Not just the health of the cyclist, but his life, and the lives of other road users, depend on the proper operation of the brakes - an important part of the bicycle. Therefore, when buying this two-wheeled vehicle, it is important to choose a model with a reliable braking system that will allow you to stop the bike almost instantly in an emergency.

{ ArticleToC: enabled=yes }

Types of brakes

Are V brakes or disc brakes used more often than others today? Making a choice in favor of a v brake or another is not always easy due to the wide variety of braking systems.

The first ones come in two types:

- mechanical, using a jacket with a cable for compression, are divided into cantilever and pincer;

- hydraulic, stopping using brake fluid pumped into the hydraulic line.

The second ones are:

- mechanical;

- hydraulic;

- hybrid, which have a disc brake on the front wheel and a rim brake on the rear wheel.

The choice of one type or another is influenced by the following factors:

- operating mode, i.e. how and where you are supposed to travel;

- the amount you can spend.

Shimano rim brakes

What is the structure of a bicycle? This is a frame with equipment that is hung on it. Such equipment includes:

- high-quality transmission;

- suitable wheels;

- installed brake system;

- suspension, etc.

The choice of attachments is based on the preferred manufacturer and cycling classification. There are four of them:

- highway option;

- urban model;

- tourist modification;

- mountain bike

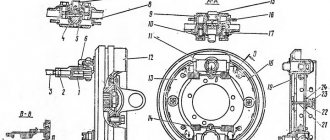

Photo 2 shows the shimano model.

Photo 2. Shimano brakes

For each type, you can select equipment from various companies, differing in price and quality.

Let's evaluate the Shimano rim brakes. First of all, this is Japan. That is class. Qualities:

- smooth setup;

- excellent braking quality;

- medium modulation, requires some settings;

- good spring;

- can be used in cold weather.

Great for walking and regular riding, can be used for cycling. The price corresponds to the quality and real durability.

V-Brakes: disadvantages and advantages

The rim group includes vibration brakes, which are much cheaper than disc ones.

This also includes:

- cantilevers;

- tick-borne

The principle of operation of the v brake (if you do not pay attention to some details) is unusually simple: the pads on both sides simultaneously compress the rim due to the force transmitted by the cable from the brake handle, as a result of which the wheel stops.

From the nineties until recently, there was no alternative to rim brakes. Most of the designs were equipped with rim brakes for the bicycle. Then disc brakes appeared, but vibration brakes have not lost their relevance due to a number of advantages. These days they are still popular and are found on many bikes. So, which one should you prefer - disc or rim brakes?

Advantages

Their high popularity is explained by their low weight, normal braking force, lightness, low cost, and ease of maintenance. It is easy to replace the cable and pads, for example, in any conditions, with a hexagon.

The advantages are also:

- the braking force they create is sufficient for driving on city and dirt roads;

- there is no alternative to them in terms of price (unless the quality is worse);

- simple design allows adjustment to be made by any cyclist who has a hex screwdriver of the required size;

- it is easy to replace brakes due to the fact that parts are available in any store;

- behave well when transporting a bicycle: the wheels are quickly released and there is nothing to break;

- have the least weight.

Flaws

Of course, like others, they have shortcomings. The most important of them is considered to be poor braking in bad weather and driving through puddles. True, it helps to somewhat correct the situation by briefly pressing the brake handle, allowing it to dry out.

The braking force is also reduced if there is a figure eight on the wheel, as well as if the gap between the block and the wheel rim is incorrectly adjusted. In order to prevent this, it is recommended to periodically tighten the cable.

Another reason for the reduced braking performance of disc brakes is the wear of the rim and pads, which accelerates when dirt gets on them. To eliminate this, special pads are installed that have grooves to drain dirt.

Prolonged braking, during which the rim heats up, also leads to rapid wear of the pads and damage to the tires. Some people consider the disadvantage of v brakes to be the fact that it is impossible to install a tire wider than 2.5 inches on the wheel.

The listed disadvantages are not so significant for the average cyclist, so we can talk about brakes of this type as the best choice.

