Replacing drum brakes with disc brakes. correct modifications

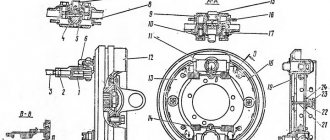

Instructions for installing the HCD on the VAZ 2101 - 2107.

The delivery set includes:

- Left caliper VAZ 2108 – 1 pc.

- Right caliper VAZ 2108 – 1 pc.

- Shoe guide VAZ 2108 – 2 pcs.

- Front brake flexible hose – 2 pcs.

- Faceplate – 2 pcs.

- Distance washer – 2 pcs.

- Brake disc boot – 2 pcs.

- Half ring – 2 pcs.

- Brake pads Ladasport VAZ 2108 – 1 set.

- Brake disc VAZ 2108 – 2 pcs.

- VAZ 2101 axle shaft, modified – 2 pcs.

Work order.

- Place the car on a level surface.

- We install wheel chocks.

- Loosen the rear wheel mounting bolts.

- We jack up the car, completely unscrew the wheel mounting bolts and remove the wheel from the car.

- Remove the brake drum.

- We turn the axle shaft until the large holes coincide with the two nuts securing the brake shield.

- Using a 17 mm socket wrench with an extension, unscrew the nuts securing the brake shield.

- Turn the axle shaft and unscrew the remaining 2 nuts in the same way.

- We remove the semi-axle from the car. This can be done with a special puller or by securing the wheel with 2 bolts to the axle shaft. With a sharp movement towards ourselves, we pull out the axle bearing from the flange of the rear axle beam.

- After unscrewing the bolts, remove the wheel.

- We take out the axle shaft.

- Remove the brake pads.

- Using a 10mm wrench, unscrew the brake pipe from the back of the brake shield.

- Remove the brake shield completely.

- We inspect the axle shaft seal and replace it if necessary.

- Take the modified axle shaft from the delivery kit.

- Install a half ring between the bearing and the oil reflective shield.

- Put the faceplate on and orient it so that the holes on the faceplate and the oil deflector plate line up.

- Place the brake disc boot on the rear axle beam.

- Install the axle shaft with the faceplate into the rear axle beam. Attention! The holes for attaching the brake mechanisms should be oriented so that the brake mechanism is located in front (in front of the bridge), the holes should be directed downward, as in the photo below.

- Tighten the 4 axle nuts.

- Attach the brake disc boot to the faceplate.

- Place the spacer on the axle shaft. Orient the washer so that the holes in the washer and the axle shaft line up.

- Install the brake disc and secure it to the axle flange.

- Install the caliper assembly onto the faceplate and tighten it with two M10 bolts. Attention. The fitting on the brake cylinder should point upward.

- Connect the brake hose to the brake pipe.

- Secure the brake hose with plastic ties. Secure in such a way that the hose does not have constant contact with other parts.

- Install the wheel. To secure the wheel, you must use extended bolts. Or replace the bolts with studs.

- Lower the car.

- Tighten the wheel bolts.

- Repeat steps 4-27 on the second side.

- Check the oil level in the rear axle gearbox. Add oil if necessary.

- Bleed the brake system.

What you need to switch to disc brakes

The standard kit for converting from drum brakes to disc brakes includes:

- 2 brake discs;

- 2 brake calipers (when purchasing used spare parts, it is advisable to immediately inspect the working area of the piston for scoring (there should not be any); before installation, the caliper must be serviced by replacing the boot and lubricating the areas under the guides);

- 2 brake hoses, as well as brackets and fasteners for their fixation;

- fittings, sealing copper washers, bypass bolts;

- 2 brake shields, which may have places for mounting calipers. If these are not provided, a plan washer is needed. Installing the anchor plate may require longer caliper bolts. If it is not possible to purchase an element, the plan washer will have to be sharpened according to an individual drawing;

- parking brake mechanism (the design of the components depends on the type of brake system you choose);

- The handbrake cable is overwhelmingly not suitable, so it also needs to be replaced.

