustment equipment that meets technical standards ensures reliable repairs and guarantees.

The auto repair center also accepts orders for spare parts and engines and sells diesel internal combustion engines. Therefore, you can buy these most important units for a car in a new or used version, as well as a contract engine at a price that is not higher than the average, at this repair center.

Dieserem car service in Sviblovo has the ability to provide services such as

- repair (including capital) of diesel internal combustion engines

- repair of diesel fuel pumps (regardless of manufacturer and type - mechanical, electronic)

- cylinder head restoration

- diesel engine maintenance (replacement of consumable fluids, gaskets, filters)

- sale of contract, new and reconditioned diesel engines

DETAILS: DIY plastic bumper repair

Experts are also ready to advise which diesel engine would be best to buy if you need to replace the engine, and how often the internal combustion engine should be diagnosed to prevent major repairs.

Since the sale of components, including the sale of Bosch injection pumps, is part of the activities of specialized auto repair centers, you can buy a Bosch injection pump of any type, be it VP 44 or VE, with guarantees and at a competitive price, directly at a car service center, and a specialist will tell you which one It is better for you to choose the fuel injection pump type.

Of course, since the purchase will be made at a technical center, you can use the services of specialists and install a Bosch injection pump on a car quickly and professionally, with confidence that this event is being carried out correctly.

Car service guarantees

As already noted, the technical centers included in the catalog provide guarantees that may apply to the repair or installation services provided to the client, and to the spare parts sold. In addition, the car owner can count on post-warranty service.

Correct selection and replacement of the injection pump bypass valve

Reducing valves have an extremely simple design, but they are constantly subjected to high loads and quite often fail. Valve malfunction is manifested by deterioration of engine performance - it loses throttle response and in some modes there is a noticeable deterioration in its performance. In these cases, it is necessary to dismantle and check the valve, and, if it is faulty, replace it.

To replace, it is necessary to select a bypass valve of the same type and model that is installed on the injection pump by the manufacturer - only in this case there is a guarantee that the valve has the necessary characteristics and will ensure normal operation of the pump. Many valves allow adjustment of the pressure at which fuel is bypassed - this adjustment must be made in strict accordance with the instructions for maintenance and repair of the car/tractor. As a rule, adjustment comes down to changing the number of washers placed under the valve head, although there are exceptions - it all depends on the specific type of device.

With the correct selection, replacement and adjustment of the pressure reducing valve, the fuel pump will operate effectively in all modes, ensuring normal operating characteristics of the power unit.

I am writing a description of my case and a solution to the problem in the BZ with the hope that it will be useful to someone. Problems with the SPV valve of diesel engines are not that common, but they do exist. Some write about problems associated with the SPV valve (electromagnetic bypass valve, or single-piston fuel dispenser), which is responsible for supplying high-pressure fuel injection pump fuel to the injectors, that they arise when the valve itself malfunctions; the plunger jams due to wear of the injection pump, due to insufficient filtration of the diesel fuel; lack of ECU control signal; airiness and leakage of the valve; breakdown of tracks or capacitors of the ECU itself; loss of engine mass; from fracture of the fuel injection pump wiring due to its drying out; from fuses, etc. They often solved all these problems by replacing the valve itself or the ECU, but there were also those who remained with the valve in their hands.

My symptoms: the car stalls when driving, refuses to start. First of all, I try to bleed the fuel filter - there is fuel, I check the separator - there is no water. After several attempts I tow it into a warm box. I'm changing the standard fuel and separator filters - it's time. I check to see if the system is air-filled, bleed the return line and power into the tank. I check the work of the “frog”. I unscrew the nozzle and check it is dry. I do diagnostics through the “DIAGNOSIS” connector by closing TE1-E1 - the “check engine” indicator lights up at intervals of -0.5 seconds - everything is fine, there are no errors. I find the SPV valve connector, check it with a multimeter, there is 10.2V on one contact - this is the red wire on the “mother” side - there is a control signal from the ECU... Phew, thank God it’s not a computer... This control signal is pulsed, and the EFI unit doses the opening and closing of the valve . When the engine is not running normally, the valve is in the closed position; in the working position, it is controlled by the minus from the ECU. The second 12V contact is black, I check - 0. I connect it to the battery in +, everywhere they write that it should click, which is not true. The engine starts and the speed is normal. Phew, thank God the injection pump and the valve are alive... We are looking further for where the +12V break is. After a long search for a solution on the Internet, I came to the conclusion that you need to dig into the SPV RELAY or “spill control valve relay”; in different cars it is supposedly installed in different places. I searched. Along the way, eliminating minor defects found) I dug through the instructions, but they don’t even mention a similar relay! I couldn’t find the diagram, so I started ringing all the relays near the left wing. I turned off MAIN RELAY 85915-60030 and what’s most interesting is that the engine started working without this relay if the valve is connected directly to 12V. I opened it, and it turned out that under the weight of the scythe, over time (it was not attached to the body), the wiring fell off the relay leg. I later learned that the EFI unit controls the opening of this valve through this relay, and under some circumstances, the valve must be closed. I soldered it, put it back and Hurray it started and everything works!

