VAZ 2109: replacing the vacuum brake booster on your own

Vacuum brake booster

The main sign that tells a car enthusiast that the vacuum brake booster has failed is difficult movement of the brake pedal. This can lead to poor braking, which can lead to a traffic accident in an emergency. On a VAZ 2109, replacing the vacuum brake booster must be carried out. Replacing the vacuum brake booster on a VAZ 2109 can be easily done on your own.

Amplifier operating principle

The vacuum amplifier is a round chamber divided inside by a membrane. On one side there is a vacuum hose connected, on the other side there is a valve that regulates the change between vacuum and atmospheric air. When you press the brake pedal, the vacuum hose is closed by the valve, and the membrane moves to the side, pushing the rod. The rod, in turn, presses on the cylinder piston. The harder we press the pedal, the more atmospheric pressure is created on the cylinder and pads.

You will be interested:How dangerous is the new coronavirus?

A serviceable and good vacuum brake booster for the Gazelle makes the braking process more reliable. Vacuum problems will not completely affect the brake system, but a stuck brake pedal can negatively affect ride quality and lead to an accident when you need to stop quickly.

Examination

Replacing the vacuum brake booster of a VAZ 2109

Vacuum booster repairs are carried out in specialized auto repair shops using equipment designed for this purpose. In the context of garage repairs on a VAZ-2109, the vacuum brake booster is replaced with the installation of a new one. Before making a decision to replace, it is necessary to check the operation of it itself, as well as the check valve.

Checking the operation of the vacuum booster

VAZ 2109 vacuum brake

To check the operation of the amplifier you need to:

- Press the pedal with your foot, thereby increasing the pressure in the brake system. The pedal remains depressed.

- Keep your foot on the pedal and turn on the engine.

- When you start the engine, the foot with the pedal begins to move towards the floor of the VAZ body, which means that the vacuum booster is working and the entire system is in good working order.

Note. In another case, the foot and pedal remain motionless, that is, in the upper depressed state, which means there is a malfunction somewhere. First you need to check the vacuum hose at the connections. Also check the check valve for leaks.

Check valve

VAZ 2109 vacuum brakes

To check the operation of the check valve:

- inspect the pipe connections;

- feel these places with your hands;

- tighten the clamps at the connections of the pipes;

- on the intake pipe fitting;

- on the non-return valve fitting, on vacuum.

Then check the valve itself. To do this, remove the rubber tube from the vacuum, using a flat-head screwdriver if necessary. Since the tube is very difficult to remove. Take a pre-prepared rubber bulb-shaped injector of suitable diameter for the fitting:

- Paste it;

- Squeeze the syringe;

- Squeeze the air out of it.

Release your hand if it remains clenched then the valve test is complete. That is, the valve fulfills its design purpose. If the injector is filled with air, then the valve will have to be replaced. You can also check the operation of the valve with your mouth:

- Blow the air out of your mouth; it should easily pass into the vacuum;

- Then apply suction; the air coming out should not be felt.

This completes the check of the brake system vacuum booster and check valve. If no defects are found in the connected parts and the check valve is working properly, the vacuum is replaced.

Vacuum brake booster VAZ 2109, device, malfunctions, repair

This vacuum booster is suitable for models:

VAZ 2108, 2109, 21099 “SAMARA”.

The vacuum brake booster is designed to enhance the hydraulic brake.

The warranty period is 12 months from the date of sale through the retail network.

Guaranteed shelf life is 3 years from the date of release, subject to storage conditions.

- Check prices by calling the number listed on the website.

Life time:

- 10,000 cycles at -40°C

- 90,000 cycles at 100°C

- 400,000 cycles at 25°C

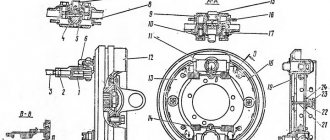

Design of the vacuum brake booster VAZ 2109

Currently, it is difficult to imagine the operation of a vehicle if the vacuum brake booster of the VAZ 2109 is not included in its design. Thanks to this unit, additional force is created, which is subsequently transmitted to the pedals of the brake system. The device is combined into a single-block design with a GTZ, while the housing is divided into two separate parts. The first part, atmospheric, is located next to the brake pedal. The second part, the vacuum part, in turn is located next to the main cylinder.

To combine the vacuum chamber and the manifold, the VAZ 2109 has a special check valve. In most cases, an electric pump is included in the design of vehicle engines for the sole purpose of ensuring stable and constant operation of the vacuum booster. After stopping the vehicle engine, the amplifier will be disconnected from the manifold through the use of a check valve. Disconnection is also carried out after failure of the working equipment.

When the pedal is activated, the atmospheric chamber is connected to the vacuum chamber. This will be followed by the movement of the follower valve, which is influenced by the pusher. The diaphragm moves to its original position at the end of the braking process. The general scheme by which the vacuum pump works on the VAZ 2109 is based on the pressure difference in two chambers, vacuum and atmospheric. This mechanism ensures the movement of the working rod in the GTZ piston.

Vacuum booster malfunctions

Despite the high quality, the VAZ 2109 vacuum booster, the price of which differs depending on the service chosen, can still fail and requires timely maintenance and repair. The first factor that the vehicle owner needs to pay attention to is that a malfunction of the vacuum seal does not contribute to the complete and final deactivation of the installed brake system. But you may experience inconvenience in driving a car, and the driver will need to exert much greater effort when pressing the brake pedal.

The main malfunctions that will require repair or replacement of the VAZ 2109 include:

- hose breakage or depressurization. The hose provides the connection between the car engine manifold and the vacuum booster. If such a malfunction occurs, the driver will hear noise or hissing inside the structure. In this case, it is worth checking the reliability of the connection of the clamps, or the hose itself, for cracks or breaks;

- malfunctions within the amplifier design itself. These include wear, aging of rubber on valves, and diaphragm rupture. This malfunction can be detected by the behavior of the valve, which begins to gradually leak air. An option to solve the problem would be to replace the rubber and diaphragm, which can be done either in a service center or by the owner himself.