Drum and disc brakes: what are the differences?

Braking systems are available in two types of design - drum and disc.

In both the first and second cases, the system’s tasks remain unchanged - to stop the car in a timely manner in case of an emergency or to lock it in one position.

At the same time, most modern cars use a combined version, when a disc brake is mounted at the front and a shoe brake at the rear.

A drum brake is a special rotating drum that is stopped by the action of the brake shoes.

The pads themselves are located inside the drum mechanism.

A disc brake is a cast iron disc in which the pads are installed not on the inside, but on the outside.

In both cases, braking occurs due to the action of the pads and the force of friction - the pads expand and stop the drum (for a drum system) or compress and compress the brake disc (for a disc system).

Drum brake device

Let's look at the design in general. This system uses two semi-circular brake pads.

They are installed inside the brake drum. On one side the pads are fixed quite rigidly, and on the other side they are developed by the piston. The latter works when the driver presses the pedal. And the higher the force, the more the piston will extend.

Springs are installed between the two pads. When the driver releases the pedal, these springs retract the pads to their base position. They are used to prevent the drum from jamming.

As you can see, the drum brake mechanism is truly simple in design. But progress and development of modern technologies are constantly moving forward, engines are developing. Those speeds that seemed unreal at the dawn of the automobile industry have become unnoticeable today. Cars often travel on the highway at speeds of up to 200 km/h. Such speed seemed fantastic even for motorsport champions 40 years ago.

At such speeds, the drum brake is no longer able to cope with its main task. Efficiency is lost. The first and only problem with brakes of this design is overheating of the pads. Hence the deterioration in work efficiency.

With the increase in speeds and power, engineers and designers were faced with the difficult task of improving the braking system. And there was nothing left to do but turn to the aircraft industry for help. That's right, because the first disc brakes were installed on airplanes. Then the system was successfully transferred to passenger cars.

Advantages of disc brakes

The above is just the tip of the iceberg. In practice, the advantages of disc brakes include:

- the pressure pad is considered more functional and efficient. The principle of disk compression has long been used in aviation and industrial technology, which once again confirms the reliability of this system;

- There is no such problem as sticking with disc brakes. Consequently, during the braking process the car behaves as stable as possible;

- Thanks to the external location of the brakes, cooling problems are eliminated.

Let us clarify the last point.

There is full access to air, which cools the surface of the system elements and prevents overheating.

Recently, ventilated discs have appeared on sale.

Their feature is the separation of the brakes into two surfaces using a jumper.

Modern cars have ventilated brakes at the front and regular disc brakes at the rear.

It's easy to explain. The front brake system takes on more load and gets hotter.

Other benefits of disc brakes.

- The self-cleaning ability eliminates brake failure or reduction in their effectiveness due to the ingress of foreign substances - dirt, oil, dust, and so on. If something gets on the disc brakes, it quickly flies off the surface;

- Openness. An important advantage for maintenance is the accessibility of all elements of the brake system. To replace the pads or inspect the system, you do not need to remove the entire drum.

Features of disc brakes

The disk mechanism is more productive. The fact is that the contact patch is not semicircular, as on a drum system, but parallel. Due to this, the pads are pressed very tightly against the surface of the disc. This makes it possible to brake much more effectively at high speeds. Replacing drum brakes with disc brakes really allows you to increase the efficiency of the system many times over.

Drum brakes get hot, but disc brakes are also subject to stress. However, the disk cools better when moving. You can also find ventilated and perforated elements on the market. Various notches allow you to reduce the braking distance significantly.

With all the advantages, there is also a negative side. Since the contact patch between the disc and the pad is higher, they wear out much faster. In addition, the disc erases faster. It is ground down by pads. The service life of the latter for a disc brake is at least three times lower than the service life of a drum brake. It's hard to say how long the brake pads last. The rate of wear depends on driving style. On average, disc pads with a calm driving style last for 25-30 thousand km.

Features of replacement: what needs to be taken into account?