Types of injection pump brand BOSCH

Bosch fuel injection pumps, of course, have the general principles of fuel pump design. They perform the same function - fuel supply, have a plunger pair and other parts and can have the same malfunctions as injection pumps of any other brand. However, depending on the type, these units may require different conditions for repair and diagnostics.

Types of Bosch pumps by design

If we talk about what types of Bosch injection pumps are available on the market, then it should be noted that in this case, first of all, you should pay attention to

- their design

- control system

Regarding the types of fuel pumps of this brand, by design, we can say that here the manufacturer has covered all segments - Bosch produces in-line, distribution and, accordingly, main fuel injection pumps. All pumps produced by this company use the Common Rail system.

Types of Bosch injection pump according to control systems

As for the classification of “Bosch” injection pumps according to the control systems with which the units are equipped, the picture here is somewhat more interesting. It is on this basis that the specifics of diagnosing injection pumps with the Bosch logo are determined.

According to control systems, Bosch fuel injection pumps are divided into the following types

- V.E.

- VE EDC

- VP 29/30

- VP 30

- VP 29

- VP 44

As for the first type of pumps produced by Bosch, VE are the simplest and most reliable units that do not require special stands for diagnostic and repair activities. And since their design made it possible to introduce any innovations, later such fuel pumps began to be equipped with ECUs.

The VE EDC pump from Bosch is controlled by an electronic unit, which greatly complicates both the diagnosis and repair of the VE EDC injection pump.

VP 29/30 is a distribution pump in which the plungers move radially, combining both mechanical and electronic components. Despite the fact that repairing a BOSCH VP 29/30 fuel injection pump is quite complicated and therefore is priced somewhat higher, its restoration is quite in demand among car owners, since the price of a new original unit is quite high.

In injection pumps of types VP 30, VP 29, VP 44, the difference is that these pumps have a different number of plunger pairs and operate on a different number of supply cycles. To repair them, the car service must also be equipped with special stands.