Vacuum booster repair

If, when calling for service, the price of a VAZ 2109 vacuum amplifier during repair seems too high, you can perform this procedure yourself. To do this, you just need to correctly follow a few steps:

- first of all, it is necessary to study the technical documentation for the vehicle, which indicates the key design features;

- explore the key features of this vacuum amplifier model, the most problematic areas;

- prepare the necessary set of tools and lubricants;

- find the power steering rod under the steering shaft and disconnect it from the brake pedal;

- find the GTZ in the compartment under the hood and remove it;

- after detecting a malfunction, repair or replace the damaged unit;

- assemble the structure in reverse order;

- Perform the necessary checks on the operation of the device.

In turn, the VAZ 2109 vacuum cleaner, the price of repairs in the service depends on many parameters. These include the technical condition of components and assemblies, the need to replace auxiliary equipment, and the quality of the materials and components used. You can find out the final cost of the repairs performed from consultants, as well as the list of necessary work. It is important to take into account that the unit rarely fails and will not require large investments from the vehicle owner.

auto-grad73.ru

Replacement

VAZ 2109 vacuum brake booster

To do this, you need a simple set of keys:

The repair is carried out in the garage, where the hood should be raised and a support installed.

Removing the vacuum

Sequence of work:

- remove the negative terminal from the battery;

- disconnect the rubber tube from the brake vacuum, first unscrew the clamp;

- disconnect the electrical power supply terminal for the level sensor from the brake master cylinder cover;

VAZ 2109 checking the vacuum brake booster

- then, inside the car, move the driver’s seat to the farthest position, as far as the runners will allow;

- lower under the steering column towards the brake pedal.

Note: if necessary due to lack of lighting, use a portable lamp with a safety flashlight.

- Using pliers, remove the locking ring from the sleeve that connects the pedal itself to the vacuum rod connector;

- remove the rod, lower it to the floor of the body.

Note: the rod connector is a U-shaped plate with holes for attaching to the pedal bar.

- return to the set vacuum;

- Now you have to carefully remove the brake master cylinder;

VAZ 21093 vacuum brake booster

- it must be removed together with the corresponding brake system pipes.

Note. This must be done so as not to add additional work of filling the brake fluid and pumping the entire brake system to all four calipers.

- clean the threaded connection on the master cylinder bushings and use a metal brush to carry out this work.

Note. Carefully unscrew the nuts, turning them forward and backward several times, so as not to strip the threads on the screws. Remove the nuts from the screws, and also remove the washers that are in a compressed state.

Vacuum brake booster

To make the work easier, use a flat screwdriver to go along the cylinder body and lightly, as carefully as possible, release them from sticking.

Note: if the nuts cannot be unscrewed, you need to drop a few drops of 70% acetic acid on them, wait 30 minutes, clean the threads with a wire brush and repeat unscrewing.

After removing the washers, you need to begin removing the brake master cylinder. It will be difficult to remove. Therefore, you need to be careful, so as not to break or bend the brake pipes too much, to apply force sharply, but not too much. The brake cylinder must be removed forwards, without deviating to the side. The last final step is removing the vacuum. It is attached to the interior partition on a bracket.

- The bracket is attached to two studs; clean the threads as indicated above.

- Unscrew the nuts and remove the vacuum along with the bracket.

Then after removal, unscrew the two blind bolts from the vacuum. Set it aside. Carefully screw the new vacuum to the bracket. Reassemble in reverse order. The price of a vacuum brake booster is 2,500 rubles. When choosing it, you should pay attention to the packaging. Manufacturer's guaranteed packaging must be made of corrugated cardboard.

- manufacturer's name;

- batch number;

- Date of issue;

- The article number must also be indicated: 2108-3510010TM.

Because there are fakes on the market. Therefore, you need to buy from trusted sellers, in stores that have been able to establish themselves on the positive side. When doing the work yourself, you need to watch the video very carefully. The most important thing will be to remember the order of repair work. For a better understanding, take a photo of the repair site. At home, number them in order in advance. Performing work one by one, move the photos down. Don’t be lazy to do this, since during assembly you can check the sequence of correct execution of the process. It also doesn’t hurt to read the instructions for car repairs to avoid unexpected situations.

Vacuum brake booster device.

Window tinting for VAZ 21099-2109-2108

Structurally, the vacuum brake booster is combined with the GTZ into one unit. For a person with developed intelligence, the scheme of action of the element in question will not present any difficulties. The body is divided into two parts, with the atmospheric part located on the side of the brake pedal, and the vacuum part on the side of the main brake cylinder.

Using a check valve, the vacuum chamber is connected to the intake manifold, which in turn is a source of vacuum. An electric vacuum pump is often used on diesel engines to ensure constant operation of the vacuum booster. When the engine stops, the vacuum booster is disconnected from the manifold by the action of the check valve, which is why the vacuum brake booster is only able to operate when the engine is active. In the event of a malfunction or failure of the element in question, a similar disconnection occurs.

Due to the follower valve, the atmospheric chamber in its initial position is connected to the vacuum chamber and to the atmosphere when the brake pedal is activated. A pusher is connected to the brake pedal; due to it, the follower valve moves. A diaphragm is connected to the GTZ rod from the side of the vacuum chamber; it facilitates the pumping of brake fluid through the piston to the working cylinders.

Due to the return spring, the diaphragm moves to its original position at the end of braking. The amplifier design may also have an electromagnetic rod drive. The active brake booster is used in the ESP system and its main purpose is to prevent rollovers.

In general, the operation of a vacuum brake booster is based on the pressure difference in the atmospheric and vacuum chambers. It is due to this difference that the pusher is activated and promotes the movement of the GTZ piston rod.

Malfunctions of the vacuum brake booster.

The first thing worth emphasizing is that malfunctions of the unit in question cannot contribute to the complete deactivation of the braking system. As a result, driving the car becomes more difficult and the driver is forced to put more effort into pressing the brake pedal.