Before proceeding with replacement, consider the following points:

- Before purchasing a replacement disk system, request a certificate for it. The presence of the latter is a guarantee of compliance with basic standards and, as a result, traffic safety;

- Evaluate the new brakes for compliance with factory standards and the possibility of installation on your car. If you install the first mechanism you come across, there is a risk of failure of the brake system or its frequent overheating;

- During the replacement process, one of the main problems is the handbrake. Be prepared that the old handbrake will have to be optimized for the new system or a new handbrake installed on a hydraulic principle;

- When undergoing maintenance, do not forget to note the fact that changes have been made to the design of the car. If this is not done, then in the event of an accident the fault will automatically fall on your car;

- make sure that information about the alteration is included in the insurance policy. Otherwise, there may be disagreements when obtaining insurance.

If the difficulties described above do not bother you, then you can safely get down to business.

Installing disc brakes on a UAZ

If you are the happy owner of a UAZ car, then when replacing the brakes, proceed as follows:

- Prepare the necessary tools - washers for “10”, studs (50*10), bolts for “12*1”, caliper holders, exchange adapters from M10 to M12, a caliper for a Gazelle car, special spacers and disc brakes for UAZ.

- Start by removing the wheel. Then remove the drum and unscrew the support “fingers”. Next, remove the old tubes and pads.

- Remove the coupling by unscrewing six bolts.

- Bend the locking ring mounted on the nut to the side. Then unscrew the latter using a special key.

- Take out the ring, remove the next nut and dismantle the hub itself. Then unscrew the nut from the studs related to the brake shield. At the last stage, remove the shield itself along with the trunnion.

- Mount the caliper holder so that it is positioned with the bosses facing outward.

- If necessary, bore the inner hole (this is easy to do using a file with a round profile). Next, press the holder into place using a hammer.

- Knock out worn studs from the hub and install new ones. Then install the spacer with a groove on the inside. Mount the spacer so that the flow part is installed in relation to the caliper.

- Mount the disc brake elements before installing the clutch. At the same time, remember the need to remove the casting “lift” on the caliper (this can be done with a grinder). Using the same tool, prepare the area on the fist. Remember that on the left caliper (as opposed to the right one), the outlet of the fitting is at the top.

- Discard the hose that connects to the copper pipe. If the connection point is sour, then you can disconnect the devices from each other by heating (a torch will come in handy here). If you can’t unscrew it, cut off the tube.

- Screw the adapter with a nut onto the hose and connect it to the tube. If there is not enough hose, use a longer product, weld a new bracket or tighten the frame and pipe.

- Install the pads, place the caliper and fix it to the holder.

- At the final stage, replace the wheels.

- If the studs protrude too much, try to use a longer socket. There is another possible problem. If the caliper does not turn well, it can be trimmed from the outside.

Installing a disc system is an opportunity to increase the efficiency of the brakes and make the car safer. But this is only one side of the coin.

Remember that by making a replacement, you are making design changes to the system, which requires additional verification and reflection in the relevant papers.

In addition, to complete the work you must have the necessary knowledge and tools.

Otherwise, experiments with the brake system may end in tragedy on the road.

Details

So, for replacement you will definitely need: - Knuckles for disc brakes with a light series of 70k axles (for example 78). You can visually distinguish a light axle from a heavy one by the spring cups (on heavy springs). Disc knuckles differ from “drum” knuckles only in the ears for attaching calipers, otherwise they are completely identical. — Brake shields. They already have tees riveted on them for the brake pipes. - Brake discs. There may probably be some nuances here: disks can be ventilated or non-ventilated. I got ventilated discs, one disc had to be bought new, I took Japan Cars C32103JC for 1160 rubles in existential. By mistake I ordered one non-ventilated Jakoparts J3302049. — Brake calipers and pads. — Brake hose from the bridge to the shield. They are very similar to the hoses found on drum brakes, but the end is different - disc brakes have a male end. All this, complete with hubs and broken electrical hubs, was purchased for 5 thousand used rubles. You will also need longer wheel studs, I took them from the hub from TLK78, length 60 mm. All other parts (trunnions, hubs, their bearings and hubs/covers, bipods, all fasteners) can be used with drum brakes. With one caveat: initially I also took the hubs from disc brakes from TLK78, but they didn’t fit (more on that below), so I had to modify the old hubs on a lathe. I also immediately purchased new kingpin bearings (4 pieces, took NTN 4T-CR-0357), a set of gaskets for the knuckle (Tzk 43204-60041), all the gaskets, new seals for the hub (90311-62001) and several adjusting “washers” for the kingpins ( I took a few pieces at 0.2mm and 0.5mm).