Fuel injection pump malfunctions and causes of their occurrence

Malfunctions in mechanisms, assemblies of fuel pumps and regulators manifest themselves in violation of the original adjustments due to wear of parts, the occurrence of extraneous noise, overheating of moving joints and fuel leakage. The main cause of pump failure is wear of its parts. At the same time, the tension in the fixed fits weakens and the gap in the moving joints increases, the correct relative position of the parts is disrupted, the surface hardness of the parts changes, foreign deposits accumulate in the form of dirt, carbon deposits, etc. One of the most common pump malfunctions is a decrease in the fuel supply and an increase in its unevenness. . Fuel supply disruption is caused by wear of plunger pairs, injection valves, plunger drivers and associated rack clamps, rack teeth and bushing gear (pumps such as UTN-5, YaMZ-238 NB), changes in the throughput of injectors and other factors. These violations reduce engine power and efficiency. Uneven supply of fuel to the engine cylinders leads to unstable operation at low speeds, interruptions in the operation of individual cylinders, and significant vibration of the engine block. Another malfunction of the fuel pump is manifested in a delay in the injection timing and unevenness in the start of injection at a multi-section pump. A delay in injection timing is a consequence of wear of a number of parts. Simple parts include: the plane of the pusher adjusting bolt; the roller axis and the pusher body and roller mating with it; ball bearings and mating sockets of the pump housing; camshaft. The change in the fuel injection advance angle is significantly influenced by wear of the plunger pairs and injection valves. Let's consider the main operational malfunctions of parts and assemblies of the pump and regulators. The following malfunctions most often occur with the cam shaft and the parts mating to it: - cut of the key of the spline bushing of the pump drive; — cutting the key of the spline gear of the regulator drive; - cam shaft failure; — failure of the cam shaft bearings; — breakage of the key and shaft of the pump cam shaft (ND-21, ND-22). As a rule, the listed malfunctions cause complete failure of the pump or a significant deviation in its functional characteristics. If the tightening torque of the cam shaft nut is insufficient, the fit of the splined bushing for the drive of pumps of the UTN-5, TsTN-8,5, -10 type and the automatic injection advance clutch for pumps of the YaMZ type may weaken and cause the key to shear off. Another reason for shearing the key is increased resistance to turning the cam shaft of the pump due to jamming of the plunger pushers, which is caused by foreign particles and water getting into the pump and regulator, as well as improper assembly and installation of high-pressure sections. The pump drive is disrupted, the fuel supply stops, and the engine does not start. If the cut of the key is not determined in time, then during further attempts to start the engine, friction may cause welding of the splined bushing or automatic injection advance clutch with the cam shaft. In this case, the fuel supply to the pump is restored, but the setting of the fuel supply advance angle will be disrupted. There is smoke from the exhaust gases and, in some cases, certain flashes in the cylinders. The latter depends on the position in which the engagement of the spline bushing and cam shaft occurred. It is possible to detect a broken key without disassembling this interface. To do this, remove the hatch from the engine (pumps UTN-5, ND-21) on the cover of the timing gears, through which the fuel supply advance angle is adjusted. Having turned the cam shaft of the pump to the position where the first section begins to feed, pay attention to the position of the blind spline in the spline sleeve. If the key is intact, the missing spline should be in the middle of the lower left quarter of the circle (as viewed from the drive side). Because of this, the key of the regulator drive gear breaks, which leads to failure of the regulator. If the lever is in the position of maximum crankshaft speed, and the load on the engine is not significant, then the engine will go into overdrive. An increase in engine speed can be prevented by moving the governor lever or rocker arm to the feed off position. Cam shaft failure most often occurs in YaMZ-240B pumps. Breakdown occurs in the most loaded areas of the automatic fuel injection advance clutch, much less often in the middle part. Failure of camshaft bearings most often occurs due to increased oil contamination. Metal shavings, sawdust, silica and aluminum oxide particles, as well as water accumulate in the high-pressure pump crankcase. If there is no oil in the crankcase, the wear rate of bearings, pushers and other parts increases. If the bearings are significantly worn, the alternation of fuel supply and injection in individual sections is disrupted. The fuel injection advance angle in all sections is delayed. Engine power decreases and exhaust smoke occurs. The engine runs unsteadily (growls) at low crankshaft speeds. Smoke may come out of the breather and drain pipe of the pump, and the pump housing will become very hot in the areas where the bearings are located. Wear and destruction of bearings is observed in the following way: - remove the low-pressure booster pump; — through a window in the housing, a small hard rod is inserted under the cam shaft; — by rocking the shaft up and down, assess the technical condition of the bearings. There should be no noticeable movement of the shaft. For LP type pumps, the booster pump is driven by a separate eccentric shaft, which is coaxial with the cam shaft and connected to it through a key and a bevel gear. Since the fuel pressure supplied to the head of the distribution pumps can reach 0.35 MPa, there are cases of cutting off the eccentric shaft drive key, as well as its breakage. In addition to wear on the working surface, the pusher has the following faults: - jamming of rollers, bushings, axles; — breakage of the thread of the adjusting bolt; - unscrewing the nut and adjusting bolt. Jamming of rollers, bushings, and pusher axes occurs, as a rule, in the absence of lubrication and contamination of the oil. Large loads on these parts and friction cause them to heat up and seize. The rollers stop rotating, and flats form on their surface. In this case, the pump shaft cams wear out intensively. Roller jamming can be detected when disassembling the fuel pump; an indirect sign of this malfunction is local heating of the pump housing. Flats on the roller may occur when the pusher rotates relative to the body. The formation of flats on the rollers leads to a delay in the fuel injection advance angle of the faulty section. If partial seizure occurs between the axle, roller and pusher bushing, then with rotation several flats are formed on the surface of the roller. With each new stroke of the pusher, the roller rotates and the fuel injection advance angle changes. The engine begins to run unstably and there is increased vibration. The appearance of flats can be determined by the height of the protrusion of the pusher relative to the pump housing. Sometimes the pusher jams (seizes) in the guide hole of the pump housing, often resulting in parts breaking. Jamming of the pusher in the upper position leads to failure of the section, i.e., stopping the fuel supply. Breaking the thread of the pusher adjusting bolt and unscrewing it leads to the fact that the height of the pusher assembly changes. Screwing in the bolt causes a delay in the fuel injection advance angle. When the pusher bolt nut is loosened, it may spontaneously turn out. When the critical height of the pusher is reached, the plunger hits the discharge valve body. If this malfunction is not corrected, other malfunctions and breakdowns may occur. In particular, a breakdown of the cam shaft bearing, plunger drive, etc. may occur. The tightening state of the adjusting bolt, its position relative to the pusher can be checked by inspection, trying to turn it with an open-end wrench, as well as turning the pump cam shaft. One of the reasons for pump malfunction is jamming of the plunger pairs. Hanging of the plunger relative to the bushing causes the rack to jam. The engine