Traditional faults include the following:

- There is a malfunction inside the vacuum booster itself, for example, aging valve rubber or diaphragm rupture. In this case, the valve will begin to leak air.

- A break or depressurization of the hose connecting the engine manifold to the vacuum brake booster. In this case, you will be able to hear the hissing of the element in question. Be sure to check the tightness of the clamps and the hose itself for breaks or cracks.

How to check the vacuum brake booster?

If the engine starts to stall, diagnose the serviceability of the vacuum booster. Depressurization is often accompanied by air suction into the intake manifold pipe; therefore, the air-fuel system that enters the engine cylinder becomes sharply leaner. As a second diagnostic option, make about five strokes using the brake pedal with the engine not running. Then, in the middle of the stroke, lock the pedal and start the engine. If the pedal falls during startup, the vacuum booster is functioning

If it remains motionless, then it is necessary to replace or repair the vacuum brake booster. During a visual inspection, it is strongly recommended to pay attention to the presence of smudges that may appear on the vacuum booster housing. The vacuum brake booster must be adjusted periodically.

For repair or replacement, it is necessary to prepare a standard set of tools or a corresponding kit.

Step-by-step repair procedure:

- Study the car's manual and determine the key design nuances of the vacuum booster.

- Disconnect the drive rod of the element in question from the brake pedal, which is located under the steering shaft.

- Remove the GTZ in the engine compartment.

- Depending on the malfunction, replace or repair this unit.

How to inspect the serviceability of the vacuum brake booster on a VAZ-2109

Checking for breakdowns of the VAZ-2109 vacuum booster involves the following actions by the car owner:

- Turn off the engine.

- Press the brake pedal 5 times.

- Press and hold the brake pedal.

- Start the car engine.

How should the VAZ-2109 ideally behave? If the vacuum device works correctly, the lever moves forward smoothly and without much effort. If you doubt the accuracy of the “diagnosis,” a clear sign of a vacuum breakdown is a hissing sound that occurs at the connection of the intake manifold pipeline to the valve fitting, which is attached in the opposite direction to the vacuum booster.

Replacing the vacuum brake booster on VAZ 2108, VAZ 2109, VAZ 21099

Welcome! Vacuum brake booster - it is attached by a bracket to the engine shield (This is the shield that separates the engine compartment and the interior of the car) and the master brake cylinder is installed in it, which, by the way, also needs to be replaced from time to time (When this cylinder wears out, problems with the brakes begin, the car may not brake, only two wheels out of all four available can brake, the brake fluid can still run out quickly and the cylinder itself can leak), thanks to this cylinder and thanks to the vacuum booster, braking occurs on modern cars, by the way, the vacuum brake works thanks to the intake manifold ( On injectors, due to the receiver) and therefore when the engine is started, the brakes are soft and very easy to press, but when you turn it off, the air pressure in the intake manifold disappears and the pedal becomes much (tangibly) heavy.

Note! Any person who has at least some experience in car repairs can replace this brake booster, and to replace it, you will need a small, but still rare set of tools, which not all people have, namely: You will need pliers, a wrench, etc. it has socket heads (If you have an extension cord, then it’s better to stock up on them), if there is no wrench, then take all the wrenches that you have, thanks to the socket wrenches and wrenches, you can also remove it, but it will be very inconvenient!

Summary:

Where is the vacuum brake booster located? In the engine compartment, it is located on the engine shield (Indicated by a red arrow), and behind the engine shield, there is immediately the interior of the car, and in the interior you can find a pusher for the vacuum brake booster, which is connected to the brake pedal (When removing the amplifier, this pusher from the pedal you will have to disconnect) and therefore the approximate location of the brake booster from the passenger compartment is very easy to determine from this pusher; when you get ready to remove the booster, you will immediately understand which pusher you are talking about.

When do you need to change the vacuum brake booster? If the brake booster malfunctions, either the brakes will disappear, or the engine will start to idle unevenly, in fact there are a lot of symptoms, because on each car the brake booster malfunction is always detected differently, on some car, whether with the engine off, or when the pedal is started, the pedal will be pressed with one force, and when you press the pedal, the idle speed will be disrupted and the car will start to stall, but the performance test is always the same, with the engine off, you need to press the brake pedal 5-6 times , the last time you need to leave the pedal pressed and start the engine of the car, and as soon as it starts, the pedal will definitely fall a little, if this is the case, then the amplifier is working.

Instructions for replacing VUT with your own hands on a VAZ-2109

Before installing a new brake unit, it is necessary to dismantle the worn one.

To do this, first disconnect the pedal from the amplifier rod. The device is dismantled based on the area where the pedal assembly is located. To do this, disconnect the 2 units that are secured with a pin; this can be done easily using a flat-head screwdriver. Next, crawl under the hood; it’s more convenient to do this when the car is on an overpass or in a viewing hole:

- Unscrew the block responsible for powering the brake fluid level meter in the car.

- Remove the bracket securing the hydraulic lines in accordance with the VAZ-2109 frame. The nut can be easily unscrewed using the marking head 10.

- Armed with a 17mm wrench, remove the main brake cylinder. Note that there are 2 nuts to remove.

- Now the vacuum amplifier is available for subsequent manipulations. Remove the pipe that connects the reinforcement chamber and the intake manifold.

- Remove the spacer from the drain in the front.

- Using a wrench, an extension, a cardan joint and a 13mm socket, unscrew the 4 nuts that secure the vacuum brake booster to the body studs.

- Remove the amplifier from the studs and remove it from under the hood.

- Inspect the reverse side of the brake booster device - all parts must be dismantled. To do this, use the head 17 to hook the two fixing nuts and remove the metal body by pulling it towards you. The boot can be removed from the rod without effort.

- Attach the bracket to the rubber seal on the new VUT, following the reverse order of steps.

Replacing the vacuum brake booster VAZ 2109 21099 2108 with your own hands

We will show you visual photo and video instructions on how to replace the vacuum brake booster on VAZ 2109, VAZ 2109, VAZ 21099 cars with your own hands.

