Category: Secrets of your car.

Previously, we looked at the features and “sores” of the 6-speed “robot” of the VAG concern - DSG-6. Today we'll talk about the infamous DSG-7 .

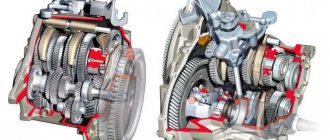

A preselective gearbox with two dry clutches was developed by VAG designers together with LUK. According to the VAG classification, this “robot” is designated 0AM.

The design of the DSG 7 is not very reliable. A large number of problems and “sores” made the box notorious. Most often, problems arose due to design flaws.

Repair manual (manual) for automatic transmission DSG 6 and DSG 7 (DQ200 DQ250 (02E))

The DSG is a direct shift gearbox equipped with a dual clutch.

Such checkpoints are also called preselective. In the 21st century, the idea of creating a new chapter in car creation arose. Many engineers began developing a unique automatic transmission that would shift as smoothly as possible and be economical (like stepped automatic transmissions), and also be powerful and reliable (like CVTs).

How does DSG work?

The main idea of the DSG is the use of a double clutch. Developers are trying to reduce clutch frictions as much as possible and place them in a hydraulic transformer. It is also necessary to eliminate the acceleration system in the donut (double, meaning turbine wheels); Only the locking clutches should remain, sliding into the corresponding connectors. All this also needs to be placed in a bagel, which is not an easy task.

DSG 7 Problems Video

In this option, the duplicating functionality of oil turbines is taken away from the “donut”. This process is also called torque transformation - a regular gear does a good job of it. But the “donut” now additionally performs the functions of regularly activating/deactivating the blocking. The DSG developers really believe that the future lies with a similar dual-clutch system. Despite all the genius, it is incredibly difficult to practically implement this idea. The problem here is vibrations, which gradually destroy the entire structure. Also, the resulting samples have too little service life.

DSG 6 (02E) DQ250

In 2003, production began of a six-speed automatic transmission with a dual clutch (also called “wet”) - DQ 250 - 02E (or S-tronic). This box was intended for cars with an engine capacity of 1.6-3.2 liters. Volkswagen has equipped many models with this automatic transmission (TOURAN, JETTA, SCIROCCO and others). Similar attempts were also made in relation to more expensive cars - Scoda, Seat. As for torque, the new automatic transmission maintained fairly high values - 350 Nm. However, at maximum loads, too strong vibrations sometimes began in the clutch itself, and the wear of its parts (especially the main drum) accelerated significantly.

The structure of the robotic gearbox was created by VAG together with an American company specializing in this field - Borg Warner. Later, this project was supported by another German company that produces torque converter clutches, Luk .

Preselective boxes produced by Getrag have a different designation - DCT (which means Dual-clutch transmission). The following models currently exist:

— PS 250 (6 DCT250) — for French cars with a 1.5-liter engine; - MPS 6 (6 DCT450) - for various cars (American - Ford and Chrysler, English - Land Rover, Swedish - Volvo); - SPS 6 (6 DCT470), a similar modification - for Japanese Mitsubishi (models with an engine over 2 liters).

There are also seven-speed PDK (which stands for Porsche Doppelkupplung) that will fit the 911 Macan or Porsche. It is extremely difficult to see them in auto repair shops, since Porsche, for example, rarely issues a 100,000 km warranty (or the repair consists of directly replacing this highly complex transmission).

DSG 6 reliability

The debut model created by Volkswagen 02 E (DQ 250) had a not entirely successful flywheel . As a result, the double-pack clutch broke regularly.

Also in the first version, the mechatronics and drum were unstable.

Today, the most popular DSG repair for this model is replacing the solenoids responsible for shifting gears. By the way, the hydraulic plate assembly located in them wears out incredibly quickly.

Simply replacing the solenoids is not difficult. True, it usually also requires changing rings, sometimes clutches, and various consumables. Such operations can only be performed efficiently by auto repairmen who have completed appropriate courses from the manufacturer.

Subsequently, the computer settings were optimized. Drivers have taken away a significant portion of the transmission's original capabilities. Therefore, the resource of the DQ 250 as a result came closer to the capabilities of competing devices - conventional step automatic transmissions and CVTs.

DSG 7 (DQ 200)

The developers assigned the second generation seven-speed automatic transmission the designation DSG OB (for Audi cars), DSG OA (for VW cars). In this case, the classification from VAG was used. The maximum torque here is not very high - only 250 Nm. These devices were equipped in such cars as Golf, Ibiza, Polo and others.