All details are summarized in the table below:

| № | Detail | Designation | Qty | State |

| 1 | Rounded fist | left/right | Used, disk | |

| 2 | Brake shields | left/right | Used, disk | |

| 3 | Brake calipers | left/right | Used, disk | |

| 4 | Brake hose | 2 | Used, disk | |

| 5 | Brake disk | Japan Cars C32103JC J3302049 | 2 | New, exist |

| 6 | Steering knuckle repair kit | Tzk 43204-60041 | 2 | New, exist |

| 7 | King pin bearing | NTN 4T-CR-0357 | 4 | New, exist |

| 8 | Hub seal | 90311-62001 | 2 | New, exist |

| 9 | Adjusting pin washer | 43233-60011, 43234-60011 | 4 | New, exist |

| 10 | Hub stud | Toyota 90942-02053 | 12 | new or used |

| 11 | Wheel bearing housing gasket | 43436-60011 | 2 | New, exist |

| 12 | Brake pads, set | Jakoparts (Nipparts) J3602054 | 1 | New, exist |

Replacing drum brakes with disc brakes

Most older cars are equipped with drum brakes. This technology is considered outdated, so any foreign car and new products from the domestic automobile industry are equipped with disc brakes. Moreover, each driver can make a replacement by improving the brake system. The operation involves purchasing new brakes, dismantling drum brakes and installing disc brakes. Drivers can perform such operations without the help of service station specialists in a garage.

Advantages of disc brakes

This procedure is not just tuning. She really makes sense. A disk system is preferable to a drum system for several important reasons:

- The pads on disc brakes have a larger contact area, therefore, braking efficiency increases.

- Better cooling. The disk is located in the open air, and on most models, numerous holes are additionally created in the metal to ensure high-quality heat dissipation.

- Brake discs require less maintenance than drums.

- Practically do not get dirty. The disc is in constant rotation, which prevents the formation of dirt on the surface. If necessary, you can clean disc brakes in a few minutes.

There is only one drawback to this system - cost. Disc brakes are significantly more expensive than their older counterparts, but purchasing them will truly be a worthwhile investment.

The optimal solution is to install disc wheels on the front wheels and drum wheels on the rear wheels. This will save you some money by buying just one pair of brakes, but will still improve your braking performance.

Installation features

The installation kit comes with instructions that describe how to perform each step. However, some features are not specified in the manual.

When replacing standard pads with disc pads, take into account the following points:

- The bracket that secures the brake hose almost always requires modification.

- If non-standard discs are installed, you need to change the parking brake cable fastening. This will prevent friction on the balancers and ABS sensors.

- Dimensions of parts may differ from those indicated in the instructions. In this case, the components are modified independently or replaced.

After conversion, you need to regularly check the tightness of the nuts, which is explained by the increased load on the system.

Replacement procedure

Installing disc brakes yourself is a rather complicated procedure. If you have never “digged” into your car, then entrust it to the professionals. Avid mechanics must first prepare a working tool. You will need ratchet heads of various sizes and handles. Also prepare a piston beater, hammer and pliers. Be sure to check the disc brake configuration. It should include the following components:

- caliper;

- hose;

- pads;

- disks;

- various fasteners.

Please note that the factory instructions for your vehicle describe how to replace the pads on drum brakes. It is recommended to read it. The replacement process is individual for each individual model, as it has its own nuances. In general, we can highlight the general steps that every motorist will encounter:

- Using a wrench or air tool, loosen the wheel mounting bolts and then remove the wheel.