Open the hood, remove the valve with the hose.

To replace the vacuum booster, we do not need to remove the master cylinder, nor do we need to bleed the brakes afterwards. Unscrew the two bolts securing the GTZ to the amplifier:

We remove the wire chip from it so that there is no tension. We remove the main brake cylinder from the vacuum booster. We go to the salon and unlatch the latch:

Use your finger to press on the rod that the latch held. We unscrew the nuts securing the vacuum booster bracket, to do this we use a 13mm socket and a cardan:

There will be 4 mounting nuts in total. After this, the vacuum can be pulled out. We fix it in a vice, dismantle the boot, unscrew the bracket:

Rules mandatory for compliance with the installation of a new VUT

When installing a new vacuum mechanism, consider the following rules:

- the VUT rod is connected to the brake pedal after placing the device on the fixing pins;

- to perfect the sealing components, lubricate the space between the brake cylinder and the vacuum device with sealant;

- the VUT rod in the VAZ-2109, which affects the main brake cylinder located on the front side of the frame, can move during transportation or installation. Therefore, to check the condition of the product, press it all the way.

Determining the correct installation of the vacuum brake booster is not difficult - the brake pedal, if the product is installed correctly, works without failure.

Video instructions on how to replace the vacuum brake booster in a VAZ-2109 with your own hands are presented below:

Replacing the vacuum booster on a VAZ 2109

After watching an educational video lesson, you will learn not only how to replace a vacuum booster , but also about the symptoms (signs of malfunction) of a failed vacuum seal.

And first, before replacing, a little background about the problem. “While driving, the engine began to tighten up, and when you give gas it goes fine, but at low speeds it jerks, and when the engine is idling, it feels as if the spark plug is not working. Checking the spark plugs may not yield anything, but as soon as you press the brake, the engine starts to run smoothly - in this case, you should listen to see if there is a hiss from the vacuum brake booster.” As a temporary solution to the situation, you can plug the hose going to the amplifier, but replacement is inevitable.

To replace the vacuum booster on a VAZ, you need to unscrew the brake cylinder nuts, pull out the cotter pin on the brake pedal and then unscrew the vacuum booster fastenings with a key set to “17”. If at the moment it is not possible to replace it with a new one, then you can try to repair the brake booster yourself.

VAZ 2109: replacing the vacuum brake booster on your own

Vacuum brake booster

The main sign that tells a car owner that the vacuum brake booster has failed is difficult movement of the brake pedal. This can lead to poor braking, which can lead to a traffic accident in an emergency. On a VAZ 2109, replacing the vacuum brake booster must be carried out. Replacing the vacuum brake booster on a VAZ 2109 can be easily done on your own.

Device of a vacuum brake booster for GAZ, UAZ, VAZ.

By design, the vacuum brake booster is in one block with the cylinder head. The vacuum amplifier housing is divided into two parts: 1 – atmospheric, 2 – vacuum.

The vacuum part is connected to the intake manifold using a check valve. And the collector, in turn, acts as a source of vacuum. For continuous operation of the vacuum brake booster on diesel engines, an electric vacuum pump is used.

The vacuum booster only works when the engine is running. This can be explained by the fact that when the engine is not running, the check valve disconnects the vacuum booster and the manifold.

The atmospheric chamber is connected to the vacuum chamber when the brake pedal is pressed. When you press the brake pedal, pressure is applied to the pushrod, which moves the valve. The diaphragm, under the action of the piston rod, forces brake fluid to the working cylinders.

Examination

Replacing the vacuum brake booster of a VAZ 2109

Vacuum booster repairs are carried out in specialized auto repair shops using equipment designed for this purpose. In the context of garage repairs on a VAZ-2109, the vacuum brake booster is replaced with the installation of a new one. Before making a decision to replace, it is necessary to check the operation of it itself, as well as the check valve.

Checking the operation of the vacuum booster

VAZ 2109 vacuum brake

To check the operation of the amplifier you need to:

- Press the pedal with your foot, thereby increasing the pressure in the brake system. The pedal remains depressed.

- Keep your foot on the pedal and turn on the engine.

- When you start the engine, the foot with the pedal begins to move towards the floor of the VAZ body, which means that the vacuum booster is working and the entire system is in good working order.

Note. In another case, the foot and pedal remain motionless, that is, in the upper depressed state, which means there is a malfunction somewhere. First you need to check the vacuum hose at the connections. Also check the check valve for leaks.

Check valve

VAZ 2109 vacuum brakes

To check the operation of the check valve:

- inspect the pipe connections;

- feel these places with your hands;

- tighten the clamps at the connections of the pipes;

- on the intake pipe fitting;

- on the non-return valve fitting, on vacuum.

Then check the valve itself. To do this, remove the rubber tube from the vacuum, using a flat-head screwdriver if necessary. Since the tube is very difficult to remove. Take a pre-prepared rubber bulb-shaped injector of suitable diameter for the fitting:

- Paste it;

- Squeeze the syringe;

- Squeeze the air out of it.

Release your hand if it remains clenched then the valve test is complete. That is, the valve fulfills its design purpose. If the injector is filled with air, then the valve will have to be replaced. You can also check the operation of the valve with your mouth:

- Blow the air out of your mouth; it should easily pass into the vacuum;

- Then apply suction; the air coming out should not be felt.

This completes the check of the brake system vacuum booster and check valve. If no defects are found in the connected parts and the check valve is working properly, the vacuum is replaced.

How to replace the vacuum brake booster on a VAZ 2108-VAZ 21099?

Note! If suddenly your vacuum brake booster fails, then proceed to replace it and buy a new one; we categorically do not recommend repairing your original one, because it is unlikely that anything good will come of it, especially since you will have to buy an additional repair kit anyway, but This is also wasted money and it is not yet known whether you will be able to correctly replace all the worn parts in it or not, then you will have to assemble the vacuum unit in such a way that the air does not bleed out of it and it works perfectly!