will not start . With partial setting, an unstable crankshaft rotation speed is observed. There are cases of failures of the plungers of the 240B pump due to an increase in the size of the pin or shank of the locking screw or greater tightening forces. The most common cause of jamming and impaired mobility of plunger pairs is water getting into the gap of precision parts. In this case, the lubricating fuel film on the rubbing surfaces is disrupted, and the plunger begins to work without lubrication. Friction causes scuffing of precision surfaces, their heating and jamming. The presence of water in the fuel causes corrosion of the plunger and liner. For the same reasons, the dispenser becomes jammed in the plunger pair of ND type distribution pumps. When the plunger jams in ND type pumps, the intermediate gear, shaft, regulator, and key connections break down. A stuck plunger can be detected by partially disassembling the pump. To do this, remove the pump cover and, observing the position of the plungers, rotate the cam shaft several times. It is more difficult to determine partial freezing of plunger pairs. For pumps of the TN type, a violation of the mobility of the plunger can be detected by unscrewing the clamps of the leads one by one. By rotating the cam shaft of the pump, control the ease of rotation of the plunger relative to the sleeve. Partial jamming of the plunger in the bushing is expressed in the form of interruptions in the fuel supply to individual sections and unstable operation of the regulator. The main malfunction of the plunger return springs is their breakage, which leads to partial, and if the breakage occurs in several places, to complete failure of the pump section. Seizing of a discharge valve is quite rare. Loss of mobility of valves, as well as plunger pairs, occurs from large mechanical particles entering the gap; deformation of the valve body from increased installation forces, fuel temperature, dynamic loads arising during operation of the valve, corrosion of its parts, misalignment of the valve relative to the seat. Sticking of the valve in the seat in its upper position leads to failure of the fuel section, and when the valve is stuck in the lower position, hydraulic shocks are heard. Sometimes large mechanical particles get into the gap between the shut-off cone and the housing seat. A broken valve shank causes the fuel supply to stop. The reasons for the failure of the injection valve can also be a decrease in rigidity, breakage of the valve spring, or the absence of a valve travel limiter in the fitting. Valve failure when it is skewed, dirt gets into it, or stuck in the upper position can be easily detected without disassembling the high-pressure fuel pump. To check the tightness of the valve: - unscrew the high pressure pipe from the faulty section, - move the pump rack to the supply off position, - create excess fuel pressure using a manual booster pump. Fuel leakage through the pressure fitting hole indicates a malfunction of the discharge valve. The pressure fitting has thread breaks, mainly for high-pressure tubes, as well as wear in the form of collapse and deepening of the seat for the tip of the high-pressure tube. If the seat is deepened significantly, the reliability of the seal and pressure fitting is not ensured, fuel leaks through this connection, and partial or complete failure of this section is observed. Defective fittings are replaced or restored by slightly shortening the sealing surface on a lathe or grinder. When the seat is compressed, the flow area of the hole decreases, the resistance to movement increases and, as a result, the cyclic feed decreases. To eliminate this defect, drill a hole in the pressure fitting. Malfunctions of the fuel pump rack and parts associated with it include the following: jamming, self-unscrewing of the clamps of the plunger arms, tightening screws of the gear rims, disconnection of the rack from the regulator parts. The most dangerous malfunction of a high-pressure pump occurs due to impaired rack mobility. When the rack jams in the maximum feed position, if the regulator effort is not enough to move it, an emergency increase in crankshaft speed occurs and the engine goes into overdrive. If sticking occurs in the feed off position, the engine cannot be started. There are cases of partial jamming of the rack in certain operating modes or increased resistance to its movement. In these cases, the rack moves sharply in the form of a jump, and the fuel supply changes accordingly. The engine runs unsteadily and growls. Jamming of the rack occurs due to high contamination of the crankcase oil (in UTN-5, YaMZ pumps). Abrasive particles, falling into the gap between the rack and the gear rim, cause a disruption in its mobility. Another reason for the rack to jam is water ingress, especially in winter. When the engine is running, water, along with air, enters the pump and is deposited in the form of dew on its walls, rack, and crowns during parking. At low temperatures, water freezes, the rack becomes frozen together with the gear rims. The engine does not start or goes into overdrive. This malfunction is most common in multi-cylinder engines YaMZ-238NB, YaMZ-240B. Moisture may enter the pump when the engine is heated with hot water in winter. The presence of water causes corrosion of the rack teeth and rims, which leads to increased resistance, movement of the rack and, in unfavorable cases, jamming. Sticking of the rack in TN type pumps can occur due to the plunger arms biting in the clamps in their extreme positions. To eliminate this defect, it is necessary to limit the movement of the rack. To do this, a split ring is placed on the rack of a TN type pump between the clamp and the housing, which after installation is bent to its normal position. Usually installing one or two old sealing washers is enough to eliminate sticking of the rack. If dirt gets into the rack-crown interface, it is enough to rinse the pump to eliminate the binding. For pumps of the UTN-5 and YaMZ types, the coupling of the rotary sleeve-plunger sleeve may become jammed, which also results in failure of the rack and the pump as a whole. Indirect reasons for the loss of rack mobility are also jamming of plunger pairs, the dispenser, its drive (for LP pumps), malfunction of the regulator, 15% of LP pump failures are due to jamming and breakdown of the dispenser drive. In order to detect the setting of the rack, the rods are disconnected from the regulator lever and the stop bracket. Then, using the pump control levers, move the rack to its extreme position. The movement of the rack is determined by characteristic clicks in its extreme positions. It is advisable to rotate the cam shaft several times. There should be no jamming or increased resistance to movement of parts. The movement of the pump rack can be seen directly if you unscrew the YaMZ limiter housing or plug. For other brands of pumps, you need to remove the cover to do this. To eliminate rack jamming, you need to find the sticking point. You can determine the seizing section by pumping up the ring gear relative to the rack. If the connection is working properly, you should feel a small gap. When freezing, remove the pump from the engine, bring it into a warm room, and remove the covers. After thawing and restoration of mobility of the slats, drain the oil and flush the pump with diesel fuel. After pouring fresh oil into the crankcase, the pump is installed on the engine. In more complex cases, sequential disassembly of the pump is required. Self-loosening of clamps, coupling screws, and toothed rims leads to section failure, expressed in irregular fuel supply. The cyclic feed in the failed section changes randomly, the cylinder operates unstable. When the fuel supply is turned off, the engine can continue to operate on one of the cylinders. The loosening of the screws occurs due to their insufficient tightening. You can determine whether the tightening screws have been loosened by removing the pump covers. In exceptional cases, it is possible to restore the adjustment approximately. To do this, fix the position of the plunger relative to the sleeve identical to other, properly working pairs. If there are matching marks on the ring gear and the rotary sleeve, troubleshooting is simplified. Fine adjustments can only be made on