Diesel injection and injector operation

The fuel from the fuel tank is directed by the supply pump to the input of the injection pump, by which it is distributed and pumped into the lines connected to the injectors. At the same time, they are opened to allow the next injection of fuel into the cylinders. When pressure drops, the injectors close.

In the fuel supply system of diesel engines, fuel injectors have special functions. With their help, direct supply and dosing of fuel into diesel cylinders is ensured at a frequency of up to 33 times per second. The injectors effectively spray fuel over the piston in the form of a torch. Different engine power systems are equipped with injectors of different designs and methods of controlling them.

One of the innovations was injectors that have sensors that detect the rise of the needle and supply impulses to special electronic control units (ECUs), which, based on them, generate commands for the injection pump.

The innovation of two springs in diesel injectors was also a significant step forward. Despite some complication, this gave the fuel supply process greater flexibility. The combustion of the working mixture has become softer, and the operation of the diesel engine has become quieter.

Features of electromechanical injectors

Electromechanical injectors gave a big impetus to the progress of diesel engine power systems. The operating principle of a diesel injector belonging to this type is as follows. Here, the fuel pressure and the force of the compressed spring are replaced by a special solenoid valve controlled by the engine ECU.

The control unit generates fuel supply indicators: when to start injection and what dose to choose. This is done by the injector valve according to commands from the ECU, which depend on engine speed, operating mode, temperature and other parameters.

As a result, the fuel-air mixture in the cylinders is more homogeneous, atomization and combustion are improved, which ensures a smooth increase in pressure on the piston, which is exerted by gases from the burning fuel.

Thanks to more precise operation of electronic injection, diesel engines have increased power, improved fuel efficiency and environmental friendliness. They have become noticeably more durable, vibration and noise have decreased.

Self-check of injectors

Let's start with the fact that automobile injectors are divided into several types, of which two types have found widespread use at different times: mechanical injectors and electromagnetic (electromechanical) injectors.

Electromagnetic injectors are based on a special valve that opens and closes the injector to supply fuel under the influence of a control pulse from the engine ECU. Mechanical injectors open as a result of increased fuel pressure in the injector. Let us add that modern cars often have electromagnetic devices installed.

To check the injectors with your own hands without removing them from the car, you can use several methods. The simplest and most affordable way to quickly check injection nozzles without removing them from the car is to analyze the noise emitted by the engine during operation.

You can identify a faulty injector by ear by the sound of the internal combustion engine if a muffled high-frequency sound is heard from the cylinder block. This indicates the need to clean the injector or a malfunction of the injectors.

Pump injectors

In this method of fuel supply, the injection pump is replaced with pump injectors. This is how they work. Diesel fuel is supplied by a booster pump to the inlet of the injector with its own plunger pair, which is a source of high pressure necessary for fuel injection. The plunger pair is driven directly by the camshaft.

The absence of fuel injection pump makes such a system compact and economical. The presence of an electric valve in the pump injectors ensures fuel injection in two pulses. First, a small dose of fuel is supplied to the engine and only then the main dose.

Fuel is supplied by a system based on pump injectors precisely in time and dose. This system makes the engine economical, its operation becomes soft and silent, and the exhaust becomes less harmful.

Some problems arise due to the dependence of the fuel supply pressure on the crankshaft speed. They are also difficult to repair and maintain due to their complex design. Pump injectors require only high-quality fuels and lubricants.

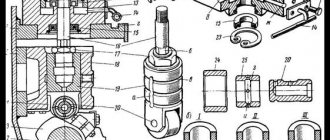

Fuel supply via injection pump

The traditional fuel supply scheme with a mechanical injection pump is reliable and has proven itself well in naturally-aspirated diesel engines in the past. This fuel supply scheme is represented by the following components:

- fuel capacity;

- coarse and fine filters;

- fuel priming pump;

- injection pump;

- injection nozzles;

- low pressure pipelines;

- high pressure channels;

- air purification filter.

The injection pump is one of the main components of the power supply system for solar motors. It is quite complicated in design, since in addition to supplying highly compressed fuel, it also ensures its dosing. In the last century, mainly diesel engines were equipped with mechanical fuel injection pumps, but they also tried to install them on gasoline engines, as an element providing direct injection.

With the help of such pumps, you can set the desired moment to start injection and supply the required volume of compressed fuel to the c/c cylinders.

Operating principle of a diesel engine fuel injector

The supply and distribution of diesel fuel in the nozzle is carried out in 3 stages:

Pre-injection. The camshaft cam transmits mechanical force to the rocker arm and pulls the plunger down. The fuel-air mixture moves through the nozzle channels, after which its flow is temporarily suspended. In the confined space of the device, a high pressure area of up to 13 MPa is formed. Under its influence, the needle overcomes the resistance of the spring and performs a preliminary supply of fuel. After the inlet valve opens and the fuel mixture enters the line, the pressure decreases.