- Next you need to remove the brake drum. To do this, find a technological hole in the structure in which the fastening element is located. By unscrewing it, you can remove the drum.

- Remove the brake pads to free the handbrake cable. Disconnect the cable from the handbrake.

- Remove the central nut. Disconnect the fist from the suspension.

- Disconnect the brake hose and remove the caliper.

- To minimize brake fluid loss, it is recommended to close the hole with a protective cap.

- If equipped, disconnect the ABS sensor.

- Disconnect the longitudinal link from the knuckle.

- Remove the knuckle through bolt from the transverse link.

- Remove the CV joint from the hub.

- Remove the bolts securing the shock absorber to the knuckle.

- Install the cam provided for disc brakes, securing it in the suspension.

- Place the disc and caliper on it.

- Install the brake pads and connect the brake fluid hose.

- Be sure to remove air from the system. Put the wheel back in place.

In a specialized technical center, the process takes about an hour, so be prepared to spend 2 or more hours in the garage. Difficulties may arise when installing the drum. The part often gets stuck, so it is impossible to remove it manually. It is permissible to use a hammer (sledgehammer), but only moderate blows can be applied so as not to damage structural elements.

Finally, it is worth checking the brake line for leaks. Inspect the underside of the car for marks and leaks. Only after this can you start a test drive. Push the pedal all the way down. Make sure the brakes actually work. Please note that during the first time of operation, a grinding noise may be observed. This is normal when the pads and discs rub against each other. The instructions for the brakes indicate the mileage after which this effect should disappear. Disc brakes can reduce braking distances by several tens of meters.

How to replace brakes yourself

In truth, it is better to change the brake system at service stations. Naturally, this procedure is not cheap, but the replacement will be carried out by a professional. As a result, you will spend much less time on repairs. And receive the appropriate quality certificate for the new type of brake system. In the event that you decide to manipulate the brakes yourself and save a certain amount of money, you will have to work hard, especially provided that this type of work is being carried out for you for the first time. So, the first thing you need to do is stock up on tools, which, in principle, every motorist should have.

Replacing the system is carried out differently for each car. Instructions are included with each vehicle (indicated in the general instructions for the vehicle). So, let's look at the universal procedure for replacing drum brakes with disc brakes:

- We remove the old drums. To do this, you need to remove all the mounting bolts on the wheel. After this, the first thing you need to do is raise the required side of the car using a jack. Then you need to secure the car as securely as possible using “shoes”. Now you can unscrew the completely torn bolts and remove the desired wheel;

- Next, unscrew the fastening nut that secures the handbrake cable to the drum. Now we disconnect the drum. But it happens that our drum gets stuck, so it becomes a little difficult to remove it. You need to take a hammer and knock on it with medium force. You need to tap around the perimeter of the drum. After the drum has given way, you need to disconnect the brake hose from the brake cylinder. Next, the hub and flange from the rear suspension arm are removed;

- Well, now we can start installing our new disc brakes. Installation is carried out in reverse order. The first step is to connect our flange. Then we attach the hub with the disk to it. Important: For new brakes, use only new bolts. After this, we install our disc, then install the brake pad guidance system and the pad itself. Next we install the caliper, but before installing it, you need to press its pistons inward. This can be done using a tool such as a screwdriver. We install the caliper and secure our structure;

- There's just a little bit left to do. We connect the brake hose, parking brake cable and caliper to the entire system. That's all, the system has been replaced. Now all that remains is to pump the air out of it and pump it a little.

About operation

Remember that disc brakes have a lifespan. For pads it is approximately 30-40 thousand kilometers. The disc is erased after 100-110 thousand kilometers. Always read the instructions for the purchased model for more accurate information. Symptoms of wear include grinding, vibration, pulsation in the brake pedal, and sticking.