a fuel stand. Disconnecting the rail of the pump from the regulator can lead to emergency situations. In the case of significant wear of the fist and the hook hook (in the ND type pump), it is possible to disconnect these conjugated parts, then the working engine sharply increases the speed of the crankshaft, which also leads to a different engine. Disconnection of the rail at the UTT-5 and YaMZ pumps occurs when the codes are dropped and breakdown. This malfunction can be used in the same way as the jamming of the rail. One of the vulnerable units of fuel equipment of the TN8.5+10 type is a regulator. The presence in the kinematic circuit of the regulator of a large number of mobile conjugation, which have small supporting surfaces and perceiving significant pressure of the variable, leads to the rapid wear of the parts and therefore to an increase in the gaps in their interfaces. Unilateral and enlarged gaps in all conjugation contribute to the occurrence of axial backlash (dead rack stroke), reaching 3 ... .5 mm. Due to uneven wear of parts, for example, the guide grooves of the mobile coupling and piles of the regulator fork, rails and its guides, bushings and others, conjugated details sometimes jam. Moreover, if the engine operates with a high fuel supply and suddenly the load is removed, the crankshaft develops a large speed of rotation, which can lead to engine breakdown. Increased noise, uncharacteristic knocks occur when the regulator parts are broken down. In cases of significant increase in mobile and weakening of the tension in motionless interfaces in the regulator, the vibration and movement of moving parts increases, overheating of the rubbing surfaces, which causes even greater wear. Outwardly, these malfunctions are expressed by the appearance of smoke from the regulator and pump. The rack fluctuations leads to the unstable operation of the engine both at constant speeds and when the load changes. The overheating of the parts is facilitated by strongly contaminated oil or its absence. The “driving” of the rails and increased noise, as a result of the unstable operation of the diesel engine, are possible in case of improper adjustment of the regulator, for example, with an excessively twisted score of the backstage (YAMZ pump), a small range between the revolutions of the beginning and the end of the regulator’s action. In the regulators, breakdowns and deformations of the following parts are possible: - gear of the drive and roller of the regulator; - teeth of conical gears of the pumping pump and regulator drive (ND pumps); - teeth of intermediate gears (ND pumps); - roller of the regulator, downs, teeth (ND pumps); - dispenser drive; - roller bearings (stubborn, etc.); - Spiral and cylindrical springs. A breakdown of gears of gears causes increased noise, knock, beating, vibration of the pump rail. In most cases, further operation is impossible. When breaking the regulator drive in in -line pumps, mutual communication supported by the regulator is violated: the supply and speed of rotation. If you do not reduce the maximum supply of the nominal or starting mode manually, an emergency increase in engine speed will occur. The ingress of water, large abrasive particles, causes jamming of precision steams and, as a result, breakdown of the regulator parts. The breakdown of the teeth of conical and intermediate gears in the ND pump regulator, as well as the deformation of the roller of the regulator, the cut of the wraps, the breakdown of the dispenser drive leads to the cessation of the fuel supply by the high -pressure section. The engine stalls and does not start. The failure of the bearings of the roller of the regulator (pump type) causes the playing of the rail, while there is a violation of the main characteristics of the regulator. With a decrease in the stiffness of the spring, the purity of the rotation of the start of the regulator to turn off the supply is reduced, and the feed adjustment coefficient changes. To serious impaired operation of the regulator leads to wear of the legs of cargo and a squeezing bearing. With these malfunctions, the gaps in the kinematic circuit of the regulator increase, the “dead move” of the rail increases. The goods are unfolding to a larger angle, their centrifugal force increases, as a result of which fuel supply is turned off faster. The degree of uneven regulator for the nominal regime can be determined by the formula: (pm. XX- PP) * 2 Q =----- ---- * 100 % (pm. XX + PP) where: Q is the degree of uneven regulator; PM xx -maximal frequency of rotation of the crankshaft at idle; PP - the nominal frequency of rotation of the crankshaft; In the new pump, the degree of uneven regulator in the nominal mode should not exceed 10%. In the process, the degree of unevenness of the regulator increases by increasing the frequency of rotation of the idle stroke while reducing the nominal revolutions of the engine. Changing the supply of fuel is carried out with increased efforts in the regulator. Increased gaps and friction force in the mating leads to the fact that the regulator does not have time to respond to a change in the load and speed of the crankshaft, as a result of which the engine works unstable, and the range of changes in the rotation of the crankshaft increases. Working at idle, the engine "growls". Another frequent malfunction of the fuel pump is not the tightness of the seals, is expressed in the leakage of fuel and oil. When fuel passes through the front oil seal, the oil in the engine lifts. Fuel leakage can cause the overflow of the pump and regulator crankcase and, as a result, the engine is. The overflow of the high -pressure pump crankcase can occur for the following reasons: - increased wear of the pumping pump; - destruction of the sealing ring or not corresponding to its size (ND pump); - maximum wear of plunger steam; - defect in the seat of a plunger pair; - A crack in the case. To determine the cause of fuel leakage, it is necessary to find the place of leakage. To do this, you need to remove the side cover and create excessive fuel pressure in the pump head in the pump head. In pumps of the TN and UTT-5 type, the leakage of fuel is most often observed in the seats of plunger pairs, which is caused by the absence of a copper sealing ring or the hit of foreign particles between the sleeve and the planting nest, as well as risks and burrs on a landing place. In distribution pumps, overflow of the crankcase fuel occurs through the dispenser drive, and the seal of the plunger pair - with a violation of the tightness of their landing. In addition to fuel enters the pump, its leak is possible in the places between high -pressure sections and the body (ND pump) on the thread of the pressure fitting. The cause of fuel leakage at the ND pump is a small tightness of studs, insufficient thickness of the rubber sealing ring. You can replace both the upper and lower rubber sealing rings with a rubber pump without violating its adjustments. To do this, remove the dispenser drive, turn out four nuts of conjure hairpins and carefully extinguish the section of the section. The plunger and drive gears remain in place. By replacing the sealing rings, carefully press the sleeve into the body. At the same time, special attention is paid to the fact that the plunger, sleeve and the dispenser take the correct working position. Then the dispenser drive is put on the pump, check the ease of its movement and tighten the nuts of the conjure hairpins. The leature of seals can cause air leaks into the system. More often, in places of air leaks are fitting fuel of a low -pressure supply pipe going to the pumping pump from the absorption, the bypass valve, the burst of the bypass pipeline. In these cases, there are refusals of some pumping elements, interruptions in the supply of fuel in separate sections. During the engine factory, outbreaks of flashes are observed, not all its cylinders work. With the loss of tightness, the bypass valve in the pump head decreases the pressure in the P-shaped channel, and as a result, the pressure of the column chamber decreases. This non -serviceability of the pump is manifested in reducing power, difficult factory, and interruptions in the engine. Violation of the normal operation of the bypass valve occurs when mud enters it, breakdown of the spring.