Next, the transmission was modified. The updated version was called DQ 200 . This time the engineers could boast of collaboration with Luk, as well as an updated flywheel. The production of dual-mass clutches DSG - 7 DQ 200 began in 2008.

How to remove and install mechatronics DSG 7 DQ200

The new version already had a dual-mass clutch (dry), connected to an improved flywheel. Moreover, these parts were moved outward from the oil bath. In this way, it was possible to solve the problems of the previous model, which caused rapid breakdown of the flywheel, as well as contamination of the solenoids and oily fluid.

In general, all new DSG models provided better protection from excessive loads. On the other hand, the advantages of such systems over conventional stepped automatic transmissions were also lost. As for the economic component, repair and maintenance of conventional transmissions remains much more profitable.

Gradually, this market segment divided: creating perselective DCTs with low torque, they use a dry clutch; For servicing more advanced engines, a wet clutch is better suited.

Common problems with DSG transmissions

Car enthusiasts, as a rule, do not have problems with these boxes for the first 3-5 years. By the way, the VW warranty for this product lasts up to 2 years for DSG 6, and up to 5 years (in some cases) for DSG 7. Still, the percentage of calls to auto repair shops with problems with DSG systems in a five-year period is quite high. Drivers complain of jerks, vibrations, incomprehensible shaking and other unpleasant situations associated with the dual-mass clutch. Sometimes problems arise with the sensor indicating the speed, sometimes with chips in the automatic transmission that interfere with the operation of the mechatronics. Almost no one undertakes routine repairs of such systems; they immediately offer a complete replacement of the transmission.

Types of DSG 7 gearboxes

Seven-speed robotic gearboxes are available in several modifications and are designed for different types of cars.

The simplest robot with a dry clutch is labeled DQ200. This transmission is designed for low-power power units. This gearbox can be found on many front-wheel drive cars that are used as an everyday vehicle.

The DQ500 is a wet clutch robot. It is more reliable and can withstand more intense use than its predecessor. Such a box can withstand torque up to 600 N*m and is used for more powerful power units. Suitable for vehicles with all-wheel drive.

Previous robot models are designed for machines with a transverse motor. For longitudinally mounted engines, gearboxes with wet clutch modifications DL501 and DL382 are suitable.

Separately, I would like to say about the new 7-speed robot DQ381. This box represents an improved version of DSG 7, which reduces the amount of harmful emissions into the atmosphere and has a reduced coefficient of friction between parts. The manufacturer assures that it is more reliable than its predecessors, but it is too early to judge this, time will tell.

Volkswagen's official response or what car owners can expect

Representatives of Volkswagen Russia did not stay away from the hype around the innovative transmission and commented on the situation with the DSG-7. According to them, since 2012-2013, the double clutch assembly, mechatronics unit and mechanical part of the gearbox have been redesigned. The problems that arose before will remain horror stories for car owners of the new DSG-7. For the most part, according to VAG representatives in Russia, breakdowns are associated with improper operation of cars with DQ200, including chip tuning of the control unit. VAG also decided to change the oil in the box from synthetic to mineral - at one time this became the reason for the global recall of cars with DSG-7. The replacement will also affect cars in Russia, but in our conditions, mineral oil in the transmission does not seem to be the best option.

In any case, the main thing in this statement was the belief that the car should only be serviced by official repair shops. The transmission structure is too complex to be trusted to third-party specialists. It's up to the car owner to decide. Although it is worth considering that Volkswagen sells hundreds of thousands of cars in Russia and repair shops have long been familiar with all the problems of DSG-7 and how to fix them. You can literally find a car service center that is ready to repair or replace any transmission part from gears to mechatronics. Just look on the Internet. Yes, and you will also be offered quite a few ways to repair the DSG-7 with your own hands, but for this you need to have golden hands. Spare parts for the DSG are also not a luxury, and it’s unlikely that you’ll have to wait for the required pad within a month.

The difference between official and third-party services is primarily in price. The range here is great - you can replace the entire DSG-7 for 300 thousand rubles and 450 thousand. The difference is serious and the majority of car owners decide to vote with rubles.