Drivers can determine the level of wear themselves. You need to look at the end of the product. As a rule, two values are located there: the original and the minimum allowable thickness. Numbers may vary depending on the manufacturer. You need to use a caliper to compare the numbers with acceptable standards. Mandatory replacement should be carried out if the wear on the disk is uneven.

This is key information about replacing a drum system with a disc system. You can search the Internet for a video of the replacement process for your car model if difficulties arise during the procedure. Be extremely vigilant, as various types of mistakes when installing brakes can cost you your life.

If the material was interesting or useful for you, publish it on your social network page:

Pros and cons of disk drives

Among the advantages is the high efficiency of the braking process. Also, this system does not heat up to the same temperatures as their drum counterparts. Disc brakes are easier to clean. The element is easy to change if necessary. They are changed when the disk is thinner than a certain parameter. The minimum thickness of the brake disc is 20 millimeters.

The disadvantages include rapid wear of the pads. Even expensive consumables have a short lifespan - only 30-40 thousand kilometers. The discs also wear out. They last for an average of 100 thousand kilometers. These brakes are more expensive to maintain than drum brakes. In summer, squeaks are possible due to counterfeit parts. It is also necessary to constantly monitor the degree of disc wear. It should be no thinner than 20 mm.

This is the minimum brake disc thickness regulated by most manufacturers. It is indicated on the end of the product and is different for each manufacturer.

Do-it-yourself replacement of a drum brake system with a disc one

Currently, many motorists are interested in various tunings. They usually associate this word with external changes to the car. Without a doubt, the exterior and interior of a car are very important, but without a good “filling” it is just a beautiful pile of metal. Realizing this fact, you will first of all want to tune the “insides” of the car. First, pay attention to safety and update the brake system. To increase its efficiency, it is necessary to replace drum brakes with disc brakes.

A similar manipulation is carried out with both the front and rear wheels. Often, drum braking parts are installed on the rear wheels of domestic automobiles or foreign budget models. It is unclear what manufacturers are guided by in this case, since it has long been known that disc braking mechanisms are much safer and more reliable.

Disc mechanism design

The disc element was considered a new step in the development of braking systems. Previously, it was installed only on aircraft, as well as huge trucks. There are higher speeds and more mass here. Let's see how this system works and whether drum brakes can be replaced with disc brakes.

So, a thin disk is fixed to the axle of the car. This can be both the front and rear axle. A so-called caliper is attached to the top or side of the disc. Its mechanism includes pistons and brake pads. When the driver presses the pedal, the pads are compressed by the piston. Between these elements there is a disk. This is how braking occurs.

Why disk ones are better

Replacing your brake systems is an important decision that should be backed up not only by a desire to stand out, but also by common sense. Changing the security design is a very important undertaking. Therefore, you should be aware of the advantages that disc braking mechanisms have over drum brakes:

- high braking efficiency due to uniform application of braking forces;

- short braking distance of the car;

- the braking mechanism works faster;

- improved functionality of the pads and disc due to heat dissipation (especially of interest to fans of fast driving).

These advantages should be enough to justify the need to change drum devices to disk ones.

The video shows the differences between drum brakes and disc brakes:

Some features of replacing braking systems

Like any manipulations with automotive systems, working with brakes has its own characteristics. You must be clearly aware that by changing the type of mechanism, you are changing the factory design of the car. These changes can lead to various consequences for which you must be prepared. So, the features:

- Replacing drum brakes with disc brakes must meet all factory standards and requirements for your car model. Otherwise, you will skid while braking, the system may fail, the brake discs may overheat, etc. As you can see, the consequences of non-compliance are very different and quite unpleasant.

- New brakes must be certified for use in the Russian Federation. At the service station where you will install them, you must be given a certificate of their compliance with the standards and requirements.

- The handbrake system will need to be replaced with a hydraulic handbrake.

- After replacement, you will need to undergo maintenance, since you have rearranged one of the factory systems. If you do not make changes, then in the event of an accident you will automatically become the culprit.