Price for fuel injection pump repair at BelAvtoDizel

If you require professional diagnostics or repair of Bosch or other brands of fuel injection pumps in Moscow, the specialists of BelAvtoDizel LLC are happy to offer you their assistance. We offer:

- Services of experienced highly qualified craftsmen. Our team is professional mechanics with specialized education who have certificates for carrying out routine and major repairs of high-pressure fuel pumps and injectors.

- Wide selection of spare parts from trusted manufacturers, including originals and analogues. Along with a solid volume of warehouse stocks, we have organized uninterrupted direct supplies of parts from leading manufacturers in our country and European countries.

- Warranty for repair work for a period of one year or 50 thousand kilometers (the condition that occurs first takes priority).

- Free transportation of fuel fittings to our center and back.

- Affordable prices and substantial discounts for regular customers and large companies.

DETAILS: Ignition switch VAZ 2110 - its diagram, repair, lubrication and replacement

We have at our disposal the most modern and reliable equipment for diagnosing and troubleshooting fuel pumps on traditional diesel engines and their modified digitally controlled versions. Detailed price list is given in the table below.

rub.

| Type of work | Name | Price |

| Repair and restoration of fuel injection pump | In-line injection pumps with mechanical regulator | 9,000 rub. |

| In-line injection pumps with electronic control | 14,000 rub. | |

| Distribution injection pumps with mechanical regulator | 7,000 rub. | |

| Distribution injection pumps with electronic control VE/VP | 7 000-9 000-12 000 |

| Name | Price |

| Diagnostics of fuel injection pumps BOSH, Zexel, Denso (A, MW, P) up to 6 sections | 4500 rub. |

| Diagnostics of fuel injection pumps BOSH, Zexel, Denso (A, MW, P) up to 6 sections with EDC | 6500 rub. |

| Repair of fuel injection pumps BOSH, Zexel, Denso (A, MW, P) up to 6 sections | From 10,000 to 14,000 rubles. |

| Repair of fuel injection pumps BOSH, Zexel, Denso (A, MW, P) up to 6 sections with EDC | From 12000 to 18000 |

What are the advantages of contacting our service center? It’s easy to identify them after the first contact with us.

- Adequate price for fuel injection pump repair in Moscow.

You may have encountered surcharges when it comes to repair work on diesel vehicles. Our service specializes in them, so we adhere to a loyal pricing policy and can offer a more cost-effective service option.

- High quality of services provided.

Worried about the safety of your car? Are you afraid that after repair it will be returned to you in worse condition than you gave it to? This will not happen if you choose experienced craftsmen working at TurboDieselService. Our specialists work carefully and efficiently, providing clients with excellent and long-lasting results. Therefore, you don’t have to worry about anything when sending your Ford Transit or any other car for repair.

- Wide range of services offered.

Your diesel car needs to be repaired, and you are tired of going to different service centers for each individual service, so do everything in one place. You can get acquainted with all our services directly on the website, which will allow you to save time.

Even before contacting us, you can find out the prices for services, clarify whether the fuel injection pump of a Hyundai Porter, Kia or Mercedes will be repaired, and then with peace of mind come to our specialists and leave your car. This approach will be convenient for you, first of all, since in the end you will not have to travel for hours to different service centers in search of something that suits you in all respects.