Removal: 1) Before you begin removing the brake booster, check whether the vacuum hose (Indicated by a blue arrow) is connected normally to the check valve (Indicated by a red arrow), be sure to start the car and see if air is leaking from this hose or from the valve ( You just don’t need to disconnect anything, everything is disconnected in the photo, just so you can understand where the valve is located, where the hose is and where this whole system is connected, by the way, the connection location is indicated by a green arrow).

Note! We fully recommend walking along the hose, it is connected to the intake manifold fitting, check everywhere to see if air is leaking from somewhere, otherwise replace the hose or check valve with a new one!

Replacement

VAZ 2109 vacuum brake booster

To do this, you need a simple set of keys:

The repair is carried out in the garage, where the hood should be raised and a support installed.

Removing the vacuum

Sequence of work:

- remove the negative terminal from the battery;

- disconnect the rubber tube from the brake vacuum, first unscrew the clamp;

- disconnect the electrical power supply terminal for the level sensor from the brake master cylinder cover;

VAZ 2109 checking the vacuum brake booster

- then, inside the car, move the driver’s seat to the farthest position, as far as the runners will allow;

- lower under the steering column towards the brake pedal.

Note: if necessary due to lack of lighting, use a portable lamp with a safety flashlight.

- Using pliers, remove the locking ring from the sleeve that connects the pedal itself to the vacuum rod connector;

- remove the rod, lower it to the floor of the body.

Note: the rod connector is a U-shaped plate with holes for attaching to the pedal bar.

- return to the set vacuum;

- Now you have to carefully remove the brake master cylinder;

Design of the vacuum brake booster VAZ 2109

At the moment, it is difficult to imagine the operation of a vehicle if the vacuum brake booster of the VAZ 2109 is not included in its design. Thanks to this unit, additional force is created, which is transmitted in the near future to the pedals of the brake accounting system. The device is combined into a single-block structure with the GTZ; in this case, the housing is divided into two separate parts. The first part, atmospheric, is located next to the brake pedal. The next reason is the vacuum part, usually located next to the main cylinder.

To combine the vacuum chamber and the manifold, the VAZ 2109 has a special check valve. Almost always, an electronic pump is included in the design of vehicle engines for the sole purpose of ensuring the measured and constant operation of the vacuum booster. After stopping the vehicle's engine, the amplifier will be disconnected from the manifold by using a check valve. Disconnection is also carried out after failure of the working equipment.

But you can observe inconvenience in driving the car, and the driver will need to exert much greater effort when pressing the brake pedal. The main malfunctions that will require repair or replacement of the VAZ 2109 include:

hose breakage or depressurization. The general diagram of why the vacuum valve works on the VAZ 2109 is based on the pressure difference in two chambers, vacuum and atmospheric. The use of this mechanism ensures the movement of the working rod in the GTZ piston.

Diagnostics of the operation of the vacuum brake booster

.

https://youtube.com/watch?v=06Jj1Cy_KxQ

How to replace a brake booster

(VUT):.

VAZ 2109

;.

VAZ 2110.

Replacing the main brake cylinder on a VAZ 2109

The vacuum brake booster (VUT) makes it easier to operate the brake pedal. This assembly is divided into two chambers - one has a permanent connection with the intake manifold, and the second is connected to the atmosphere when the brake pedal is pressed.

The unit is located under the hood behind the brake master cylinder. Through the rod it is connected to the brake pedal.

Symptoms of a Malfunction in the Vacuum Brake Booster of a VAZ 2109

Welcome friends to the auto-repair of your website pages. The Vacuum Brake Booster (VUT) is designed to significantly reduce brake lever pressure during all types of braking, resulting in increased comfort and natural braking performance.

Vacuum brake booster

The brake booster is vacuum, installed on all modern cars, both Russian and imported, and has enormous characteristics and performance, which significantly reduces the degree of pressure on the brake pedal for all types of braking.

Let's take a closer look at the brake booster (Sport), it is intended for models such as VAZ 2109, VAZ 2110, VAZ 2114 and others. You should also remember to read the article on changing brake water at home.

This will fully ensure improved ergonomic tactical and technical characteristics of your car, namely a reduction in brake pedal pressure during critical and normal braking by two, in other words, from 13 kg to 7 kg with a deceleration of 6 m/s2.

Additionally, installing a vacuum brake booster will significantly reduce the time or reaction a driver has to apply the brakes in the event of a roadside emergency.

By its design, the vacuum brake booster is combined into one common unit with the main brake cylinder. In the initial state, the special atmospheric channel is closed, and the other vacuum channel is open.

In this case, the membrane installed on both sides from the inside will be affected by equivalent pressure, therefore, with the help of a return spring, it is constantly in its original position.

When you press the brake pedal, the pusher (rod), having begun its movement, moves to the side and closes the vacuum channel, here the atmospheric channel opens. Then the diaphragm itself is influenced by atmospheric flows on both sides.

Symptoms of a faulty vacuum booster and replacement of a VAZ 2109. Do it yourself!

Checking status

The corresponding signs may indicate the need to change the vacuum booster or the brake master cylinder.

The primary sign of VUT failure is an increase in the force that must be applied to the pedal to brake.

To be sure of the problem, perform the following check:

- Turn off the engine;

- Press the brake pedal 5-6 times in a row;

- Press the pedal to the floor;

- Start the engine;

- If the VUT is working properly, the pedal will immediately go up.

Checking the condition

If you have a VAZ 2109 carburetor engine under the hood, you can determine the VUT malfunction a little differently in the initial stages:

- Initially, the pedal will work normally, you will have to apply a little force, braking occurs normally;

- But at the same time the engine stalls at idle;

- When you press the brake pedal, the idle speed calms down;

- By pressing the gas in neutral gear, failures occur in the carburetor;

- If such symptoms are observed, with the engine running, remove the pipe from the VUT fitting and plug it with your finger or other available tool;

- Has the idle speed stabilized? In this case, replacing the vacuum seal cannot be avoided.

If such a malfunction is detected while driving, you can continue driving only if the VUT is turned off.