In conclusion, it is worth saying that the DSG-7 has many advantages, otherwise cars equipped with the “German robot” would not have been sold in such quantities. At the same time, car services are filled with cars not only with the notorious DQ200, but also with torque converter automatic transmissions, CVTs, and conventional “mechanics”. There is no ideal transmission, and it's up to you to decide what's best for you. You shouldn’t change your decision just because of reviews on the Internet.

Passat price in Russia

The cost of a German sedan in 2020, depending on the configuration and engine, can vary between 1,580,000 - 1,960,000 rubles.

Price of a car with a 1.4 liter engine with 125 hp.

- Trendline price from 1,580,000 rubles;

With a 1.4 liter engine producing 150 hp.

- Trendline price from 1,630,000 rubles;

- Comfortline price from 1,710,000 rubles;

- Highline price from 1,850,000 rubles.

Cost of Passat with 1.8 liter 180 horsepower engine

- Comfortline price from 1,820,000 rubles;

- Highline price from 1,960,000 rubles.

As a result, we can say that the Germans have created a very good car with an interesting design, a high-quality interior and excellent technical characteristics, including dynamics and fuel consumption. Regarding the DSG-7 DQ200 robot, we can say that its main advantages are low fuel consumption, excellent dynamics and speed of operation, but on the opposite side of the scale is reliability. Yes, the transmission has become much more reliable than the versions before 2014 and there are fewer and fewer complaints from owners, but we would only risk buying a passat b8 on the secondary market if the price is attractive. Of course, robotic transmissions are the future; there are rumors online that Volkswagen is developing a new 10-speed transmission. So if you are considering buying a car with a robot, we would recommend paying attention to the more reliable DSG-6 robot with a wet clutch, which is very reliable and has an excellent safety margin. A car with this gearbox can be bought without fear on the secondary market, as for the Passat up to the DSG DQ250, as we wrote earlier, it is only available with diesel engines.

edit this post

Mechatronics malfunctions

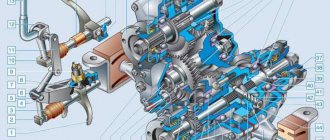

Another common problem with DSG 7 is a malfunction of the mechatronics, on which the operation of the box as a whole depends. The mechatronics consists of, in fact, the ECU itself (electronic board) and the valve body.

Unfortunately, in the case of DSG 7, many owners are faced with mechatronics breakdowns already up to 100 thousand km, and some only at 30-40 thousand.

In VAG cars of the model range until 2012, the most common problem with the “robot” was a burnt-out mechatronics electronic board. As a result, the car did not drive at all, sometimes the engine did not even start.

The manufacturer explained the reason by using incorrectly selected transmission fluid. During operation, synthetic oil left its additives in the form of a sediment on the current conductors of the board, which led to short circuits and overheating of areas of the board. Essentially, it was fried in transmission oil.

After the manufacturer began to use mineral oil, the malfunctions of the DSG 7 mechatronics practically disappeared. There are still problems with the failure of sensors and solenoid valves during operation - then the board will also have to be replaced.

As for the other part of the mechatronics - the hydraulic one - problems with it occur regularly and regardless of the date of manufacture of the car.

A design error in the form of a weak aluminum accumulator housing in the device leads to the fact that under high pressure and load the housing simply bursts or part of its wall comes off along with the accumulator itself. The result is that the car does not move.

This problem is solved by regrinding or replacing the accumulator body, or by using a whole arsenal of welds and various seams designed to hold the broken part together.

The owner of DSG 7 recognizes problems with mechatronics by the fact that the box stops loading in modes D and R, and even or odd rows of gears disappear. Transmission fluid leaks from the mechatronics.

As a rule, the mechatronics of the box can be repaired, but this is a labor-intensive and very expensive process, which not every specialist will undertake.

Mechanical wear

Wear of the box bearings is manifested by noise during movement, which increases with increasing engine speed. Moreover, with such a howl and hum from the unit, a complete set of bearings will have to be replaced, and this is already considered a major overhaul of the mechanical part of the “robot”.

The owner becomes aware of a problem with the 6/Reverse fork by the inability to move in reverse and engage even-numbered gears. In advanced cases, the box simply goes into emergency mode.

The solution to the problem is to remove the box and install a new plug.

When a car runs over 100 thousand kilometers, the issue of wear on the toe of the input shaft of odd gears arises. The reason is untimely replacement of the needle bearing in the crankshaft and its destruction. In this case, you will have to repair not only the box itself, but also repair or even replace the crankshaft.

The life of the input shaft oil seal is approximately the same - 100 thousand kilometers. It is better to change it, like the needle bearing, along with replacing the clutch kit.