Types of fuel pumps

First, let's look at the types of fuel pumps for diesel cars, since each of them has its own characteristics and typical fuel injection pump malfunctions. So, knowing what type of pump it is, you can better understand the principle of operation and the immediate cause of the breakdown. Regardless of the type of high-pressure pump, you need to understand that the main unit is the so-called plunger pair - a piston (plunger) and a cylinder (bushing).

There are two main types of injection pumps:

- with direct action and mechanical action of the plunger;

- with battery injection.

However, high-pressure fuel pumps are still divided into classes according to their design. In particular:

- Rows . As the name implies, their working sections are arranged in one row, and fuel is supplied to each cylinder in turn.

- Distribution . With such pumps, one section can supply fuel to several different cylinders. Such devices can be single- or double-plunger.

- Multi-sectional . Another name for them is V-shaped or hydraulic accumulators. They are used for highly powerful, but low-speed engines. They are quite rare.

With direct injection fuel pumps, pumping and injection occur simultaneously. The mechanical drive of the plunger is responsible for this. With battery pumps, fuel is supplied in separate cycles, first it enters the pump accumulator, and only then into the injectors. The most modern systems are controlled electronically and are called Common Rail. They work based on information from numerous sensors located in different parts of the car.

Another injection system is a pump injector. In this case, they are combined into one mechanism. This system simplifies pressure control and also increases reliability, because if one injector fails, the engine will continue to operate, albeit with less power.

High-pressure fuel pumps were also invented for gasoline engines. They are used in engines with direct fuel injection. The pump's job is to supply gasoline under high pressure into the cylinders, where the fuel is directly mixed with the air mass, forming a mixture that is ignited by the spark plug.

Diesel repair and maintenance at the JBMotor car service center (Noviye Cheryomushki metro station)

The JBMotor auto repair center in Cheryomushki is a full-fledged auto repair shop that provides comprehensive services related to repairs and routine maintenance for diesel engines.

- capital, diesel engine overhaul

- assessment of the condition and restoration of fuel injection pump

- replacing the cylinder head or repairing it if necessary

- replacement of consumables - oil, filters (oil, air), antifreeze

All these and other technical restoration measures are carried out at a professional level, in compliance with all technical requirements of the manufacturers.

Diesel engine diagnostics

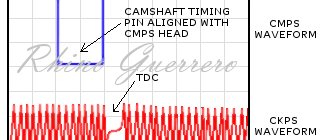

Diesel engine diagnostics in our technical centers are carried out using several types of procedures. Thus, computer diagnostics of a diesel engine, auditory and visual assessment of the condition of the unit are possible. Process diagram:

- We visually evaluate the unit without dismantling, evaluate the auditory manifestations of the defect and indirect signs;

- We connect computer equipment to read error codes;

- Deciphering errors, defining the problem;

- Defects of spare parts, determination of the list of parts for replacement.

- We fill out documents for repair of the unit.

Particular attention is paid to the fuel system, we check everything down to the smallest detail - from compression to timing marks, assess the condition of the injectors, and so on

We can perform diesel diagnostics on weekdays and weekends. High-quality fault detection: scanning and decoding error codes, comprehensive inspection, recommendations for troubleshooting diesel engine breakdowns. We offer reasonable prices for this service and guarantee passage without long waiting in line when you make an appointment on our phone number

. For any questions, call our operator!

You can familiarize yourself with all the advantages of our service stations on the main page.

The choice is yours

If you notice that your diesel car does not drive as well as before, if you want to quickly solve the problem, choose an offer from experienced technicians who work with such cars. Our Bosch injection pump repair service in Moscow will definitely suit you in all respects, and you will be satisfied with your choice.

After all, as a result, you will not have to once again look for a normal specialist who will cope with your breakdown and will know all the intricacies of the device of your particular brand of car. In “TurboDieselService” you will find such a specialist much faster, and he will work efficiently and with a long-term guarantee of the results of the repair work carried out for you.

Services of the Dieserem technical center (SVAD) for the repair of engines and diesel injection pumps

The named auto repair center carries out a number of works related to

- replacing diesel components (gaskets, glow plugs, filters, fluids, timing belt (chain), cylinder head cover, etc.)

- engine repair (overhaul, diesel overhaul)

- replacing the diesel engine assembly (removal, installation, configuration)

- work according to the regulations prescribed for these internal combustion engines

Of course, this list is not complete. To find out what other services are provided at this company, use the phone number listed above on the website.

The mechanics of the Avto-MDA diesel repair workshop, which is located near the Sviblovo metro station, the Botanicheskiy Sad metro station and the Babushkinskaya metro station, guarantee the quality of the work performed.

Auto service center Avto-U (metro station Yuzhnaya)

- Carrying out computer and instrumental diagnostics of the motor

- replacement of consumables - glow plugs, cylinder head gaskets, filters, antifreeze

- Removing a faulty diesel engine from a foreign car

- sale and installation of new diesel engines

- repair of all types of fuel pumps from different manufacturers

- cylinder head inspection and repair

Having been engaged in diesel repair for several years now, this auto repair shop guarantees the high quality of any proposed work and provides a warranty period. Whether it is necessary to repair or restore a diesel unit, adjust the fuel injection pump, replace any diesel spare parts, or perform diagnostics - these and many other works are quickly and efficiently performed by the mechanics of the Avto-U center for the repair of diesel engines, located in the Southern Administrative District, in close proximity to the Warsaw Highway.