Replacing the vacuum booster on a VAZ 2109

After watching an educational video lesson, you will learn not only how to replace a vacuum booster , but also about the symptoms (signs of malfunction) of a failed vacuum seal.

And first, before replacing, a little background about the problem. “While driving, the engine began to tighten up, and when you give gas it goes fine, but at low speeds it jerks, and when the engine is idling, it feels as if the spark plug is not working. Checking the spark plugs may not yield anything, but as soon as you press the brake, the engine starts to run smoothly - in this case, you should listen to see if there is a hiss from the vacuum brake booster.” As a temporary solution to the situation, you can plug the hose going to the amplifier, but replacement is inevitable.

To replace the vacuum booster on a VAZ, you need to unscrew the brake cylinder nuts, pull out the cotter pin on the brake pedal and then unscrew the vacuum booster fastenings with a key set to “17”. If at the moment it is not possible to replace it with a new one, then you can try to repair the brake booster yourself.

Choice

We will give some recommendations regarding the choice of a new vacuum amplifier.

Selection criterion

Required parameters

The cost of a good vacuum cleaner is now about 2.5 thousand rubles. These are not the most expensive, but not the cheapest Chinese options. Optimal for VAZ 2109

This packaging, used by a genuine manufacturer, is made of corrugated cardboard

The label should be clearly legible - the production batch number, the production date of the part and the name of the manufacturer itself

The vacuum unit corresponding to the technical parameters of the VAZ 2109 has article number 2108-3510010TM

You should not buy from market traders. There are many good, trusted spare parts stores in any city. Don’t be shy to ask for certificates, documents for parts

Choosing wisely

Now there are a lot of fakes on the market. Such parts cost the same as the originals, but last much less.

Replacement of VUT

First, remember that repairing the vacuum booster is impossible. This unit is removed and replaced with a new one. In theory and in practice, some do. But at your own responsibility.

Now about the replacement itself.

- Disconnect the brake pedal from the booster rod. The units are connected to each other by a pin. Dismantling is carried out in the area of the pedal assembly and here you will need a simple flat-head screwdriver.

- Let's go and open the hood.

- Disconnect the power supply to the brake fluid level sensor.

- Remove the bracket that holds the hydraulic lines to the frame. A 10mm socket is useful, which is used to unscrew the nut.

- Disconnect the brake master cylinder. To do this, unscrew the 2 nuts holding it to the vacuum unit. Assess the condition of the GTZ. If necessary, replace it too.

- It is not necessary to disconnect the hydraulic lines from the brake cylinder (master). The pipes are quite long, so they can easily be moved to the side so that they do not interfere with the work process.

- Disconnect the pipe that connects the vacuum chamber to the intake manifold.

- Remove the spacer from the front struts.

- Unscrew the 4 nuts that hold the vacuum housing to the car body studs.

- Remove the unit from the studs and pull it out through the engine compartment.

- On the drive fork side, there is a seal with a bracket on the return of the amplifier. He secures the assembly to the frame with 4 studs. They need to be removed. To do this, use a 17mm head to remove 2 nuts, after which the iron structure is removed. Just pull it towards you. Be sure to pull the boot off the stem.

- Install the mounting bracket and a new rubber seal onto the new vacuum booster. Now you can begin full reverse assembly.

How to replace a defective vacuum booster on a VAZ 2109: list of actions

The initial task of repair is to disconnect the pedal from the amplifier rod. Dismantling is carried out in the area of the pedal assembly: it is necessary to disconnect the two units connected to each other by a pinned pin using a flat-head screwdriver.

Further work is carried out in the engine compartment:

- disconnect the power supply connector for the brake fluid level sensor;

- dismantle the bracket that secures the hydraulic lines relative to the car frame (unscrew the nut with a head to “10”);

- disconnect the main brake cylinder by unscrewing the two nuts securing it to the VUT using a 17" wrench.

Note. When changing the brake booster, do not disconnect the hydraulic lines from the master cylinder. The lengths of the pipes make it possible to move the unit outside the working area.

After access to VUT is opened, the plan for replacing the vacuum booster of the VAZ 2109 brake system comes into force, including the following measures:

- disconnect the pipe connecting the amplifier chamber to the intake manifold;

- remove the front strut strut (installed additionally);

- unscrew the four nuts that secure the amplifier housing to the body studs (use a set of wrenches + extension + universal joint + head on “13”);

- remove the assembly from the studs and remove it from the engine compartment.

operating principle On the back side of the amplifier (on the drive fork side) a seal is installed and a bracket is attached, through which the unit is connected to four studs on the car frame.

The parts must be dismantled: it is enough to unscrew the two fastening nuts with a “17” head and remove the iron structure by moving it towards you. The boot is easily pulled off the stem. Having mounted the mounting bracket and rubber seal on the new amplifier, you can begin installing the VUT, which proceeds according to the reverse scenario. When installing, you should pay attention to three facts:

- The vacuum booster rod should be connected to the brake pedal immediately after the unit is seated on the mounting studs (before tightening with nuts);

- experienced owners additionally apply sealant between the brake cylinder and the VUT, indicating the imperfection of the sealing elements;

- the VUT rod acting on the main brake cylinder (located on the front side of the housing) may move during transportation or installation (it is necessary to check and, if necessary, install correctly by pressing until it stops).

For your information. An incorrectly installed actuator rod will result in the brakes not working after assembly.

Master brake cylinder

It is not uncommon to discover problems with the master cylinder when checking the condition of the brake assembly.

When changing the vacuum seal, it would be logical to study the current state of the gas turbine engine and, if necessary, replace it.

The replacement procedure itself is as follows.

- Disconnect the negative terminal from the battery.

- Disconnect the wire block from the fuel oil level sensor. It is located in the tank and is built directly into the lid.

- Use a special wrench for brake pipes to loosen their tension. There is no need to unscrew it completely.

- Unscrew the pair of nuts that secure the GTZ to the vacuum chamber. Only now can the brake pipes be completely unscrewed.