We recommend:

- Bicycle brake pads

- Hydraulic brakes for bicycles

- Installing disc brakes on a bicycle - basic tips

Meaning of the term "brake"

0-9 [B

]

Brake

means brake || to brake; slow down # hand ~ on handbrake on (signal); ~ on differential shaft differential brakes; ~ on transmission shaft central brake on the transmission shaft; ~ out of adjustment unadjusted brake; to apply the ~ s brake, turn on the brakes; to ~ hard to brake sharply; to loosen the ~ release the brake, release the brake; to put on ~ s slow down, slow down; ~ with two leading shoes absorption brake ~ power absorption brake air ~ pneumatic brake adjustment free ~ non-adjustable air-cooled brake ~ air-cooled brake air-operated cable ~ air-operated hydraulic brake ~ brake with hydro-pneumatic drive air-operated linkage ~ brake with traction pneumatic drive air-over hydraulic ~ brake with hydro-pneumatic drive air-pressure ~ brake with pneumatic drive automatic ~ automatic brake auxiliary ~ auxiliary brake; parking brake band ~ belt brake belt ~ band brake block ~ shoe [drum] brake boosted ~ brake with booster cable ~ s brake system with cable drive cablet(-operated) ~ brake with cable drive cable-operated hand ~ hand brake with cable caliper (disk) drive ~ cam(-actuated) disc brake ~ cam-operated cam brake ~ cheek cam brake ~ clasp shoe brake ~ clutch type disc brake ~ clutch type disc brake, high overlap disc brake clutch ~ clutch brake column-mounted hand ~ hand brake with a lever on the steering column combined compressed-air and hydraulic brake with hydropneumatic drive compressed-air ~ brake with pneumatic drive constant-pressure parking ~ parking brake that does not lose effectiveness when pressure changes in the pneumatic drive contracting ~ band brake ; brake with external clamping pads contracting band ~ differential band brake ~ brake with separate drive to the front and rear wheels; differential brake disk ~ disc brake divided-system hydraulic ~ s brakes with separate hydraulic drive on front and rear wheels drive line parking ~ transmission parking brake drum ~ drum brake dry band-type ~ dry band brake dual primary ~ brake with servo action when the vehicle is moving in both directions duo-servo ~ two-block servo brake dynamometer ~ dynamometer brake eddy-current ~ induction brake effective ~ effective brake electric ~ electric brake electric dynamic ~ electrodynamic brake electromagnetic ~ electromagnetic brake emergency ~ emergency brake; emergency braking brake emergency contracting ~ drum (block or band) emergency braking brake emergency hand ~ manual emergency braking brake engine ~ engine used for braking; brake engine engine exaust ~ device for slowing down movement by throttling the exhaust exhaust ~ device for throttling the exhaust (when the car is braking by the engine) expanding inside ~ brake with expansion pads inside the brake drum expanding wedge ~ brake with expansion pads, expanded by a wedge expansion ~ brake with expansion pads pads inside the brake drum external ~ 1. band brake; brake with external clamping pads 2. brake located on the outside of the wheel external cheek ~ band brake; brake with external clamping shoes external contracting ~ band brake; brake with external clamping shoes externally acting ~ brake with an external working surface of the drum fade-free ~ brake that does not lose efficiency when heated fan ~ fan brake, moulinette fixed-caliper disk ~ disc brake with a rigidly fixed caliper floating caliper disk ~ floating disc brake caliper fluid ~ brake with hydraulic drive foot ~ foot [pedal] brake foundation ~ s main brakes (if the vehicle has an auxiliary brake) four-wheel ~ s brakes on four wheels friction ~ friction brake front-wheel ~ front wheel brake full energizing ~ servo brake full-width hub ~ brake with a drum the width of which is equal to the length of the wheel hub half-servo ~ brake system with a booster that reduces the necessary pressure on the pedal hand ~ hand brake hand lever ~ hand lever brake hub ~ hydraulic wheel brake ~ brake with hydraulic drive hydraulic boost ~ brake with hydraulic booster hydraulic ~ with vacuum power brake with hydraulic drive and vacuum booster hydraulic foot ~ brake with hydraulic drive from the pedal inner ~ brake with expansion shoes inside the brake drum inside ~ brake with expansion shoes inside the brake drum internal expanding ~ brake with expansion shoes inside the brake drum internal expanding drum ~ shoe brake with internal expansion shoes internally acting ~ brake with the internal working surface of the drum internal wheel ~ wheel brake with shoes inside the brake drum knee ~ band brake lever ~ lever brake liquid ~ brake with hydraulic drive liquid-cooled ~ liquid-cooled brake liquid cooled disk ~ liquid-cooled disc brake load-sensitive ~ brake with a device for automatically adjusting the braking force depending on the load magnetic ~ electromagnetic brake master clutch ~ multiple-disk clutch brake ~ multi-disc oil brake ~ hydraulic brake outer ~ 1. band brake; brake with external clamping shoes 2. brake located on the outside of the wheel ordinary ~ service brake overrunning ~ inertial brake outer-band ~ outside-mounted band brake ~ brake located on the outside of the wheel overrunning trailer ~ overrun brake on a trailer parking ~ parking brake pedal ~ pedal [foot] brake plvoted shoe ~ brake with a pivotally mounted shoe plate ~ plate brake pneumatic ~ brake with a pneumatic drive power ~ 1. power brake 2. dynamometer brake progressive ~ progressive action brake; a brake that slows down the vehicle proportional to the amount of pressure on the pedal Prony ~ Prony brake (for bench testing) prop shaft ~ central [transmission] brake pull-out hand ~ hand brake activated by pulling the handle quick-action ~ rear-wheel brake ~ s rear wheel brakes regenerative ~ regenerative rim brake ~ rim brake rudder ~ steering stop safety ~ S-cam safety brake ~ S-cam brake self-actuating ~ self-locking brake self-adjusting ~ brake with automatic adjustment self-energizing ~ brake with self-braking, self-jamming brake self-energizing parking ~ self-closing parking brake semi-energizing ~ brake with one clamping (primary) shoe service ~ service brake (as opposed to a parking or emergency brake), foot brake (in a car) servo ~ servo brake; servo-actuated brake system ~ servo-and-power brake ~ servo brake; brake system with servo-assisted amplifier ~ servo brake; brake system with amplifier shoe ~ side-friction shoe brake ~ brake with energy absorption by friction on the end surfaces single-sided disk ~ disc brake with one-sided friction lining sliding caliper ~ disc brake with movable caliper solenoid ~ electromagnetic [solenoid] brake split-system hydraulic ~ s brakes with separate hydraulic drive on the front and rear wheels steering ~ steering-clutch brake steering-clutch ~ steering-clutch brake stopping ~ parking brake strap ~ band brake swinging caliper ~ disc brake with swinging caliper caliper disc ~ disc brake with swinging clamp tire ~ brake acting directly on the toe tire ~ trailer foot brake ~ transmission trailer brake ~ central brake, transmission parking brake ~ parking brake interlocked with the transmission tread ~ triple servo shoe brake ~ twin-action power brake shoe ~ dual drive brake twin disk ~ double-disc brake two-leading shoe ~ brake with two running shoes two-shoe drum ~ two-shoe brake two-trailing shoe ~ brake with two running shoes vacuum ~ brake with a vacuum drive vacuum-operated hydraulic ~ brake with a hydraulic vacuum drive vacuum power ~ brake with vacuum booster water ~ brake with hydraulic drive water-cooled ~ brake cooled by water wedge ~ brake with expanding pads, wedge-actuated ~ brake with expanding pads, spreading wedge-operated ~ brake with expanding pads, expanding wedge wheel ~ wheel brake Meaning of other words: the meaning of the term brainpower, the meaning of the term brail, what the term braiding means, what is braided, decoding the term braid