Operating principle of fuel injection pump

Engines of different makes and models may use different types of fuel pumps. However, all fuel injection pumps have a common operating principle. The main task of this unit is to supply portions of diesel fuel into the combustion chambers under high pressure in strict accordance with the engine operating cycles. At the same time, the amount of fuel supplied by the device can be different; it depends on the operating mode of the engine - the higher the load on it, the more diesel fuel the injection pump pumps.

The main parts of a high-pressure pump are a plunger, which acts as a piston, and a cylinder sleeve. Depending on the principle of their operation, the following types of injection pumps are distinguished:

- direct acting pumps;

- battery type models.

All direct injection injection pumps are characterized by the following operating features:

- the plunger is driven mechanically;

- fuel injection and fuel injection occur simultaneously;

- the pressure required for injection is created by a moving plunger.

Battery-type pumps use a different operating principle, called separate: diesel fuel is pumped into a special battery in the pump design, then it is supplied to the injectors.

Diesel engine manufacturers also use fuel injection pump classification according to device features:

- in-line - each cylinder is connected to a specific pump section, which provides power to it;

- distribution - can be 1- or 2-plunger, each section can supply diesel fuel to several cylinders;

- multi-section - used on high-speed diesel engines.

The general operating principle of high pressure pumps is as follows:

- The booster pump forces fuel from the tank and sends it to the injection pump. The pressure reducing valve ensures the required operating pressure when diesel fuel enters the pump section.

- The cam shaft, connected to the crankshaft, actuates the plunger, which in turn delivers fuel directly to the cylinders.

- Under the action of the cam shaft, the plunger moves upward in the sleeve cavity. At the same time, the exhaust and intake valves open sequentially.

- The plunger creates pressure in the sleeve, which leads to the opening of the discharge valve. Through it, the fuel is directed directly to the spray nozzle.

- Excess fuel volume is removed from the plunger through special channels and returned to the tank through the drain fitting.

For stable operation of the high pressure pump, coordination of all stages is required. In addition, this unit is sensitive to the quality of the fuel used and the operating mode - if they are violated, certain malfunctions of the fuel injection pump of a diesel engine may appear. This will require expensive repairs, during which you will not be able to use your equipment.

Bosch injection pump malfunctions and their causes

To understand whether the Bosch injection pump should be repaired or diagnosed, the car owner should pay attention to some points that may indicate malfunctions in the Bosch fuel pump. First of all, such a signal can be increased consumption of both fuel and oil. Also, the engine may be difficult to start; at high or even medium speeds, its power may suddenly disappear.

Typically, the fuel injection pump may malfunction due to low-quality or contaminated fuel. Although the system is equipped with an oil filter, this part cannot always protect the pump from any particles or water. In this case, the nozzles and plungers may also come under attack.

How to determine fuel injection pump malfunctions

Please note that it is best to test the high pressure pump on professional stands specifically designed for this purpose. They allow you to find out the operating characteristics of the pump and other elements of the vehicle’s fuel system. However, such a check is only possible in a car service center, since such a stand is specialized and expensive equipment. In garage conditions, it is possible to carry out only a partial check of the fuel injection pump and determine only the main fault, while other possible faults will not be noticed!

Checking the presence of water in plunger pairs

To do this, you need to remove the timing belt and carefully twist the pulley. If it rotates with variable force, then everything is fine and there is no water in the pump. If rotation occurs under the influence of significant force and does not occur at all, then moisture is present. This is very harmful for both the pump and the engine as a whole, since the motor will work with increased effort when starting, until it completely jams (failure).

Adjusting the injection pump manufactured by Bosch

The service technicians included in the catalog know how to check the BOSCH injection pump, including on a special stand, and also understand the principles by which the Bosch fuel pump is adjusted.

When adjusting Bosch fuel pumps, it is necessary to take into account that the stand must be configured to work with a specific type of injection pump.

During adjustment, the specialist sets the operating parameters of the fuel injection pump. This technical measure is always carried out after any intervention in the operation of the Bosch pump, since during restoration the parameters inevitably go wrong.

- DIY Bendix starter repair

- DIY plastic bumper repair

- Repair kit for the main brake cylinder - equipment and how to use it for repairing the GTZ

- Airbag repair after deployment

Features of operation and replacement of parts

The pressure reducing or bypass valves themselves have a simple design, which ensures their reliability and durability. At the same time, they operate under high load conditions, which leads to relatively rapid wear and failure. Problems with the bypass valve are immediately reflected in engine performance in the form of a decrease in its performance in certain operating modes. In each case, it is necessary to dismantle the device and check its performance. If there are any problems, the entire device must be replaced (it is inexpensive and in the vast majority of cases there is no point in making repairs).

When purchasing a new bypass valve, you need to pay attention to options of a similar model and type that were installed by the manufacturer. This ensures that the device will perform its functions and ensure normal operation of the pump. Additionally, many models allow you to adjust the pressure, allowing you to ensure optimal engine performance. In this case, the setup process must proceed in full accordance with the attached instructions for vehicle maintenance and repair. Fundamentally, such an adjustment usually involves placing or removing a certain number of washers under the valve head.