Total

There are many preselective gearboxes, “robots” are gaining popularity and VAG has not abandoned its DSG. But it was this version of the dual-clutch gearbox that gained notoriety, which still overtakes it today. You definitely shouldn’t choose a used car from a German concern, produced before 2013, with this unit. You will get a number of expensive problems that are not even related to driving conditions or poor care, but to design flaws.

Only relatively new cars produced after 2013 should be considered for purchase. A number of shortcomings have been eliminated. But you definitely won’t be able to save money on servicing the DSG-7, and it is not designed for heavy loads—the owner should remember this.

- We talked in detail about the design, pros and cons of DSG “robots” here.

- We looked at the features of VAG CVTs here.

Classic DSG7 problems

Let's try to look at the most common problems with a dry DSG. What you may encounter when using it.

- Vehicle vibrations when shifting gears from first to second and back. This is caused by the clutch discs closing too abruptly. The effect is the same as if you suddenly release the clutch when shifting on a conventional “mechanics”. The error occurs in this case in the mechatronics unit and is “treated” by flashing it or, in extreme cases, replacing it.

- Vibrations in 2nd gear when driving at low speeds. The problem is the lack of a torsional vibration damper on the second clutch. VAG engineers considered that it was enough to install the damper on the first clutch, as the most loaded one. It has a large friction area, while, like the second, the friction area is reduced. The design of the DQ200 0AM box itself does not allow the installation of two torsional vibration dampers - due to the geometry of the box, the entire body will have to be redone. LUK, the company responsible for creating the DSG-7, has released a clutch with a modified friction material. The vibrations did decrease, but did not disappear. VAG is trying to fix the problem with a new software update, but mechatronics will not be able to solve the technical problem of the design. In any case, the “second squabble” will remain with the DSG-7 until the new box comes out.

- Knocks in the gearbox when driving at low speed. The manufacturer's official explanation is that: “The gearbox contains a large number of closely spaced parts. Under some conditions, vibration of unloaded gears and gearbox parts may occur. Structurally, the amount of oil in this gearbox is relatively small, which contributes to a more intense transmission of sounds from the gearbox to the outside. These noises only affect acoustic comfort; these sounds do not affect the performance of the gearbox and its service life and are not regarded as a defect.” It turns out that you will not be able to contact the service with this problem, so before purchasing during a test ride, decide for yourself whether this noise suits you or not.

- Shocks when starting to move and switching to modes D, S, M. The range of reasons here is quite large. The malfunction may lie in the clutch unit, in the mechatronics, or in the engine-gearbox combination. In any case, a car with involuntary jolts should be diagnosed at a service center.

- Mechatronics failures. A number of problems are also mentioned here, but they are usually associated with the software version and vehicle operation. Early models suffered from mechatronics failures caused by software errors much more often. Now most of the problems have been eliminated by constant updating of the “brains” and the electronics behave more or less friendly, but they are not immune from operating errors. DSG-7 differs from DSG-6 in that it is installed on middle-class cars with lower requirements for the engine and speed, but with the expectation of a comfortable, quiet ride. Any racing “tricks”, such as, for example, a quick start with the brake held down, can be driven on the DSG-6 - it is saved by an oil bath. For DSG-7, this may cause premature repair.

If we sum up the problems described, then they all lie in the complex technology of the box. VAG wanted to make the perfect transmission for everyone and is now paying the price for being too hasty with it, modernizing the transmission year after year.

Types of DSG boxes

In order to make the driving process more comfortable and safe, automobile concerns are constantly offering some new developments, improving the systems of their cars. At one time, with the advent of the automatic transmission, a real breakthrough occurred in this area. Years have passed and today there are even newer and more advanced systems. We are talking, first of all, about the DSG 7 gearbox from Volkswagen, which, in comparison with a conventional automatic transmission and a conventional manual gearbox, has a number of undeniable advantages:

- There is no loss of engine power when changing gears using the DSG. This allows you to achieve maximum acceleration dynamics and save good money on fuel - your car will consume 10-15 percent less gasoline;

- DSG 7 supports switching mode between automatic and manual transmissions, allowing the driver to independently choose the level of driving comfort.

These are two main advantages of the DSG 2020, but they are what made this gearbox a real hit, both at the time of its introduction and today. By the way, more than a million of these gearboxes have already been produced, and Volkswagen is not going to stop.