Disc brakes

This type came from motorcycles and at the beginning of its expansion was a brake used by extreme sports enthusiasts. Today its niche has expanded, so it is found on recreational bikes and budget cross-country bikes.

This type of brakes is divided depending on the type of drive into mechanical and hydraulic disc brakes. In the first case, the force is transmitted to the pads using a cable, in the second - by brake fluid filling the hydraulic line. Mechanical ones have the same problems that the v brake cable drive has, but they have improved braking.

Advantages

The advantages include:

- the most powerful braking among brake systems for bikes;

- operation without loss of power in bad weather (snow and rain);

- no fear of “eights” and no wear on the rims;

- longer life of discs and pads;

- no need for maintenance (for hydraulic);

- heating of the brake disc, rather than the wheel rim, on long descents;

- Tire size is not important;

- attractive appearance.

Flaws

But they also have many disadvantages:

- design diversity even in the same model range, which eliminates interchangeability;

- difficulty in finding spare parts and maintenance;

- difficulty of repair in the field (requires special tools, cleanliness, concentration;

- difficulty in transportation (it is easy to bend the disc when the wheel is removed), but straightening it is quite difficult;

- the danger of oil getting on the disc during lubrication, which leads to brake failure and requires replacing the pads, which is quite expensive;

- toxic brake fluid used in many DOT models). In case of careless maintenance, contact with the frame leads to damage to its coating;

- the risk of brake fluid boiling during long descents, which leads to loss of control over the bicycle;

- problems with installing the trunk;

- greater weight than v-brake;

- high cost (2-4 times compared to analogues).

Where are disc brakes installed?

From the above, a conclusion suggests itself: in the segment of bicycles priced above 20 thousand rubles, v brake brakes have clearly lost their position. This is due to the fact that frames and suspension forks are increasingly being produced with holes designed for disc brake calipers installed on expensive bicycle models.

But, on vehicles in the segment up to 15 thousand rubles, i.e. On budget models, they are not installed, so this niche still belongs to v-brake brakes.