Main injection. Starts after lowering the injector plunger. The inlet valve closes, which leads to a rapid increase in pressure to 30 MPa. After reaching operating pressure, the needle rises and injects the fuel-air mixture into the combustion chamber. The maximum volume of injected fuel corresponds to the maximum engine power. At the same time, fuel consumption increases significantly compared to the normal operating rhythm of the power plant.

Additional injection. Required for cleaning the particulate filter, removing soot and other contaminants.

As you can see, the design of a diesel engine fuel injector is quite complex, so its repair requires special professional equipment. Unqualified maintenance in most cases results in a complete loss of device functionality.

However, modern fuel injectors are quite reliable devices that practically do not require outside intervention. The only condition for uninterrupted operation is the quality of diesel fuel, otherwise pollution occurs and operating efficiency decreases.

Common Rail fuel supply

Today it is considered to be the most effective for supplying fuel to engines running on diesel fuel. Its appearance dates back to 1997, which after a few years became very common. The common rail or battery fuel system is now found on almost all diesel engines. The design of the diesel injector is somewhat different here. Compared to others, this system provides significant fuel savings, increased environmental safety, noiselessness, but most importantly, it creates greater fuel supply pressure in front of the injectors.

What fundamentally distinguishes the Common Rail scheme from others is that the order of obtaining greater pressure and the supply of fuel are separated chronologically. Diesel fuel is supplied from the tank to the system by a booster pump. It is clarified in the filters, leaving impurities and other contaminants on the filter elements.

Through low-pressure lines, fuel enters a mechanical injection pump, which pumps fuel into the ramp, where the fuel accumulates before injection. In this scheme, the fuel pressure is not related to the current operating mode of the engine.

Based on the data provided by the sensors on the engine ECU, the dose that the pump should pump into the fuel rail is determined. This occurs by opening the metering valve, after which the fuel enters the ramp. In the accumulator it has a predetermined pressure, which is maintained by the regulator.

After the required volume of fuel is supplied to the ramp, the ECU issues a pulse to open the injectors according to the operation of the engine. While one process cycle lasts, such a system performs injection in three stages:

- preliminary (with its help, the temperature in the c/s increases, which contributes to the rapid process of self-ignition). Their number is related to the operating mode of the motor: for a no-load mode there can be two of them, an intermediate mode - one, at maximum power - none;

- main (directly ensuring the functioning of the motor);

- additional (it warms up the gases, which promotes more complete combustion of carbon and reduces harmful substances in the exhaust).

Common Rail can split the supply phase into 7-9 portions, and the pressure value can reach 300 MPa. Such capabilities make it possible to increase the cyclic volume of fuel injected into the cylinders, which immediately leads to an increase in the power of cars with diesel engines.

This power system requires diesel injectors of the electrohydraulic and piezoelectric type. The former are controlled by electromagnetic valves, and the latter by piezocrystals, which significantly increases their operating speed.

The Common Rail system requires only high-quality fuel, as they use sophisticated injectors assembled from high-precision components and parts. Moreover, their complete tightness is required. If for any reason the valve position is open, the pressure in the rail will drop and the fuel supply will stop.

HEUI system - injection of the 21st century, American style

A. Vinogradov, based on materials from Caterpillar, illustrations from Caterpillar

When they say “developed state,” they usually mean that this country has a powerful industry, and do not think about the fact that along with its economic power, the state has received a considerable set of environmental problems. That is why in these very “developed countries” the main engine of progress is not so much competition as environmental legislation. And every year it becomes more and more severe, because no matter how you look at it, you still need to breathe...

Achieving compliance with gradually tightening environmental standards seems to be easy. It is enough to limit the maximum fuel supply to a certain limit, lower than the smoke limit. In this case, some power will be lost and efficiency will deteriorate slightly, but for the time being such losses can be compensated for by turbocharging. This is exactly the path that Russian engine manufacturers are taking today, having achieved compliance of their products with Euro-1 standards.

But the USA and Western Europe are not Russia, and there they need to withstand competition with very strong rivals, and Euro-1 is already a passed stage for them. This means that the engines of the future should not only be more environmentally friendly than their predecessors, but also more powerful and more economical. And this can be achieved by increasing the accuracy of the fuel supply system while simultaneously improving mixture formation due to better fuel atomization and the use of complex injection algorithms. And then not only Euro-3 standards, but even Euro-4 are not scary.