Features of the brake system replacement process

If you decide to replace drum brakes, you should know about some features of such castling:

- you will lose the current service warranty if the manufacturer does not provide a free choice of the brake system, and you do not carry it out at a service station;

- the result of the replacement must be within the framework of existing standards, otherwise you will put your life (and the lives of passengers, as well as pedestrians) in danger;

- since the condition of the brake system affects road safety, its parts are subject to certification in Russia, ask for the document from sellers or service station technicians;

- the handbrake will also have to be replaced with another one, with a hydraulic drive;

- the replacement must be recorded in the papers on the technical condition of the car, otherwise in case of any accident you will find yourself an agent provocateur in the eyes of the law.

Replacing braking systems yourself

You can replace one type of mechanism with another at any service station. This is not a cheap procedure. Pros - professionals will not need a lot of time for this and they will issue you an appropriate certificate of quality for the new brake system.

If you want to save on work, then you need to stock up on time and patience. Such structural manipulation of car brakes is not simple and certainly not easy. To carry it out, you first need to stock up on the necessary tools. In general, replacement of pads is carried out with a standard set. In addition to this kit, you will need a disc brake system installation kit. It includes:

- caliper;

- hose;

- pads;

- disks;

- faceplates;

- bolts, washers and other fasteners.

Video shows replacing drum brakes with disc brakes:

When purchasing a car, instructions for its operation should have been included. It describes in black and white point by point what needs to be done in order to replace the brake pads (from time to time they wear out and new ones need to be installed). Using these instructions, you can remove old drum mechanisms.

To install the disk system, you should read the instructions, which are also sold in the kit. In it you will find a detailed description, diagrams, etc.

Remember, for each model and brand of car, replacing brake systems is carried out differently, and to be more precise, it has its own characteristics. Next, we will present you with the main actions, which are as unified as possible.

So, first of all, you need to remove the drum brakes. To do this, remove all the fastening bolts that are on the rear wheels, fix the front ones with available materials and support the required side with a jack. Attention, for safe operation, securely secure the vehicle. Now unscrew the bolts and remove the rear wheel.

Next, you should unscrew the nut that secures the parking brake cable. Now you can remove the drum. Very often it sticks and needs to be torn off. For this you will need a hammer. For greater effectiveness, strike with medium strength and high frequency. After removing the drum, disconnect the brake hose from the brake cylinder. Remove it, the hub and the rear suspension arm flange.

Now let's start installing the disc brakes. To do this, first attach the flange of the suspension arm, and then the hub with the disc to it. Use only new bolts. Next, install the brake disc, pad guides and pads themselves. Before installing the caliper, press the caliper pistons inward using a large flat head screwdriver. Now you can install the caliper and secure the entire structure.

Video about installing rear disc brakes:

Next, you need to connect the brake hose, handbrake cable and caliper to the system itself.

After replacing the brake system, experts recommend bleeding it and removing air from it.

From all of the above, it is necessary to take away the most important thing. First, disc brakes are indeed more efficient and will make the car safer, but any manipulation of factory parts is a design change that must be recorded in certain documents. Second, replacing these parts yourself requires time, space, special tools, knowledge and skills.

Rear disc brake installation process

The order of work is determined by the features of the kit being installed, but you need to follow the general plan of action.

The first step is to remove the drum brakes by following these steps:

- Removing the rear wheel. After this, the drum clamps are removed.

- Removing the drum. The brake hose must be squeezed and removed.

- Unscrewing and removing the hub, oil seal and bearing.

At the second stage of repair work, a new kit is installed.

Rear disc brake assembly.

To do this, perform the following steps:

- Place the bracket. The bearing, hub and oil seal are returned to their previous position.

- Place the brake pad and secure it. The part is fixed using standard elements. If the thread is painted over, use an M10 tap.

- Mount the caliper by pushing it onto the bracket. You need to check the rotation pattern of the disk. The part should move freely.

- Place the brake hose. Mount the cable located between the handbrake and the pads. Achieve the required tension of the element.

- All of the above is done on the other side, after which the correct placement of the brakes is assessed. After installation is complete, the system is tested.