- Remove the cylinder from the studs.

- If necessary, remove the brake fluid reservoir itself at the same time. To do this, you need to carefully rock the tank and remove the leg from the bushing.

- Assess the condition of the removed cylinder. Also be sure to check for any defects on the tank. If there are any, be sure to replace the brake fluid reservoir with a new one.

- Armed with a new GTZ, put it in place and tighten the nuts. Fasteners can be fully tightened immediately.

- Install the reservoir and fill it with brake fluid to the maximum mark.

- Now a very important step is to extract air from the cylinder. To do this, you need to close the holes in the front brake pipes with your fingers. At the same time, your assistant should gently, but not sharply, press the brake pedal. This will create pressure in the system. Continue this manipulation until you feel liquid coming out of the holes.

- As soon as the liquid flows, put on the tubes, install and fix them in place. In this case, the brake pedal cannot be released.

- By analogy, the rear tubes are connected. When they are installed in place, there must be pressure in the system, that is, the brake pedal is pressed to the floor.

After completing the replacement of the turbocharger, do not forget to bleed the brake system according to the rules.

Disassembling the unit with the TJ tank

It is quite possible to change the vacuum seal and cylinder with your own hands. The work will take a few hours, but will save a lot of money on visiting a car service center.

Replacing the vacuum brake booster of VAZ 2109.

The vacuum brake booster (VBR) is the heart of your car’s braking system. It is this that creates sufficient force for good braking; the safety of driving a car directly depends on its serviceability.

Today’s article is devoted to the symptoms of a faulty vacuum brake booster, and I will also describe a step-by-step procedure for replacing this part on a VAZ 2109 car.

Checking the vacuum brake booster VAZ 2109

>Often, when the VAZ 2109 brakes are ineffective, it becomes necessary to check the vacuum brake booster.

Vacuum brake booster VAZ 2109

The very name of this unit speaks about its purpose: with the help of a vacuum, the effect on the main brake cylinder from the brake pedal is enhanced. So, if you need to press the pedal very hard to make the car brake, you need to check the vacuum booster. Checking the vacuum brake booster of a VAZ 2109 is as follows: 1) With the engine not running, press the brake pedal and hold it with your foot.

Press the brake pedal

The pedal presses on the VUT rod

When the VAZ 2109 engine is not started, the vacuum booster is not yet working. Just for fun, try coasting down a hill with the engine not running. It becomes much harder to brake. This is something to keep in mind when you are being towed: you need to start braking early. 2) Turn on the ignition and start the car, the brake pedal should fall down a little.

Turn on the ignition

Why? But because when the engine is running, a vacuum is created in the intake manifold of the VAZ 2109, which, through a hose with a check valve, increases the pressure on the pedal. Vacuum from the engine intake manifold helps push the brake pedal. 3) If at the moment when the engine started the brake pedal did not go down, then the vacuum brake booster of the VAZ 2109 is faulty and must be replaced. However, before you run to the store to buy a new one, you need to check the hose from the brake booster to the intake manifold. The check valve must also be checked.

Check valve VAZ 2109

Checking the hose comes down to checking that the clamps are securely fastened and that there are no cracks in the hose itself.

Attaching the hose to the manifold

If there is an air leak through the vacuum brake booster hose, the VAZ 2109 will stall at idle. If you're lucky, you can even hear the air leak. The characteristic hiss of air sucked into the hose will indicate a leak. The check valve is a simple thing; it can also be checked easily. For some reason, all repair and operating instructions for the VAZ 2109 recommend checking the check valve using a special bulb. For example, I don’t have it, but I need to check it. Therefore, simply checking is done with your mouth. That's the whole point. The valve only allows air to flow in one direction: into the intake manifold; it should not allow air to flow back. We remove the valve and suck in air through it: air should be sucked in from the manifold side, but not from the VUT side. That's the whole test.

Signs of a faulty vacuum brake booster.

Signs of a VUT malfunction include:

- Insufficient braking efficiency;

- “Heavy” brake pedal (I wrote more here);

- Reducing engine idle speed when pressing the pedal.

At the first two signs, the “vacuum seal” should be checked; it is not at all a fact that it has failed. When the idle speed decreases when you press the brake pedal, first, you need to check the air leaks into the vehicle’s intake tract, as well as on all vacuum hoses. If there is no air leak, the part needs to be replaced.

Vacuum ignition timing regulator does not work

The vacuum ignition timing regulator is designed to change the ignition timing (ignition timing) depending on the load on the engine (when the throttle valve is opened or closed).

It works due to the vacuum in the intake manifold of the car engine.

Using the example of the vacuum ignition timing regulator of the VAZ 21093 car, we will try to figure out why it happens that it does not work.

Signs that the vacuum regulator is not working

The engine pulls poorly after pressing the gas pedal

Instead of some “pickup” after pressing the gas pedal and increasing engine speed, the driver feels a lack of traction and the engine “goes dull.” This is especially noticeable when driving uphill.

Causes of vacuum regulator malfunction

Loss of tightness

Since the entire operation of the vacuum regulator is based on supplying a vacuum (vacuum) to its body, the slightest violation of the tightness of this system leads to malfunctions.

The “culprits” for the loss of tightness: the tube (jumped off, frayed), the body of the vacuum regulator was leaky.

The diaphragm is “broken”

The main working part of the vacuum regulator is the diaphragm (membrane) in its body. Due to its movement under the influence of vacuum, the distributor support plate moves and the ignition timing increases or decreases. If the diaphragm is damaged, this entire system simply will not work.

Sticking rod and/or support plate

Even a slight wedging of the support plate or rod will lead to the fact that the ignition timing will not change since the vacuum regulator does not have enough power to move it.

Rod of the vacuum ignition timing regulator and the distributor support plate for VAZ 21083, 21093, 21099 cars

Clogged fitting and its channel with the outlet hole in the carburetor

Due to soot deposits emitted into the intake manifold during engine operation, the opening of the vacuum supply channel going into it into the vacuum regulator system becomes clogged over time. In particularly advanced cases, both the channel and the fitting under the tube become clogged. The vacuum from the intake manifold stops flowing into the tube and then into the regulator body, and it stops working.