Whether to buy a bike with mechanical or hydraulic disc brakes depends on how the bike is going to be used. It is recommended to give preference to disc brakes if their benefits are truly needed. In other cases, choose a reliable, lightweight, simple and durable V-brak.

Avid rim brakes

Let's analyze their pros and cons.

- The workmanship is high.

- Great modulation option.

- Weak pads.

- Well configurable.

- Durability – within two seasons.

- Not always available for sale.

Introducing the avid brakes in photo 3.

Photo 3. Traditional view of the avid brake

Great for riding in the park and on city streets.

Setting up the brakes

Setting up V-brake brakes

Setting up the v brake is not a tricky matter, because the pads can be adjusted in several planes. The pads need to be replaced if the abrasion has reached the grooves designed to drain dirt. Even in this case, the surface of the pads should have uniform wear. Otherwise, it can be argued that they are not installed correctly. But they will still have to be replaced. To do this you need to have the appropriate tool, including a hexagon. The trunk, if any, must be removed so that it does not interfere. Next, holding the brake levers together, remove the tip of the shirt, which serves as the beginning of the cable. After this, they proceed to replacing the spare part.

Replacing cartridge pads

Cartridge pads are easier to change. The rubber gasket requires replacement. The metal frame is not used. Having taken out the rod that holds the pad, it is carefully moved to install the pads, which are marked “right” and “left”. Having installed them in place of the worn ones and secured them with a rod, the work is considered completed.

When installing conventional pads, the main thing is not to confuse the sequence of installation of parts after replacement. After installation, it is necessary to adjust the pads.

Adjusting the pads after replacement

The adjustment is necessary because, operated by pressing the brakes on the handlebars, they must grip the rim tightly to brake the wheel. In addition to correctly adjusted columns, the quality of braking is affected by the condition of the cable, so it is recommended to make sure that it moves freely in the jacket, that the weave is intact, and that there are no tears. If this is not the case, the cable needs to be changed so that in a critical situation you are not left without brakes.

The adjustment is made using the nuts available in the pad fasteners and adjusting the angles of inclination in them. All of them need to be loosened by squeezing the brake all the way. Then manually set the pads to a horizontal position and press them firmly against the rim (first the back part, then the entire pad). But at the same time, they should not touch the tires. Once you are sure of this, tighten the nuts without changing the position of the pads.

It is also necessary to adjust the levers. To do this, there is a cross-shaped screw that regulates the tension of the spring that holds the levers. The spring will be more elastic if the screw is tightened more. But it will be harder for the lever to move. Unscrew the screw and loosen the stroke.

Video: Setting up rim brakes

Instructions for replacing disc brakes

The process of setting up disc brakes cannot be called complicated. This can be done without the help of specialists.

Necessary:

- center the caliper, securing the wheel, in relation to the rotor, using the included washers of various thicknesses, which should be installed between the caliper and the mount on the frame;

- you can change the position of the caliper by tightening the bolts with different forces and selecting the thickness of the gaskets up to a millimeter;

- The pads should be moved apart if the rotor rubs against them by unscrewing the special hexagon on the caliper. This will cause the brakes to work later;

- You need to screw in the hexagon to reduce the stroke of the brake lever;

- To prevent air from entering the system when carrying out work, there is no need to turn the bike over and press the handle when there is no oil in the system and the rotor is not installed between the pads. Otherwise, they may shrink, and to open them you will have to remove the caliper;

- After completing the operations, the bolts must be tightened again and checked to see if the brake disc is warped.

Video: How to set up a disc brake

About the brakes

At first, uninitiated glance, this is one of the simplest car controls. I saw an obstacle - I braked, something incomprehensible was happening ahead - I braked, poor visibility - I braked. But this can be done in different ways. If everyone is used to ABS, and it is literally on everyone’s lips, then the brake assist (BAS) system sometimes causes some confusion.

What happens when you press the brake pedal? Without considering in detail the operation of the braking system as a whole, we should simply note that the force generated on the pedal is transmitted to the brake pads, which causes them to operate, reducing the speed of the car. This is how it looks in its simplest form, but in modern cars - Mercedes, Nissan, Toyota and others, a similar process is much more complicated.

Its operation involves such components as ABS, which prevents the car from skidding, and EBD, which optimally determines the amount of braking force on different wheels, determined by driving conditions. But this, as it turned out, is not enough for timely emergency braking. Everything is quite simple - in order to ensure the greatest efficiency of the brakes, the pedal must be pressed quickly and completely. When a situation arises that requires an urgent reduction in speed, this is often done with a delay, especially by inexperienced drivers. To avoid this, the brake assist (bas) system is used.