The listed conditions mean that the injection pressure must exceed 1000 kgf/cm2, it must be controlled electronically, and the mechanical drive of the plungers should be abandoned. The Common Rail system is one of the possible solutions, aimed at relatively small and high-speed diesel engines in cars and small trucks. Another solution is offered by Caterpillar, which traditionally produces heavier engines.

The fuel injection system created by Caterpillar was called HEUI (pronounced “heey”), or in full, Hydraulically actuated Electronikally controlled Unit Injection, which can be translated as “Hydraulically actuated and electronically controlled injection device.” It was born because there was a threat of loss of competitiveness for the company's smallest and most popular engine, the six-liter 3116B.

In contrast to the Europeans, who were looking for fundamentally new ways, American engineers tried to make maximum use of the capabilities of existing systems. They did not completely abandon pump injectors, but equipped them with a hydraulic drive. Now, instead of a cam, oil from the engine lubrication system works, supplied through a special line at a pressure of more than 230 kgf/cm2 (3,300 psi). It acts on the oil plunger, which moves the fuel plunger, which, due to its smaller diameter, creates high injection pressure - more than 1400 kgf/cm2 (20,000 psi).

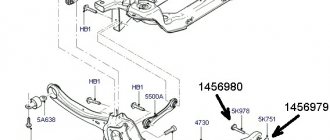

Hydraulically driven and electromagnetically controlled unit injector is the main element of the HEUI

The solenoid valve that controls the injection has moved from the fuel channel to the oil channel. At the same time, it is under pressure traditional for hydraulic systems, which has a positive effect on its operation. Now almost any given injection algorithms can be implemented.

The pressure in the oil line is much higher than the working pressure for the lubrication system and is created by a special pump. It is made in the form of a mounted unit and also supplies fuel to the pump injectors at a pressure close to oil pressure. Together with the pump injectors, this unit forms the mechanical basis of the system.

The pressure in the oil line is controlled using a solenoid valve by an electronic unit. The block also controls the operation of the pump injectors and sets the injection law, which in the HEUI system is two-stage. First, a “pilot injection” of a small dose of fuel is performed. Thanks to this, combustion of the main portion of fuel occurs better.

Solenoid valves of unit injectors and high pressure oil lines are the devices with which the electronic unit controls the entire operation of the engine. To do this properly, it takes into account a number of parameters: engine speed, charge air and coolant temperatures, gas pedal position.

However, the capabilities of the control unit are much wider. It receives information from the speedometer and tachometer, the car's speed sensor, sensors in the transmission and brake system. All received data is stored in memory. Therefore, using a computer you can easily configure the fuel supply system. In addition, with the help of the control unit, company managers can monitor the operation of the machine and its operator. Thus, a well-protected tamper is already built into the engine and there is no need to pay for a special device.

Thanks to HEUI, injection pressure is independent of engine speed. HEUI gives the engine good efficiency with excellent environmental performance, ensures easy starting in cold and hot weather, no white smoke in the exhaust and good performance in mountain conditions.

Caterpillar has been producing the system since 1992. As standard equipment, it is installed on the company’s most advanced and most technically rich engine - 3126B. But the 3116B, well known to Russians, can also be equipped with it. Thanks to HEUI, the six-liter engine literally got a “second wind” and the company has no plans to discontinue it yet. However, this system can be found not only on machines with the “CAT” brand. It is installed on diesel engines of Isuzu cars, as well as Ford (with Navistar International engines).

Compared to Common Rail, the HEUI system looks more complex. Indeed, it has not one, but two “common lines” - oil and fuel, connected by hydraulically driven pump injectors. For relatively small diesel passenger cars, such a system looks cumbersome. However, let’s not forget that on heavier engines the moving parts of the injectors are larger, and therefore it is very difficult to achieve good performance of an electromagnetic injector for Common Rail. And today there is still no confidence that the European system will be able to compete with the American one in this area.

Now each of the injection systems of the 21st century occupies its own niche. However, HEUI is already installed on Isuzu passenger cars. So the competition between these two approaches is bound to intensify over the next millennium.

Repair of diesel injectors

So, the reliable operation of diesel engines largely depends on the condition of the fuel injectors. Therefore, these devices require constant attention (diagnosis) and timely technical maintenance. If they break down or become permanently worn out, they must be repaired or replaced immediately.

The Diesel-Motors service center performs any repair of a diesel injector, no matter how complex it may be, and installed on diesel engines of cars, regardless of the brand. In this case, the injector is assigned a new code. Our specialists will offer the highest quality and inexpensive service and repair of your car’s power plant.