How to troubleshoot the vacuum ignition timing regulator?

The operation and serviceability of the vacuum regulator can first be checked. To do this, with the engine running, remove the regulator tube from the fitting on the carburetor and create a vacuum in it with your mouth (suck air towards you). The engine speed should immediately increase, since due to the vacuum created, the diaphragm in the housing bends, moves the thrust, and it, in turn, moves the support plate counterclockwise, making the angle earlier. More information about ways to check the serviceability of the vacuum ignition timing regulator on the page: “Checking the vacuum ignition timing regulator.”

If this does not happen, check the condition of the tube and the tightness of its fit on the fittings. We remove the distributor cover and check the condition and ease of movement of the rod and support plate. The regulator body and diaphragm can only be checked by replacing it with a new one or a known good one.

We replace damaged parts and check again.

Notes and additions

If, after eliminating the malfunction of the vacuum ignition timing regulator, the engine continues to be “stupid,” we check the centrifugal ignition timing regulator, the power mode economizer, the gas pump, and the carburetor accelerator pump, since they are also responsible for increasing the power and throttle response of the engine.

More articles on the ignition system of the carburetor engine of the VAZ 21093 distributor

Malfunctions Checking and repairing the centrifugal ignition timing regulator “Runner” of distributor 2108, 2109 Distributor VAZ 2108, 2109 principle of operation Adjusting the ignition timing by rotating the distributor on VAZ 21083, 21093, 210 99

Replacing a VAZ vacuum brake booster on a 2109 car - step-by-step instructions.

The operation of replacing the “vacuum seal” is not very complicated and does not require special tools.

However, there is no need to rush when replacing VUT. Attention and accuracy should be your faithful assistants when performing this operation.

- Disconnect the VUT rod from the pedal.

It is necessary to pull out the cotter pin that connects the VUT rod and the pedal. To prevent the cotter pin from falling out, it is secured with a locking bracket; it can be easily removed using pliers.

- Disconnect the main vacuum hose from the vacuum tube.

It's simple! There is no need to unscrew anything, the hose (indicated by the red arrow) is simply removed from the VUT fitting, with a little force, but it can be removed.

- Disconnect the brake master cylinder (MBC) from the brake booster.

In order to disconnect the GTZ from the “vacuum manifold”, you need to unscrew two nuts (indicated by the red arrow, the second nut is located on the opposite side of the master brake cylinder). After we have unscrewed the main turbocharger, we move it closer to the front of the car, trying not to greatly deform the brake pipes.

There is absolutely no need to create extra work for yourself and unscrew the brake lines from the main circulation pump (indicated by green arrows). By unscrewing the brake lines from the main circulation pump, you will air the brake system and after replacing the vacuum brake booster it will need to be bled. To do this, you need brake fluid and an assistant who will pump the brake fluid with the pedal while you bleed air from the system.

- Disconnect the VUT from the car body.

The amplifier is attached to the car body through a bracket. It, in turn, is attached to the car body with four nuts that you need to unscrew. At this stage you will have to sweat a little. Because access to the bracket mounting nuts is difficult. Have a little patience and everything will work out.

After the nuts are unscrewed, remove the vacuum seal from the engine compartment.

- Disconnect the mounting bracket from the VUT (as in the photo).

The VUT is attached to the bracket using two nuts. Unscrew these nuts and disconnect the part. Fortunately, this is not very difficult to do. Access to the nuts is great.

- Install the mounting bracket onto the new brake booster.

What you did in the previous paragraph must be repeated in reverse order. Install the mounting bracket onto the new vacuum seal.

- Install a new vacuum brake booster on your car.

Install the new part on the machine in the reverse order of disassembly. I pay special attention to the connection between the VUT rod and the brake pedal; many people forget to do this. I would like to draw even more attention to the mandatory installation of a locking bracket on the cotter pin securing the brake pedal to the rod of the vacuum brake booster.

After final assembly, recheck the tightness of all nuts and bolts. Check the installation of the vacuum hose. As you can see, the procedure for replacing the vacuum brake booster on a VAZ 2109 does not require any special skills or complex tools. The most important thing is attention, accuracy and a small set of the simplest keys.

Replacing the vacuum brake booster

We remove the main brake cylinder without disconnecting the brake pipes from it. How to remove and install the main brake cylinder of a Gazelle car

1. Use a screwdriver to loosen the clamp

2. Remove the vacuum supply hose from the fitting.

3. The hose can be removed together with the fitting.

4. Using a screwdriver from the cab side, remove the lock washer.

5. Holding the pusher eye bolt with a 19mm wrench, use a 17mm wrench to unscrew the nut

6. Remove the bolt from the pusher eye.

7. Remove two plastic bushings from the pusher eye

8. Using a “13” socket with an extension from the cab, unscrew the four nuts securing the amplifier to the partition of the engine compartment

9. Remove the amplifier.

10. Remove the paronite gasket.

11. We install the new vacuum booster in the reverse order; in this case, for proper operation of the brakes, the position of the adjusting bolt must be adjusted.

To do this, hold the pusher with an “8” wrench and use a “10” wrench to unscrew the lock nut.

12. Then, using an “8” key, unscrewing or tightening the bolt,...

13. We achieve a position in which the gap between the mating plane of the amplifier and the bolt head is in the range of 1.35–1.65 mm.

14. After this, holding the bolt, tighten the locknut.

Having lubricated the plastic bushings, install the amplifier, and then adjust the brake pedal travel.

To do this, hold the amplifier pusher with a 8" wrench (shown on a removed amplifier for clarity), and unscrew the lock nut with a 14" wrench

15. By rotating the pusher eye, we set the distance between the center of its hole and the mating surface of the vacuum booster housing - 131–133 mm. Install the brake master cylinder.

The free play of the brake pedal when the engine is not running should be 3–5 mm.